How to make an opening gate. How to make an automatic swing gate? Automation issue for sliding and sliding gates

Currently, many owners of country houses and summer cottages have fully experienced all the advantages and advantages that automatic gates provide. Their installation allows the car enthusiast to quickly and easily enter the territory of his site, without wasting precious time opening complex and heavy entrance gates. The main thing is to correctly select and mount the gate structure and equip them with a reliable and durable automatic system. Initially, you need to decide on the model of the gate and the technology for its installation.

In many European countries, sectional doors are the most common type of security device for garages and suburban driveways. In terms of technical equipment, their design is separate sections, interconnected by hinges, moving along guide rails fixed along the opening and shifted under the overlap of the room. The movement of this type of garage door leaf is carried out along the vertical plane. This is very convenient in everyday use, since no additional space is required to open the gate, even if the car is located directly in front of the entrance.

For ease of use, sectional doors can be equipped with a side door or a built-in wicket.

A separate door significantly increases the convenience of everyday use of the garage, reduces heat loss in the room and increases the level of security of the facility. Indeed, if there is a door or a wicket, it is not necessary to raise the gate entirely to enter the box.

An important advantage of automatic sectional doors is the availability of a reliable and convenient access restriction system. In advance, you can select a rotating latch or a special latch to open the system only from the inside of the room. To close the structure from the outside, an automatic deadbolt lock with a stable pin and a secure latching washer is installed.

A well-chosen control system will provide the facility with high reliability at an affordable price. The installed drive with the gate leaves closed is additionally a high-quality locking device.

The gate is controlled by an electric drive using a remote control or a stationary device.

If there is a likelihood of permanent or temporary power outages, a special system is provided in the device for prompt emergency shutdown of the automatic electric drive and activation of the manual control mode.

Sliding gates

To protect the entrance area to any territory and its arrangement, sliding gates operating in automatic mode are increasingly used. A steel cantilever pipe is welded to their bottom. During the operation of the structure, it moves along roller carriages, which are installed on a special organized foundation. The bottom corner of the sliding gate in the closed position is rolled into the catcher by the end roller. This movement prevents lateral vibrations of the device during the opening of the web.

Installation of sliding gates requires the construction of an independent foundation.

Consider the following:

- The installation begins with the arrangement of an independent foundation, a base located in the opening and on the side of it, in the direction of the opening of the structure.

- The frame of sliding gates and their fastenings must be highly wind-resistant.

- It is necessary to install a special retaining part, which increases the width of the leaf structure towards the door opening.

- Sliding gates should be provided with an effective anti-burglar system and special protection against adverse external factors.

Video

The following video will help you to understand the device and installation of sliding gates in more detail:

Swing

The most widespread type of entrance gate for many decades remained traditional swing structures. As before, they are still very popular today due to their affordable price, security guarantees and system reliability. In addition, they are very comfortable, functional and have a wide range of design and architectural solutions.

Today, beautiful and prestigious swing gates made of forged leaf, equipped with a durable and comfortable automatic opening system, are in wide demand. The frames and filling themselves can be made from any building materials.

The swing gate design consists of the following elements:

- A metal frame made of steel pipes. The frame section is selected taking into account the dimensions of the structure, wind and operational load of the canvas.

- Steel inner frame, designed for finishing decoration with openwork forged products, sandwich panels, special wood or corrugated board.

Limitations in the choice of an electric drive are related to the width of the gate leaves and the total weight of each individual structure. Special attention should be paid to the location of the automatic drive, which can be located in different places. The drive can be attached to the leaves or gate posts, to the supporting columns of the structure or outside the entire system.

Lifting gates

As for sliding and swing gates, they are used both for arranging garages and for entering the courtyard. Lifting gates are installed exclusively in garages. They represent a canvas that rises and slides under the ceiling of the room.

Overhead gates are in great demand among consumers, as they are convenient in operation, high protective properties against unauthorized entry, and also at an affordable price.

Overhead gates can be divided into 2 subtypes: pivoting and sectional. Generally speaking, the design of these gates is similar, there are differences in the set of components, as well as in the order and method of their installation.

The essential difference is that sectional doors are more flexible and flexible, more reliable, and pivot structures are simpler. The safety of the latter is ensured only by the integrity of the canvas.

Sectional doors are made of sandwich panels and nothing more, and for pivoting doors, a profiled sheet, wood or insulated panels can be used.

There are 2 options for saving without losing quality:

- Install the gate from the manufacturer according to the diagram attached to it.

- Make your own up-and-over doors according to the drawings.

Which of these options to choose is up to you. However, if you do stop at the second option, then it is better to immediately give preference to a simpler design of overhead gates.

In order to save as much as possible on materials, you should accurately calculate them in order to purchase the actually required amount.

To save money, you can sacrifice the appearance of the gate, refusing to decorate it. As for the lifting mechanism, then you can also save money by installing a manual drive. But, you see, the use of an automatic electromechanical device is more convenient. I would not like to save money at the expense of comfort.

The main elements of overhead gates are the frame, the door leaf and the lifting mechanism. Any material that matches the exterior of your home can serve as a canvas. The frame is made of a metal profile or square pipes. They can be fastened together with a weld seam or bolted fasteners. As for the lifting mechanism, the choice here will be more complicated:

- Linkage mechanism - assumes precise alignment of the guides vertically, ensuring smooth movement of the gate up / down.

- The counterweight system provides for the passage of a cable through the block, on which the counterweight is attached. This design has the right to life when it comes to the installation of heavy gates.

So, you will need:

- Profile / square tube for the frame.

- Fasteners.

- Channel bracket.

- Pins.

- Spring.

First you need to make a frame. Embed it a few centimeters into the concrete base. It must be installed in the opening and secured with pins. After that, collect the canvas that needs to be sheathed with a metal shield. Punch holes in the shelves for spring bracket installation and rack mounting. In addition, holes must be made for the channel bracket on which the spring will be supported.

Now you need to work with the spring. It needs to be connected to the bracket. This can be done using a metal shim. Then make the hooks and add a tension adjuster at the bottom.

The next step is to make and fix the hinge assembly and the plate with the hole on the frame, and, accordingly, the end of the lever. Then make the rails from the corners. One end of the rail must be welded to the plate mentioned above, to which the channel is welded. Then it must be fixed to the ceiling of the frame.

It is important to set the guides as horizontally as possible. This way, you ensure that the lifting gate can open / close without hindrance. Now the installation of the canvas, as well as automation, is being carried out.

Video

Photo

In the photos you can clearly see the options for making automatic gates:

Automatic drive - an invention that allows you to open the gate by pressing a button on the wall of the garage or remotely from the remote control. True, in order to equip the entrance structure with automation, you need to have a clear idea of the gate structure. Another prerequisite for the smooth functioning of the drive is the correct installation and adjustment of the equipment.

The device and the principle of operation of the gate with automation

The design and function of automatic gates is determined by their type. And the sashes standing on the territory of the house are:

- lifting (sectional, lifting and turning and roll);

- retractable;

- swinging.

Sectional doors

Automatic sectional doors look like a structure with a leaf that, when opened, goes up, that is, it is removed along special guides to the ceiling of the room.

Sectional doors are absolutely safe to operate, because when opening the door leaves the door up.

The main advantages of sectional doors include:

- compactness, because in the open state the doors do not reduce the area of the garage or other building;

- operational safety, since the lifting web cannot damage the hood of the car, which sometimes happens when using a swing structure;

- security against burglary at the proper level;

- reliable thermal insulation.

But automatic overhead sectional doors have a rather significant drawback - the ability to install only in rooms with a small area.

Automatic overhead gates differ from sectional sash designs. It is a one-piece canvas that covers the entire space of the opening. Such a sash moves up along the guides and changes its position from vertical to horizontal. A door with a solid leaf has the same advantages as a sectional design, but is considered the best option, since it does not release heat at all and more effectively protects the room from intruders.

Up-and-over doors let in less heat and are more vandal-resistant than sectional doors

Rolling shutters (roller shutters)

For automatic rolling gates, the main element is a soft leaf made of aluminum plates, a drum on which the material is screwed, and boxes to protect the entire structure. Among the advantages of such gates, it should be noted:

- wide range of sizes (admissible web width - 12 meters, and height - 10 meters);

- compactness (compressed);

- the possibility of installation in any premises, not excluding garages and shopping malls.

True, roll-up doors cannot be called reliable, since their strength is highly questionable.

Rolling shutters can cover large openings, but they are not strong enough

Console-type automatic sliding gates consist of a leaf that provides access to the room, going to the right or left side of the opening to the building wall or fence. This structure is equipped with roller bearings, partially hidden in the foundation and responsible for the movement of the sash. The rollers are protected by a beam that protects them from moisture.

When the sliding gates are closed, the door leaf is above the opening - at a distance of a centimeter from the ground. Special guides attached to the fence supports or to the wall of the room are responsible for opening the gate.

The sliding gate leaf moves along a special rail fixed to the foundation

Owners of buildings with sliding gates usually point to the following undeniable advantages of the design:

- installation in an opening up to 12 meters wide;

- the ability to easily open the gate, both automatically and manually;

- impeccable thermal insulation;

- perfect strength.

Hinged gates with an automatic drive are a design with two reliable leaves that are hinged and attached to both sides of the opening. To open such a gate by pressing a button, you need to install two electric drives. The swing structure can provide access to the premises by removing the sashes both inside and outside the building.

Swing gate leaves can be opened both inward and outward

The main advantages of automatic swing gates include:

- ease of construction;

- ease of installation work;

- the ability to use in any conditions.

The only thing that does not speak in favor of swing gates is the relatively inconvenient operation.

Preparation for construction: drawings and diagrams

When planning to build a gate, be sure to perform a drawing that reflects the size and location of the main parts of the structure. If you plan to build swing gates - the most popular option - then before drawing up the schemes, they think over what the length of the flaps will be. In this case, the width of the carriageway and the type of car (in the case of constructing a garage door) are taken into account.

The length of the swing gate leaves should be selected taking into account the width of the entrance area

Usually for swing gates, leaves are made 1.5–2 meters long. And the standard height of the canvas, regardless of the type of construction, is considered to be about two meters.

The frame and leaves of swing gates are usually made of metal profiles or square pipes.

Material selection

When thinking about a project for creating an automatic gate, you should pay attention to the choice of material for the canvas. The doors of the structure, which open automatically, should be light, which means that it is more reasonable to construct them from corrugated board, polycarbonate or sandwich panels.

Sandwich panels provide good thermal insulation of the interior and are lightweight

Often, in the construction of automatic gates, a professional sheet is used, which has earned popularity due to its large number of advantages:

- light weight;

- a large and interesting choice of colors (for example, a coating with an imitation of natural stone or wood);

- acceptable cost;

- long service life;

- simple installation.

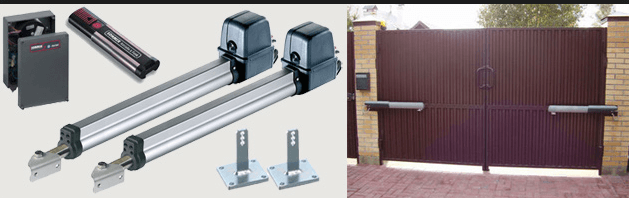

In addition, when preparing for the construction of an automatic gate, it is necessary to seriously approach the choice of an electric drive mechanism. We will have to decide which automation is more suitable for the sashes or the canvas - lever or linear.

Linear actuators are more compact and are mounted on metal poles

If we evaluate the drives by their appearance, then the linear mechanism, which is distinguished by its compactness, seems to be the best. True, it is not customary to install it on wide pillars and to automatically open the doors, which are removed inside the room.

Lever drives are used on gates with wide stone pillars and inward opening doors

To determine the choice of an electric drive, you need to measure the distance between the inside of the post and the hinge. When this value is not more than 1.5 cm, a linear actuator is used. If the indicator is different, then the gate is equipped with a lever-type mechanism, the cost of which is slightly higher.

Calculation of material and preparation of tools

Swing gates, which are installed much more often than sliding or lifting structures, are assembled from the following components:

- bolt;

- support pillars on which the sash will be held;

- frame made of metal elements;

- sash;

- garage hinges;

- door handles;

- two electric drives.

In addition, you will need various materials and fasteners:

- reinforcement rods with a diameter of 1.4 cm;

- two iron pipes with different sections (60x40 mm and 40x20 mm);

- sheets of material for sash sheathing;

- 2 pipes with a cross section of 10x10 cm;

- mortar of cement and sand;

- solvent, primer and alkyd enamel;

- electrode;

- three-wire cable;

- self-tapping screws for fastening metal parts;

- mounting plates (for drives);

- brackets and dowels;

- PVC tubing with insulating material inside.

For the manufacture of the frame and casements of swing gates, metal pipes of various sections are needed.

To mount the gate and install the automation, you need certain tools:

- angle grinder;

- shovel;

- welding machine;

- drill;

- screwdriver;

- measuring tape, building level and ruler;

- brush for metal processing;

- paintbrush;

- indicator screwdriver;

- insulating tape;

- hammer and pliers;

- residual current device.

Step-by-step instructions for making automatic gates

Making a gate involves performing a number of actions:

- Anchoring in the ground at a depth of one meter of two metal pipes with a section of 10x10 cm, for which it is required to create a glass-type concrete foundation.

Gate posts are concreted in a pit one meter deep

- The construction of the gate frame - it is welded from pipes with a section of 40x20 mm. The transverse partition gives the structure the necessary rigidity.

- Cleaning the metal frame from corrosion and alternate treatment with a solvent, primer and alkyd enamel.

- Fastening to the hinge structure (by welding).

- Installation of embedded parts required for laying wires, a meter from the ground level.

- Sheathing of the metal frame with the selected material.

Sheathing made of metal profiled sheet is attached to the frame using roofing screws

- Hanging the produced leaves on the hinges.

- Checking the evenness of the structure by means of a building level.

Choice of automation for swing gates

For swing gates, both linear and lever automatics are suitable. The first option is two electric drives with a worm gear or hydraulic mechanism inside. In some cases, the installation of linear automatics is impossible, and therefore a lever drive is installed on the gates - a massive and durable structure that requires deep planting of the leaves. Lever-type automatics are an excellent solution for swing gates composed of leaves up to 5 meters wide.

The drives designed for sliding gates are the same: they consist of a mechanism with a pinion gear and a toothed rack fixed to the door leaf. The motor of this automation sets the rail in motion and thereby changes the position of the gate. It is started by pressing the necessary buttons on the control panel, which is located on the side of the door structure.

Wiring diagram for connecting automation

Setting up automation

In order for the automation to work, you need to connect it according to the diagram attached to the drives. Typically, setting up a gate leaf opening mechanism is as follows:

- A special plastic cover is put on the engine, screwing the protective cover with a regular screwdriver.

- A board is mounted in a red connector, while switch "1" is put in the "off" position, and switch "2" - in the "on" position.

- The wires are connected to the red connectors, fixing the wire jumpers between the desired pins.

- A key fob code reader is connected to the automation.

- Check the operation of the drives.

Video: installing automation on swing gates

There will be no problems with the operation of automatic gates if you use them, guided by some rules:

- make sure that nothing interferes with the functioning of the leaves, that is, to clear the gate movement zone;

- if necessary, carry out structural repairs, that is, replace worn parts, lubricate moving parts and adjust the mechanism;

- in case of any failures in the operation of the drive, contact the specialists, because any equipment can suddenly fail.

Video: do it yourself swing gates

By placing an automatic gate in a garage or other room, you can operate it without any hassle. For example, to put a car in a garage, you will need, while driving, just press the desired button and wait for the doors to open automatically. It is very convenient and practical.

Automatic control of the entrance gate makes it easier and safer for a car to enter a plot or garage. The advantages of an electric drive are obvious - you can open and close the doors directly from the car's interior, and in order to let the car into the snow-covered courtyard, guests will not have to say goodbye (albeit for a short time) to a warm, cozy room. The high price for high-quality factory automation forces craftsmen to look for more affordable options. And they are. Today, reliable automatic gates can be built with your own hands. Everything you need to do this can be found in the garage or bought for a pittance at market debris.

Automatic gates: features, advantages and disadvantages

If you do not take into account the overly original designs, then all existing gates can be divided into three groups:

- recoil;

- swing;

- garage.

Swinging structures have the richest history and are familiar to everyone from two sashes, which are attached to the side support posts with hinges. Such gates are simple and reliable, but require space to open before entering the site or courtyard. Swinging sashes are an irreplaceable option for narrow passages and, in comparison with other structures, have maximum reliability. The biggest disadvantage of this type of gate is the increased requirements for the stability of the side posts. Insufficient stiffness of the struts over time leads to their tilting, and this, in turn, causes the leaves to jam. The disadvantage is that their automation requires a pair of synchronously operating drives, while other systems require only one actuator.

To automatically open swing gates, a pair of synchronously operating drives is required

Sliding gates have a canvas that can be pushed aside literally close to the fence. Depending on the supporting surface, sliding systems are divided into three types:

The sliding system is the most practical since it does not depend on the availability of space in front of the entrance.

Sliding gates are used today both in private households and for equipping parking lots, open areas and various industrial facilities.

As for the disadvantages, they include the need for arranging the foundation and a more complex structure than that of swing gates. In addition, do not put a canvas sliding to the side on a narrow section - you will need at least 5 additional meters away from the passage. Despite this, it is sliding gates that are the easiest to automate and are distinguished by the highest convenience and reliability in work.

Although all the structures described above are suitable for arranging a garage, lift-and-turn, sectional and roller shutter mechanisms are considered "truly garage". Such systems are the most difficult to manufacture in artisanal conditions, so they are practically not used by home craftsmen.

Automation drives

There are several ways to convert the rotary movement of the electric motor shaft into the translational movement of the actuator:

- using a crank mechanism;

- screw or worm gear;

- by means of a rack and a gear wheel;

- chain transmission.

Using these kinematic schemes, a reliable, efficient drive can be built even in a garage or small home workshop.

For swing-open sashes

To make swing gates automatic, linear or lever-type drives are installed on their leaves. The first include mechanisms with a worm or screw drive, operating on the principle of changing the length of the stem. Lever structures are called structures, the principle of operation of which resembles the movement of a hand. They consist of two levers that are connected by a movable hinge.

Factory linear actuator

Most often, linear drives are used - they can be installed on swing gates with leaves that open in any direction. If the canvases are hung on stone or brick pillars, then it is easier to use one of the lever mechanisms - they are not so demanding on the location of the fulcrum.

In artisanal conditions, linear systems for automatic door opening are most often represented by factory actuators for satellite antennas or homemade screw drives. For lever structures, ready-made mechanisms are also used - they are drives of automatic window lifters or wipers. As for homemade products, you can also find original solutions from a gear motor and a composite lever on the network.

At home, the drive for swing gates can be made from car windows

Automation for sliding curtain

To mechanize sliding gates, you can use a factory automation kit, which includes a drive, a toothed rack and a control unit with sensors. If there is a desire to save money, then an equally reliable system can be assembled from a suitable electric motor with a gearbox, a pair of stars and a long chain from automotive or agricultural equipment.

Diagram of a homemade drive for sliding gates

Production of automatic swing gates

For swing gates, the industry produces a variety of lever and linear actuators, designed for various supply voltages and opening forces. These mechanisms are distinguished by high strength, reliability and are able to ensure the operability of the structure in any weather conditions. They could be called an ideal choice, but there is only one thing - more than 300 euros will have to be paid for a couple of simple actuators and a control unit. That is why automatic swing gates are best done by hand.

Swing gate design

Preparatory activities

In order for the gate to be comfortable and practical, several factors must be taken into account:

- installation site;

- opening method - inward or outward;

- sash dimensions;

- type and method of mounting support posts;

- the type, as well as the method and points of fastening of the drives;

- method of laying cables to actuators;

- type of power supply (only from the mains or with a backup battery);

- design features of the retainer;

In addition, it will be necessary to take into account the peculiarities of the materials from which the gate will be made. Only after answering this question, you can proceed to the design of the structure and the choice of the drive.

Sash size

When determining the size of the gate, they are guided by the width of the vehicles that will enter the site. For the passage of light vehicles, an opening of 2.5 m will be sufficient, while trucks and tractors will require a carriageway with a width of 3.5 m. In the case when the narrow road near the site does not allow making the necessary maneuver, the passage is widened by 1.2 - 1.5 times. Also, pay attention to whether the open doors will protrude into the roadway. In the case when the door design does not exclude such a possibility, the double thickness of one leaf must also be added to the size of the opening.

If the configuration of the site allows you to make a wide gate, you should not neglect this opportunity. Who knows, maybe in a couple of years it will be necessary to drive a construction crane or a dump truck to the site? As practice shows, an opening 4–4.5 m wide will be enough for the passage of any vehicle.

Material selection

For the manufacture of the gate frame, steel profile pipes are best suited - they have high strength, and, which is very important, make the structure as rigid as possible. Suitable for filling the door leaf:

- metal sheets;

- polycarbonate;

- corrugated board;

- boards or picket fence;

- forging.

The gate looks elegant and original with a combination of different materials. For example, forged elements with a polycarbonate or wood base.

Swing gates can be made openwork, filled with metal bars or forged elements

As a rule, the thickness of the owner's wallet has the greatest influence on the choice of material for the gate. Nevertheless, if you do the sash yourself, you can save on wages for a specialist and, due to this, choose a more expensive forging or stamping.

For the manufacture of support posts, you can choose:

- steel pipes or channels;

- hardwood timber;

- reinforced concrete;

- stone or brickwork.

The choice of material from which the pillars will be made should take into account the weight of the canvases. Otherwise, under the weight of the shutters, the posts will converge and closing the gate will require significant efforts - there can be no question of the normal operation of automatic devices in such conditions.

The production of swing gates is not very complex, and their design involves the use of original sketches. There is no need to follow any drawing exactly - it all depends on the imagination and financial viability of the owner of the site. Nevertheless, we present to your attention the drawings and diagrams of automatic swing gates. We hope they will help you create your own project without hard-to-fix errors and annoying oversights.

Photo gallery: diagrams and drawings of automatic gates

Swing gates with a wicket embedded in one of the leaves

Swing gates with a wicket embedded in one of the leaves  Swing gates with double filling with corrugated board

Swing gates with double filling with corrugated board  Swing gates with a wicket and a reinforced frame

Swing gates with a wicket and a reinforced frame  Swing gates without wicket

Swing gates without wicket  Swing-open sash automation scheme

Swing-open sash automation scheme  Wiring diagram of swing gate drive

Wiring diagram of swing gate drive  Swing gate automation scheme

Swing gate automation scheme

What you need in the process

For the construction of swing gates, you will need a lot of different materials:

- for the installation of support posts - metal pipes, stone or brick. If the pillars are made in the form of masonry, then the metal should be prepared for the mortgages;

- for the manufacture of the frame - shaped pipes with a cross section from 60x60 mm to 40x20 mm;

- to fill the frame - steel sheets, corrugated board, wood, polycarbonate or forged elements;

- loops;

- details of the locking mechanism.

The best choice for equipping automatic swing gates is hinges with a mating surface and a support bearing.

Embedded parts are metal elements that are installed in masonry joints for the subsequent fastening of sashes and other structural details. They are made of thick sheet steel, metal corners, channels, etc.

For the stability of the structure, the metal racks will need to be concreted, and a foundation should be built under the pillars of stone and brick. To do this, it will be necessary to bring sand, crushed stone and cement to the site.

You can make a swing gate drive from new or used parts and assemblies from vehicles and household appliances. So, as parts of the automatic opening mechanism are suitable:

It is very easy to make a remote control system from a simple car alarm by connecting the electric motors of the drives through a conventional 12-volt relay. In addition to these parts, you will need limit switches, a signal lamp and installation wires.

For the manufacture of gates, no special tools or any professional devices are required. As for the automatic drive, it all depends on its design - you may have to grind some parts on a machine or order from a familiar turner. For the rest, you should prepare or purchase:

- welding machine (best of all is a small inverter, which is convenient to move around the site);

- angle grinder (in the popular way "grinder");

- riveter;

- electric drill with a set of drills for metal;

- set of wrenches;

- roulette;

- building level;

- scribe made of tool steel.

In addition, excavation and concrete works will require shovels, containers for bulk materials and mortar, materials for formwork and ramming. Do not forget that metal surfaces will need to be weatherproof, so buy a rust converter, metal primer and outdoor alkyd paint in advance.

Construction stages

Step-by-step instructions for the manufacture of automatic swing gates will allow you to systematize the process and avoid mistakes in work.

Installation of support legs

Installation of support legs with and without reinforcement

Metal or wooden pillars must enter the ground to a depth of at least 1 m, otherwise, under the weight of the shutters, they will shift from the vertical position. In order to install the supports, you must:

With a significant mass of each canvas, as well as in the case of making pillars of stone or brick, lower dressing of metal racks and arrangement of the foundation will be required.

Reinforcement of pillars and foundations for the installation of automatic swing gates

The work is carried out according to the following algorithm:

After pouring, the concrete must stand for at least 10 days, which can be spent on making the sashes. Throughout this period, the base of the supports is periodically watered with water - this will increase its strength and avoid cracking.

Sash welding

To prevent the frame from being twisted by the "propeller" during welding, it is recommended to equip the simplest slipway in a clean and level place. For this, wooden blocks and slats are used, from which a flat horizontal structure is assembled.

Sash welding jib

The main reason that leads to a violation of the geometry of the sash during operation is the wind load. Therefore, the door frame should be as rigid as possible - especially for canvases filled with materials such as polycarbonate and corrugated board. The best material for making a frame is a profiled steel pipe. The installation procedure for the supporting frame is carried out in several steps:

After that, the counterparts of the hinges are welded to the posts and the sashes are hung in place. It's too early to start painting work - this is done after the brackets for attaching the drive mechanism have been mounted.

When installing the sash in place, you can use any suitable props

How to build a drive

After installing the gate, proceed to the installation of the automatic drive. To determine which of the mechanisms - linear or lever, is suitable, measure the distance between the plane of the canvas and the outer edge of the pillar (marked with the letter M in the lower figure).

Installation diagram of a linear drive on swing gates

If the specified dimension exceeds 150 mm, then a linkage mechanism is used. Otherwise, a linear type actuator can be installed. It belongs to the more modern and aesthetic. If linear automation needs to be installed on massive pillars made of stone or brick, then niches with mortgages for fastening the drive are made in the masonry.

Mounting an actuator in a niche is one way to combine a linear actuator with massive pillars

A linear gate opener with leaves weighing up to 100 kg can be made from two actuators for satellite dishes. All that is needed for this is to attach the brackets to the door leaves and posts for their fastening. When choosing actuators, preference is given to devices with a stroke of at least 350 mm.

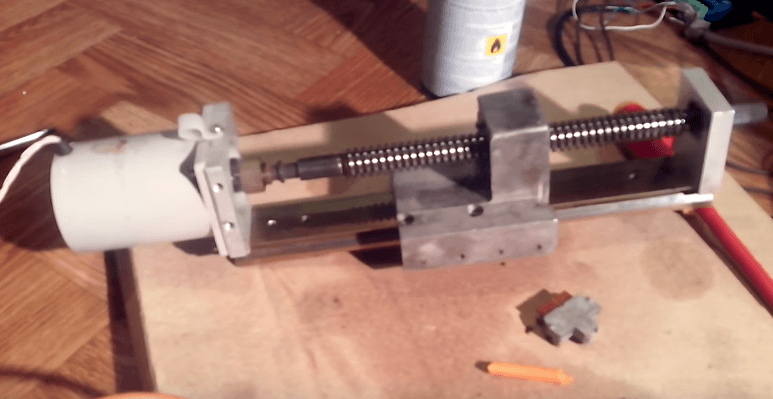

For heavier gates, the linear drive can be manufactured by yourself. Here's what you need to do this:

In the process of work, you will need all the same grinder, a welding inverter and an electric drill, as well as another locksmith tool that every owner has.

The drive is manufactured according to the following scheme:

- The protective cover is removed from the jack, the handle and gears are dismantled. With the help of retaining rings and washers, a retainer is constructed to prevent longitudinal backlash of the screw.

A used jack must be completely disassembled and cleaned

- Using the grinder, dismantle the support platform of the lifting device.

- The wiper mechanism is disassembled - in the future, only an electric motor with a gearbox is needed.

Wiper motor complete with gear

- A connecting sleeve is made from a section of a profile pipe 20x20 cm with a length of 6–8 cm, which is attached to the jack screw.

Installation of the connecting sleeve is carried out by welding

- Drilling is performed in a square bar of 18x18 mm, in which a thread is cut for the gearbox shaft.

- Mount the counterpart of the connecting sleeve on the wiper motor.

Mounting the connecting plate

- A number of holes are made at the corners of the plate, corresponding to the connecting dimensions of the gearbox housing.

- The electric motor and the screw part are assembled using long studs and nuts.

Homemade gate drive assembly

Another option for manufacturing a drive from a Zhiguli jack is shown in the figure below. The mechanism looks more cumbersome, but it is not necessary to dismantle the planetary gear and think over the fixation of the working screw.

Another version of the drive from a wiper motor and a jack from the VAZ "classics"

In the case when only a lever mechanism is suitable for automating the gate, you can use the power window drive of the GAZ car or modify any suitable gearbox with a pair of levers.

Window regulator drive for GAZ car

To connect the drive to a 220 V network, a step-down transformer with a 12 V rectifier is used. Limit switches are used to turn off the electric motor in extreme positions. In this case, it is necessary to think over how the engine reverse will be carried out. Perhaps a few electrical circuits that are used on real structures can help you with this.

Photo gallery: electrical connection diagrams of automatic gate drive parts

Electrical circuit diagram with relay for swing gate drive

Electrical circuit diagram with relay for swing gate drive  Connection diagram of swing gate drive elements

Connection diagram of swing gate drive elements  Scheme for the implementation of the reverse

Scheme for the implementation of the reverse

Installation and adjustment of the drive

To install the drive to the posts and shutters, it is necessary to weld the usual U-shaped brackets, which will provide a movable connection.

Coupling unit for operator and gate leaf

It is best to use hardened bolts with a diameter of 8-10 mm as the axis of rotation. It is better not to use galvanized Chinese hardware from the nearest building store - steel that is too soft will wear out quickly, and this does not contribute to reliability and safety.

And now - some useful tips for installing and configuring the drive from specialists who are engaged in the installation of automatic gates:

- the device is installed with an electric motor and a lever down, preferably along the upper edge of the canvas;

- first of all, the mechanism is fastened to the pillars, and then to the gate leaves;

- after installing the drive, the gate must be opened manually and the limit switches must be set;

- the power supply must be connected with the drive locked;

- in order to avoid damage to the electric motor when the shutters are blocked, a device is introduced into the electrical circuit that turns off the network with a sharp increase in the current strength;

- a warning lamp is installed in a conspicuous place, which will turn on when voltage is applied to the electric motors.

After installation, check the smoothness of opening and the clarity of the operation of the "limit switches". The electric motor and gearbox are protected from precipitation by means of casings that can be made from improvised means.

Video: swing gates with a homemade electric drive

For a person who knows how to handle a welding machine and a "grinder", the manufacture of entrance or garage doors is a common thing. Automation of the process of opening them is quite another matter. Many give in to a more complex design due to the lack of a drive, others are intimidated by the electrical part. Nevertheless, it is not difficult to make a reliable, efficient opening system. The main thing is that its mechanism matches the type of flaps and their weight.

"A skilled craftsman and a handicraftsman brings joy to himself and to people." You don't know what else to do this in the yard, if everything has already been redone, and your hands are itching? We can suggest an idea. Gates that open and close themselves automatically. Lovers of comfort have long appreciated the very idea of remote control of gates, and other motorists envy them, especially at a time when it is pouring rain outside. It is clear that most have to open the gate leaves on their own, but doing it in bad weather is an extremely unpleasant task, and besides, not everyone wants to flop in wet clothes on the seat and dirty it. Below we will tell you how to make an automatic gate for a garage or a fence with your own hands, providing detailed instructions with photo and video examples.

What are the mechanisms

Nowadays, there are several types of street gates:

- swing;

- recoil;

- roller shutters.

Swinging is a classic look. The gate consists of two leaves, which are fixed on pivoting hinges to a vertical base, deeply and firmly installed steel frame. For manual or automatic opening of the shutters, you definitely need a space in front of them.

If you want to make an automatic swing gate for a summer residence with your own hands, we advise you to watch this video:

Homemade sliding mechanism

Sliding on rollers, usually one leaf, a technically simple design, since the weight of the gate is distributed on the rollers, and additional reinforced guides are installed to withstand wind and lateral loads. Such mechanisms have some features in operation, but at the same time, it is enough just to make the mechanical part for them with your own hands.

If you are interested in this option for an automatic fence gate, we recommend watching this video review:

Homemade recoil mechanism

The idea of \ u200b \ u200bmaking sliding gates

Roller-type garage doors are a set of metal and plastic slats, interconnected with a movable lock, placed in guide grooves and connected into one single structure. Moving along metal guides, the segments are bent, positioning themselves under the ceiling and freeing the entrance to the garage.

Swing-over garage doors perform a complex maneuver, going up and freeing the passage. The automatic lifting mechanism for them is difficult to install and operate, so we will not consider it within the framework of this article.

Operating principle

The swing gate opening mechanism is a set of two motors and an automation system that monitors the position of the leaves and the sequence of their opening / closing, as well as picks up and recognizes the commands from the remote control. A sash with an overhead groove profile must start movement first when the gate is automatically opened and end the movement of the last one when closing in order to avoid jamming and damaging the leaves. Also, the movement should stop at the extreme points of the flaps position. The power of the motors directly depends on the weight of the shutters and the smoothness of their movement - the heavier, the more powerful the motor and gearbox are needed to control them. It is also worth considering the area of the canvas, the effect of the wind on them. On a windy day, it is much more difficult for motors to move the gate. It is better to foresee and make emergency opening of street gates, in the event of a breakdown or lack of electricity, in manual mode.

In both factory and homemade drives, they mainly use an actuator or linear drive, which is shown in the photo below:

It is a threaded rod that is connected to the motor and rotates on bearings. Due to the rotation of the stud, the mating part - the coupling, is screwed along the thread, thereby moving along the stud. This drive design is also sometimes called worm gear.

The reduction ratio depends on the thread pitch, the smaller the pitch, the more force the actuator can transmit, but the speed in this case decreases. As an electric motor, you can use a motor reducer for car wipers or window regulators.

The mechanism of automatic sliding gates is quite simple to implement. One motor, one gearbox. The transmission of linear motion can be on a rack with teeth, or through a motorcycle chain. Automation monitors the extreme positions of the sash, closed or open. The main highlight is the rigid sash structure and the system of rollers that hold this structure during closing and opening. It also resists lateral load during wind. The main task is to make the balanced sash easily and effortlessly walk on the rollers and guides. During the development of the gate, it is necessary to provide for emergency opening in the event of a breakdown or power outage. As e-mail the drive is also possible to use the motor from the window regulator or wipers.

Automatic garage doors, in turn, are also divided into roller shutters (they can also be called sectional) and up-and-over. This type is problematic to do on your own due to the complexity of the production technology. Their plus is that the production takes place on an individual order in the workshop, and the installation is carried out in a whole block, so it does not take much time.

Outcome

Now on the market there is a wide range of mechanisms and elements so that you can make your own automatic gates with remote opening and closing from the remote control.

In our article, we tried to acquaint readers with existing types of mechanisms and suggest an idea for self-assembly or choosing a suitable option for automatic gates for a country house, indicating the points that need to be paid more attention, namely.

The hallmark of the house is. After all, the first thing that a person sees when he comes to visit is a fence, a gate and a gate.

In recent years, automatic gates with remote opening of swing type have become more and more popular. The owners install similar structures in the garage, house and various premises. Thanks to the practicality and convenience of swing gates, there is no need to fear unauthorized entry into the house. Homeowners get the opportunity to quickly open the gate without any effort.

Selection of the necessary materials and equipment

Do-it-yourself automation for swing gates is very simple if you have all the devices necessary for carrying out the work. Automation consists of several devices:

- electric drive;

- Remote Control;

- rack;

- signal light;

- photocells.

To carry out work on the installation of automatic equipment, you must have:

- welding machine;

- pliers;

- hammer;

- fasteners;

- screwdriwer set;

- electric drill with drills of various calibers;

- several types of electrical wires of various cross-sections and sizes.

All materials and equipment can be easily purchased at any hardware store.

Preparatory stage

Do-it-yourself automation for swing gates is installed after observing certain rules. In order for the electric drive to operate for a long time and reliably, the following sequence of actions should be performed, checking:

- Smoothness and ease of the process of opening / closing the leaves. If you do not follow this stage, then soon the gate or wicket will fail, which means that they cannot be used for their intended purpose.

- There is sufficient clearance between the door leaf and the road, which will help smooth movement. The structure should open freely, while it should not interfere with people passing by and passing vehicles.

- The space required to open the gate without touching the surfaces of other buildings. Doors should open freely so as not to lose their presentable appearance and break.

- The presence of welded parts to posts and shutters, while welding is carried out in the horizontal plane. The degree of quality of the welded elements is checked so that the automatic system works for a long time.

- Space required to attach the device to automatically open the gate.

It is necessary to provide devices that restrict the movement of the doors, so that when they are opened excessively, they do not break. They are welded on the surface of pillars or embedded in the ground.

Gate swing method

Currently, according to the opening mechanism, specialists distinguish two ways of opening the gate.

Swinging inward

For the design, it is necessary to purchase linear or lever actuators. Their difference lies in the need to use side structures. If channel posts or thick metal pipes are purchased, then the use of linear automatic elements is optimal. Such an electric actuator, or electric drive, is very cheap, so a large number of people who want to install a structure choose it. Lever automatic components are rare because they are several times more expensive than linear ones. Installation on concrete supports is not possible, therefore, in this case, a lever gate opening system is used.

Swinging outward

The design can be applied if there is sufficient space near the house on the street. In this situation, the use of any automatic elements is recommended. Usually, the owners opt for an electric linear swing gate. Automatic parts are installed on the top of the gate. This greatly simplifies all work. Financial and time costs will be minimal.

Having carefully examined all the positive and negative aspects of each of the systems, having talked with professionals, you can even solve the problem of choosing an installation method, which is difficult for people without work experience.

How the device works

To set up the actuator, you just need to decide on an automatic electrical system suitable for the operating conditions, which will help to automatically open the swing-type gates at the moment of need, without applying great effort. The electric drive model is selected depending on the following parametric data:

- door weight;

- the size of the valves;

- the frequency of use of the electric drive;

- the strength of the wind.

When choosing a design, you should carefully consider each of the above factors. If this is not done, then the electric drive may fail after a while. Before mounting an automatic electric drive for swing gates, you must carefully review the diagram and carry out the preparatory stage. Preparation consists in:

- inspection of swing gates;

- identification and elimination of malfunctions during installation work.

Ease of opening is characteristic of the correct building envelope. If something interferes with this, you need to deal with the reason. Usually the problem is solved by lubricating the hinges, aligning the structure of the posts, etc.

Installation of automation

Automation for swing gates is installed very quickly, even if a person does the installation with his own hands. In the process of work, the following steps must be observed:

- by the person himself, the installation of the electric drive is carried out;

- attaching the electric drive to the plates on which the installation will be carried out;

- the wiring and connection of the electric wire to the control system is carried out;

- installation of additional mechanical devices that can protect a person when using an electric drive (travel stop, lock, lock, etc.);

- debugging the system with which the electric drive works and is programmed;

- installation of safety components when working with an electric drive;

- checking its ability to work the structure.

If desired, you can install a signal lamp and various photocells. But this should be done after all the work on setting up the automation has been completed.

Important! If the master does not have experience in installing an electrical automatic system, he may interpret it incorrectly when using the circuit, which will lead to a large number of errors and inoperability of the device. To identify the causes of the failure and eliminate them, you must carefully study the diagram.

The craftsmen give advice: to make an automatic swing gate with your own hands, all stages of the assembly process must be consistent. Everything should be done, correlating with the drawings, instructions and checking the effectiveness of the device at each of the stages.

If you have the necessary knowledge and skills, you can quickly and in a short period of time install an automatic system that sets in motion the device for opening and closing the gate.

2018-02-20