Do-it-yourself armchair drawings and assembly diagrams. DIY armchair - step-by-step instructions for creating upholstered furniture

6732 1 2

How to make a garden chair: a drawing and a detailed description of the assembly

Have you decided to buy a chair made of plastic or a wicker rattan lounger for your country house? Do not rush to spend money, because simple and at the same time comfortable furniture can be made of wood with your own hands. I offer a simple step-by-step instruction for self-assembly of a chair from wooden boards. But first, let's decide what kind of furniture you would like to see in your summer cottage.

Requirements for country wooden furniture

In order to determine what country chairs should be, imagine in what conditions and for what purpose this furniture is used.

A country chair is a design with a seat, back and armrests. If you attach runners to the supports, you can swing on the chair. Country chairs are used for a short rest both in the country house itself and near it.

The operating conditions can be described as difficult, since most of the time the furniture is used outdoors.

So, what qualities should distinguish garden furniture?

- Durability... Furniture should last as long as possible, despite precipitation, direct sunlight and other environmental factors.

- Simplicity and ease of use... Furniture should be easy to carry so that it can be taken out of the house if necessary and then brought back. Ideally, furniture should unfold at all.

- Low cost... The chair should be inexpensive, and preferably made with your own hands from available materials.

- Aesthetic appeal... The chair, which will be used in the country, should decorate the interior and exterior of a country house with its appearance.

How to prepare for work

First, select a drawing. If the furniture is being made for the first time, the simpler the drawing, the better. In our case, the drawing is simple, but the finished furniture will be beautiful, stable and durable.

After the drawing is ready, we calculate the amount of materials and buy everything you need. In our case, a board with a cross section of 30 × 150 mm will be used to assemble the frame. For the lining of the seat and backrest, we use a board with a section of 25 × 100 mm. Self-tapping screws for wood with a length of 40 mm will be used as fasteners.

Preliminary stage - cutting out the main elements

In accordance with the drawing, we calculate the complete set of structural elements and cut the required number of parts from the board. We use a circular saw for longitudinal and transverse cutting. For a curvilinear cut, we use a jigsaw.

After cutting along the cutting line, small chips or, on the contrary, protruding fibers will be noticeable. In order not to remove these defects on the finished furniture upon completion of the assembly, immediately after the end of cutting, go along the edge of the cut with sandpaper.

Manufacturing process

| Illustrations | Assembly step by step |

|

How to screw in a self-tapping screw? Almost all connections in the chair will be made using self-tapping screws, so you need to know how to screw them in correctly. We fix self-tapping screws with preliminary drilling of holes with a diameter of 2 mm. If you turn the self-tapping screw without pre-drilling the holes, there is a risk of cracks. Under the head of the self-tapping screw, we drill a sweep for the diameter of the head and a depth of 3 mm. We recessed the self-tapping screw in the secret below the surface of the board. |

|

Front legs... We make two parts shown in the diagram. The lower part of the part will be the front leg of the chair, and the crossbar will be attached to the central recess. The top of the piece will be the armrest holder. |

|

We combine the front supports into a single unit... We install a 70 cm long crossbar in the central recesses on the front supports. All connections are made with wood glue and reinforced with 2 self-tapping screws on each side of the crossbar. |

|

Attaching the armrest holders... Overlay to the front supports we attach the upper parts of the sidewalls 60 cm long. We maintain a right angle between these two parts. We fasten it with wood glue and 4 self-tapping screws for each joint. |

|

Hind legs... We cut two parts from the board, like those shown in the diagram. The length of the legs is 63 cm. The butt ends of the legs are cut at an angle of 75 ° and 115 °, respectively. |

|

Attaching the rear legs... We put the rear supports on the outside of the armrest holders, so that the cutting line coincides with their surface. The end point of the bottom of the rear legs should be flush with the back edge of the armrest holder. |

|

Strengthening the hind legs... So that during operation the rear supports do not disperse to the sides, we install a transverse brace between them and tighten the entire assembly with self-tapping screws, 2 pieces on each side. |

|

Seat holder... The seat trim will be attached to the horizontal holders. The horizontal holders will be attached with the straight edge to the front cross-brace, and the beveled end will be attached to the previously installed cross-brace of the rear supports. |

|

How to install the seat holders... The diagram shows the location of the three seat holders and their distance in relation to each other. As usual, we fasten the parts with self-tapping screws. |

|

Backrest and rear legs... The 61 cm pieces of board are attached to the outer seat holders. The attachment must be made so that the end of the backrest holder is flush with the lower edge of the seat holders. |

|

Backrest trim... On top of the previously installed backrest holders, we fill the strips with a gap of 20 mm between adjacent planks. |

|

Seat... The seat strips are attached in the same way as the backrest strips. |

|

Armrests... We attach pieces of the board 64 cm long to the sidewalls, as shown in the diagram. We fasten it with wood glue and self-tapping screws. We use at least 2-3 screws for each armrest. Round the edges of the armrests in front of the chair. |

We continue to work

After the assembly is completed and the chair is ready, it remains to complete the finishing work, as a result of which the furniture will become not only reliable, but also beautiful.

Since the assembly was carried out on self-tapping screws, there were recesses on the surface of the wood, made for their heads. Fill the grooves with wood putty, matched to the tone of the boards. Apply the putty with a spatula and level it immediately.

When working with putty, remember that such compositions are applied in a layer no thicker than 1-2 mm.

After the putty has completely dried, the wood surface is carefully sanded. For grinding we use a sander with replaceable skins. We use sandpaper alternately, changing the abrasiveness from 400 to 800.

After the chair is sanded, we clean it of dust and soak it with linseed oil in two layers, with a break to dry the previous layer. Impregnation is needed, firstly, in order to reduce paint consumption and, secondly, in order to make the wood more resistant to decay. After the drying oil has completely dried, apply a couple of layers of paint.

Can varnish be used? Since putty was used when working with lumber, stains will peep through the varnish, therefore, in our case, the use of a continuous layer of paint is preferable.

The photo shows the finished result, which will look exactly the same if all the listed assembly steps were performed correctly in the sequence in which they are given in the instructions.

Let's sum up

It is not at all difficult to assemble a comfortable chair for a country house or a summer cottage, and now you will definitely cope with this task. If you have any questions while assembling furniture, ask them in the comments to the article.

November 10, 2018If you want to express gratitude, add clarification or objection, ask the author something - add a comment or say thank you!

Upholstered furniture is relevant at all times. It is found in city apartments, private houses, dachas, and even in personal plots during the warm season.

Soft is an important attribute of any living room, nursery or bedroom. They are provided by different manufacturers in a wide range. But, in order to save your own savings and acquire original and exclusive furniture, you can try to make it yourself.

An upholstered foam chair is of two types:

Material

In this article, we will focus on an upholstered chair made of foam rubber. Therefore, we will consider the features of the filler. The main advantages of using foam rubber as a filler include:

When choosing foam rubber, attention is paid to:

- rigidity of the material;

- density;

- orthopedic properties.

Suitable as upholstery material:

Dimensional drawing

Before proceeding with the manufacture of the chair, it is necessary to make a preliminary drawing with all dimensions, materials of manufacture and fastening systems for individual elements.

An adult product with a frame will have the following dimensions:

- width - 75 cm;

- height - 90-95 cm;

- seat height 45 cm from the floor;

- for the manufacture of legs, a bar with a square section of 55 cm is selected;

- side bars - 40 cm;

- the height of the armrests is 20 - 30 cm.

When manufacturing a frameless chair, a detailed pattern of the future product is made. It will consist of:

- 6 wedge-shaped parts;

- round bottom;

- tops.

A standard adult beanbag chair will have the following dimensions:

- height - 1 - 1.2 meters;

- diameter - 1 meter;

- the diameter of the lower bottom is 30 cm, of the upper one - 15 cm.

As for children's models, their sizes will be as follows:

- height - 60 cm;

- bottom bottom diameter - 25 cm;

- top diameter - 11 cm.

How to do with a skeleton?

A traditional, soft, framed piece is the more common option. To make it, you will need to prepare materials, tools and experience in joinery.

Attention: in frame upholstered furniture, only the legs of the product will be visible, the rest of the parts will be covered with foam rubber and upholstery.

Instruments

Of the tools you will need:

From materials you will need:

- lumber (most often consumers prefer 20 mm plywood);

- screws;

- thin nails;

- foam rubber and upholstery;

- joiner's glue;

- stain;

- glossy paint.

Manufacturing

The process of making a classic version of an upholstered chair is quite simple:

As for the finishing, this is the treatment of the product with wood stain and paints and varnishes... This will not only give the furniture an attractive appearance, but also extend its life. Since paint or varnish will reliably protect the product from increased moisture and other negative factors.

Advice: As for decorating an upholstered chair, it can be supplemented with small pillows.

Frameless option

The second variant of making an upholstered chair made of foam rubber is the simplest model of a beanbag chair.

Instruments

Of the tools you will need:

Materials required:

- fabric (for making inner and outer covers);

- filler (foam rubber);

- two zippers, one 40 cm long, the other 1 meter.

How to make?

The manufacturing process of a soft frameless chair is as follows:

That's the whole simple process of making a frameless bag chair. As a decoration on the product, you can sew an applique from a well-chosen fabric..

Photo

As a result, you will have a convenient and stylish decor element:

Useful video

You can watch the details of the manufacturing process in the following video:

Conclusion

In conclusion, it is worth noting that it is quite easy to make a soft armchair with your own hands. If you know the basics of carpentry, it's worth building a wireframe model. If you sew well, make a frameless chair. Both options have their advantages. They harmoniously fit into any interiors and delight owners with comfort in operation, attractive appearance and high technical characteristics.

In contact with

Frameless furniture appeared on the Russian markets quite recently. But thanks to its many benefits, it quickly became popular. But the price for such a novelty is often too high.

In the meantime, making an upholstered chair with your own hands is not difficult at all. This kind of work will not take much of your time. And you can involve children in sewing and decorating such an original decoration for your room.

Preparatory stages

Before you start doing, prepare a detailed drawing. If you do not carefully calculate all the required dimensions, then you may get a completely different result than you expected.

The easiest way is to make a soft chair in the shape of a pear or an ordinary bag.

Figure 1. An example of a drawing of a simple chair.

But you can give it the shape of a pyramid or, for example, a cube. Often, ottomans are made for children's rooms in the form of a drop or a funny animal, for example, a dragon.

An example of a drawing of a chair of a fairly simple form is shown in Fig. 1. Naturally, you can change the dimensions given in it at your own will.

The next step is to choose the fabric. You will need two types of matter. For the inner cover, get a thick enough fabric with a tight weave. Otherwise, the filler balls may come out of the bag over time. For this purpose, satin, coarse calico, fabric intended for sewing naperniks are well suited.

But the outer cover can be sewn from any material. Denim, artificial leather, fur or velor furniture will look good in any interior. The color of the material depends only on your taste, preferences and the appearance of the room.

In order to, you need to buy a special filler. Usually frameless furniture is stuffed with expanded polystyrene. It can be purchased at stores that sell furniture repair products.

Be careful when purchasing this product remotely (for example, from a catalog or via the Internet). This filler is very light and bulky. To transport 10 kg of "balls" you will need a cargo gazelle, because it will not fit into an ordinary car. When buying a filler, pay attention not to the weight, but to the volume of the package. To sew an upholstered chair, you need a bag with a volume of 200-250 liters.

If desired, expanded polystyrene can be replaced with foam crumbs. It can be obtained by crumbling, for example, decorative tiles used to decorate the ceiling.

Some experts advise to stuff frameless furniture with hay or buckwheat husks. But, using natural materials, remember that they should be changed about once every 5-6 months. Vegetable fillers absorb moisture well, which can lead to mold growth. In addition, such materials are quickly compressed, and the soft chair will lose its volume and elasticity.

Back to the table of contents

Sewing a frameless option

In order to make an armchair of the dimensions indicated in the drawing, you will need the following materials:

- fabric for the inner cover (with a width of 150 cm) - 3 m;

- fabric for the outer cover (with a width of 150 cm) - 3 m;

- zipper, 22 cm long;

- sewing thread;

- materials for decoration (edging, braid, ribbons, inlays).

Start by cutting out all the necessary parts. Don't forget to leave seam allowances! They should be 1.5-3 cm.

First, you need to prepare templates for all elements of the upholstered chair. They are usually made from paper or plastic wrap (if you want to make reusable patterns). When creating patterns, allowances do not need to be taken into account.

The finished piece is placed on the seamy side of the fabric and traced around the office with chalk or a piece of soap. The patterns leave a space equal to the allowances between the details. If you provide the same allowances for all parts, then the elements do not need to be marked separately. It is enough to fold the fabric in several layers and circle the pattern once.

Sewing should start with making the inner cover. "Petals" are sewn to the bottom in turn. Then the sidewalls of the long pieces are sewn together. One seam must be left with a packing hole. The top part is sewn last.

Next, a cover is made. It is done in the same way, only a zipper is inserted into one of the seams. To do this, the seam is sewn from below, to a length of 3-5 cm. Then a pass is made equal to the length of the zipper, and it is sewn to the end. The parts sewn in this way are turned inside out, and the allowances for the fastener are folded and ironed. The zipper is placed under the workpiece from the wrong side and pinned to the seam allowances. First, a stitch is laid on one side, trying to position it as close to the teeth as possible (usually special feet for sewing machines are used for this), then on the other. Finish the zipper with double seams at the beginning and end of the zipper.

Additional decor will make the chair a unique detail of your room. It can be decorated with embroidery, appliqués, decorative braid. This finish only depends on your personal taste.

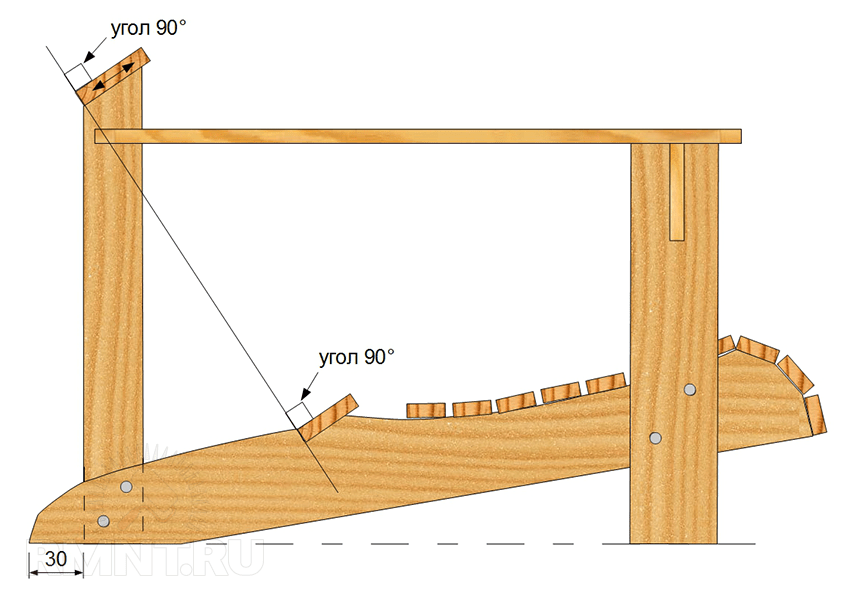

In the considered option for making the Adirondack chair with your own hands, the design features are preserved, but there are no difficult joinery connections. It will not be difficult to repeat the project by making wooden parts according to our drawings and assembling the product using screws.

The work uses a planed 20 mm pine board, galvanized screws 4.5x40 mm, bolts 10x60 mm with a square headrest and nuts with washers. A jigsaw and a sander will speed up the process, and a hand router will allow you to neatly round the edges, but all workpieces can be cut out with a regular hacksaw, and the burrs can be removed manually with sandpaper.

The device of the Adirondack chair: 1 - back strap; 2 - screws; 3 - upper cross member; 4 - back leg; 5 - side support (spar); 6 - bolts; 7 - armrest; 8 - front leg; 9 - seat strip; 10 - armrest support

The device of the Adirondack chair: 1 - back strap; 2 - screws; 3 - upper cross member; 4 - back leg; 5 - side support (spar); 6 - bolts; 7 - armrest; 8 - front leg; 9 - seat strip; 10 - armrest support

Manufacturing of parts

The most difficult elements of the chair are the two side supports of the seat. Make a full-size paper template for the side members.

Side support drawing

Side support drawing

Draw the bottom side of the part, lift the first perpendicular line from the left and two more at the appropriate angles to point A. Mark point C and draw a cutout for the cross brace as shown in the diagram.

Mark a 75 ° corner with vertex C, extend the bottom side with a line. Draw an arc with a radius of 116 mm, measure the corner at point D and connect them with a segment.

Draw a rounding between points A and B, using a square grid or an improvised template as in the photo.

Place the cutout template on the board, avoiding large knots and leaving small ones away from the edges of the blanks. Trace the contours and saw the parts using a saw on straight sections, and cut out the curly contours with a jigsaw. Guide the blade in the direction of the grain to reduce the amount of wood chipping.

Transfer the drawings of the remaining elements of the chair to the boards, also using a template, or draw directly on the blanks and mark the next identical part according to the first cut out.

Drawings of parts: 1 - upper backrest guide; 2 - the lower cross member of the back; 3 - armrest (2 pcs.); 4 - armrest support (2 pcs.)

Drawings of parts: 1 - upper backrest guide; 2 - the lower cross member of the back; 3 - armrest (2 pcs.); 4 - armrest support (2 pcs.)

The shape of the curvature of the armrests is not constructively important; you can draw them by hand or using a template. Mark the second part mirrored so that the chips when sawing are at the bottom of the workpiece.

Detail drawing: 1 - backrest strip (7 pcs.); 2 - seat strip (8 pcs.); 3 - front leg (2 pcs.) 4 - back leg (2 pcs.)

Detail drawing: 1 - backrest strip (7 pcs.); 2 - seat strip (8 pcs.); 3 - front leg (2 pcs.) 4 - back leg (2 pcs.)

Grind the ends, joining identical workpieces together if possible. Mill the edges of the upper surfaces of the armrests and backrest slats, or simply soften the sharp edges with a sander.

Assembling the chair

Wooden furniture always starts to rot from joints, the inner surfaces of which cannot be processed on a finished chair. Therefore, cover the parts with 2-3 coats of antiseptic before assembly.

Most of the chair components are connected with screws, the pilot holes for them are drilled with a combination countersink, matched to the thickness of the screws. When they want to hide the caps, they are deepened and closed with glue plugs.

Place the unnecessary board on the table, and on top place the left side support and front leg. Align the workpieces according to the drawing, mark the drilling points.

Chair sidewall assembly diagram

Chair sidewall assembly diagram

Make holes for the bolts and fasten the parts together. Install the rear leg by positioning it perpendicular to the bevel of the support. Assemble the right side of the frame in the same way. Connect the sides of the chair with the lower cross member of the backrest and the first bar of the seat.

Install supports on the front legs, fixing them with clamps for convenience. Fasten the armrests with the screws.

Attach the upper backrest guide by aligning it with the lower cross member. Right now it is possible to correct the possible accumulated millimeter inaccuracies of marking and uneven cuts.

Small errors are eliminated by shifting the head rail and trimming the corner under it. As a last resort, you will have to unscrew the bottom bar and adjust the cutout.

Mark center lines on the cross-boards and center plank of the back. Holding the latter at the top with your hand or grabbing it with a clamp, drill a pilot hole and tighten the lower screw. Check the vertical position and secure the top of the rail.

Screw all the strips one by one at regular intervals. Take a string and tie one end to a pencil and the other to a nail attached to the junction of the seat and back. Draw a radius of curvature, cut the planks along the markings and sand the edges.

After adjusting the width of the last seat rail, replace it. Inspect the assembled chair and sand the marks, chips and other defects. Sand thoroughly the upper surfaces of the backrest and seat parts.

Coat the wood with oil if you want to keep the natural shade. Use a synthetic resin glaze to create an opaque colored surface.

Each person wants to make the atmosphere of his house or apartment as cozy and comfortable as possible, but at the same time unlike any others.

The uniqueness of the interior can be achieved with the help of hanging chairs. They can be purchased at furniture stores or made by yourself.

Today, on the Internet and in specialized magazines, you can find drawings of chairs of various designs and shapes.

In our article, we will look at how to make such a chair with your own hands.

Varieties of hanging chairs

Today manufacturers offer a huge assortment of hanging chairs, among them there are those that can be made by hand.

Such furnishings can become an unusual accent in the design of a room. Below we will consider several options for chairs that you can easily create yourself.

Swing chair

In the manufacture of original hanging swing chairs, a variety of materials are used. Such models are characterized by an elegant appearance, a fairly simple design, a hard or soft frame. They will perfectly decorate the dacha.

They can also be used as an original piece of furniture for a bedroom or children's room, a terrace.

Cocoon armchair

This is one of the most common hanging chair models. The difference between such an armchair is the presence of walls that hide the inside of the armchair.

This product is created to enjoy solitude, and children also like it very much, as it looks like a hanging house. Only natural materials are used to make the cocoon.

Nest armchair with hoop frame

These are the most popular chairs. They can be equipped with a lot of decor and perfectly complement modern interiors. For such models, a variety of weaving techniques are used.

What are the chairs made of?

When choosing materials for the chair, it is necessary to take into account its specifics.

If you have settled on a swing chair, then you will need thick fabric, different types of artificial ropes and wood bars.

To make a chair in the form of a cocoon, you will need rattan, willow twigs, bast, branches of bird cherry or rakita.

For a chair in the form of a nest, a hoop made of plastic or steel, a durable fabric that is resistant to wear, synthetic filler, special cords for weaving, a variety of wooden bars are suitable.

For the seat itself, the following techniques are used:

- Macrame;

- Patchwork technique;

- Knitting;

- Tatting.

Do not forget that the selected materials and fasteners are suitable for the planned load.

Note!

Master class on creating an armchair

This is the simplest type of hanging chair you can make yourself. To make it, you will need:

- dense material - 2 m;

- wooden beam - length 1 m, radius 3 cm;

- several carbines (0.11 m), designed for weight up to 0.16 tons;

- cable with a diameter of 1-1.15 cm with a breaking load up to 3200 kgf;

- paints, brushes, nylon threads.

From the tools you will need a drill, a sewing machine, an iron, scissors, a ruler.

We work miracles step by step

Step 1. Fold the material in half, measure 0.18 m from above and cut off the resulting triangle.

Step 2. Bend the edges of the canvas by about 1 - 1.5 cm and carefully hem them.

Step 3. Making pockets for the cable. To do this, bend the edges on the long part by 4 cm and sew them on a typewriter.

Note!

Step 4. On each side of the wooden beam we make 2 holes. There should be a gap of 5 cm between two adjacent holes and approximately 0.8 m between pairs of holes.

Step 5. Insert the rope into the central holes and fix it with knots. First, in the middle of the rope we make a knot for the carbine.

Step 6. Pass the ends of the cable through the prepared fabric, insert them into the free holes and fix them with knots.

Step 7. We attach a pair of carabiners to the hook pre-attached to the ceiling, which are connected to each other. This will add reliability to the design. Insert the rope into the last carabiner.

You can decorate the swing chair with bright pillows.

Note!

Hanging chairs are a fairly popular piece of furniture. They can easily become a highlight of your interior.

We hope that this article has convinced you that making a stylish beanbag chair or fashionable hammock chair with your own hands is a snap.

These self-made products have a unique charm. They are sure to amaze your guests with their singularity.

Photo of a chair with your own hands