Tool box with wood with hands. Store tools Simply: Make a wooden box with your own hands

Reading time ≈ 5 minutes

This owner always takes care of the preservation of its tools. Even a small set should be stored ordered, neatly. A skilled master can assemble the capacity of the tools and fixtures on their own. Below will be talking about how to make a tool box with your own hands. Presented photos and video will help in work.

Externally, the box looks good and stylish, he immediately declares a serious approach to the life of his owner. Its dimensions (70x40x45 cm), that is, 70 cm in width, 40 cm deep, 45 cm in height. This is quite enough to accommodate the hand tool. In the drawer 3 retractable tray, as well as the top folding cover, which opens the bulk compartment. Such boxing allows you to protect the tools from dust, organize safe storage.

Required tools

For the manufacture of a wooden box, the following tools will be needed:

- a circular saw;

- milling machine;

- grinding;

- clamp;

- a hammer;

- nippers;

- file;

- wood hacksaw;

- chisel.

Step-by-step instructions for making tools

Optimal material for the manufacture of frame - oak wood. It is a wonderful durable material that is distinguished by strength and resistance to mechanical effects. It is better to take the basis - glued plates with a thickness of 19 mm. This material has no bitch and rotten inclusions. Using a circular, a strip of 38 mm wide is cut off.

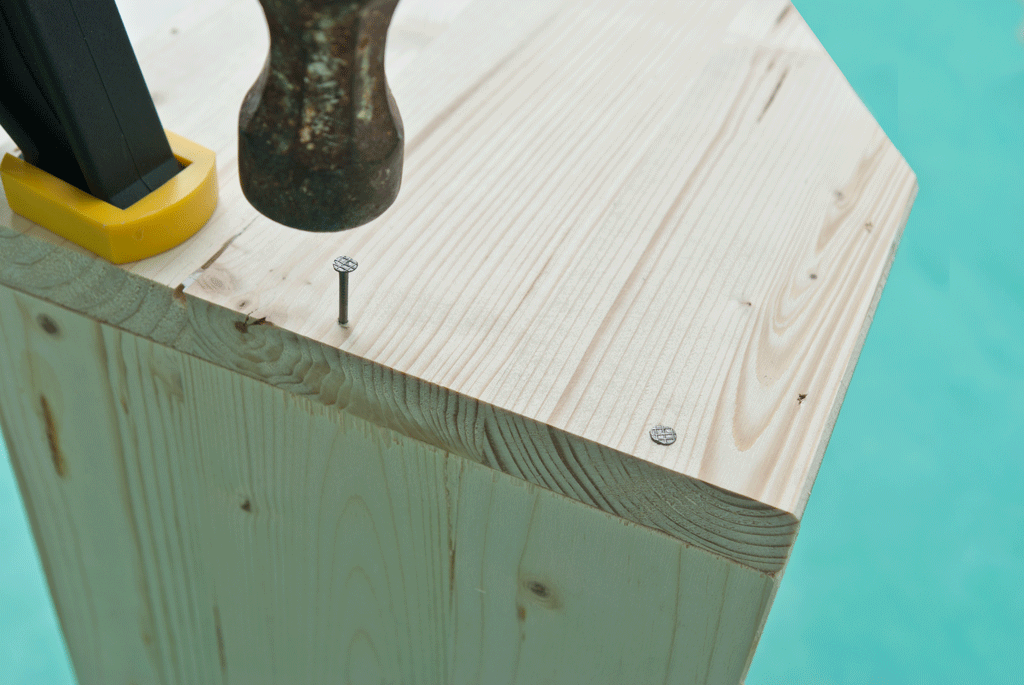

In order for the individual elements when gluing, the individual elements are shifted relative to each other, in the first part it is slightly ripped off the carnations, the pads remove his hat, and then focus on the protruding sharp tip.

The boards are additionally missed by glue and fix.

The glue spoke on the joints of the details is removed by the chisel, only you have to wait to glue a little snack.

As a result, it should be part of 38x38 mm. Her end grind.

The edge should be cut strictly at an angle of 90 °, so cutting off the detail of the desired length, you must not forget about the coal of the cut.

This technique will help make sure the cutting angle accuracy.

The location of each detail is marked in order not to get confused when assembling.

In each part over the entire length, the groove is cut, it must go strictly in the center.

The grooves can be made either with the help of a stationary circular saw, or with a milling machine.

On the details that are intended for the manufacture of vertical corner supports of the frame, make the transverse markup.

In the rear corner items make another longitudinal groove. In the front corner reference parts it is not needed.

For the subsequent attachment in the end part of the blanks, it is necessary to find the center, noting the point of intersection of diagonals.

It is necessary to carefully check the compatibility of the blanks.

Billets are processed with a file.

In a freely assembled frame, there are marks to subsequently lengthen the grooves.

The grooves are drunk with a tree with a tree.

The chisel is removed all too much.

These billets are needed for drawers. A corner is cut off from the end part.

Each billet is drilled for fastening with bolts.

Observing accuracy, you need to resolve the prepared details.

On the details intended for attaching and separating 2 drawers, cutouts are performed at an angle of 90 °.

By installing the details for the movement of the boxes in place and fixing them, gradually begin to fasten them.

Corners of plywood blanks are cut into the photo.

The walls of the lower boxes are attached to the sheets of plywood using selflessness.

To one side side attached horizontal parts from plywood. At first they do without the use of glue.

During fixation using clamps, you need to check the diagonality to match the sizes.

Retractable drawers are made of plywood.

The grooves can be chopped up either on a stationary saw, or with a cutter.

Details of drawers are fastened with glue.

The side parts of the boxes must have grooves for movement on the planets fixed inside.

For strength, the side parts are fastened with dowels that are cut into the flush.

For reliability when gluing, small carnations are partially driven into the surface of the front wall of drawers, their caps are removed.

Attaching the front panel to drawers, look, is smoothly located individual elements.

When gluing it is necessary to observe the limit accuracy, there should be no gaps.

At the end make the top frame of the box of plywood.

To make an exact incision at an angle of 45 °, it is desirable to use a special tool.

Billets for the frame are connected and fixed when gluing with a stretch strap.

This article is about how to make a wooden box for tools. If you have a lot of tools and you want to keep them in order, the best thing you can do is create a simple tree drawer. From our experience, we consider them very useful, as they are easy, durable and give a lot of places to store tools Do not forget that you can adjust the size and design, according to your needs.

The main components of the toolbox are made of 20 mm boards, as they have a beautiful appearance, and very durable. In addition, we recommend that you glue offices of connections and copold everything by itself by cuts. Try to screw the screws as you symmetrically as possible.

Upon completion of the assembly, it will be necessary to open the entire surface of the box. Make sure all the edges are smooth. Otherwise, you can damage your hands about sharp edges. Also, do not forget to check that the caps of all the screws are at a level with a wooden surface. Get rid of dust and chips before painting.

What do you need to make a wooden toolbox

In order to make a wooden tool box, you need the following:

Materials

Instruments

- protective gloves, glasses;

- ruler;

- chalk, roulette, level, joinery pencil;

- and drills.

Advice

- Pre-drill holes in wooden components before spinning screws.

- Make a handle from a cylindrical stick.

Time

- 1 hour

Drawer design

Creating the simplest wooden toolbox - one of those projects that can be done in less than an hour. But it can make your life easier, especially if you work a lot with tools.

Smart Tip: Before connecting parts, add some glue into the joints. Immediately remove excess glue with a dry cloth, otherwise it will be difficult to remove it after drying.

The first step of the project is the markup. As you will see in the next stage of the project, we will use 1 × 8 boards to make a box for tools. Therefore, you must use a joinery pencil and a carbon line for marking lines on wooden boards.

In order to get accurate cuts, we recommend using an electric qq or a good circular saw. Make sure that the saw has smooth teeth, otherwise it can tear the edges.

Smart Tip: In addition, check that the blade will pass exactly along the section line before sawing.

In the picture, all the components needed for the drawer. The circular machine can simplify work, since many cuts must be made at an angle.

You must use this drawing in the manufacture of components for a box. Make sure you checked all measurements twice, otherwise the components may not match each other.

After creating wooden parts, you need to drill holes across the edges. As you can see in the picture, you need a plank on a wooden bar to prevent surface damage. Drill three holes at the bottom and two holes on the sides.

Smart Tip: If you do not have experience in wood processing, you must figure out the guidelines for pilot lines. Make an indent from the edges to prevent wood cleavage.

If the edges of the lower part are not smooth, you must carefully paint them with 120 sandpaper before assembly.

Bottom ends Mix the joinery glue to strengthen the connection. Excess glue Remove with a dry cloth, otherwise you will spend time to clean it.

Press the components strongly and leave half an hour. If you use good glue, it will sprinkle the joints of the joints well.

Nevertheless, tighten the screws in the drilled holes.

In order to get a solid construction, we recommend using self-tapping screws. Work carefully to prevent damage to the wooden components.

Smart Tip: Align all parts before twist. As you can see in the picture, the edges must be smooth.

After installing all components together, the tool box should be similar to the one that is depicted in the photo below.

Make a handle from a cylindrical wooden rod. The diameter of the handle is about 20 -25 mm.

Smart Tip: Use the ruler to cut the rod of the desired length.

Add some carbon black glue to both ends of the rod before installing it in place. Then drill the hole and tighten the screws. Hold the handle while spinning, otherwise it can be shifted.

Smart Tip: Leave about 15 mm from the top edge to a wooden handle.

Do not forget to smooth out the edges of the wooden components with emery paper.

Smart Tip: Clean the drawer from dust and chips before painting.

After completely skill the entire surface of the box with sandpaper.

Smart Tip: Apply several layers of paint, varnish or verse to improve the appearance of wood and protect the materials from rotting.

If you want your drawer to have the same dimensions as in our article, we specify that 1 inch is 2.54 cm.

The idea to make a stainary box was long ago, but all the hands did not reach. As soon as the time fell back. The choice of materials was based on what was at hand. Side panels made of pine, pen of ash, side planks made of beech, bottom of plywood (pine) when choosing sizes proceeded from the size of the existing material. The beech planks in their past were a 45 cm parquet size. The height of the box is 30 cm. Internal size 14 cm / 40. At the bottom of the box was made compartment for chisels and lobby saws. We also have landing places for drills and feathers on the tree. When assembly used glue on a tree D3, screws and minor nails. In general, it turned out a very compact and functional joinery box, in which everything you need at hand.

Started from the cover of the blank for the side wall of the box.

Chose the rails for

Fitting obtained billets

Sliding drawer for chisels

Scuffed side stops for chisels

Putting of side planks

Each man in the house (apartment) must have a screwdriver, a hammer and at least a handful of different nails. If this is a master with "golden" hands, then you need to have a whole set of various tools for which a comfortable box is needed.

Toolbox do it yourself

Many tools (hammer or hacksaw) can not always be placed in standard fixtures for storing and transferring tools. Therefore, the craftsmen are preferred to make the capacitance of the desired size with their own hands. Consider the stages of work, how to make a tool box.

Selection of material

It can be used: metal or plywood. But the classic is the tree, which for a long time there was the basis of a joinery. Therefore, it's easier to make a wooden box for tools.

Type of shell

You should consider in advance and measure where the chest doors will be located, handle options. The design can be open or closed so that large items can be placed. It can be a big box with cells or design artwork.

Interior decoration

The model may be simple for storing different trifles or multifunctional: separately a row with holes for various screwdrivers, pencils, glue, pliers, etc.

Convenient boxes in several floors, they can insert into each other or extend. The main thing is to achieve maximum order in the location of the details so that it is separately nails, screws, roulette, power tools, etc.

In the manufacture of a specific model, it is necessary to take into account the operating conditions:

- storage place (apartment, basement or garage);

- humidity level;

- temperature;

- the frequency of applying devices and devices (professional activity or for home).

Designs for tools boxes

Before buying a compact model for different tools, we list the varieties of structures:

- Boxes are made of solid durable materials, more often rectangular. Side can be a pair of retractable compartments. Fold or removable cover with lock. The model is convenient for permanent movement.

- The set of drawers is a set of open trays of a different size convenient for home.

- Case - a compact durable suitcase, conveniently wide disclosure, and necessarily the presence of a handle on the side. Large tools will not fit.

- Organizer is a low container with a multitude of cells. There may be a case or bedside table with small cells.

- The tray is similar to an outdoor box with deepening, no handle. Not convenient for transportation.

- Bag is similar to sports, handles. The model is roomy, but not reliable, and the fabric misses moisture.

- The backpack is adapted for storing tools, but inconvenient to get them.

- The container is a compact closed product with a multitude of boxes and sections, some removable. Transformers are especially convenient.

- The trolley is used on the factories, it is a large container on wheels with a comfortable handle. Many sections, move easily on closer distances.

Tool clothes

- This is a vest with pockets, where various tools are distributed.

- Bag on the belt is an indispensable thing when repairing.

- Apron with ties on the neck and belt with pockets.

- Case for storage in a folded form.

Types of best toolboxes

The material from which structures for storing and moving various tools are made important role:

Wheel Toolbox

Models from plastic (metal) with vertical housing with 2 wheels. Comfortable handle and castle, the model accommodates many sections. The only minus is a high price.

Aluminum

Boxes made of aluminum are the most durable and reliable. Popular Metal Boxes for any tools:

- Fit 65610 is an aluminum housing, equipped with a handle, inside mobile partitions, weight 1.5 kg.

- Dexter is the most compact box for small details.

- Wilton 16910u is a comfortable aluminum suitcase with steel loops. Weigh 3 kg, has many pockets on the lid.

Car boxes

- Bawer is a universal model, attached comfortably under the car's frame. Autostask is durable and reliable, made of galvanized steel, but the weight is 12.4 kg.

- KAMAZ is a simple reliable metal design for long-term storage of any inventory.

- I-580 is the most convenient model of polyvinyl chloride (shockproof plastic with 3 types of steel). Weight 35 kg, Capacity 90 liters, Reliable locks, perfectly protected from moisture.

Large tanks

- Stanley Mobile Job Chest has the greatest practicality, dimensions: 962: 600: 600 mm, made of thick plastic, affects the capacity.

- StanleyFatmax with the most thoughtful functionality. Line with latches, inside 3 sections, there is a lower section for large tools. Pens on the sides, wheels make it a popular model.

- PELI 0450 - It is considered the most mobile: 3 handles and reverse wheels. Hermetic shockproof case of stainless steel case, volume sections, containers easily insert each other. The only minus is a lot of weight and volume.

For balcony

Inexpensive models are suitable for storage on the balcony:

- Fit - Case is perfect for small parts, you can change the sizes of cells. Durable plastic latch.

- LOT-3 - affordable, inexpensive and compact, there is a handle, colored trays.

- Mospromtar for home, no sections, but there is a lid.

It is more convenient in everyday life organizers for ease of transfer to any place.

Code Code

- Brauberg - used to transport valuable things. A shock-resistant case made of steel 8 mm and plastic, inside 6 cells.

- Hairway - with the greatest protection (metal with plastic), locks with code with 2 sides of the model, dimensions: 420x215x330 mm.

Metal

- Intertool is a popular drawer of 5 compartments, a reliable lock and a comfortable handle.

- Stanley Expert Cantilever is practical and convenient, 5 folding departments, protection against fingertips, comfortable handle, but heavy.

Plastic Toolboxes

- Stanleyclassic from shockproof plastic, comfortable design.

- Tayg is made with striking rationality, all compactly posted.

Professional

Stanley is reliable and indispensable, corrosion protection, handles are equipped with soft inserts. Removable links inside, special education for drills, etc.

Bosh LT-BOXX is simple in performance, but reliable. The strength of the product provides acrylonitrilbutadenstrol.

Stock Foto Tools for tools

Each man will agree that a high-quality and multifunctional tool box is a practically indispensable thing in the farm. Many masters prefer to buy ready-made boxing in the nearest store, which presents a wide range. But such a device can be made independently, in accordance with personal wishes. Moreover, the manufacturing process itself is not considered difficult, even the newcomer can cope with this task.

Classification of tools boxes

There are several main criteria, due to which multifunctional products can be divided into several basic groups.

By material from which the case is made:

By type of stored tools:

Construction of modern boxes

Speaking about the design of such boxes, there is no form of their form, but the method of opening and the presence of auxiliary sections. Standard today are constructions such:

Plywood Box Making

To make the tool box with your own hands from plywood, you will need such tools and materials:

Before getting to the manufacture, you need to carefully work out the project of the future product (the drawing can be done on a computer or on ordinary paper). The required calculations are made, the main dimensions are recorded. Thereafter all tags need to be transferred to plywood sheet. You can do this with the help of a conventional line, roulette, marker or even a pencil. All blanks for the future drawer are cut on the outlined lines. It also needs to be noted all the grooves and cut them on the blanks. The unevenness in the process of operation can be treated with a chisel. It is thanks to the groove that the final design of the box will turn out to be stronger and durable.

At the next stage, the entire design is assembly. To glue small parts, use high-quality joinery glue. The main sides of the box are also sampled among themselves. To improve the result, they must be tightly pressing each other. It is best to use a special strip of rubber. It is impossible to remove it until the glue is completely dry. On the doors need to round the corners.

A comfortable handle for boxing with tools can be made from MDF. Initially, the layout is drawn directly on wood and only after that cut out. When the handle is ready, the surface must be processed. It is mounted using joinery glue and screws. If there is no desire to make a handle yourself, then it can be purchased in a construction store. The main criterion of the right choice is high strength and reliability. Now you need to attach the outer lid of the drawer and the door. All items are applied to their places, and then the pencil marks areas for fastening the loops.

A comfortable handle for boxing with tools can be made from MDF. Initially, the layout is drawn directly on wood and only after that cut out. When the handle is ready, the surface must be processed. It is mounted using joinery glue and screws. If there is no desire to make a handle yourself, then it can be purchased in a construction store. The main criterion of the right choice is high strength and reliability. Now you need to attach the outer lid of the drawer and the door. All items are applied to their places, and then the pencil marks areas for fastening the loops.

To organize order in the box you can make small compartments. All components are cut into the same principle as the box. Pages are made and glued together. On one of the sides of the box, you can make a special compartment for storing twigs. The most convenient is the option, where this function is performed by special inserts with plywood slots. Velcro is glued to the other side of the drawer to store cables and extension cables.

Wooden drawer manufacturing technology

It is this option that is considered a classic joinery. The drawings of this portable storages were printed in magazines another 50 years ago. For the manufacture of it will take a high-quality board with a thickness of 10 to 20 mm., as well as a tree hacksaw. Thanks to the simple manufacturing technology, many masters still choose this particular option.

The classic design does not provide for individual compartments or special multifunctional fixtures. The final product will have a kind of tidy deep box with a comfortable handle along the entire length. This shape of the handle has a practical purpose. After all, if the weight of the tools used is unevenly distributed, you can always find the point of the center of gravity.

The classic design does not provide for individual compartments or special multifunctional fixtures. The final product will have a kind of tidy deep box with a comfortable handle along the entire length. This shape of the handle has a practical purpose. After all, if the weight of the tools used is unevenly distributed, you can always find the point of the center of gravity.

A practical addition can perform a plug-in section with its own handle, the height of which occupies 50% of the entire box. This insert can be used for a small tool (sewed, dumping, small keys), as well as consumables (bits for screwdrivers, tape, swell). For its manufacture, you can use any kind of wood.

Universal Case from plastic canister

If you want to make a box for the tools with your own hands, but there is no plywood leaf, then you can use a conventional plastic canister. For work you will need:

- Hacksaw.

- Plastic container.

- Fastening elements.

The canter used must necessarily be a rectangular shape with a comfortable handle that should be located in the center. In addition, it should be equipped with a twisting lid, which will be used as a lock.

The process of making the drawer is simple enough. With the help of the knife, it is necessary to make cuts in the canister. The first cut must go on the center of the neck and the tary handle, the cork is best removed, And the upper wall is cutting through. The second cutter is performed solely in the horizontal direction. It is best if it is located at the top of the canister, on the end sides. The plastic container itself must be cut from the upper wall at a distance of 4 cm, and on the side of 3 cm.

The process of making the drawer is simple enough. With the help of the knife, it is necessary to make cuts in the canister. The first cut must go on the center of the neck and the tary handle, the cork is best removed, And the upper wall is cutting through. The second cutter is performed solely in the horizontal direction. It is best if it is located at the top of the canister, on the end sides. The plastic container itself must be cut from the upper wall at a distance of 4 cm, and on the side of 3 cm.

When all saws are made, the canister can be revealed. To do this, you need to bend all the side parts of the top cover with the halves of the handle. In such a box, you can store various materials for fasteners: nails, bolts, screws, nuts. The upper part needs to be closed, folding the handles together. This device is fixed using a twisting cover.

To the drawer turned out as strong as possible, at the end walls it is necessary to make additional gaps. In the lid or in the walls, small holes are drilled in which the hooks are inserted, as well as nuts with nuts.

Metal Boxing for Tools

This option is most suitable for experienced locksmiths that have the necessary equipment and material. Factory metal boxes for tools are made of light metal types, such as aluminum. As a result, the product is obtained as easy and durable. But at home, working with aluminum is much more complicated.

This option is most suitable for experienced locksmiths that have the necessary equipment and material. Factory metal boxes for tools are made of light metal types, such as aluminum. As a result, the product is obtained as easy and durable. But at home, working with aluminum is much more complicated.

This version of the metal box will be able to make even a beginner. After all, the most common box and special partitions will be made of metal. Initially, you need to prepare the main material - galvanized steel (0.4 mm thick). From the tools you need to prepare:

- Marking caliper.

- Metal kitty.

- Line.

- A hammer.

- Passatia.

- File.

- Sharpened cerno or marker.

- Anvil.

Next, drawing and markup is made. Mark only those places that will later need to be removed. Now you can proceed to trimming with scissors for metal. After pruning all extra, a peculiar geometric figure (winged rectangle) should be obtained.

Next you need to use anvil. Tapping with a hammer, gradually bend the edges of the workpiece. It is better not to work in chaotic order, all actions should be consistent. One sidewall is bent firstAnd then another. To wrap sticking parts, passed passages.

After these manipulations, you need to walk the hammer over the entire design to align it. In this case, there will be a small metal box for storing tools. In the future, you can experiment not only with dimensions, but also with forms of such boxes.

In almost every home there are certain tools. When it becomes too much, you can independently make a multifunction box for storage. Experienced masters believe that it is this boxing that is considered an integral attribute for storing various devices. Such boxes can be stored in the workshop and even take with you to the long road.