Anti-burglary of garages (protection against burglary). How to reinforce swing and sectional garage doors

A blank fence is needed to protect and protect the private territory of a land or summer cottage. Naturally, the fence must have an entrance. At first, a wicket was enough, then a gate for the crew was required, and later for a car.

A metal gate and a wicket will provide an entrance / exit to the courtyard and guarantee safety for the residents of the house. Previously, iron gates were sheathed with sheet metal 3-5 mm, in modern conditions corrugated board is popular.

According to the method of opening, all types of metal / wood gates can be divided into two groups: swing and sliding.

By the type of wicket device: built-in (inside) and free-standing (side by side).

You can buy ready-made gates from a profiled sheet, order manufacturing by size or do it yourself. Let's take a closer look at the last option - homemade gates, as a cheap and affordable option.

Since swing gates are a simpler construction to manufacture, we will describe how to make swing gates from corrugated board on our own. The strength and aesthetic properties of the profiled sheet, as well as the price / quality ratio, allow us to speak about the advisability of such a choice of facing. As for the wicket, we will describe two options for the device.

Do-it-yourself door made of corrugated board -

step-by-step instruction

Step-by-step technology for manufacturing a structure with a separate gate.

Stage 1 - the dimensions of the gates made of corrugated board with and without a wicket

Note that the installation of swing gates involves taking into account the layout of the territory of the site / yard.

Width of corrugated doors

The width of the door opening is determined based on the width of the car (including mirrors) plus one additional meter for the margin.

The width of the pillars (columns) is also taken into account. If the gate is installed with a free-standing wicket, there will be three pillars. In addition, you need to take into account the size of the gaps between the support posts and the frame of the frame. As well as the size of the gap between the leaves of the swing gates, taking into account the parameters of the fittings.

- The optimum door opening width is 4500-5000 mm.

- The standard width of a corrugated wicket door is 1200 mm.

Advice. Since one sheet per sash is not enough, it is advisable to calculate the sash width based on the width of the corrugated sheet.

The table shows the dependence of the width of the gate wing on the width of the profiled sheet.

Material prepared for the site www.site

Height of corrugated doors

The height of the swing gates made of profiled sheet is 2200-2500 mm. This is due to the standard length of the corrugated sheet - 2,000 mm. Although the manufacturer can offer any length with a step of 50 mm.

In addition, the gap from the bottom (between the gate leaves and the ground) is taken into account, which is necessary to ensure the functioning of the gate when ice forms and high snow cover. The gap under the gate is 150-300 mm.

The height of the gate is influenced by the presence of decorative elements on top. For example, the use of forging makes it possible to increase the height of the gates made of corrugated board and decoratively decorate the structure, as a result of which the entrance group looks more respectable.

Advice. If the clearance from the ground seems too large, you can install a removable strip at the bottom of the gate, which must be removed at the beginning of winter.

Stage 2 - Drawing of the gate from corrugated board

A diagram or drawing of a swing gate is necessary to simplify the calculation of the amount of material and assess the rigidity of the structure.

Two ways to make swing gates:

- with one large leaf (single leaf)... The disadvantage of this method is that you need a lot of room for the gate to maneuver, as well as their large windage. A decrease in windage due to additional frame details leads to an increase in the load on the hinges, which in turn leads to a distortion of the sash. This method is suitable only for gates with a small opening width or for installing a wicket;

- double-leaf (double-leaf)... All the disadvantages described above are eliminated, but the manufacturing cost increases due to the addition of loops and frame elements. A device with the same or with different sash widths is possible. Double-leaf swing gates have the advantage that they are more resistant to wind load.

The scheme of a swing gate made of corrugated board should contain:

- the total width of the opening. It will be necessary, if necessary, to make a maneuver - when the gaps increase or the size of the fittings changes;

- the width of each sash;

- number, width of racks and depth of racking of racks;

- the configuration of the frame with an indication of the width of its constituent elements;

- location and width of the gate. This is an important aspect. Manufacturing a wicket door from corrugated board at the same time as a gate frame will shorten the project implementation time. And if the wicket is located inside the gate frame, the drawing will take into account its location when marking and cutting blanks;

- location of the hinges;

- place and method of installing the lock;

- the location of the internal door retainer (vertical latch).

On the drawing of the gate made of corrugated board, elements of the frame reinforcement are mandatory. It is the visualization of the future gates that makes it possible to understand which of the elements to use and determine the place of its installation, taking into account the wind load.

Ways to strengthen the gates from corrugated board:

1. weld on a corner for rigidity.

This method is suitable if the width of the flaps is insignificant (up to 1,500 mm, each). The corner can be solid (gusset) or in the form of a corner lintel (spacer). The wider the corner or the closer to the center the lintel is installed, the stiffer the gate frame will be.

2. make the frame inside or above the frame.

In the first case, workpieces with a smaller cross-section are placed in the cells of the frame, and are tacked by welding with a step of 200-300 mm.

In the first case, workpieces with a smaller cross-section are placed in the cells of the frame, and are tacked by welding with a step of 200-300 mm.

A continuous seam is not allowed in order to exclude deformation of the metal due to heating (so that it does not lead and twist).

In the second, a smaller pipe is welded over the main frame. The figure shows a top view of such a gain.

In the second, a smaller pipe is welded over the main frame. The figure shows a top view of such a gain. 3. Install cross or diagonal jumpers.

It is important to set the jumpers correctly here. If the wicket made of corrugated board has an insignificant windage and it is enough for it to install one transverse lintel perpendicular to the long frame elements, then the situation with the gate is more complicated. In this case, it is wiser to use a diagonal jumper.

Methods for installing a jumper on a corrugated board gate are shown in the photo.

Gate stiffeners - location options:

a) Despite the apparent simplicity, this option is quite thoughtful, since it guarantees the integrity of the gate leaves. On the one hand, it will be held in hinges; from above, the possibility of deformation is excluded due to the reinforcement of the corners. From below it will be held by horizontal clamps (latches);

b) This is the most economical of the options presented, but it only creates reinforcement in the middle of the frame. The only advantage is that it makes it possible to install a lock on a jumper.

v) the disadvantage of this option is the weak reinforcement of the upper inner corners. Strong wind can deform the sash;

G) in this case, there is no reinforcement of the left inner corner;

e) in this case, there is no reinforcement of both internal corners;

e) perfect option. The insertion points of the lock, the installation of hinges, lower clamps and the upper corners are reinforced. This method eliminates torsion of the frame.

Advice. The wider the sash, the more the frame is reinforced.

Stage 3 - tools and material for the gates made of corrugated board

A drawing of a gate from a profiled sheet is a visual aid for calculating the material. For manufacturing you will need:

- corrugated board - for cladding. It is preferable to take a wall one, because it has a large working width.

- self-tapping screws or rivets for fastening the profiled sheet;

- metal pipe with a cross section of 60x60 mm and above - for supporting pillars;

- a pipe with a section of 40x40 or 60x20 ... 60 mm. - for elements of the sash frame (frame);

- pipe 20x20 to strengthen the frame (if necessary). 20x20 is suitable for a frame made of 60x20 pipe. 30x30 - if a 60x30 pipe was used.

Craftsmen advise buying all pipes with a thickness of 3 mm, not 2. Their price is somewhat more expensive, but for beginners it will be much easier to weld them. The metal heats up more slowly and does not deform as quickly.

- metal sheet for forming kerchiefs (if necessary);

- hinges, locks (latches, latches, plugs), lower clamps;

- metal primer and paint;

- decor elements (forging).

From the tool you will need: a welding machine, a grinder, a screwdriver (drill and riveter), a tape measure, a level, a plumb line, metal scissors, brushes and consumables for the tool.

Stage 4 - installation of support pillars for gates made of corrugated board

Installation of corrugated board doors begins with the installation of support pillars. The most common way to erect gate posts is to excavate with subsequent concreting.

How to install gate posts correctly

- dig a hole with a garden drill. The use of a shovel increases the consumption of concrete. The larger the support diameter, the larger the recess diameter should be. For a pipe with a cross section of 60x60, the diameter of the drill should be 120 mm.

How deep should the gate posts be buried? The installation depth is 1/3 of the length of the support

- pour a mixture of crushed stone and sand into the depression. The thickness of the pillow is 150-300 mm. The pillow is designed to prevent the influence of frost heaving of the soil and ensure the outflow of water from the base of the support, thereby slowing down its destruction;

- prepare the support (cover with an anti-corrosion primer);

- install the support strictly vertically. The slightest deviation will lead to a distortion of the entire structure. The correctness of the installation is checked with a plumb line or level;

- concrete the support. While the concrete is setting, you can start making the frame;

- close the upper part of the support with a metal plate or a special decorative element. As a last resort, pour concrete into the post (concreted from the inside) to avoid water ingress and thereby prevent the column from collapsing.

What kind of corrugated gate posts can I use?

In addition to supports made of metal pipes, you can install a concrete pillar or use piles. Supports decorated (faced) with brick or stone (brick pillars) look beautiful. When calculating the width of the door opening, the material of manufacture and the width of the support should be taken into account.

(banner_advert_2)

Stage 5 - manufacturing of a frame for gate leaves from corrugated board

Before starting production, you need to measure the width of the gate and wicket opening again in order to make timely changes to the dimensions of the leaves.

Manufacturing technology:

- the metal is dissolved into blanks. It is advisable to make the cut at an angle of 45 ° for a more reliable attachment. Although butt welding of parts is also encountered, it is easier to cut workpieces and weld them;

Advice. Craftsmen advise welding the upper corners at an angle of 45 degrees, this will prevent water from flowing into them, and the lower ones can be butt-welded.

- each workpiece is cleaned of dirt and rust;

- weld the frame elements together. Moreover, first the blanks are baited, and after checking the geometry, they are welded with a continuous seam;

- the frame is reinforced (if necessary);

- welded seams are carefully cleaned;

- degrease the frame, cover with a primer and paint the welded joints. After the paint is dry, paint the frame completely.

Advice. Manufacturing of gates from corrugated board requires great precision in keeping the dimensions. When making a sash frame, it is better to make the frame slightly smaller than larger. In the first case, in order to eliminate the gap between the leaves of the swing gates, it will be enough to weld the cover strip on one leaf of the frame, where it is adjacent to the second. In the second, you will need to cut the frame and reduce its width.

Stage 6 - installation of hinges for swing gates made of corrugated board

Garage hinges (awnings) are used to install the gates.

How to properly weld the hinges on the corrugated board gate?

First, the hinge is welded onto the support post, then onto the door frame at a distance of 200-300 mm from the edge of the sash frame. Please note that the location of the hinge affects the position of the door in the open state. If you want the gate to open in both directions, the loop is butt welded to the support. If only in one - the loop is placed on the frame. To prevent the sash from reaching the fence, a limiter is installed.

How many loops to weld on the gate?

If the gate is reinforced, three hinges are required for each leaf. If lungs, two are enough.

Stage 7 - installation of corrugated board on the gate

The professional sheet is mounted on one or both sides of the frame. The installation rules are not complicated, but their knowledge and observance will help to install the corrugated board on the gate correctly.

In general terms: it is necessary to ensure reliable fastening of the sheet to the frame by fixing the profiled sheet through one lower wave of the sheet. In this case, the profiled sheet is also screwed to the diagonal or perpendicular lintels. And two sheets are connected to each other at the top of the wave (on the crest).

For fastening, rivets or self-tapping screws are used. The rivets look more elegant (especially those matched to the color of the profiled sheet), self-tapping screws exclude the possibility of water flowing into the installation site. Of course, this is not as critical as on the roof, but the appearance of rusty smudges over time cannot be avoided.

Stage 8 - installation of fittings (accessories for gates)

Additional elements:

- lock for swing gates made of corrugated board. Installed after the sash is hung.

Types of locks and how to insert / install (installation rules):

- hinged. It is necessary to provide hinges for the lock when welding the frame and fastening the corrugated sheets;

- overhead. Installed on a transverse lintel, most often on an additionally welded flat sheet of metal. Or it is screwed with hardware directly to the frame. The masters do not advise using welding for mounting the structure of the locking mechanism, because the lock needs maintenance and replacement;

- mortise. The lock cuts into the plane of the pipe; a metal pocket is used to hide / decorate the installation site.

- the bottom retainer of the swing gate leaf is needed to redistribute the load from the lock and additionally secure the lower part of the swing gate leaf from the wind (wind load).

- a latch on the gate (deadbolt), designed to close the gate from the inside (blocking). The latch is more suitable for a wicket, and for swing gates, a lock (deadbolt) is used.

- automatic equipment for swing gates. It allows you to open the gate remotely, which is very convenient when it is cold, raining or dark.

- security system: outdoor surveillance camera, warning lamp, alarm.

Hinged gates made of corrugated board with built-in wicket

Separately, we will talk about how to make a swing gate with a wicket from corrugated board. This option is used when the opening is not wide enough to install a gate and a separate wicket.

Wicket positioning options in the gate

Locations:

In the manufacture of sash frames, they are made in different sizes. Then a narrower sash serves as a wicket.

In the manufacture of sash frames, they are made in different sizes. Then a narrower sash serves as a wicket.

This is the cheapest option, since the load on only one goal post increases, which will require the installation of an additional hinge and reinforcement of the frame. In general, costs will decrease.

In the middle of the gate leaf. The option with the location in the middle is good because the frame of the wicket acts as a reinforcement for the frame of the sash. And the installation of hinges not in the center, but closer to the top and bottom of the gate, will further strengthen the structure.

In the middle of the gate leaf. The option with the location in the middle is good because the frame of the wicket acts as a reinforcement for the frame of the sash. And the installation of hinges not in the center, but closer to the top and bottom of the gate, will further strengthen the structure.  Closer to the support pillar. In this case, the main load falls on the support post, because both the door frame and the wicket frame rest on it.

Closer to the support pillar. In this case, the main load falls on the support post, because both the door frame and the wicket frame rest on it.  Closer to the inner edge of the valve. This design is the most "flimsy", its weak link is the junction of two leaves and a wicket. In the last three cases, during the manufacture of the frame, an additional frame for the wicket is provided. Moreover, it is made more reinforced than for a free-standing wicket, since it bears the wind load, which acts on the corrugated board gate leaves. Please note that the wicket will greatly overload the frame, which means that additional hinges and reinforcement of the sash frame will be needed.

Closer to the inner edge of the valve. This design is the most "flimsy", its weak link is the junction of two leaves and a wicket. In the last three cases, during the manufacture of the frame, an additional frame for the wicket is provided. Moreover, it is made more reinforced than for a free-standing wicket, since it bears the wind load, which acts on the corrugated board gate leaves. Please note that the wicket will greatly overload the frame, which means that additional hinges and reinforcement of the sash frame will be needed. In general, the technology of manufacturing gates from corrugated board with a wicket inside is carried out in the same way as manufacturing gates with a separate wicket. All the nuances are pondered during the drawing process.

Advice. The lower retainer for such models of swing gates made of profiled sheet is required.

Advantages and disadvantages of corrugated hinged gates

Advantages (pluses):

- comparative simplicity of design and manufacture;

- low, in comparison with sliding gates, cost;

- ease of use and maintenance;

- availability for the installation of automation;

Disadvantages (disadvantages):

- requirements for free space for maneuver (opening will require the release of an area equal to the width of the gate leaf);

- the need to take into account the wind load;

- the need to provide for the fastening of open gates in order to avoid their unauthorized closing (lock, stop, locking devices);

- installation of a limiter so that the open gate does not damage the fence curtain and does not block access to the wicket;

- the complexity of care in the winter season, which consists in the need to remove snow over a large area.

Approximate prices for swing gates made of corrugated board

Conclusion

As you can see, with some effort, you can make and install swing gates from corrugated board with your own hands in 1-2 weeks, which will decorate the entrance group and will reliably serve as a beautiful business card of a private house.

Today, there are many options for manufacturing entrance gates to the adjacent territory of a house or enterprise. One of the simplest, most reliable and economical ways to manufacture gates is to use profiled metal sheets.

Gates made of corrugated board have high strength indicators, have an attractive appearance and a long service life. At the same time, the technology for installing such gates is quite simple, which allows you to make them yourself.

Structurally, a gate made of a profiled sheet is a frame made of a metal profile with a fixed profiled sheet. The frame is mounted on the posts with the help of hinges - and the gate is ready. The posts can be either metal or wooden. For wood, the optimal diameter option is 200 mm; for metal, the thickness of the post may be less.

The pillars are deepened by about a third of their total length. In this case, the height of the above-ground part should be 500 mm higher than the height of the gate leaf to provide some clearance from below and from above. In the pit, it is necessary to make a gravel or sand cushion, and it is advisable to fill the post itself with concrete - this will increase the reliability of the entire gate structure.

For installation on a frame, it is recommended to choose a profiled sheet marked "C" as a canvas. It denotes relatively light galvanized steel wall sheets with a low rib height. Due to its lightness, working with such a sheet is quite simple. The low weight also reduces wear on the hinges, extending the overall service life of the doors.

One of the main problems of corrugated doors (as well as fences made of this material) is high wind loads. Because of them, a sheet of corrugated board can simply be torn off the frame, not to mention the fact that the gate can open spontaneously, etc.

Various techniques can be used to reinforce the corrugated board gate.

- Firstly, this is a high-quality installation of pillars, that is, the use of a pillow and concrete pouring. If the pillars are installed securely, then the gate will not go anywhere.

- Secondly, the door frame can be reinforced with stiffening ribs from a metal profile. The simplest option is to install diagonal beams crosswise (in the form of the letter "X"). The profile in this case is welded at the corner joints of the frame beams. Stiffening ribs not only prevent the sheet from bending under the influence of the wind, but also serve as additional attachment points.

- Third, the mount. The step of fastening the corrugated board to the frame or stiffeners should not exceed 150 mm. It is best to use rivets as fasteners, not self-tapping screws. The latter can be torn out, both by the wind and by intruders. With rivets, this operation is more difficult.

- Fourthly, pay attention to the quality of the welding of the frame under the gate. The overall strength of the gate will depend on the quality of the frame assembly.

- Fifth, special holes in the sheet web will help to reduce wind loads. This method is applicable only if you are not afraid of the possibility of prying eyes on the site, and do not feel sorry for the sheet itself.

Before we talk about how to install pillars for swing gates, let's highlight the product - gate pillars. There is always a misunderstanding about gate posts. There is generally disagreement over whether the gate posts should be considered part of the gate itself or not. For some reason, many Customers are 100% sure of this and are perplexed when they are told that this is not so. The client believes that in principle a gate cannot exist only as two separate leaves, and even more so without welded hinges. Or at the other extreme, when the Customer still admits the existence of such a complete set of gates without pillars, but it should be quite cheap. Of course, the easiest way is to direct such a customer in the further search for the gate he needs and not save your nerves on explaining elementary things that are axioms for the gate manufacturer. But the fact that there are no extra customers is a fact. The opinion that swing gates must necessarily be equipped with gates is completely groundless. Like if there are gate wings and they cannot hang in the air, the gate hinges must be attached to something, and if so, then the gate set must also include the posts for the gate. Only a person who is very far from construction work, does not represent the technology of installing gates and the sequence of installation of products when erecting a fence, can have such a logic at the expense of the gate. In fact, the gate posts are installed much earlier than the gate itself, and it is the dimensions of the gate that will be taken from these posts. That is, the pillars of the gates are already ready and look good, but the gates themselves are not even in the sketches. The posts for the gates are, it would be more correct to say, part of the complete set of the fence. An intelligent builder erecting a fence is always interested in where the gates and wickets will be. And he always starts with the installation of posts for gates and wickets. And then he performs the laying of bricks or other material.

Installation options for pillars for metal gates

Installing gate posts is not an easy job. If you do not have experience in the correct installation of pillars for gates, the result will be disastrous. The pillars of the gate will tilt over time, the gate will wedge or stop working normally. All of this can be avoided. What you need to know before you start installing gate posts.

The first is to pay attention to the material of the gate posts. A suitable material will be thick-walled rolled metal. For example, a hot-rolled channel 14, 16 or a channel of a smaller section, pre-welded into a box. Profile pipes with a cross-section of 100 x 100 mm and a wall of at least 5 mm can also serve as metal posts for the gate. The thicker the pipe wall, the stronger the gate post.

Second, in the construction of metal pillars for gates, lower crossbars should be present at the base. Ideally, before pouring concrete, the pillar should rest on the crosspiece of the corner 50, 63. And the other crosspiece should be submerged 100-200 mm from the ground surface. The length of the cross beams varies from 500 mm to 1 meter.

Third, it is mandatory pouring concrete into the base of metal gates for gates. In this case, the post for the gate must be installed at a depth of at least one and a half meters, and somewhere more. It all depends on the composition and properties of the soil, where the pillars for the gate will be installed.

Fourth, do not neglect pouring liquid concrete into the gate post. This will make it possible to make a strong reinforced concrete post with external reinforcement from the hollow pipe, thereby achieving the most rigid post structure possible.

Fifth, it is safer if the foundation of the gate pillars will be part of the general foundation of the fence. And concreting during the installation of pillars for the gate will be carried out simultaneously with the general pouring of the foundation.

Sixth, it is more expedient to provide additional fastening between the gate post and the fence in its upper part. If you are laying out a brick fence, then the brick pillar inside which the pillar for the gate is hidden must be additionally tied with a thick metal strip with the fence itself. It often happens that a brick post from the load of the gate tilts and breaks away from the masonry of the fence, forming a crack between them.>

Seventh, sometimes, in difficult clay soils, it is impossible to install the gate posts in a strictly vertical position and fix them securely. In this case, additional upper and lower cross-members (jumpers) must be used between the gate posts. The lower lintel is made of metal, similar to that used for the gate posts, and is buried in the ground to a depth of 300 - 400 mm. In the future, a normal passage is arranged over the lower bulkhead. The upper cross member is installed along the upper ends of the gate posts. Of course, the upper lintel will not add beauty and neatness to the gate, but this is a necessary measure and very effective. The upper cross member must be made removable to ensure passage in the event of a tall vehicle or the transport of bulky cargo through the gate.

How to install gate posts is a much more difficult task than it might seem at first glance.

If it will be enough for the fence that the pillars just stand and do not fall, then the gate is a mechanism, for the well-coordinated operation of which, it will be necessary to observe a certain position of both of its doors.

Therefore, the installation of poles for is the most difficult and important task in their construction.

According to the stiffness to the pillars, all gates can be divided into groups:

- Bolted gates, electronic lock; gates with heavy leaves; gates that could be damaged by passing trucks.

- Gates that can be locked with a chain or barrier.

Products of the first type are usually placed where they often need to be opened and closed - for example, at the entrance to a large trading base. Usually such a passage has a considerable width - about five.

And in some cases - even more, so that two cars, up to eight meters wide, can easily part. In this case, the leaves can weigh from 500 kg to four tons.

Yes, and in a private house, many will want to have a gate that closes with an electronic lock - they can be opened and closed without leaving the car, or just look out of the window who has arrived and open the gate for him without leaving.

Before you install the pillars for the gate, you need to know that the most stringent requirements are imposed on them here. They must ensure the reliable operation of the bolt mechanism, the stable position of both leaves relative to each other.

The gates, which are locked with a chain, do not impose any special requirements on the stiffness of the posts.

The chain, although it does not provide sufficient protection against penetration, will still be an obstacle to the penetration of thieves.

Here it will be enough to ensure sufficient strength of the pillars by themselves - after all, when using the gate, it is still possible that they will be hit by a trailer when.

It will also not be superfluous to ensure the maintainability of the poles. Barriers also do not impose any special requirements on the posts. The exception is electronic barriers with the beam fixing when lowering on the stop.

In this case, the same requirements are imposed on the posts as for the gate of the first type. In addition, they must be stronger - the barrier at the entrance is easier to miss in the dark than a closed gate. The disadvantage of chain-locking gates is that you have to open and close them manually.

Gate material

- By far the best material for pillars today is a metal pipe - round or square. It does not have too much mass so that the pole can be erected by one or two people without the use of technology. Pouring concrete inside the pipe or backfilling with lime will create an electrochemical positive potential on the pipe surface and increase the resistance to rust by several times; in addition, products from galvanized pipes can be ordered.

- The second option is reinforced concrete. For heavy gates, this is not very good - constant bending, cyclic loads, the likelihood of an accidental dynamic impact by the side of a trailer or wheels will quickly render them unusable. Reinforced concrete pillars are much more suitable for a fence. Brick pillars have the same drawback - except for cases when there is a metal pillar inside, and the hinges are attached directly to it with the help of outboard anchors, through the thickness.

- Finally, the third option is wood pillars. Wooden giants will be rather exotic and are used quite rarely - due to their low resistance to decay and low bearing capacity.

Installation of pillars for bolted gates or heavy gates

Installing the pillars for the gates so that they do not walk is possible only by making a reliable foundation and ensuring their rigid connection with each other. Communication can be carried out at two points - at the bottom of the entrance, at the crossing through the gate and at the top of the pillars. Usually they are welded together at these two points, having laid two I-beams between them.

But for the upper fasteners there is a rather serious limitation - sometimes it may be necessary to drive through vehicles that exceed the dimensions of the posts and the upper beam in height. Therefore, the latter is made removable.

When equipping an entrance to your own site, when you plan to drive only your own car, it is quite possible not to make a solid foundation for the gate, but to make separate ones for each post. In this case, the pillars are simply welded in the lower part with a thick I-beam, and the same beam is made from above, but removable, inserted into the welded sockets and having welded pins for insertion.

Thus, you can safely enter and leave on your own, while good stable operation of the electronic lock and opening mechanism will be ensured, and the skewing of the pillars can be avoided.

However, this does not negate the laying of the foundation for each pillar separately, which should go below the freezing depth for such gates. In the entrance area, a concrete platform is usually made. It will be very good if the I-beam, which is welded between the pillars at the bottom, is thicker. In a layer of concrete, it will be reliably protected from rust, since concrete gives a slightly alkaline reaction of the medium and prevents the oxidation of the metal.

For heavier gates, it is necessary to make a solid foundation. Usually it is made in the form of the letter "H" with a transverse bar strongly elongated horizontally.

The foundation is usually filled with solid,. Its depth should be below the freezing depth. Everything is done according to the same rules as the construction of a strip foundation for a house. The thickness of the foundation grillage is about 50 cm. Theoretically, 30 will be enough, but the width of 50 allows you to save on formwork and pour the foundation into a spacer with the walls of the trench.

Extensions-buttresses are made near the pillars in both directions, perpendicular to the entrance. Usually, even for heavy gates, a buttress in the area of a post with a total length of one meter is quite enough. The foundation is reinforced before pouring.

An I-beam is welded between the pillars at the bottom of the entrance, near the surface. Then it is poured into concrete, together with reinforcement - concrete will be a reliable protection for it from.

It is advisable to install an I-beam at the top of the pillars. Considering that usually heavy gates require large and heavy posts, the girder must fit.

It will be difficult to remove and put in place - you will have to fit the crane every time. Therefore, it is better to immediately lay a significant headroom in the pillars and simply weld the beam to them tightly, once and for all.

Poles for wickets

Using the same technology, you can install pillars for gates and wickets - with the difference that here you can take thinner pillars, it is enough to put round ones with a diameter of 50 mm or square ones with a width of 50 mm, wall thickness - 3 mm.

It is undesirable to take a smaller wall thickness - it will be difficult to weld hinges to thin metal, and this will affect the durability of the gate.

Considering that 2.5 meters is quite enough for a person's passage, the pillars can be safely tied together at a height of 2.5 meters by welding the crossbar.

The second bundle is at the bottom, where the entrance is. It is advisable to concrete it so that it does not rust. The standard width of the wicket is 90-120 cm. In such a passage you can freely walk in winter clothes, and with a baby carriage, and even bring a wheelbarrow with the ground.

How to concrete the pillars for the gate - on the video:

Have you noticed a mistake? Highlight it and press Ctrl + Enter to let us know.

You will need

- - pipe Ø100 mm;

- - corner 100x100 mm;

- - angle grinder ("grinder");

- - welding machine;

- - cement;

- - sand;

- - edged board and timber for formwork;

- - carpentry tool;

- - shovel and bayonet shovels.

Instructions

Cut the blanks for the gate. For racks, use a Ø100 mm pipe or a 100x100 mm angle. Their length is determined by the sum of the height of the gate and the length of the ends embedded in the ground (0.8-1 m). With a planned door height of 2 m, the length of the workpieces should be 2.8-3 m.

Make the jumper connecting the posts from a corner 100x100 mm. Its length must be equal to the width of the gate. For standard gates, it is taken equal to 3 m. If a pipe is used as a rack, cut off one corner shelf on both sides at an angle of 30 ° and give its edge a concave shape. This is done so that the edges of the corner fit well to the posts when they are welded.

Assemble the gate frame from the blanks on the ground, choosing a more even place for this. It should look like the letter "H" - two posts and a jumper laid between them at a distance of 2 m from their top (or 0.8-1 m from the bottom). In this case, two conditions must be ensured: the parallelism of the racks to each other and the perpendicularity of the lintel in relation to the racks.

Weld the jumper to the uprights. Both corner shelves must be securely welded with a continuous seam. Weld any pieces of metal to the jumper in two or three places, pointing them down. They will play the role of reinforcement, firmly connecting the lintel to the foundation.

Dig a trench to fill the foundation. Its width should be 350-400 mm, length - 3.5 meters (for 3-meter gates). The required depth of the trench is determined taking into account the depth of freezing of the soil, its type, and the level of groundwater. For simplicity, you can take it equal to the depth of freezing of the soil in your area, which can be found on construction sites.

Make wooden boards from edged boards and assemble formwork from them. Its dimensions in the plan should be 0.3x3.3 m. It is advisable to make the walls of the formwork slightly expanding to the bottom - in order to avoid the pushing effect of the soil on the foundation.

Install the gate into the formwork so that the lintel is flush with the ground and the posts are vertical. To do this, place supports made of stones or metal under the posts or the lintel and fix the posts on both sides with stops. Place reinforcement made of any kind of metal in the formwork - wire, scrap metal profile, etc.

Prepare a sand-cement mortar with a ratio of 1: 4 (cement: sand) and pour it into the formwork. To use less mortar, fill the formwork with stones and broken bricks. While pouring, tamp the mortar with a shovel. The surface of the poured foundation must be level with the ground and the lintel. Before hanging the gate itself, allow the solution to harden - at least a week.

When the territory of the site is fenced off, the question always arises about the need to install a gate. They are of several types: swing, retractable, opening in one direction or lifting. You can install on your own only hinged or opening in one direction Gates... The rest are installed on special structures with the participation of specialists in this field.

You will need

- - hinges

- -bolts or welding machine

- -pillars

- -smooth bar

Instructions

In summer cottages and in private houses, swing doors are usually installed Gates... This design is the presence of two doors, welded from iron or made of plank. In some cases, carved or forged Gates.

To install the gate, dig in the pillars by measuring the made leaves. The posts can be made of iron or wood. Pour both those and others with cement mortar for strength and reliability.

The hinges can be welded to the posts and Gates m or fasten using bolts. Shop hinges are not suitable for door installation. They are unreliable. Order heavy-duty homemade hinges from any turning organization or purchase from a market that sells homemade parts. They should be on a ball mechanism to make it easy to open Gates without making any effort.

The most difficult process is the installation and fastening of the gate. It is impossible to carry out this procedure alone, because the doors made of any material are quite heavy. They need to be hung at a distance from the ground that does not interfere with their opening.

Place a block of the desired size down the gate along the length of both leaves. Install one sash on it and weld or screw on the hinges. This is done first from above, then from below.

The second gate leaf must be installed in accordance with the first and welded or screwed on the hinges. And do the same. First, the hinge is screwed or welded from the top, then from the bottom.

If you installed a block, then both doors should be at the same distance from the ground so that when they are closed, distortions do not occur.

Related Videos

Owners of their own plots try to install such gates so that they are both beautiful and comfortable, and would fit well into the overall design. Wood structures are considered the most affordable and simplest to perform.

Those wishing to make their own wooden gates first need to draw up a design drawing. This helps to more accurately represent the scope of work, to purchase the necessary materials in advance. When drawing up a drawing, one must try to ensure that all parts and structural elements are in full accordance with each other.

How to install gate supports

Vertical supports must be made of wooden beams. Their size must be calculated as follows: add another meter to the height of the gate for deepening. The greater the depth at which the supports are installed, the more stable and durable the structure is. So during the operation of the door, the likelihood of skewing is reduced.

Remove debris from the location provided for the support posts. Dig holes - their diameter should be 20 cm larger than that of the supports. Tamp the bottom of the hole and make a crushed stone pillow. The part of the pillar that will be filled with concrete must be pre-treated with a compound that will protect the wood from decay - for example, bituminous mastic. Use a plumb line to check the verticality of the post. The pit with the installed pillar must be poured with concrete and wait until it dries.

Gate manufacturing

To make one of the goal posts, you will need one bar for the top and bottom, two bars for the side posts, two for the middle lintel. The dimensions for the gate are calculated depending on the size of the machine. All parts must be treated with antiseptic impregnation.

The details of the frame are laid out on a flat surface; holes must be drilled at the joints. Pins are inserted into them - they give rigidity to those places where the parts are connected. Jumpers from a bar are installed in the middle of the frame. At the corners, jibs are attached, which are bars with cuts at the ends at an angle of 45 degrees.

When calculating the height of the frame, it must be borne in mind that the sheathing boards should protrude 20 cm from the bottom and top of it. The boards must be prepared before sheathing - cut to the size required by the calculation and work with a plane. They can be attached to the frame and tightly to each other, and with a certain pitch. After all the planking boards are in place, the top must be trimmed and cleaned with sandpaper. Now hinges are attached to the sash - for this, self-tapping screws with a screw thread are used. Self-tapping screws can also be used to fix the mountings to the posts.

The distance from the bottom of the gate to the ground should be at least 5 cm. The closed gate is fixed with latches, latches or locks - the method is chosen by the owner. It is better to paint the gate when assembled.

Related Videos

The fence is an important element of the fence. During its construction, it is necessary to determine what supports it will have. Its reliability and longevity depend on this. Pillars can be wood, metal or concrete. Once you've made your choice, get to work.

You will need

- - pillars;

- - cord;

- - pegs;

- - saw;

- - drill;

- - gravel;

- - bitumen;

- - wedges.

Instructions

Installation of poles for fence start by marking the fenced-in area. Do this with a cord. Calculate the correct number of posts, crossbars and canvases.

Hammer in the pegs where the posts are installed. Check again that the marked line is correct. The pegs must be exactly on the marking pitch. A crooked fence will not be strong.

Mark the height of the post. She must be higher than herself fence a few centimeters. Considering the underground part, saw off the excess.

anti-burglary of garages (protection against burglary)

We offer several types of protection against burglary (opening) garages:

1. Installation of protective rings from a Ø219mm pipe on external locks - with such protection it turns out that it is impossible to cut the padlock and it is very difficult or impossible (still depends on the lock) to slip a crowbar or a pry bar under the lock's door and break it.

2. Installation of "Crabs" - corners or pins are welded onto the gate from the inside, which, when closed, go beyond the gate frame. Thus, when cutting the hinges from the outside, the gate will not open, because will not give "Crabs".

3. Installation of a good garage interior lock, with a large cross-section and bolt movement, having a simple and reliable design.

4. Additional welding of the hinges through the corner or reinforcement.

5. Reinforcement, if necessary, of the gate with thicker-walled metal.

6. Reinforcement of walls and ceilings with reinforcement bars.

7. Welding additional ears for external padlocks.

8. Installation or replacement of internal bolts on a large diameter bar up, down or between themselves.

9. Floor concreting with reinforcement.

10. Welding to neighboring garages (if not against the owners)

also other ways of anti-burglary of garages and metal doors are possible, after individual measurement.

Departure for measurement (inspection) in Samara is free of charge.

If you do not have electricity, this is not a problem, we have a generator-power station.

For those who are interested in garage safety, we recommend reading:

Some car owners consider the garage to be a safe hideaway for storing a vehicle. But statistics say that it was here that a lot of cars were looted. The intruders are quite professional in robbing and stealing cars from garages that are well closed. How can such troubles be prevented?

Let's take into account that there are different types of garages. Reinforced concrete garage is the most reliable one. Of course, they can hack it too, but only with the help of a bulldozer or jackhammers. The second most secure garage will be a brick garage. Much depends on the material from which it is made. Silicate blocks can also make holes with a simple crowbar, the robbers do it quickly and without noise. And the most vulnerable are metal garages. Experienced thieves can crack them in 5 minutes. Especially accessible are those metal structures that are not attached to the floor, they can be opened even by a group of novice teenage robbers.

Consider a number of recommendations for garage locks:

- It is necessary to install casings made of metal (rings from a pipe) so that the suspension lock becomes an inaccessible object for the raiders. Of course, if they have a crowbar, it probably won't help. But then you can use locks with hidden rods. They have a fairly streamlined shape. Use also internal locks in your garage. It is important that they cannot be opened from the inside.

- If there is no wicket, put several locks on the garage door. Make the distance between them equal to 40 cm. This is important to distribute the load when trying to break with chains or crowbar.

- Observe this rule when installing locks: there must be elements of its mechanism hidden inside the lock. Then the thief cannot unscrew them.

The design of the gate itself is of great importance. It happens that they are hacked by force. They rip it out right by the root. Of course, this is done in deserted places. Make the gate monolithic, without external handles. Do not forget that around the entire perimeter of the gate, there must be strong corners or a profile inside. The hinges must be well welded to the frame of the garage itself, and it is better to strengthen it. Do not bolt them down as this will make the job easier for the burglars. It is better to screw, weld, nail in a timely manner, in other words, to firmly connect the visor and the frame at the garage. You will have to spend a lot of time on this, but it will not steal your car. The most unprotected boxes with a tin or slate roof, especially if it is nailed down. It is also good to weld the garage to neighboring garages, if not against the owners.

A number of other recommendations:

- Choose a garage in busy areas.

- The area should be well lit.

- The most reliable way of protection in this case is an alarm. It is triggered when entering garages, sends special signals to the security services. While the robber is busy in the garage, a patrol arrives and detains him. The owner is informed by SMS about the arrest of the thief.

If you need professional advice in Samara, call us and we will come for a measurement and help you choose the optimal list of burglary protection.

First and foremost for the safety of your garage is knowing that you are at risk. Excessive self-confidence in such matters is the first assistant to the criminal. A few more tips on how to protect your garage.

Often, criminals entering the garage are not even interested in your car. The garage can even be opened because of food supplies for the winter in the cellar or an expensive radio. Somehow, the garage of your humble servant (before the work on its strengthening) was opened only in order to break through the “entrance” in the wall to the neighboring more protected garage and take a foreign car out of it. So much for you ..

Rule # 1:

When choosing a garage, you need to look not only at the strength of your future doors and walls, but also those of the neighboring ones.

Rule # 2:

The concept of "safety" refers not only to the garage itself, but also to the surrounding area. If your garage is located in a not very prosperous area of the city, it is poorly lit, and besides, it is poorly visible from the outside - be sure, sooner or later, uninvited guests will visit it if it is not properly fortified.

Rule # 3:

What if you already have a garage? Then take a look around. If there are bushes nearby or there is an old fence blocking the visibility of your garage, then it is advisable to remove these obstacles. Garage lighting is also worth considering. It is especially easy to solve this issue by installing powerful lights on the roofs of the outer garages in garage cooperatives. In this case, energy costs can be divided among all garage owners.

The external protection seems to have been sorted out. Now let's go directly to the garage itself. What can you do to strengthen your garage?

Gates:

The gates, by virtue of their specificity, are the weakest link in the external wall complex. In order to make the gate impenetrable, their sashes must be made of metal with a thickness of at least 2-3 mm and welded onto the frame from a profile of at least 50 mm. It is advisable to make a gate frame from any profile of at least 60mm (preferably more). The box itself must be securely connected to the walls or beams, because very often seemingly impregnable gates fly out, it is worth pulling them with a cable tied to the car.

You can also weld rods onto the loops - this will significantly increase their resistance to sawing. The same applies to the eyelets for the locks.

I think there’s no need to remind you of a strip of metal that prevents you from pushing the crowbars between the gate leaves - everyone should have it.

Now let's remember about "latch" type slide locks that fix the gates, usually you close these simple metal rods, and the door still hangs, but it is worth weld metal on them so that the fit is tight.

Locks:

I will not talk about the castles. Better to give you a quote from the 8th issue of the magazine "Autoreview" for 2002:

“… There are many relatively inexpensive and at the same time very worthy domestic products. Pay attention to the products under the trademarks ZGTs, Klass, METTEM, Gerion, Kerberos. When starting a conversation with the seller, ask to see locks specially designed for installation in the garage (the letter "G" must be present in the labeling of such a product). Immediately return back those that can be opened from the inside without the help of a key (having climbed into the garage through a tunnel or a hole in the wall, the thief should not be able to open the gate). After that, select products certified for at least the third class of burglary resistance (this parameter must be indicated in the passport). If the letter "L" is present in the marking of the lock, it means that it is intended for installation on the left (when viewed from the side of the hinges) gate leaf. And vice versa.

What type of security mechanism is optimal for a garage lock? Suvaldny, the key of which is made in the form of a double-sided "butterfly". Disc locks also work well.

If the gate of your garage does not have a wicket, then it is better to buy two or three mortise or overhead locks. They must be installed so that the vertical distance between the key holes is 300–350 mm - this will ensure a more even distribution of loads when attempting a rough break. Regardless of the type of locking device you choose, its design features and model, three basic rules should be strictly observed. Firstly, the secrecy mechanism of the lock installed in the garage should in no case protrude beyond the leaf of the wicket or gate. Secondly, the fasteners must be made with bolts with a diameter of at least 8 mm, or better to weld the lock. And thirdly, you need to make sure that the fastening elements of the locking device cannot be turned off from the outside.

Walls:

For walls, you can recommend creating a powerful frame from the corners and scalding this frame with a metal mesh, you can also advise for the ceiling. Note! Very often, concrete floors just lie on the walls. It is very easy to lift them with a hydraulic jack and get inside. Ceiling tiles should be connected to the walls with heavy duty metal pins.

Finally:

1) Installing a howler (you need to place it in a hard-to-reach place) triggered when the gate is opened can scare off any uninvited guest. The howler monkey can turn off both outside and from the nutria.

2) It is advisable to make a secret button for lighting or to unscrew the plug from the flap when leaving. The lack of light will make life difficult for any burglar.

3) A small bolt, inconspicuous among the rest, firmly pressing the sash to the box (in this case, you will have to carry a wrench with you) - another obstacle for a burglar.

We can also make a metal safe from 3-4mm steel with internal locks for storing valuables, weapons, etc. and weld it to the garage wall.

Call us and we will help you to reliably protect your garage and car in Samara! We also carry out any repair of garages in Samara.

When building a garage, many nuances are taken into account. One of them is the height of the gate, and we are talking not only about the height of the opening, but also about the height of the shutters above the ground level. The article will discuss the reasons why it is important to correctly calculate this height. In some cases, you have to raise the garage door higher due to certain circumstances. The article will also describe several ways in which this can be done.

Why raise the gate

When it comes to the need to raise the gate, it is about swing structures. For folding structures, there is no such problem, since they are able to automatically change their level. There are several reasons why you have to resort to raising the gate:

- wear of the hinges;

- deformation of the frame;

- incorrect design;

- violation of the integrity of the foundation;

- vehicle replacement.

Old gate structures are made of sheet metal, which has a thickness of 3 millimeters or more. By itself, such a gate design is quite heavy, so it is normal that over time they begin to sag. The reason for this may be the poor quality metal of the hinges. The rods lose their strength and the flaps partially tilt forward. This makes it difficult or impossible for the gate to close normally.

Another reason why the gate needs to be lifted is the wear of the metal corner. In most cases, beams with a width of 20 cm are used, but to save money, small corners are used, which begin to deform from constant loads. In this case, the geometry of the frame is violated, which leads to problems with the gate. When properly designed, swing gates are never placed flush with the ground. Even when properly installed, this approach can be a problem in winter. The metal can deform under the influence of low temperature and the sash will not open, since it will cling to the asphalt.

Another problem that manifests itself at a low gate level is precipitation. If a significant amount of snow falls in winter, then you have to work pretty hard to clear the space near the gate before entering or leaving the garage. With heavy rainfall, water will simply seep into the garage, which can create serious problems, especially if the garage has a viewing hole or basement. In some cases, due to ground movements, there may be a problem with the deformation of the lower part of the frame. This also leads to the need to raise the gate. Walls can also deform, which lead to the collapse of the gate and the impossibility of opening it.

Gate lifting methods

In most cases, it is best not to do the lifting work alone. Due to the heavy weight, you can get serious injuries to the hands and the musculoskeletal system. There are several ways to lift, below will be considered the same:

- repair washers;

- reduction of the bulkhead;

- decreasing the threshold level;

- trimming the gate.

Each of these methods requires its own arsenal of tools.

Repair washers

This option for increasing the height of the flaps above the ground level can be considered one of the simplest. Repair washers will help in the event that the flaps do not open well due to wear on the hinges. With proper skill, the work of installing the washers can be done independently. In this way, you can usually raise the sash by 1 cm. To implement the idea, washers of the required thickness are selected or a selection of several elements is made. The hole in the washer must be such that the hinge stem can freely enter it. The washer only needs to be lubricated on one side. The second should be fixed on the hinge.

To carry out the operation, it is necessary to raise the sashes, but do not remove them completely. It is enough to achieve the formation of a gap into which the washer can crawl. It is necessary to choose a jack that can be freely rolled under the sash. If there is no such option, then you can build a metal loop, part of which will be under the sash, and the second is clearly fixed on the jack. Alternatively, the trolley jack can be installed under the sash by lifting it up. To do this, it opens perpendicular to the wall and several wooden wedges are driven under it. While performing these actions, it is necessary to hold the gate so that it does not tilt to one side.

Using a jack, it is possible to repair deformed parts of the gate, which caused sagging. In this case, the jack is installed as far as possible from the hinges, and the sash is lifted. As you rise, it is necessary to perform blows with a sledgehammer, which will help level the deformed place. It is better to perform alignment in several small passes, then the result will be most effective. It should be understood that with severe deformation, the ideal result may not be achieved. If the frame was aligned, then the place of bending must additionally be reinforced with a corner, which is welded on top.

Note! If the doors are aligned with a wicket, then it is not worth removing it. If this is done, then after the procedure, it may not fall into place. Instead, it is necessary to firmly secure the door with ties or welding tacks.

Reducing the jumper

This option for lifting the sash can be called one of the most difficult and time-consuming and costly. But the result obtained can be considered the most effective. This option is also called frame lifting. To implement it, you will need to completely remove the garage door leaves. In some cases, the frame may not be dismantled, but it is necessary to free it from the clips that hold it in the wall. These can be metal pieces of reinforcement that are driven into the holes. It will be easier to lift if brickwork is used as a lintel at the top of the frame. In this case, it will be enough to remove one or more rows. Everything will depend on the required lifting height of the garage door frame.

If there is a concrete lintel above the frame crossbar, then more effort will have to be made. When using a standard element, it will be possible to raise the gate by about 10 cm. This is due to the fact that it is at this level that concrete is located, and then there is reinforcement. You will need a hammer drill with a long drill. The diameter of the drill is selected in 10 or 12 mm. The grinder marks the line along which drilling will be carried out. It should be horizontal and located directly below the reinforcement. Holes are drilled in a row without a large gap. The next step is to install the chisel and begin beating the upper part of the jumper. Once the task is completed, it is necessary to remove the remains of concrete and level the surface of the lintel.

The next step is to raise the frame to the required height. If the metal clips have already been cut off, it is necessary to walk with a perforator with a chisel in those places where the frame is concreted in the wall. It must be completely free and move freely. There are two ways to raise the frame:

- wedges from below;

- jack from above.

In the first case, it is necessary to act from the middle. In this place, a strong scrap is placed and a slow rise begins. It is not worth starting from the edges, since the door frame will simply jam in the opening. After lifting a little, you need to substitute wooden spacers under the frame. Then you can go alternately to the left and right edges. As soon as one of them is raised, a wedge is also placed under it. It should be understood that the extreme points can be more difficult to succumb than the central one. When it is possible to achieve a large gap, one or more rolling jacks are installed in it.

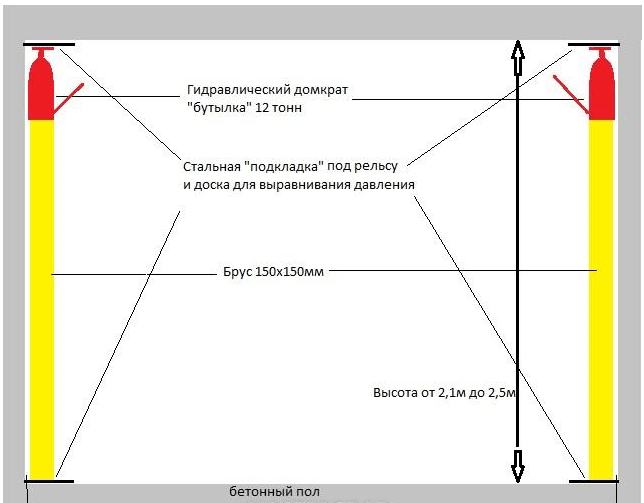

Further lifting is done using jacks. In this case, it is important to act synchronously with an assistant or to lift to a small level on each jack in turn. Do not try to do everything quickly, as the frame can be skewed. If this happens, then it is necessary to lower one of the jacks and knock with a sledgehammer on the frame of the garage door. The operation can be performed in another way. If it is impossible to place spacers and a jack under the threshold of the frame, it is necessary to do this under its upper crossbar. Jacks in this version are mounted as shown in the diagram above. High supports are made of beams for them. A gasket from the board is placed on top of the head so that there is no dismount. The lifting of the garage door frame must also be carried out evenly.

Note! In some cases, the threshold can be connected to the foundation, so it cannot be lifted. Then the frame struts are trimmed and the top is lifted separately. After that, small sections of the door frame will need to be boiled out of the corner.

After such an operation, the gate hinges do not need to be digested in most cases, since they are mounted in their usual place. The question arises in relation to the lower part of the gate, since a gap is formed there, equal to the lifting height of the frame. It can be closed by welding sheet metal onto the gate. It is also suitable for forming a threshold that will prevent rainwater from entering the room. The latter option is necessary if the gate was initially too low.

Threshold level

This option of increasing the height of the gate with your own hands does not imply the dismantling of the gate and is one of the simplest options. It is worth noting that it can be implemented only if the threshold height is sufficient and there is a small margin. Do not use this method when the bottom of the frame is almost level with the road. To implement the plan, you will need to install horizontal struts that will temporarily fix the frame. The gate leaves open and the lower part of the frame is dismantled.

You should not throw it away, since this element will be used in its place. The next step requires a jackhammer or powerful rock drill. You will need to knock down part of the concrete threshold. After reaching the required level, the lower part of the door frame is welded into place and the horizontal struts are removed. You can start filling the threshold with cement mortar.

Gate trimming

This method is the simplest and most undesirable one. It can be realized only if the total height of the gate is quite large and it is not planned to buy a large car. The method of trimming the gate is used only when it is necessary to understand the level of the threshold so that water does not get inside. You will need a grinder to work. The first step is to separate the sheet metal from the sash frame at the bottom. The bottom bar is completely cut out, but you will need it later. After that, it is necessary to determine to what height the gate will be trimmed.

Chokline or thread with paint beats off the line along which you want to cut. The grinder cuts off the lower part of the sheet material of the gate along the marked line. In principle, this can be done by weight, but the best option would be to completely dismantle the sashes and perform the cut in a horizontal position. In this case, there is less chance of biting the canvas and getting injured. After trimming each leaf, it is necessary to weld the bottom strut into place. Next, the gate is mounted in its place and the threshold is filled. There is a video about three options for raising the gate below.

Summary

As you can see, in some cases, raising the gate is necessary due to certain circumstances. It can be done in several ways. Some of them can be combined for optimal results. Another way to raise the gate is to replace the casement version with a roller shutter. In this case, the gate will rise and not move. In this case, it is possible to expand the opening to the required dimensions before installing the door.