Beautiful carved platbands on the windows. Wooden platbands on windows carved pattern patterns

> TurnClies on plastic windows - what is why you need and how to install

Hello everyone!

For the weekend with the family went to friends to the country, celebrated their country housewarming.

The house turned out to be fame, only the windows decoration immediately rushed into the eyes. The junctions between the window design and the wall were not very beautiful.

Upon arrival home sent her specialist to them to install the platbands.

Now the connecting seam is securely hidden, and the windows finish looks worthy.

And your windows are decorated in the right way? If not, we read what to happen to what is further.

The procedure for finishing plastic windows with their own hands

The decoration of plastic windows is regulated by standards. If you take preliminary work, this is GOST 30971. You can see the first to see the perimeter of the window, where you need to use anchor plates (Appendix B), why the vapor barrier membrane is needed.

The decoration of plastic windows is regulated by standards. If you take preliminary work, this is GOST 30971. You can see the first to see the perimeter of the window, where you need to use anchor plates (Appendix B), why the vapor barrier membrane is needed.

The performance of the rules almost guarantees that the design does not lead from the wind, the mounting foam will not crush, leaving the frame without support.

In fact, the most dispute causes exactly the method of attachment, and not the decoration of plastic windows.

As for finishing works, here you can practically observe the same thing.

Helpful advice!

The decoration of plastic windows is to install the windowsills, slopes and platbands.

And so that this is all beautifully looked. Actually, the topic of the conversation today about the finishing of plastic windows.

Upon completion of the installation of the frame, we usually see a naked span with a plot of mounting foam. As can be seen from the standards, you need to be covered with a vapor insulating membrane, which is recommended if this forgot the builders.

Upon completion of the installation of the frame, we usually see a naked span with a plot of mounting foam. As can be seen from the standards, you need to be covered with a vapor insulating membrane, which is recommended if this forgot the builders.

Even before finishing plastic windows. This ensures moisture outflow from the layer of thermal insulation, and the water has the property to penetrate everywhere.

Did not notice on the outside of the frame such plugs of plastic? Did you think that these are assembly elements that are not related to the decoration of plastic windows? The plugs cover the holes leading directly to the glass.

This eliminates the sucker effect formed by the presence of a plurality of rubber seals. What is exacerbated by the presence of moisture inside.

How? That's how. The moisture will still penetrate inside the plastic window through the seals. As a result of the sash it would be hard to open, as well as to remove the glass wall when necessary.

Successful operation of plastic windows shows that these are useful. So, the vapor barrier membrane governed by the standard is also needed to keep the insulation dry.

The vaporizolation membrane is still more expensive than film for greenhouses, so hot heads came up with the following version of the event of events:

- It is necessary instead of a vapor barrier film to finish plastic windows to buy polyethylene for greenhouses.

- Then the catal machine is taken like that used in the USSR for manual laying of asphalt. This is such a shaft of a decent diameter, freely rotating on the grippers of a long handle.

- The shaft in our case is made from the smooth lounge. For example, you can try to find a suitable log in the store and cut off so much so that it is not hard to roll.

- The cylinder is sitting in the possibility of uniformly sharp cloves of small size. This is done so. You need to drive the nails a number behind next and bite the ticks under an acute angle. The work of that, also not forget that you only need a little spike on the surface.

- The resulting unit (do not forget about the handle) rolling polyethylene to finish plastic windows.

The essence of this invention is as follows. Each one knows that the vaporizolation membrane still passes water. Yes, yes, just the rate of penetration is very limited. It is necessary for what.

As we have already said, moisture will still penetrate everywhere. As a result, thermal insulation loses partially or completely its abilities. There are a number of other negative factors.

As we have already said, moisture will still penetrate everywhere. As a result, thermal insulation loses partially or completely its abilities. There are a number of other negative factors.

If we tightly seal the mineral wool layer, then condensate will fall inside the temperature. All this will be rotted (bacteria is also everywhere). Nothing good will come.

The essence is that gradually through a vapor barrier membrane surplus moisture will volatile. And the new water will no longer penetrate in the volume to cause any negative consequences.

The usual leaky polyethylene will pass into the water with large portions. Outside it will be atmospheric precipitates, and people living in the room, breathable, throwing steam.

Why does Malyshev say that in winter we have a reduced level of relative humidity in the apartment?

Couple leaves concrete buildings under the action of heating systems.

Have you ever thought about how it does it do it? Right! Through concrete walls and other ways.

As a result of polyethylene, it uses water well - it is water, and not a couple - and the rest creates a hermetic storage. The liquid will be stored inside, search exit and not find.

On the inner surface of the polymer will also accumulate condensate drops. In general, this is not the best solution to save on such trifles as a vaporizolation membrane. But for particularly persistent, we give the example.

So, imagine:

- Rain is coming. Drops got behind plastic windows and got to our leaky polyethylene.

- It's how to try to keep water in Sweat. Through the fine holes in the moisture film ash rushing inside.

- Mineral wool (polyurethaneretan significantly to a lesser extent) is perfectly like a liquid. Then the rain will pass. But inside the moisture will remain. We believe that there is no need to explain how difficult it is to dry wool. Whoever believes, let him try to wash the mattress in his bathroom. And then in the comments will share their impressions about how - willingly or not - Vata was dried in it.

The difference between the vaporizolation membrane is that it does not let the water. Quite quite. Couple - yes, but not a drop of water.

So, any finishing work begins with the fact that the presence of a pad of a vapor barrier membrane is checked.

If this step is missed, then you need to fill the gaps in the knowledge of construction by their own actions.

We also mention that the use of polyurethane foam also does not exempt from the need to install a vapor barrier membrane, but it is necessary to add to this account for another time, because the review comes too long.

Installation of slopes and plastic windows

We would still like to add that for laying a vapor barrier film, sometimes you need to cut the excess mounting foam. So! The first is the starting profile. Most of all, it looks like an old-circuit letter G.

That is, in contrast to the modern one from the end, there is still a stick, about a third of the distance to the base. So here.

That is, in contrast to the modern one from the end, there is still a stick, about a third of the distance to the base. So here.

Semi-cylindrical self-pressing should be fastened to this profile long side outside around the perimeter of the window. The top face of the letter G falls on the side of the window, forming a beautiful junction.

Under the other, the edge of the slopes need to put the crate. A small rack thickness is nailed around the perimeter of the inner part of the window opening. What is the value in centimeters?

Choose from two reasons:

- When installing on a dowel-nails, a tree should not crack.

- The clamping screws used in the installation will include at an angle of about 45 degrees. The thicknesses and width of the rails should just be enough for this. To again there were no cracks.

The next step is to install slopes at the place. The inner end of them adjacent to the room is usually split under the F-profile.

The gap is made to fill out by the stroke or piece of plastic for consumer strength and more rigid fastening.

Sunshine is inserted into the starting profile, then the opposite end is screwed to the crate. Places of angular joint will close platbands. In fact, this is a F-profile that needs to be slipped under the slope of the middle car.

For this place where the screws are present, it should be reached by 20 - 30 mm. Gently insert platbands.

It remains to close the corners with a sealant. Silicone glue with a thin flower put on all corners, is unnecessary removed with a plank or straight hand. The decoration of plastic windows is not finished yet.

The windowsill remained, and many of them rightfully consider the main part of all work.

Resperating the company building materials always creates training rollers for the use of products. So the buyer immediately sees, for which the fee is charged, and the money spends more.

Resperating the company building materials always creates training rollers for the use of products. So the buyer immediately sees, for which the fee is charged, and the money spends more.

As for the windowsides, the company Werzalit has been tried here. They offer as many as three versions of the interior.

We do not exclude, however, that there are others:

1. The first method is based on the use of ordinary cement. While the solution is prepared, you need to align the windowsill in the level. One end of the profile sits under the window, the second hangs over the wall.

This is a separate conversation, because there is no such position of the window sill. An adult man may well break the profile if it comes. That's why Werzalit limits the maximum hang of the window sill ten centimeters.

Note!

Werzalit limits the maximum hang of the window sill ten centimeters.

In every place you need to put just so much so that the windowsill rose horizontally. It is recommended to use the solid solid wood sooped by antiseptics for this.

Cement is not completely applied, but large cakes. And in front of each of the inside of the windows, the mounting plates of the intricate configuration are attached.

For a day (minimum), the windowsill pressed to the top of the window opening with special struts. In everyday life, this is replaced with good, sweaturated bricks.

2. In the second case, the installation is carried out completely on glue. Moreover, the bases of the planks must stick to the window to the window, and there should be anxious between the rolls.

2. In the second case, the installation is carried out completely on glue. Moreover, the bases of the planks must stick to the window to the window, and there should be anxious between the rolls.

It turns out quite a strong design, and the intervals already after drying can be pouring the mounting foam or thermal insulating material. In the learning video and it is recommended to pave mineral wool.

3. Installation on the steel console is also kept on glue.

It was a review about how the decoration of plastic windows is performed.

source: Remvizor.ru.

Carved plastic platbands on windows with photos

Plastic platbands on the windows have a number of advantages over wooden: do not rot, do not lose weight, do not affect fungus.

Plastic platbands on the windows have a number of advantages over wooden: do not rot, do not lose weight, do not affect fungus.

The functions are the same as on wooden: close the joints of the window box with the wall, prevent moisture penetration into the mounting gaps, increase the heat-insulating and soundproofing characteristics of the windows.

Carved plastic platbands on the windows (see photo) are most often used for PVC windows, but they can also be used for wooden structures: their color, design and texture are very diverse, from ordinary white to dark, colored, various wood imitation: oak, nut, ash, wenge, etc.

You can choose the material to the tone of the facade (for example, if the facade is lined with siding), or make the windows with contrasting.

The main thing is that new elements do not violate the stylistic unity of the facade.

Helpful advice!

For example, on the windows of a log "Teremka", the White PVC platband will not be placed.

But the product with the texture of a tree and made as a carved wooden platband will perfectly fit into the design of the log building. Photo of the best solutions See below.

PVC casters for windows is not the only solution - there are still polyurethane platbands. This material is lightweight, resistant to temperature differences, moisture and other weather whims, aesthetic and plastic.

PVC casters for windows is not the only solution - there are still polyurethane platbands. This material is lightweight, resistant to temperature differences, moisture and other weather whims, aesthetic and plastic.

Polyurethane platbands do not have to be straight, they can be made on a round window-porthole.

Polyurethane platings are often used by themselves, but within the framework of the general design of the facade: from polyurethane you can make "stucco" bas-reliefs and other decorations.

There are platbands from dense foam. But because of its fragility, they are practically not used.

Window platbands can be overhead and telescopic: the latter are a kind of designer (often complete with dogs), where all the elements are joined with each other with finished locks.

With them often used plastic platband for slopes.

Plastic platbands for plastic windows are mounted with self-draws, nails, synthetic adhesive compositions. In the absence of locks for fastening the elements between them, their ends are spilled under 45 degrees.

Plastic platbands for plastic windows are mounted with self-draws, nails, synthetic adhesive compositions. In the absence of locks for fastening the elements between them, their ends are spilled under 45 degrees.

There are removable products: in this case, fastening elements from metal are installed on the windows and platbands are snapped. It is very convenient if there is a desire to change them from time to time.

Or there was a need to replace damaged.

On economic buildings, you can edit the platbands bilateral scotch. But this method of attachment is not too reliable and will not stand the strong wind.

Forms are flat on the form of plastic windows (the most familiar option - see photo) or profiled, for example, convex.

The profile can be symmetric and asymmetric, curvilinear and combined, there may be various combinations of corners and convexities in it.

Note!

Shaped platbands can be used both in the room and on the facade.

Plastic platbands on the windows usually have a very large thermal expansion coefficient. Plastic does not twist and does not swell from water. Installation is quite simple and does not require the creation of large technological gaps.

source: ENOZA.RU.

Plastic windows - products are very functional and reliable. But in some cases, when the window is set to one level with the wall, the question arises in how to improve the junction between the window frame and the wall itself.

Even with a very high-quality installation, the junction always remains. And this problem is allowed to solve platbands for plastic windows.

Functions of a platband on plastic windows

The main function is to connect two mating surfaces so that the appearance of the walls together with the windows has looked complete.

The main function is to connect two mating surfaces so that the appearance of the walls together with the windows has looked complete.

In addition, the platband closes the connecting seam from the effects of external negative factors: moisture, direct sunlight.

To a certain extent, the platband protects and from temperature drops. But it depends on the material from which it is made.

Well, the last feature is decorative. Although many put this feature in the first place. But it all depends on the material and form of the platband.

What are the platbands on plastic windows

The simplest platform options are flat. This is the most common and budget option. The advantage of such platbands is the simplicity of their installation, ease of production.

The simplest platform options are flat. This is the most common and budget option. The advantage of such platbands is the simplicity of their installation, ease of production.

If there are no sizes in the decoration of plastic windows, it is flat ones that are installed.

Profiled platbands differ from flat coasperes for the external surface of a certain convexity. Moreover, this surface may have a different profile, both symmetrical and asymmetrical.

The profile can be performed not only in the form of a curvilinear surface, but also have different angles. May have a complex, combined profile, where rounded surfaces and angles are combined.

Types of shaped type having a embossed surface from the outside.

Helpful advice!

The relief on the surface of the platbands can be quite complicated. And these platbands can be made of wood or imitate wood.

Carved platbands are real works of art made of various varieties of wood. Although, by and large, carved platbands from wood do not always look beautifully with plastic windows and do not always fit into the style of the house.

Materials for the manufacture of platbands for plastic windows

One of the most common materials is plastic sheet type. Mainly plastic is used for the manufacture of flat plates. Plastic can be monolithic or have a structured inner part.

Plastic perfectly transfers temperature differences, humidity, direct sunlight. It can be released with different color, which makes it possible to choose the platbands on plastic windows under the color of the walls.

What is very important, the plastic has a low elongation coefficient. Due to this, when the temperature drops, the plastic platbands are not started to deform.

And you do not need to leave large thermal gaps when installing. Due to the fact that plastic does not absorb water, its deformation is excluded from swelling and other similar processes.

The second version of the trimming of artificial materials is platbands of PVC or polyurethane. Compared to conventional plastic, the use of PVC or polyurethane allows you to make platbands not with a flat surface, but with a profile.

Or receive platbands having a complex outdoor configuration, casting or pressing.

Polyurethane makes platbands for plastic windows, imitating carved platbands from wood. At the same time, the drawing can be quite complicated.

PVC and polyurethane perfectly carry the differences of humidity, react little to heating with straight solar rays, resistant to low temperatures.

Tubes of this type can be used for installation both indoors and outside.

The following material used to produce platbands - MDF. These are usually flat platbands or profile types. Basically such platbands are used for internal installation.

The following material used to produce platbands - MDF. These are usually flat platbands or profile types. Basically such platbands are used for internal installation.

The fact is that with all due respect to the MDF, this material is not well tolerating the serious differences of humidity, which can be observed during the outer installation. If you install a platband from MDF on the street, its operating time is sharply reduced.

Another variant of the material of the platbands is a dense foam. The advantages of such a platband consist in lightness, high thermal insulation, resistance to moisture and frost. However, foam platbands have very low mechanical strength.

The most expensive are platbands from a natural tree. They can be flat, profiled, shaped. In addition, they can have threads on their surface, obtained both machine and manually.

It was the tricks with a thread made manually, have the greatest value.

It was the tricks with a thread made manually, have the greatest value.

Profiled platbands on plastic windows are somewhat cheaper. This is due to the fact that the basic operations for creating a profile are performed on machines.

Similarly, the shadow surfaces on wooden platbands are made on the machines.

For wood, some drawbacks are characteristic. With incorrect finishing processing, moisture can penetrate inside the structure of the tree.

Over time, this moisture can cause strain or during drying cracking.

Moreover, wooden platbands are not always suitable for style under plastic windows. It is rational to use only if the house is made of wood, and not from other materials.

Methods for attaching platbands on plastic windows

Tubes on plastic windows can be mounted in various ways. The most common mount with the mounting elements to the wall or to the frame of the plastic window.

In some cases, an attachment is applied using adhesive compositions.

There are removable platbands on plastic windows that are attached with special latches. On the principle of action, such latches resemble buttons on clothing. On the frame frame, metal elements are attached to which the platband is snapped.

Another way to attach a platband is bilateral construction tape. But this fastening is possible if there are no serious wind loads.

source: Gennadiy.info.

Do you need platbands on plastic windows

The first and, perhaps, the main purpose of the overhead planks, which are more known as naschalniks or platbands on plastic windows, is the decoration of mounting gaps.

The first and, perhaps, the main purpose of the overhead planks, which are more known as naschalniks or platbands on plastic windows, is the decoration of mounting gaps.

Not always (and, to be honest, then almost never) Installation of the window can not be made so that there is no irregularities, gaps, gaps and other "production costs", which are obtained between the frame and the wall.

Moreover, some such gaps do not appear immediately, but over time, due to the natural shrinkage of the building.

Accordingly, that the installation looks fully finished, and the window looked beautiful and aesthetically, easier and cheaper than other types of finishing works (plaster or drywall), just install the finished framing (the sloping system) and, as my grandmother says, "Crane Stamp" .

But, this is not the only one, so to speak, duty.

In addition to the purely investigation function, the platbands serve as an additional barrier on the way at drafts, moisture and dust, which are trying to penetrate the streets to the room using the most microscopic gaps and holes.

And by the way, the nickniks extend the timing of the operation of the windows.

Note!

So do not doubt - the plastic windows are needed.

Putnquiries are used for both internal and outdoor decoration, may be in form:

- flat;

- rounded;

- figured;

and according to the method of fastening there are:

- overhead;

- telescopic;

recently, there are also platbands with a cable channel, where you can hide the wire from the air conditioner or Internet wiring.

Installation of casualin

Before installing platbands, the window opening needs to be thoroughly aligned (believing and deploying the remnants of the mounting foam) and check using the level so that the angles are straightforward, and the joints are perfectly smooth.

Before installing platbands, the window opening needs to be thoroughly aligned (believing and deploying the remnants of the mounting foam) and check using the level so that the angles are straightforward, and the joints are perfectly smooth.

Fastening of overheads on plastic windows are produced using special glue, "liquid nails" or screws (self-draws). The joints of the panels with the window frame are treated with silicone sealant so that they are completely sealed.

Work is a delicate, requires special skills, so not to damage the thin bar, it is better to entrust the installation of specialists.

Telescopic have an additional protrusion (builders call it "wing"), which is located at right angles to the plane plane.

This protrusion is inserted into the grooves of the box and, as a result, it turns out a complete closure of the joint.

This installation system is called hidden, since there is no fasteners or decorative plugs on the front side.

Cash care

No special care platings do not require. Conditions are the same as for PVC profile: Use a soft napkin or ordinary sponge and liquid detergents (pasty may contain abrasive substances).

When washing the glasses, do not use any aggressive chemical solutions (these are those that contain acids or solvents), as they can also damage plastic.

Where can one buy

As a rule, PVC platbands can be bought in the same company where you make an order for the manufacture and / or installation of plastic windows.

They are related to the discharge of accessories, but the platbands are not a prerequisite when installing the window, they can be included in order, and you can buy and put separately.

You can order platbands of individual sizes from manufacturers or acquire from their official representatives.

Standard sizes are:

- Length: 2200 mm

- Width: 40, 50, 60, 70 mm

Just like PVC profile, platbands on plastic windows can be white, colored or laminated.

source: vibiraem-okna.ru.

Plastic platbands and methods for fastening

Plastic platbands and methods for fastening

Cashbar are designed for decorative design of the window or doorway.

Tubes are not obsolete at all, as many, decor element say. These overhead strips allow you to hide different slots formed between the wall and the frame.

Even the essential defects that have become noticeable, for example, after a building shrinkage, you can hide with them.

Mounted on the windows of the framing give them a finished look.

The shape of the platband can be any: flat, rounded, curly (carved).

Currently, the building materials market boasts a large variety of overhead planks made from different materials:

- veneer;

- steel and aluminum;

If the house is wooden, the platbands must be made of wood (exclusive carved). If the house is stone or brick, then it will be perfectly decorated with framing from a natural or artificial stone.

Such windows will acquire a well-kept, elegant look and become a bright element of the facade of the house. Perfect decorative window planks made of artificial sandstone. They will retain their beauty not one ten years.

However, the most popular and inexpensive today are PVC platforms (from plastic). The fastening occurs with nails, screws, screws, special glue.

However, the most popular and inexpensive today are PVC platforms (from plastic). The fastening occurs with nails, screws, screws, special glue.

To avoid their damage, installation work must be accurately. If you do not have the skills of such work, then it is better to apply to experienced specialists.

PVC planks are available in various colors, so they are easy to pick up for any interior of the room.

By the method of fastening, the platbands are:

- telescopic;

- overhead.

The telescopic planks have a protrusion (wing) located to its plane at right angles. This protrusion is included in the groove of the box, due to which the full closure of the junction is achieved.

After installing the plastic window, the installation of slopes is always required. By installing the top panel into the fastening profile, the platband bend onto the wall and secure it to the wall of screws. Also install the side panels of slopes.

After installing the plastic window, the installation of slopes is always required. By installing the top panel into the fastening profile, the platband bend onto the wall and secure it to the wall of screws. Also install the side panels of slopes.

And finally, we will apply silicone sealant on the corner joint.

Also currently produced framing for windows and doors with cable channel. They have inside the canal in which telephone, computer, television wires can be hidden, which are usually hanging garland.

In addition, they do not need nails for their attachment, so there are no decorative plugs on the front side, nails or screws. Tubes have a hidden installation system.

About the old tradition to make and install carved platbands on the windows in the wooden house remembered relatively recently, when the first boom of construction of log cabins from the rounded log and timber was held. Having lived a few years in a new wooden house, the owners are almost always beginning to treat him, like a living being, so it is not surprising that surprisingly beautiful carved patterns, which serve as decoration and protection and protection began to appear on the windows and entrance doors.

Functions and purpose of carved platbands

Most experts engaged in the culture and history of wooden architectural monuments, note that carved platbands on the windows, photos are almost a status thing. The house without carved patterns looks like a wooden, albeit even very large and beautifully decorated, with platbands - turns into terme.

Traditionally carved platbands on the windows are set for two purposes:

- Protection of slots around the perimeter of the window frame from the penetration of rain, snow and wind blowing;

- Supplements and decoration of window opening, facade of a wooden house as a whole.

For a wooden house, builders are traditionally offered with a glass window frames from a glass or metal-plastic window profiles. Ordinary plastic PVC platbands can be ordered in a carb. That's just choosing a picture or pattern, most likely, will not come out, carved plastic platbands on the windows are made according to traditional stamping patterns and only give the form of handmade.

Tip! Today, many restoration workshops and firms have at their disposal three-coordinate milling machines capable of cut in automatic mode from polycarbonate, foam and epoxy plastics pattern of any complexity.

Such work will cost anything, but the quality of carved platforms for plastic windows will be even higher hand cutting. It remains to choose a drawing and pattern.

On the third task of the casing on the windows rarely, which of the owners of the house can tell more or less intended and reliably. We are talking about protective functions that protect the wooden house from the "bad eye", diseases and unborn guests. You can relate differently to beliefs and traditions, but it will be clearly not superfluous to take into account the specifics of the selection of a pattern for the platbands.

Patterns and shapes on carved wooden platbands

It is clear that any self-respecting owner will not hang on the windows of a wooden house. The first raised platbands, the process of selecting the topic and the picture can be delayed, therefore it is not necessary to abuse the use of symbols, the meaning of which is incomprehensible or unknown. If the mystical and cultural part of carved platbands creates psychological discomfort, you can relate to carvings as a method for decorative design of window openings of a wooden house.

They were invented to decorate carved platforms it is no coincidence and was kept and transmitted almost unchanged. Most wood-cutter masters cut simply as copiers, so planning and deciphering the drawing will have to be on their own.

Tip! In any case, before using carved wooden platbands on the windows with templates and pictures of incomprehensible content, it makes sense to try to figure out the values \u200b\u200bof thread elements, patterns and figures.

For example, animal figures and images have always symbolized positive wishes to the prosperity and prosperity house:

- Snake or Dragon always denoted wisdom and power to protect the house;

- Birds in flight means good and friendliness sitting in the corners - attention to guests and news;

- Fish, deer, beams of wheat and grapes mean the wish of wealth.

It was not customary to portray pets and figures of people, especially in one canvas with curly plants and flowers.

More modern drawings on carved wooden platbands typically have a traditional regular ornament.

It can be intertwined flowers, the leaves of the grape vines, laid in the regular pattern. In the carved compositions of the XVIII-XIX century, more modern images of columns, porticors and drops used in the wooden architecture of that era have already appeared.

Most of the carved platbands must be ordered from the masters of the cutters. If you wish, it is not difficult to make carved platbands on the windows with your own hands on templates or finished schemes. The simplest lines and drawings can be transferred to the workpiece and cut out the engraving nozzle, with more complex schemes will have to tinker and remember the lessons of drawing at school.

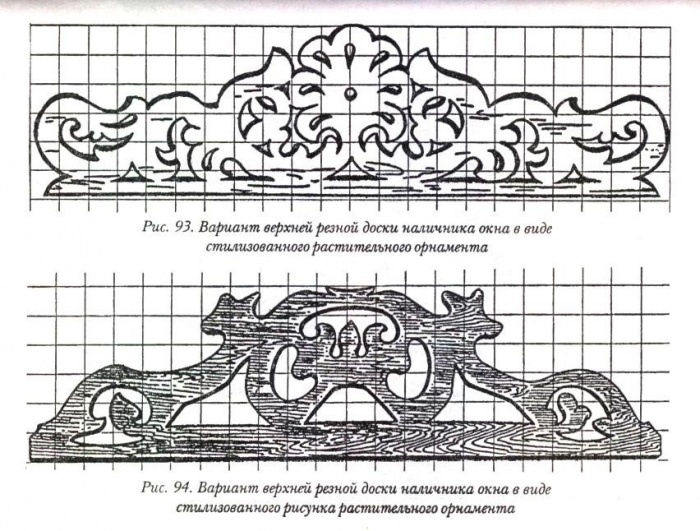

The upper part of the platbands was called eyeling, this is the most complex and beautiful part of the decor, on the one hand, the warehouse set the total tone of the carved composition, on the other, performed the visor functions above the window opening. At the top of the composition was a diadem, symbolizing the rising sun, and in the center necessarily a medallion or crown from plants. The lower part of the window was closed by a carved apron, usually in the form of a revealed veser.

If the mystical and cultural part of carved platbands creates psychological discomfort, one can relate to carvings, simply as a method for decorative design of window openings of a wooden house.

The usual intertwined pattern from the vine or colors will be far from any mystical filling, while the beauty of platbands and carving windows of the wooden house will only increase. In carved platbands with a regular pattern there is a serious advantage over a complex multi-tier composition:

- First, the templates of carved platbands on the windows are transferred to a wooden or plastic blank much easier and faster than a drawing with a complex multi-tiered composition;

- Secondly, even if you cut the intertwining vine or kant with your own hands and allow small flaws, to see them in the patterned field will be almost impossible, the psychology of a person will be arranged.

Therefore, before making carved platbands on the windows, select a simple pattern for yourself, with a minimum number of individual details. Even the most uncomplicated drawing on facing planks will be able to transform the appearance of the wooden house window.

Options for making carved platbands with their own hands

Wood carving has always been and remains a fairly expensive event, so instead of buying ready-made platforms, cut or stamped on furniture equipment, you can try to make decorative planks with the simplest patterns with your own hands. At home or in a joinery workshop, you can use one of three methods:

- Transfer the template to the prepared board and cut patterns using a engraving kit;

- Pull patterns under a carved polyester or epoxy resin concubine with subsequent color or laminate film trimmed;

- Cut the overhead pattern of the platband with the electrol bias.

Before you try your hand in the manufacture of carved platbands, you need to choose the appropriate material. For threads and engraving, solid wood varieties will be required, the beech or oak will fit well, a little worse pine or spruce, a poplar and aspen will not fit. For clippings of the invoice pattern, you can use a conventional sex board, but the material should not have bitch, defects or complex weave fibers.

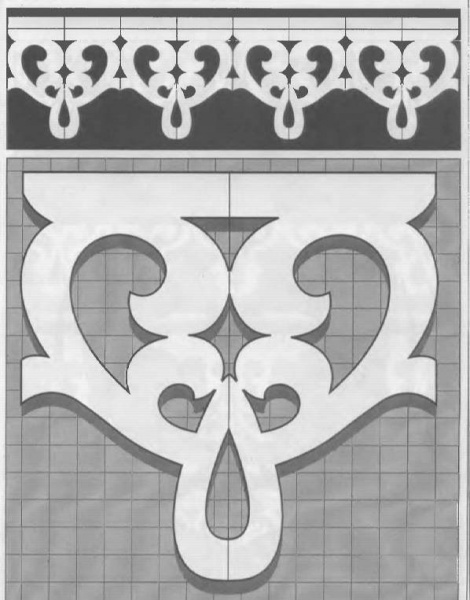

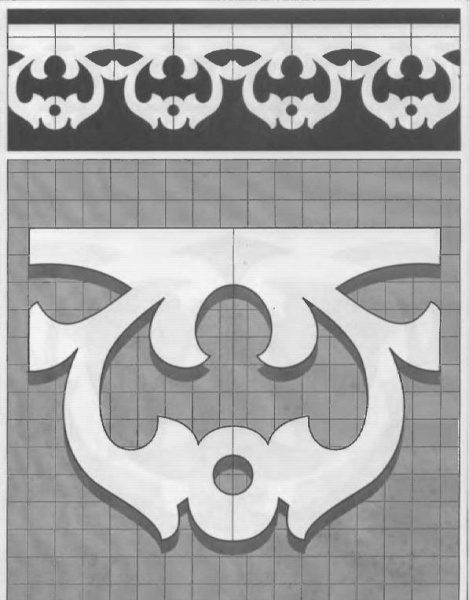

Pattern Template Templates

For the manufacture of the most simple patterns, you can use the simplest drawings of intertwined plants, colors, grapes. In fact, it is flat tracing from more complex carved reliefs. This pattern can be used to decorate the vertical side planks of the platband.

To decorate the eyebrow, it is necessary to search for non-regular, but single patterns, for example, a composition of symmetrically located shapes or weaves of plants.

The same pattern can be translated into the contour line and turn into a flat ornament, which is simply cut out of plywood, boards, or even MDF slabs.

The most complex embossed or volumetric patterns are manufactured in a setway. Initially, ordinary plates are made of planes, individual cladding elements are carefully seen in the size of the window and are collected in the finished frame.

All other decorative elements are consistently cut out of wood, differ from the casting polymer or cut from MDF plate, after which they are grinding, ground and pasted on the prepared frame.

Production of carved patches do it yourself

Most often, the patterns under the finishing of the window are cut from the waterproof OSB plate in the form of overhead decorative elements. Initially, a piece of drawing is being developed for tracing, a piece of millimeters and using the program.

Next, it is necessary to make a working pattern, with which you can transfer the pattern to the wooden substrate an unlimited number of times, a photo. For this printer, the drawing is glued onto a sheet of fiberboard and cut off by a spinning nozzle to a drill or conventional metal scissors.

After the marking of the wooden billet, you can start cutting machine. The easiest way to perform feeds with an electroll bias on a joiner's workbench.

On the line of executed propilov, it is necessary to remove the champecker with neatly sandpaper, so that with further processing the facial surface of the carved pattern was not cleared. If a fairly thin strap was chosen as a workpiece, then the carved part of the decor can be pasted on the tissue basis.

In the same way, small overhead elements are cut out in the form of rhombuses, squares, rings, pigs. After squeaking, the carved elements are stuffed on a hydrochloride with a stone for grinding wood. Using a circle, it is enough to simply give a rhombus or any other geometric shape the necessary shape, form a face or transient curvilinear planes.

After sticking the decor, carved platbands are ground with hydrophobic impregnations and expose aging. This is done in order to remove the whiteness of the freshly linked tree. For this, solutions of iron, copper, chromium salts are used. As a result, it is possible to pick up the color and shade of the carved platband to the tone of the wooden window frame. It remains to open the tree with varnish or oil impregnation and install a carved decor on the window.

Conclusion

Very often, the owners of wooden houses instead of making new decorative elements prefer to buy old carved platbands, preserved in the villages, abandoned houses and buildings. Often the cost of a set of carved platforms for the three windows of the building of the building is cheaper than the manual carving of one platband with a modern master. In some cases, among the old decoration, there are real works of art made by hand by the masters of the last century. Such carved platbands are usually subjected to deep restoration and are installed not on the outer parts of the windows, but indoors.

Starus architecture is invariably associated with carved platbands on the windows. A similar form of design of houses is distinguished by a species manifold. A few decades ago, masters have lived in each region, possessing the own style of creating decorative elements. Today's return to the origins is accompanied by revival of interest in finishing windows using carved platforms.

Purpose of framing

The word "platband" speaks about its location - "on the face", that is, one of its functions is to decorate the facade of the building. Therefore, people tried to express their individuality through it and decorate the windows with a carved framing. In addition to the decorative role, the windows on the windows, first of all, perform a constructive function, closing the gap between the frame and the opening. This prevents penetration into the house of dust, protects against precipitation, drafts and extraneous sounds.

Magic properties were also attributed to carved platbands. It was believed that the framing of the window of a certain form of a plank protects against the evil eye and serves as a peculiar guard. Therefore, in the bizarre patterns, various figures and plants weighing a specific semantic load were viewed.

In modern architecture, the functional purpose of platbands for windows is as follows:

- Competently selected carved decoration allows you to visually pull out a low structure or expand a narrow wall.

- The ability to manifest individuality and issue a building in accordance with the treason of a certain era.

- Allows you to achieve a single architectural ensemble between all buildings on the site.

- Protection of slots from the penetration of external negative factors (precipitation, noise, dust).

- It is one of the elements of the heat shield of the house.

Note! Sometimes platbands are the only version of the window framing. It mainly concerns wooden log cabins when the use of other materials is unacceptable due to the loss of a harmonious appearance.

Carved finish, especially made of wood, has a number of features that should be taken into account during operation:

- Dependence on the influence of atmospheric factors. Moisture and temperature differences are invariably damage to decorative design.

- When selecting the framed, the properties of the rock should be taken into account from which platbands are made and take care of quality processing. Timely preventive activities prolong the service life for the window.

- Often, difficulties arise when combining wooden carved elements with modern plastic frames. With this combination, it is preferable to install windows that imitate the wooden texture.

The value of carved elements

The desire to comply with the ancient traditions requires knowledge of the meaning of various elements of carved platbands:

- The sun is usually placed on Kokoshnik. It symbolizes life and energy.

- The personification of wisdom and fertility is concluded in the image of the snake.

- The symbol of harmony between spiritual and material desire is the cross in the carved platband.

- The feeling of unity with nature is emphasized through vegetation.

- On the hospitality of the owners of the house are evidenced by earrings.

- Connecting elements of all times is the silhouette of a bird on the window.

Characteristics of materials and forms

Natural and artificial materials are used to produce platbands on the windows. Traditionally carved elements were made of wood, resistant to atmospheric factors. The characteristic of the properties of individual breeds will help determine the most suitable view:

- Larch is minimally susceptible to rotting processes, but is not suitable for the production of carved framing due to its fragility.

- Aspen, alder and linden - most convenient breeds for creating an open-air decor on the windows. However, piercing and soft wood of carved platbands need special processing due to the ability to absorb moisture well.

- Tubes for windows from oak, ash or beech is characterized by resistance to negative atmospheric influences, but the processing of carved elements is burdened by difficulties, overcoming which you will receive a durable decor.

- A good choice will be birch or pine wood, allowing you to perform a neat carved decor. At the same time, the platbands have sufficient strength for external exploitation.

- Small carved window decorations that are fixed on the main elements can be made of cherry or apple tree.

Tip! Regular renewal of the coating of wooden platbands with waterproof paint or varnish will provide them with a long service life.

What other materials are used in the production of linings on the windows and what are their features, consider below:

- Laminated MDF allows you to accurately simulate the color of any tree of wood, but is intended exclusively for internal use.

- Plastic windows are harmoniously combined with platbands from a similar material (PVC), which is not subject to rotting, has a wide color palette resistant to solar radiation. The color of the platbands is selected taking into account the finishing of the house in the tone or contrasts with the facade.

- For the windows of the round form, polyurethane products are ideal, characterized by ease and unpretentiousness in care.

- Metal planks are fixed in order to protect the mounting seam, connecting them into a single whole with a profile box.

There are two main ways to install platbands:

- The invoice is the most common method when designing windows. For fixing, special glue or nails are applied.

- The telescopic method involves a M-shaped platband manufacturing, allowing the product to enjoy the product by entering the grooves of the box. It is often used to finish door openings. Its characteristic difference is the lack of traces of fasteners.

Templates and threads

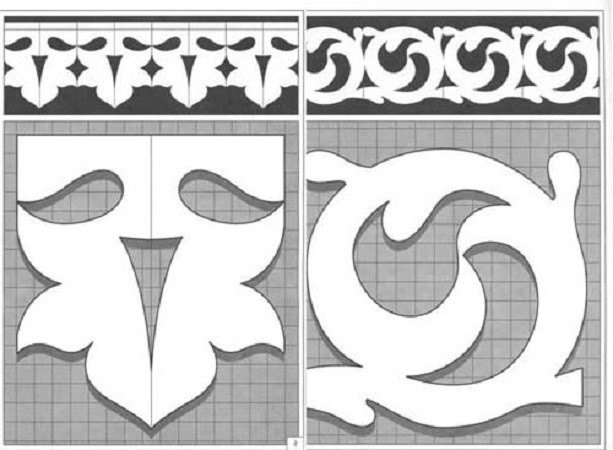

The carved forms of platbands give the window of individuality, but in order to make them, templates will necessarily need. The presence of wood thread skills allows you to choose a complex ornament. If the skills work with the tree is not enough, it is better to find a light pattern for platbands on the windows. We suggest learning:

- variants of patterns of single elements and their general view;

- top, bottom and lateral details of decoration.

They can be copied completely or supplement the pattern with their details. Having liked drawing of a carved platband or its fragment must be enlarged on a scale taking into account the size of your window. For the manufacture of carved templates, dvp, dense cardboard or paper apply. It is advisable to draw up windows with platbands with the same thread. Please note that it is much more complicated to make small carved elements, but they come into disrepair faster than others. In this case, a partial replacement of the frame will be required.

A warning ! Be sure to consider the slope at the top of the carved platband. This will prevent snow accumulation and ensure timely removal of water.

The top of the platband on the window is called Kokoshnik, the bottom is a towel. Contours of plants, animal images and geometric shapes obtained the greatest distribution in the ornament of carved coats.

Key details of the drawing for any platband on the window are:

- lower planka or bottomroom lounge;

- vertical rail;

- top plank.

The scheme may also contain all sorts of shoulders, van supplies or to diadem. A detailed description of the names of the carved decor elements is presented in the diagram below:

If your windows have a different size, experts advise to make a drawing with an intermediate rapport repeating the required number of times. For the Rapport you can choose one or two elements repeated alternately. An example of such a scheme is shown in the photo below:

Make a wooden carved framing on the windows in several ways:

- The greatest decorativeness and squint are characterized by slotted platbands. The product is performed from a tree of light tones or subjected to a subsequent coating of white paint. This window design on a darker wall looks sophisticated and exquisite, remotely reminding Vologda lace.

- With overhead thread, separately cut parts are fixed on a solid board by gluing or navigation. This technique allows you to make a window with a simple platband. The protruding elements often cover contrast paint.

Sometimes both types of thread are combined.

Manufacturing process

Deciding with the pattern, material, type of thread and the method of fastening the platbands, can be directly processed to the manufacture of a carved frame on the windows.

Important ! The drawing on the workpiece needs proper placement. Prevent cracking of the thread will allow the location of the elements along the fibers of wooden blanks.

Pattern places where it is necessary to make slits, it is better to mark with color. Work on the manufacture of platbands consists of the following steps:

- Removing the measure from the window.

- For the slit thread, the boards with a minimum thickness of 30 mm are selected, the consignment method allows the use of a thickness of 10 mm thick. All work is made with a dry lumber.

- Cut blanks.

- For dense fitting of a carved platband with an inside, wood is chosen on a slight depth (1-2 mm).

- The pattern applied with the use of the template is cut. For the formation of the holes, drills of various diameters are used, the jigscription will be needed to perform a slot. To arrange a beautiful cut, the jigsaw entry point is observed by the resulting hole.

- All carved elements of the windows are cleaned with grinding paper. From non-split holes, wood dust is removed using a vacuum cleaner.

The overhead carving provides for the fastening of the finished elements to a wide platband on nails with remote hats. Enhance the strength of the compound will allow the glue from the wrong side of the pen. Apply the screws are not recommended due to the danger of damage to the carved section of the compound.

Carved platbands are installed on wooden windows using deaf or cross-cutting spikes. The first option is distinguished by a reliable compound and a complex installation process. The second way is simpler, but less reliable. The installation of carved elements on the plastic window is carried out using liquid nails.

Preliminary protective processing of carved platforms and regular preventive care will provide long-term preservation of an attractive appearance of the window.

After installing windows in a wooden house there is always a gap between the wall and the window frame. The easiest way to eliminate it is the installation of platbands. In addition to functionality, they play the role of a decorative element that adorns the facade of the house and makes it a look unique and completed. Some of the most beautiful are carved platbands from a tree.

Types of pallets from wood

To date, platbands exist not only wooden, but also wood-fibrous, plastic and even ceramic. But the most popular material for their manufacture still is wood. This is due to its environmental friendly, affordable price and high aesthetic qualities. In addition, wood can be restored, thereby extending the service life.

Smooth or profiled from solid bars. If further platbands are painted, coniferous rocks are used, most often pine. When manufacturing from valuable wood, they are covered with varnish. Nails, screws or liquid nails are protrude as fasteners.

With figured carvings from solid bars.Mainly made from valuable wood and varnished. Cold can be mounted on both screws and simply and liquid nails.

Smooth or profiled from glued bars. They can already be done with a decoration of laminating film or veneer of expensive wood breeds, which makes it possible to eliminate the need for additional finishing processing. But, there are also without finishing, intended for painting.

Stylized under a certain style.The most expensive type of platbands that are made exclusively under the order.

In addition, they are divided into appearance on flat, shaped and curly platbands.

Flat.The cheapest and simple type of platbands. But has a low aesthetic value.

Shaped. Most often they have a convex surface that has rugs, protrusions or grooves. They stand more expensive than simple flat. This is due to production technology for which the use of special equipment is necessary.

Wooden on wooden figures. They are elements of the decor and give the house individuality. They are produced on special machines equipped with vertical cutters. In this case, the desired drawing is programmed, and the machine automatically produces the surface milling. But, despite the latest technology, the possibilities of such equipment are limited.

And only the master can make an openwork relief. The price of a wooden handmade platband will depend on the complexity of the ornament and the wood breed.

But the main difference of manual milling from the machine is that the machine does not make through threads, but only causes a drawing to a certain depth of wood.

Wood for making platbands

If you need to make a flat or shaped platband, then a simple pine is used. For the manufacture of carved, wood is necessary for soft rocks, such as linden. It is easy to process even manual tools and is easily grinding. But because of its high hygroscopicity, needs a high-quality finish coating. This implies the application of several layers of paintwork.

In the regions where significant temperature differences are possible, as well as high humidity or on the contrary, the dry climate is made, wooden platbands made of dense and solid wood. These include birch and oak, which are extremely difficult to process, but they will serve not one decade. Therefore, platbands from these tree breeds are most often manufactured on milling machines.

The only disadvantage of all types of wooden platbands is high hygroscopicity, which over time leads to their cracking and drying. You can avoid this periodically updating the protective paint layer.

Tools necessary for the manufacture of carved platbands

Through thread the most affordable way to decorate platbands for non-professionals. It will not require special skills, it is necessary to have only patience, the diligence and feeling of beautiful.

A large number of firms are offered, a variety of platbands manufactured by an industrial method. But much more pleasant to make it yourself. As a tool, manual milling machines, ordinary or electric jigsaws, various types of drills, chisels and hacksaw can be used.

Basic rules for the manufacture of platband

Making wooden platbands do it yourself, it is important to consider that after installation, they should not impede normal opening windows. Therefore, the internal sizes of the platband are made more than the size of the window frame by 2-3 cm.

The upper part of the platband is called "Kokoshnik", if necessary, it can be increasing, which scrapes the details of spikes. The lower part is called "towels" and is attached to the tilt from the wall for water drain. She also has a thread, in style coinciding with the "Kokoshnik" carving, but the plank for it should be 1 cm thicker than the top plank.

Before installing the platband, you need to navigate the rails around the perimeter of the entire window - this will allow you to fully close all the irregularities of the wall. Shakes, at the same time, should be carefully seized.

All platbands are performed in a single style.

Preparation for work

For the manufacture of a carved platband from a tree, it should be selected on the board 3-4 cm thick. It is optimal for free opening of window sash. The width should be sufficient to cover the edges of the walls and protect them from moisture. Olha, linden, aspen, or coniferous rocks can be used as wood.

Choosing a small ornament is not the most successful solution. It will be poorly distinguished at a distance, and for the manufacture requires more time and special thin tools. Therefore, the ornament should have large elements that are clearly seen from afar.

The location of the carved elements along the fibers of the tree will protect the platband from cracking. This applies to wood of coniferous rocks.

First use uncomplicated patterns. The simplest for beginners in the thread are round pattern elements that are simply drilled by a drill. Below are sketches of samples of wooden platbands.

In more detail about their manufacture can be taken on video.

Installing platbands on the windows

Stencils can be made independently or transfer the drawing from already ready-made sketches. Initially, the pattern is applied to the workpiece, then the hole is drilled with the drill and the necessary ornament is cut from it. Further, the carved platbands must be finely polished by sandpaper.

After carved blanks are made, they should be connected correctly. In total there are two ways to connect: on the spikes or compound in drapes. The first way is much easier and more popular, the second is used extremely rarely.

For fastening of the platband use special glue. It is important that it is synthetic, since mushroom may appear in the organic connection, as well as moisture. All this is very harmful to wooden platbands.

If the elements are attached to nails, it is desirable for all the joints to lubricate with glue, and only then fasten with nails. We should not forget about the processing of glue of all joints and especially spikes.

On the windows, platbands are easiest to install with the help of wood screws. You can decorate their caps using widths mixed with glue, which will crumble in the future. But even without this work, the screws will be practically invisible on a general background.

Finished platbands must be covered with a protective composition, which will extend their service life for many years. To do this, it is better to use special impregnations that are periodically updated. The paint, whatever qualitative, it is, will begin to crack and peel, but it will be much more difficult to correct it.

When choosing a pattern of the future platband, it is very important to take into account the stylistics of the whole house, because they must harmoniously complement it. Here are some examples of the photo of wooden carved platbands.

In most cases, carved platbands are used when decorating windows of wooden houses. But due to the fact that buying a ready-made platband today is quite problematic, it is easier to make it with your own hands.

Important! All platbands, albeit the highest-quality, have one significant drawback - they need protection against atmospheric precipitation.The manufacture of platbands on the windows is traditionally begins with the preparation of all necessary.

Stage 1. Equipment

During the work, the following tools will be needed:

Stage 2. Selection of Material

For ordinary platbands it is better to use pine, while for carvings it is recommended to take soft rocks, for example, a leipt (the last one, moreover, it is much easier to process manually).

Important! The only minus of linden is hygroscopicity - easily eliminated by applying several layers of paint and varnish coating.

Solid wood should be chosen in three cases:

- with high humidity of the climate;

- with too dry air;

- if there are significant temperature fluctuations.

The solid rocks can be attributed to the birch and oak. They are quite difficult to handle with manual instruments, so the milling machine will be required, but it will serve such a tree several times longer than linden.

Stage 3. Important moments in the manufacture

Finished wooden platbands should not prevent the opening of the flaps at least 90ᵒ. Regarding other parameters, they are selected individually in accordance with the size of the opening. For fasteners, you can use the spikes or to connect the elements in the hardwood.

Important! In the future, to apply to the surface of large images, the upper part of the platband can be increasing. For fasteners, spikes are used, and the decoration itself is called "Kokoshnik".

The lower part of the product is manufactured by the same carved method and should include the SCOS required for the drainage. It is characteristic that the thickness of the lower part should exceed the thickness of the upper minimum of 1 cm.

On both sides of the opening, small rails are nailed - they will hide the differences of the walls (if any). The thickness of the rivers must match the width of the gap, at least approximately. The final fastener is carried out only after a thorough fit of the joints.

Important! If the sash opens to the street, then the platbands need to be installed 3 cm above the window itself.

Stage 4. Pattern selection

Since ancient times, the platbands have been decorated with the most fancy patterns, which were believed to protect the house from unclean strength and evil. Today, the manufacture of carved platforms is mainly qualified by the Master.

Important! To dotubes on windows with their own handsYou must first find a good stencil, which will create a pattern of any complexity even without special wood thread skills.

Often, professionals themselves enjoy stencils, only one-time individual orders are performed without them.

Stencils today are freely sold in a wide enough assortment. They consist of such components:

- lower plank;

- top plank;

- vertical rails.

In addition, additional decorative parts can be present and shoulder, and so on.

Stage 5. Frame Production

Initially, frame is formed from pre-sliced \u200b\u200belements. The mount is carried out with the help of spikes that are fixed in the holes by the Nagils. To create spikes, an electrolovka is usually used, although the usual hacksaw with small teeth is suitable. A small knife is used to remove sawdust.

The width of the finished frame, as well as the platbands described above, should not interfere with the free opening of the flaps on 90ᵒ. The frame itself should be more windows at least 2 cm.

Step 6. Production of platbands

Step 1. At first, the drawing from the stencil is transferred to a tree through a copy.

Step 2. Then the jigsaw is taken with a thin mall and minor figure skating elements are cut.

Step 3. From the outdoor side of the pattern of the pattern, it is cut in so that the cloth passed along the edge of the workpiece.

Step 4. In any case, it will have to turn the saw in the workpiece. It is simple to do it enough, you only need to use one of two existing ways:

- upon reaching the rotation, several mutually accelerated propilovs are carried out (the saw should be the possibility of turning into any angle inside the hole);

- you can go to another way - make a small loop that will allow you to go on the back.

Important! Modern jigsaws allow you to do the contiguities at an angle of 45-90ᵒ, thanks to which you can not only make the smallest sections, but also give the decorative element more rich and bulk form.

Step 5. If you need to cut a closed figure in the center of the product, the hole is drilled in the middle of the removed item. After that, the Lobzik canvas will be easier to move in one direction or another.

If the workpiece is quite thin, then when it is handling it is possible to do without electric drills. For this, the electrolybiz is taken and rests on to the workpiece at right angles. Next, the tool turns on and the hole seems to be scratched at the deepening of the canvas in the tree.

These are all key aspects of the manufacture of window platbands. Actually, the entire procedure comes down to a reusable repetition of the actions described above, but their specific combination depends only on the skills and complexity of the pattern.

It is worth noting that there are other methods of manufacture that differ from the above described above. For clarity we advise you to see the thematic video.

Video - production of window trim

Find out which it is better to choose, as well as consider varieties and ways of installation, from our new article.

Prices for platbands and dough for windows and doors

Platbands and dough for windows and doors

Fundamental rules. What can not do

Below is a list of rules that will help avoid the most common problems.

- As a starting material, it is recommended to use a 3-4 cm board with a thickness.

- Do not immediately grab the complex patterns. First, it is better to practice on ordinary round items that easily make a drill.

- The width of the workpiece should be such that it is enough to cover the ends of the walls and protection against moisture.

- Carved elements should be located along the fibers of the tree - this will prevent cracking.

- When choosing a stencil, it is better to pay attention to patterns with large elements, since small ones will look crumbly, as a result of what finish will not have the desired decorative effect.

Important! Before starting work, the future time and money costs should be calculated, as well as the expediency of the very beginning. In the absence of high skills in working with wood and interest in the process itself it is easier to buy ready-made platnis.

Moreover, it is desirable first to familiarize yourself with the photos of various products. So you can find a suitable option or learn inspiration for the personnel of creating something.

Stage 7. Installation of the product on the window

Now it remains only to install ready-made carved platbands on the windows, for which special glue is used. It is important that it is not organic, otherwise, due to the susceptibility to biological influences, he hurts and the products itself.

You can use the plumbing glue - there should be no problems with it.

Important! If the mount is carried out with the help of nails, the spikes and joints should be missed in advance with adhesive solution.

Another option that is able to further simplify the installation procedure is to use self-tapping screws instead of nails. It will be easier for at least due to the lack of risk to damage the platband or the surrounding surfaces with a hammer.

Important! Self-tapping caps are very easy to disguise. It is necessary to mix wood sawdust with glue and the mixture obtained to smell the hats. It is advisable to do it before painting windows so that the hidden fixing elements also acquire the necessary color.

The final coloring procedure is also quite simple. Some protective material is applied over the finish (not only paint, but also, for example, varnish, impregnation). It is advisable to do this in any case, since such a coating significantly extends the operational term of products.

Paint, as you know, peeling, so it is advisable to take it instead. It is much easier to periodically update the impregnation than to eliminate the cramped paint. And the latter, as you know, will surely crack.

As a conclusion

It is commendable that people seek to follow the traditions of their ancestors, because it is especially true in the current conditions of active urbanization. For independent manufacture of window platbands, it will take some time and appropriate equipment. The procedure is complex, but the result with interest will pay off all costs. Moreover, it is possible to save a considerable amount of money, since the manufacture of platbands for one window to order will cost an average of 2.5-15 thousand rubles.

Video - Variants of Put