Pe pipes for heating. Polyethylene pipes for heating private premises

XLPE - innovative material for the manufacture of pipes. Unlike ordinary PE, it can withstand high pressure, the action of chemicals, hot water.

It is used for pipelines of cold and hot water supply, heating.

Installation of PEX pipes is not difficult, but has features, knowledge of which will help to correctly perform the installation.

XLPE pipes for heating and water supply systems

New material exhibits properties of metals and polymers. Cross-linked polyethylene is a thermoplastic polymer with a three-dimensional structure.

Cross-stitching technology creates intermolecular network, similar to a crystal lattice of substances in a solid state.

Thanks to this, flexibility is maintained, the melting point increases, resistance to thermal deformations, scratches and cracks. The material is designated PEX, where X stands for stitching.

Application in residential buildings

XLPE is used for piping external and internal engineering systems residential buildings: heating, sewerage, hot and cold water supply.

Preferred areas of application:

- Warm floor.

- Heating systems working with coolants at low temperatures.

- Intra-apartment water supply.

Photo 1. Installation of warm water floors with red cross-linked polyethylene pipes in the room.

- Heating with horizontal distribution.

- Drains.

Important! Molecularly modified polyethylene is environmentally friendly and safe: it does not emit toxic substances, therefore it is used for living quarters. When burning, it decomposes into compounds harmless to humans: carbon dioxide and water.

Technical properties

- Combustion temperature - 400 ° C.

- Melting - starts at 200 ° C.

- Average density - 940 kg / m 3.

- Stretching without tearing - in the range 350-800%.

- Retention of characteristics at temperature down to -50 ° C.

- Thermal conductivity - 0.38 W / mK.

- Flexibility.

When operating under standard conditions (coolant temperature within 75 ° C) XLPE will last about 50 years old. With constant use with extreme loads: increased pressure, 95 degree coolant the service life will be reduced to 15 years.

Sizes and diameter

PEX pipes are produced with a diameter 10-280 mm and wall thickness 1.7-29.0 mm... Supplied in coils in pieces 6, 8, 10, 12 meters each.

According to the degree of resistance to pressure, XLPE pipes are divided into the following types:

- light: 0.25 MPa (2.5 atm);

- medium light: 0.4 MPa (4 atm);

- medium: 0.6 MPa (6 atm);

- heavy: 1 MPa (10 atm).

The above pressure is nominal, the data is valid when pumping water t 20 ° C.

Advantages and disadvantages

Polyethylene crosslinked at the molecular level retains positive qualities of standard PE and gains new advantages:

The disadvantages of XLPE pipes include UV sensitivity and slow destruction by free oxygen penetrating into the structure from the air.

Attention! To eliminate unwanted contact of PEX pipes with air, use anti-diffusion protection... Handle such a coating with care so as not to scratch it during installation, transportation. Products protect from ultraviolet radiation special additives, which are included in the composition at the production stage.

You may also be interested in:

Types of PEXAU pipes

- Universal- are equally suitable for use in different areas: for arranging a water floor, hot and cold water supply systems, autonomous, central heating.

Photo 2. Universal pipe made of Rehau Pautitan flex polyethylene, suitable for any type of heating.

- Specialized- have a narrow scope. Designed for a certain type of pipelines, for example, only for cold water supply or individual heating.

Depending on the conditions of use, water or non-freezing liquids - antifreezes are used in XLPE heating pipes.

In standard mode, the heating pipes operate at the limit temperature up to 95 ° C and pressure up to 10 atm... In an emergency, they withstand temperature fluctuations up to 110 ° C with a two-fold increase in pressure.

Varieties of pipes from the leading manufacturer Uponor

Uponor (Finland) produces pipes of four types:

- Aqua pipe- for hot and cold water supply.

- Comfort Pipe Plus, Radi Pipe- for underfloor radiator heating, cooling systems.

- Combi Pipe- universal.

- Comfort Pipe- for underfloor heating systems.

Photo 3. Pipes made of cross-linked polyethylene Uponor Comfort Pipe, designed for underfloor heating.

Size range of products made of cross-linked polyethylene 15-110 mm... Supplied in coils 50-540 meters each, 6 meter segments.

The German company REHAU produces a large assortment of pipes of the series RAUTITAN:

- FLEX- are flexible, used for cold, hot water supply, floor, radiator heating of residential premises.

- STABIL- universal, have an inner aluminum layer.

- HIS- universal use in temperature conditions up to 70 ° C up to 10 atm.

- PINK- for underfloor heating, radiator wiring in residential, public buildings.

Connection - Slip-on sleeve fittings, size range 12-250 mm... Pipes are supplied in straight lengths 6 m each or in bays 25-125 meters.

Mounting

There are three ways to connect PEX elements:

- Compression fittings- suitable for water supply (cold and hot). If necessary, the water supply system is disassembled at any time.

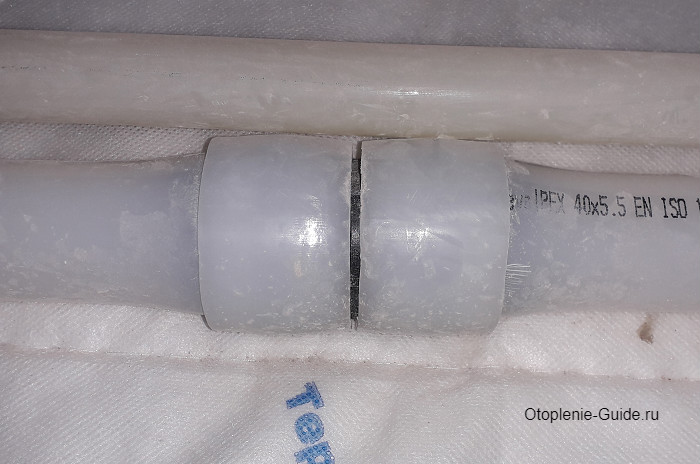

- Press fittings- a permanent connection is obtained. The method is based on the ability of cross-linked polyethylene to recreate the shape.

- Electrofusion fittings- the most durable and reliable connection. The method requires skills in working with welding equipment.

Attention! When choosing the installation method, take into account the pressure that will be in the system. Compression fittings withstand up to 2.5 atm, press fittings - up to 6 atm, electrowelded - give a monolithic connection.

Instruments

Depending on the chosen installation method, you will need:

Electrofusion couplings- type of fitting in the form of a sleeve with built-in heating terminals.

Reference! Fittings are pipeline connecting elements used for assembly and joining, for branching, pipe turns. Main material: brass, but produced polyethylene, polyvinyl chloride, polypropylene, combined parts.

Preparatory work

Before starting the installation, ensure that the workplace is clean - at the joints dust and dirt must not penetrate.

Guided by the radiator wiring diagram, prepare the required number of fittings and pipes. XLPE is flexible, so fix the pipes to the wall using the brackets.

Check collector outputs- they must be in good condition. To avoid the formation of condensation on the "cold" system and heat loss of pipes with hot water, prepare additional thermal insulation.

Operating rules and connection to the radiator

- A high-quality cut is the key to the tightness of the joint. Cut the pipe strictly at 90 °- perpendicular to the horizontal axis.

- Ensure that the cut surface is completely flat- without cuts, roughness, waves.

- Select only dedicated fittings for connections.- for cross-linked polyethylene.

- If you need a pipe bend, first warm up the area to be bent with a construction hairdryer.

- When using the electro-welded method monitor the temperature of the device. XLPE can overheat and burn.

- For quality installation follow the pipe and fitting manufacturer's instructions.

The flawless operation of the heating system is the key to a comfortable and cozy stay of households indoors in any weather. Modern materials and technologies used in the installation of heating systems make their work long and efficient. The main element of any heating system is the pipes that connect all the elements and communications. The choice of pipes should be approached very responsibly, since the service life of all equipment and its serviceability depend on this.

Recently, the arrangement of the heating and water supply system is carried out using polyethylene pipes. This material has properties that give it a great advantage over other analogues. However, during the operation and installation of cross-linked polyethylene heating, some technical features of this material should be taken into account, which should be learned in more detail.

Features of polyethylene pipes

Conventional polyethylene pipes, with the designation PE, are used for the installation of heating, sewerage and water supply systems, including drinking water supply. Pipes made of such material have some features, among which the following can be distinguished:

- Resistance to subzero temperatures. Operation and maintenance of polyethylene systems is allowed at -20 degrees. This is important when carrying out any production work in the winter, including the installation of new equipment and the repair of damaged areas.

- Flexibility and ductility. These properties make it possible to avoid deformation of pipes, not only during bending. Flexible pipes for heating made of cross-linked polyethylene are able to expand when the working medium freezes and shrink when it thaws. In this case, the product takes on the previous shape.

- The use of polyethylene pipes at a temperature of the working environment no more than 40 0 C.

The latter feature can be called a disadvantage, but progress in the scientific and technical direction helps to solve the problem. Thanks to this, special pipes made of cross-linked polyethylene were designed, which can be used in water supply and heating systems with a coolant temperature of up to 90 0 C. The new material has the designation PEX.

Characteristics of XLPE pipes

To obtain a material with higher strength characteristics, polyethylene was subjected to high pressure treatment. As a result, the polyethylene molecules formed stronger cross-links.

To obtain a kind of "stitching", the following methods were used:

- Polyethylene was placed in an electromagnetic field and irradiated with electrons.

- The material was treated with peroxide.

- The polyethylene was treated with nitrogen compounds.

The result of each method was a durable and thermally stable polyethylene, which is quite suitable for use in individual and central heating systems, radiator and panel type, in hot and cold water supply systems, as well as for the "warm floor" and "snow melting" systems. Polyethylene pipes obtained as a result of treatment with peroxides are of higher quality.

For the operation of pipes made of cross-linked polyethylene, certain requirements must be met:

- The maximum value of the operating temperature is no more than 90 0 C. However, in extreme cases, products made of cross-linked polyethylene can function for a certain time at temperatures up to 100 degrees.

- The operating pressure in the system cannot exceed 10 bar, provided that the heat carrier is heated to 90 degrees, or 25 bar when the working medium is heated to no more than 25 degrees.

One of the features of cross-linked polyethylene is high oxygen permeability. This property is a disadvantage of the material, since it limits its use in its pure form, especially in closed-type heating systems. To eliminate this drawback, cross-linked polyethylene is reinforced with a layer of aluminum foil or protected with a special polyvinylethylene coating.

Connection of polyethylene heating pipes

XLPE pipes are connected using fittings made from a variety of materials, including polymers, brass and bronze. Polymer fittings are characterized by high quality and have shown themselves only from the best side for a long time. That is why the products are very popular with the consumer.

The process for fitting XLPE pipes is as follows:

- With the help of a flaring tool, the end of the connecting pipe is given a larger diameter by expanding it.

- A fitting nipple is placed in the resulting hole.

- Using a press, the tension sleeve is fixed to the pipe. This makes the connection more durable.

The use of such a technological process increases the service life of the joint and increases its strength. At the same time, the operational period of the connection completely coincides with the life of the cross-linked polyethylene pipes. If necessary, the heating pipes can be insulated with an appropriate material.

Advantages of polyethylene pipes for heating

Cross-linked polyethylene pipes have a large number of advantages, due to which they stand out from the general group of pipes used for the installation of heating systems. Of the most significant advantages, the following can be distinguished:

- High temperature resistance and excellent strength characteristics... Unlike polypropylene and conventional polyethylene pipes for heating, the new material will not change its shape when exposed to high temperatures.

- Resistance to the formation of foci of corrosion... Compared to copper products, XLPE pipes do not corrode. Moreover, this process does not occur either within the structure of the material or on the surface.

- No build-up inside the pipes... The inner walls of PEX pipes are not covered with layers after transporting any aggressive medium. In this they differ from most steel pipes, which after a certain period of time become less productive due to a decrease in flow velocity.

- Restoration of the previous form... Many pipes lose their shape as a result of certain mechanical influences. However, XLPE pipes can expand or contract to certain parameters when exposed to low temperature or mechanical stress.

- Negligible mass... The light weight of the material makes it more convenient to transport XLPE pipes and facilitates the installation process.

- Easy installation and great possibilities... PEX pipes can be laid in any pattern, including kinking or a large number of bends. Connecting with fittings simplifies the installation process, as it eliminates the need for welding equipment, soldering and gluing.

- Environmental Safety... Cross-linked polyethylene belongs to the group of environmentally friendly materials, therefore, PEX pipes can be used to transport clean drinking water.

However, such pipes cannot be called completely flawless due to the presence of some shortcomings.

disadvantages

Firstly, when connecting XLPE pipes for heating using brass fittings, the list of materials used for screed or plaster is limited. It is better to exclude those that can cause corrosion of the fitting, so as not to degrade the quality of the system.

Secondly, XLPE pipes are characterized by low resistance to ultraviolet radiation, so it is better to use them in closed systems and communications.

Thirdly, it is recommended to use PEX pipes in systems that have pressure and temperature values that correspond to the threshold values of the pipes. When choosing pipes made of cross-linked polyethylene, you should carefully study the technical characteristics of the general system and the features of the living quarters where it is planned to install a heating system from the specified material.

The practical use of cross-linked polyethylene for heating shows that the material fully complies with the parameters and conditions of modern systems that function flawlessly on Russian territory.

Polyethylene pipes have been used for cold water supply systems for more than half a century. But hot water was not previously supplied through them, since polyethylene collapses when heated. This disadvantage has been eliminated thanks to the development of technology. A method for the production of cross-linked polyethylene (PEX) was developed. According to it, a stream of electrons is passed through the material, as a result of which the bonds between the hydrogen and carbon atoms are destroyed, and the neighboring, previously unconnected molecules form strong molecular chains.

This procedure contributes to the fact that pipes for heating from XLPE are durable, resistant to high temperature and pressure. In addition, polyethylene can be chemically crosslinked: using hydrogen peroxide or by incorporating silane into it. Depending on the method of joining the material, cross-linked polyethylene for heating acquires its own special qualities, which can be useful in various operating conditions.

This procedure contributes to the fact that pipes for heating from XLPE are durable, resistant to high temperature and pressure. In addition, polyethylene can be chemically crosslinked: using hydrogen peroxide or by incorporating silane into it. Depending on the method of joining the material, cross-linked polyethylene for heating acquires its own special qualities, which can be useful in various operating conditions.

The German company REHAU produces some of the best pipes of this kind, such as Flex, His, Pink and Stabil. Although the price of pipes for Rehau heating is quite high, the demand for this product is not decreasing. XLPE pipes have many advantages. These include:

All these "pluses" affect the cost of the product. But pipes made of cross-linked polyethylene for heating, the price of which is quite high, are still in demand.

disadvantages

There are few disadvantages of polyethylene pipes, and most of them are easily removable:

Technical indicators

It is recognized that polyethylene pipes for heating, the technical characteristics of which meet high requirements, can be used for heating systems, the coolant in which has an operating temperature of 90 degrees, and sometimes warms up to 95 degrees. In the event of a malfunction, they will withstand the boiling point of water for a short period of time. Products are elastic, as they have a high rate of linear expansion. Its coefficient is 0.12-0.14 mm / mK. This contributes to the fact that reviews on XLPE pipes for heating are always only positive.

It is recognized that polyethylene pipes for heating, the technical characteristics of which meet high requirements, can be used for heating systems, the coolant in which has an operating temperature of 90 degrees, and sometimes warms up to 95 degrees. In the event of a malfunction, they will withstand the boiling point of water for a short period of time. Products are elastic, as they have a high rate of linear expansion. Its coefficient is 0.12-0.14 mm / mK. This contributes to the fact that reviews on XLPE pipes for heating are always only positive.

The pressure that pipes withstand depends on the temperature of the water in the system.

At a temperature of ninety degrees, it should not exceed 10 bar, and at temperatures below twenty-five degrees - 25 bar. The strength of the pipes will become even higher if they are reinforced. The cross-sectional size of these products varies significantly, which is why the cost of the product also varies. For example, a cross-linked polyethylene heating pipe, the price increases with an increase in the diameter of the pipes.

At a temperature of ninety degrees, it should not exceed 10 bar, and at temperatures below twenty-five degrees - 25 bar. The strength of the pipes will become even higher if they are reinforced. The cross-sectional size of these products varies significantly, which is why the cost of the product also varies. For example, a cross-linked polyethylene heating pipe, the price increases with an increase in the diameter of the pipes.

Mounting

It is carried out with the help of special tools and auxiliary parts - fittings (with unions at the ends) and couplings. In addition to the commonly used brass fittings, there are plastic fittings commercially available. They are cheaper, but no less functional. First, couplings are put on the pipes. Then fittings are inserted into the pipes, after which the couplings are pushed onto the junction from above, pressing the polyethylene. The result is a sealed and durable design without threads and the use of rubber gaskets.

It is carried out with the help of special tools and auxiliary parts - fittings (with unions at the ends) and couplings. In addition to the commonly used brass fittings, there are plastic fittings commercially available. They are cheaper, but no less functional. First, couplings are put on the pipes. Then fittings are inserted into the pipes, after which the couplings are pushed onto the junction from above, pressing the polyethylene. The result is a sealed and durable design without threads and the use of rubber gaskets.

This installation method was developed by Rehau. Its experts came up with the idea of expanding Rehau heating pipes at the ends with a special device - an expander (it will be needed for installation).

This installation method was developed by Rehau. Its experts came up with the idea of expanding Rehau heating pipes at the ends with a special device - an expander (it will be needed for installation).

The order of work is as follows. A sleeve is put on the polyethylene, then the bell is expanded with an expander. After that, a fitting is inserted into the pipe until it stops, and a coupling is put on on top. Previously expanded polyethylene quickly regains its shape by tightly gripping the fitting. As a result, Rehau XLPE for heating after installation is much more reliable than mounted systems with threaded, welded and other connections.

When choosing a product, it is worth examining the markings applied to it. It should not be blurry, rub off on contact with fingers. Ask your dealer if the product contains a layer that prevents the penetration of oxygen into it. If you buy Rehau heating pipes, it is better to install them with professional tools from the same manufacturer, which ensure high quality installation.

When choosing a product, it is worth examining the markings applied to it. It should not be blurry, rub off on contact with fingers. Ask your dealer if the product contains a layer that prevents the penetration of oxygen into it. If you buy Rehau heating pipes, it is better to install them with professional tools from the same manufacturer, which ensure high quality installation.

XLPE pipes are used for heating systems, cold and hot water supply.

The main thing is to buy a product of a well-known brand and install it with high quality. Such products are not subject to corrosion. Therefore, if consumers follow the operating rules, they will not require emergency repairs for a long time, no matter how high the humidity of the premises or the harsh winter.

Reinforced plastic and, of course, polyethylene, which will be discussed in this article.

Uponor XLPE pipes + Danfoss ball valves.

Polyethylene pipes for heating are made of cross-linked polyethylene PE-C (PE-X, stands for Cross-linked polyethylene, where PE is PolyEthylene, X is Cross-linked) ).

Leads to floor-standing radiators.

Advantages of PE PEX pipes

- The operating temperature of the coolant is up to + 95 ° С (for a short time up to + 110 ° С).

- Durability. Service life of 50 years or more.

- Mechanical strength. The high molecular memory of the material allows it to recover its shape after deformation.

- Corrosion resistant. Deposits and sludge do not form on the inner walls, which distinguishes them favorably from their metal counterparts, which periodically need to be washed and cleaned. The cost of such work may exceed the cost of new pex pipes by several times.

- High hydraulic characteristics, which are ensured by the smoothness of the inner walls of the PEX pipes. Due to the fact that no deposits form on the inner walls, there is always good hydraulics in the heating system. Formation of a smooth surface (roughness coefficient of about 0.0005 mm) is ensured by a special Teflon coating of the extruder.

- Resistant to harmful bacteria.

- Not damaged by freezing water.

- Light weight (1 m 16 mm pipe weighs about 90 g).

- Low oxygen permeability (0.02 gr.per 1 m³ / day). PEX XLPE pipes are covered with an ethylene vinyl alcohol protective film that prevents oxygen from entering the pipe.

Uponor at the construction site prior to installation.

Note! Almost complete oxygen tightness is ensured when the pipe is reinforced with a layer of aluminum foil (PE-X-AL-PE-X, PE-X-AL-PP, PE-X-AL-PE). The only drawback of such a pipe is its inability to recover from mechanical stress. The crosslinked polyethylene reinforcement technology was developed by Kitetechnology B.V. (UK) in 1979.

- Resistant to hydro shocks.

- Ease of installation.

Uponor XLPE pipes on sound-absorbing material "Thermozvukoizol" + tee and Uponor rings.

disadvantages

- High price. The price of the REHAU Rautitan Pink pipe 16 mm x 2.2 is about 75 rubles / m. The price of VALTEC PEX-EVOH 16 mm is 59 rubles / m.

Note! PEX XLPE pipes are UV-resistant, therefore a protective cover is recommended for outdoor use.

Evolution Uponor Q&E.

History

The technology of "crosslinking" polyethylene was developed by the Swedish chemist Thomas Engel in 1968. However, the scientist believed that his invention could not compete with more modern products and sold the patent for the invention. In 1972, the WIRSBO company (Sweden) began industrial production of PEX pipes and still occupies one of the leading positions in the market.

Uponor Radi Pipe 40 × 5.5 EN ISO 15875.

Expansion tool Uponor Q&E REMS Power Ex Press, 1063701. Expansion head for 40x5.5mm pipe included. Made in France.

Production

"Stitching" is the process of joining molecules into a three-dimensional network through the formation of crosslinks. During crosslinking, some hydrogen atoms are detached from polyethylene molecules, which are composed of hydrogen and carbon atoms. As a result of this, a free bond is formed, which is used to connect the links of the molecules to each other.

Uponor Aqua 25 x 3.5; 20 × 2.8.

There are 4 ways to produce XLPE:

- Peroxide (PE-Xa) - heating of polyethylene in the presence of peroxides. This is the slowest production method, but at the same time the highest quality. It is characterized by a high degree of crosslinking of carbon atoms, on average about 82%.

- Silane (PE-Xb) - material treatment with moisture containing silane and catalyst. The degree of crosslinking is about 65%.

- Electronic (PE-Xc) - processing of the material with electrons. The degree of crosslinking is about 60%.

- Nitrogen (PE-Xd) - the most rarely used method.

Note! The degree of crosslinking affects the molecular memory, density and elasticity of the tube.

Polyethylene pipes for heating are sold in coils of 100 and 200 m, this allows the installation of large areas without the use of additional fittings.

Cordless expansion tool Milwaukee C12 PXP-I10202C.

Milwaukee C12 PXP-I10202C.

Milwaukee C12 PXP-I10202C Kit.

Expander Case Milwaukee C12 PXP-I10202C.

Installation of XLPE pipes

Unlike the installation of metal pipes, which requires special knowledge and skills (welding, soldering ...), without which it will not be possible to perform the work efficiently, such skills are not required when installing sewn polyethylene pipes. All that is needed is a set of tools and strict adherence to a predetermined plan.

Uponor Q&E Manual Expansion Tool S 5+ S 3.2. Article 1004064.

The following tools are required for installation:

- Expander (expander);

- Various nozzles for expander: nozzle for expanding a polyethylene pipe; nozzle for connecting pipes to radiators;

- Press;

- Press attachments;

- Lubricant and brush for cleaning the tool;

- Pipe cutter.

Note! The joint obtained in this way is very reliable and even stronger than the pipe itself.

Video

Crosslinked polyethylene is a type of polyethylene produced physically and chemically, in which molecules are crosslinked. The bonds created at the molecular level are very difficult to break, which makes this material very durable and high-tech.

Nowadays, polyethylene material is becoming more and more popular in the construction industry and is used for sets of piping systems, for hydronic heating and cooling systems, for internal water pipelines, high voltage insulation of electrical cables.

Also, polyethylene is used for:

- natural gas;

- offshore petroleum applications;

- chemical purposes;

- waste water transportation;

- slag emissions.

Such technologies have found wide application in the laying of water pipes, since cross-linked polyethylene is used for the manufacture of pipes, thanks to which they are able to bring up to 40% more drinking water into the house. It has been proven that they are gradually becoming the dominant technology in the delivery of water to the home, so in the next few years they will become the main trend in the construction business.

Heating history in different years

In mass production in the 20th century, water pipes were made of galvanized steel, but when used, they caused great inconvenience to the consumer. Due to problems with intense rust build-up, the volume of water passing through was significantly reduced. In the 1960s, galvanized pipes were replaced with plastic pipes with fittings.

Now the most popular way to transport water in hydraulic heating systems is the installation of polyethylene pipes.

XLPE is best suited for recirculating hot water in your home, so this is the best solution. Therefore, more and more often, copper and galvanized pipes are being replaced by polyethylene ones.

Benefits of XLPE

XLPE has gained popularity among consumers for its flexibility. The pipe can be bent at a wide angle. In addition, they can work with a small radius of turns, sometimes supported by a metal bracket.

They can work from the point of distribution of the fastener without cutting or splicing. The installation allows the water supply line to be installed directly from the source using only one connection at each end.

Installation involves minimizing all kinds of pipe bends, which means that water flows out under good pressure, which is very favorable for showers, toilets and sinks.

The cost of the material is quite reasonable and the price is affordable for almost everyone.

Pipes made of XLPE are easy to install. Their installation is less laborious compared to copper or galvanized ones, since there is no need to install torches or solder. There is also no need to glue in order to attach the fittings.

The risk of fire during installation is excluded, while it is present during soldering, since wick lights are used. Fire may result from flame and high temperature. When using polyethylene, this problem will not arise.

Special properties

HDPE (Low Density Polyethylene) has special properties that contribute to the strength and long-term service of the material. HDPE manufacturers offer a validity period of about 25 years. If the pipes are made using the cross-linked high-pressure polyethylene (LDPE) method, then they are more resistant to destructive properties and corrosion.

Suitable for hot and cold pipes

Convenient location of color framing eliminates any confusion. Typically, red is used for hot water and blue for cold water.

Environmental benefit

Polyethylene is more environmentally friendly than copper and zinc.

Disadvantages of XLPE

Unfortunately, these pipes also have their drawbacks. Let's consider them in more detail.

Degradation from sunlight

Polyethylene cannot be used in places where a lot of sunlight is concentrated. Direct sunlight will degrade the quality of the material.

Insect damage

The material attracts insects, which penetrate the plastic heating system, causing holes and, consequently, water leaks.

Can't use glue

It negatively affects the polyethylene material, causing it to prematurely age. Such heating systems are often severely affected by the use of adhesive for insulation. Therefore, insulating materials must be selected very carefully.

Negative health effects

It is believed that polyethylene material is bad for human health. This is due to the large accumulation of harmful chemicals that enter the water flowing through the pipes. Substances such as tert-butyl ether and butyl alcohol are very harmful.

Installation of a polyethylene heating system

There are two ways to install XLPE pipes: using compression fittings and press fittings. The first option is much simpler. The algorithm of actions in this case is as follows:

- direct the threads towards the connector and slide the crimp nut onto the pipe;

- then put the split ring on the pipe, but its edge should recede from the pipe cut by 1 mm;

- push the pipe onto the fitting socket as far as it will go;

- complete by tightening the crimp nut using wrenches.

Remember to tighten the nut very carefully so as not to damage the pipe with excessive force.

When installing using press fittings, special press equipment is required. And the installation itself is carried out as follows:

- slide a continuous clamping sleeve onto the pipe;

- fully insert an expander of the required size into the pipe;

- smoothly bring the expander handles to the stop and hold them in this position for a few seconds;

- push the pipe into the fitting until it stops;

- press the sleeve onto the fitting using a press.

It is worth giving preference to pipes sewn from polyethylene, and this will be the best solution for heating a house. Such a system will serve for a long time without causing any significant inconvenience to the tenants.