Characteristics of concrete panels and fasteners. Insulation Penoplex (EPS) - Characteristics, Scope and Installation

The need to insulate houses located in the cold regions, no one has doubts. Experts considered that the loss of heat energy through the walls not protected from the exposure to low temperatures and other elements of the building structure reach thirty-five percent.

The use of insulation reduces inefficient heat consumption, which allows the use of less powerful heating equipment and significantly reduces the cost of the heating of residential premises. For these purposes, the penplex is widely used, the technical characteristics of which are optimal. This material is an extruded type of foam. Externally, it looks like a foam, but is manufactured on another technology.

"Penoplex" is suitable for the insulation of all parts of the houseSpecial properties of extruded polystyrene foam "Penoplex"

The unique performance of Painopleks acquires as a result of the characteristics of its manufacture. At the beginning of the production process, heating is obtained by a homogeneous liquid melt of polystyrene granules. Then a foaming agent is introduced under high pressure, which is a carbon dioxide. It is evenly distributed throughout the volume of the melt.

At the final stage, the foamed polystyrene is subjected to the extrusion or extrusion process through the calibrated holes. This achieves the special performance properties of extruded polystyrene foam, not accessible to other insulation.

When the finished substance is cooled, carbon dioxide is replaced by air from the environment, and completely closed cells with a diameter of about eight hundred millimeters are formed. As a result of the described material transformations, the technical characteristics of the fasteners become unique. The most important characteristic of thermal insulation materials is the thermal conductivity, and the inferno has this parameter - one of the best.

Line for the production of "PENEROPLEX"

Line for the production of "PENEROPLEX" Fairly low thermal conductivity coefficient

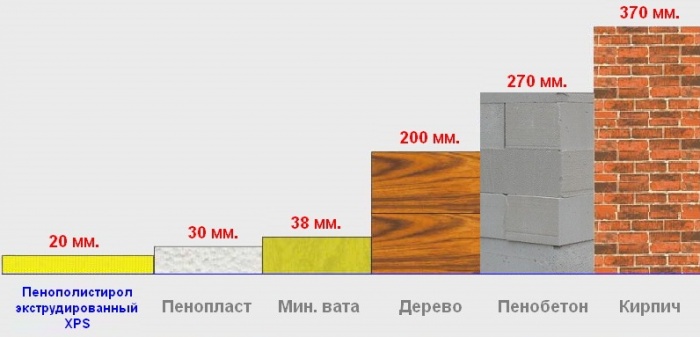

The low thermal conductivity coefficient of the polyplex, constituting 0.03 W * m * 0c, is explained by its cellular structure. The parameter is practically not changed over time, it is extremely minor than it and make up from one to three hundredths from the initial value. On this operational parameter, the Penoplex exceeds the foam and other heat insulators, for example, mineral wool. The thermal conductivity of the polyplex in comparison with them is one of the lowest.

If we estimate the thermal insulation properties of the polyplex in comparison with the brick, then the insulation with a thickness of 50 mm corresponds to a brick wall with a thickness of 925 mm, and a 30-millimeter material will replace the 555 millimeter wall.

Water practically does not absorb

The hygroscopicity of the product is striking: it practically does not absorb water. Fully placed in the water plate during the month absorbs moisture just six tenths of its volume. It is all absorbed in the first ten days, then the process is completely stopped. Moisture penetrates only in the top layer of the plates of the extruded foam.

"Penoplex" water does not favor

"Penoplex" water does not favor Couple almost misses

The leaf of a thickness of 20 mm practically does not miss the water vapor, especially the fastep 50 mm thick or 100 mm. When finishing the surfaces of the penplex of the arrangement of additional vaporizolation is not required. Parry permeability is practically no different in its challenges from Ruberoid. In some cases, for example, when finishing the walls from the inside, this operational property is rather a disadvantage, since it does not allow the walls to breathe.

Has high compression strength

High compressive strength, component of two hundred and seven of pascals, depending on the scope of application, is explained by the uniformity of the structure. Uniformly distributed tiny cells improve the strength quality of the material. It does not change his sizes when squeezed. This allows the use of material to perform heat insulation and other surfaces experiencing heavy loads.

The bulldozer "Penoplex" will not dismiss

The bulldozer "Penoplex" will not dismiss Process and mount the insulation is easy and easy

Mount and process extrusion foam easy and easy. It is possible to cut it using an ordinary sharply knife. Plates are distinguished by a low weight, so when working with them is not required to spend significant physical efforts. Installation can be carried out with adverse weather conditions: under snow or rain.

Chemically - practically passive

Polystyrene foam, from which the Penoplex is made does not enter the reaction of chemical interaction with most of the substances used in the construction work. The following chemically aggressive substances do not have a negative effect on it:

- acid and alkali;

- bleaching powder;

- carbon dioxide and oxygen;

- ammonia, propane, butane;

- cement solutions;

- oils and alcohols.

Some of the organic solvents can soften and disrupt the shape of the insulation. These include: diesel and gasoline, aromatic hydrocarbons (type benzene and toluene), oil paints and tar, acetone, ethers. It is worth noting the high biological durability of the material: it does not rot and does not decompose.

Ecologists have no questions to the material

If in the production of technological norms, the PHP is an environmentally friendly material, there are no issues to it. You can work with an insulator without personal protective equipment. However, it is necessary to take into account his artificial origin and understand that chemical components can evaporate under the influence of certain factors, for example, with long heating with straight solar rays.

By fastness to fire - not at all

Exposure to open flame leads to the ignition of polystyrene foam. The gramifications class differs depending on the purpose of use. The impregnation of this material with compositions that prevent fires does not lead to full fire safety. With high-temperature exposure, the material will be melted, turning into a fluid mass that is extremely toxic and caustic smoke.

Visual characteristics of flammability insulation

Visual characteristics of flammability insulation The total result - serves a long time and reliably

The term of the insulation is determined by the number of cycles of negative and positive temperatures withstanding material without destruction. This parameter shows the ability of the insulator to withstand the seasonal differences in the temperature of the external environment.

The tests have shown that extruded expanded polystyrene does not lose its operational qualities for fifty cycles of defrosting.

This value determines the duration of the life of at least fifty years. During the studies, the material was subjected to various negative impacts of the external environment, such as strong wind and rain, frost and ultraviolet radiation. In all cases, he showed himself worthy.

Specifications of various types of material

Penoplas is widely used to perform thermal insulation of elements of building structures. As a result, depending on the purpose of use, the technical characteristics of individual types of material differ. Plates of 20, 30, 50 and 100 mm thick, different strength and flammability are produced. For example, Penoplex 31 has low compression strength indicators, therefore it is used mainly for insulation of pipelines and containers, and there are materials that are used to insulate the runways of airfields.

"Pleeping Wall" - for insulation of walls

Penoplex Wall is used to insulate the walls of houses. The name appeared not so long ago, earlier this material was marked as penoplex 31 with antipirens. Good results gives its use for thermal insulation of bases, facades of buildings, internal and external walls of houses. At the same time, the walls are shed only if it is impossible for any reason to lay insulation outside. The consolidated characteristics of the material are shown in the table below.

| Characteristics of "Wall Polymplasses" | |

| Characteristic | Value |

| 0,03 | |

| Density, kg / m3 | from 25 to 32 |

| Strength, kpa | 200 |

| 0,5 | |

| Group of fire preserves | G3. |

| -50 +75 |

This insulation showed itself very well with the well masonry wall, that is, with voids inside. In this case, the wall thickness when the material laying the inside is obtained several times less than with traditional brickwork, but does not inferior to the standard version by the ability to hold heat. In addition, the Penoplex "Wall" can be applied on plastered facades of buildings.

"Pastex Wall" in the wall of the building

"Pastex Wall" in the wall of the building "Painting the roof" height is not afraid

For the roof insulation, the roof was used, which was previously labeled as Penoplex 35. This material can be thermal insulation of any type of roof. Currently, it is very often equipped with a roof of a lightweight type and even a flat roof, the base of which is profiled sheets of metal. This insulation allows you to significantly improve the service life and reliability of the operation of similar coatings. The consolidated characteristics of the material are shown in the table below.

| Characteristics of "Roof Polystone" | |

| Characteristic | Value |

| Thermal conductivity at 25 ° C, W / m ∙ єС | 0,03 |

| Density, kg / m3 | from 28 to 33 |

| Strength, kpa | 250 |

| Passenger in 28 days,% of volume | 0,5 |

| Group of fire preserves | G3. |

| Operating temperature range, ° C | -50 +75 |

The so-called roof of the inversion type allows the roof for different purposes. For example, it is possible to plant flowers and trees on it, creating an island of greenery, or post a parking lot. In this case, the substantive loads of the "Roof" substantive loads are used to save the heat.

Installation options "Polelet Pleelle"

Installation options "Polelet Pleelle" "Penoplex foundation" is used in accordance with the title

The scope of this insulation is understandable from its name. Durable material plates are able to withstand significant loads, they can be used in the construction of garden tracks, basement floors, flooring, wherever the material does not require high resistance to fire. The consolidated characteristics of the material are shown in the table below.

| Characteristics "Polymplast Foundation" | |

| Characteristic | Value |

| Thermal conductivity at 25 ° C, W / m ∙ єС | 0,03 |

| Density, kg / m3 | from 29 to 33 |

| Strength, kpa | 270 |

| Passenger in 28 days,% of volume | 0,5 |

| Group of fire preserves | G4 |

| Operating temperature range, ° C | -50 +75 |

The entire range of tasks associated with the arrangement of fundamental bases and equipment of basements is easily solved using the use of the "Fundam" font expression. Waterproofing the underground part of the house and its base allows to reduce the pressure on them soil water, prevent moisture penetration inside.

"Pleesoplex Fundam" in the case

"Pleesoplex Fundam" in the case "Painoplex Comfort" for a pleasant setting on the balcony and in the sauna

Penoplex "Comfort" is a universal brand of thermal insulator. It can be used when carrying out any work. You can warm the saunas, balconies or loggias, there is a comfortable and pleasant atmosphere everywhere. It is possible to use for insulation of such structural elements such as foundation, base, roofing and walls. The consolidated characteristics of the material are shown in the table below.

| Characteristics of "Comfort Polymplats" | |

| Characteristic | Value |

| Thermal conductivity at 25 ° C, W / m ∙ єС | 0,03 |

| Density, kg / m3 | from 25 to 35 |

| Strength, kpa | 200 |

| Passenger in 28 days,% of volume | 0,5 |

| Group of fire preserves | G4 |

| Operating temperature range, ° C | -50 +75 |

The material is ideal for use in rustic private construction. The plates of this insulation well withstand the impact of high humidity, so it is used in the construction of pools, baths and saunas. You can get acquainted with this type of insulation in more detail in the article.

"Penoplex Comfort" provides comfort on loggia

"Penoplex Comfort" provides comfort on loggia Penoplex 45 for Personal Aerodrome

If it suddenly wants to build a personal airfield, the penurex 45 is not better suitable: it can even withstand the weight of the aircraft. This material can not only insulate the roof of an inversion type, it is also used for thermal insulation of motorways, railways, airfield runways. It is done to prevent damage to the coatings as a result of a very unpleasant natural phenomenon - the swelling of the soil. The consolidated characteristics of the material are shown in the table below.

| Characteristics of "Polymplats 45" | |

| Characteristic | Value |

| Thermal conductivity at 25 ° C, W / m ∙ єС | 0,03 |

| Density, kg / m3 | from 35 to 47 |

| Strength, kpa | 500 |

| Passenger in 28 days,% of volume | 0,4 |

| Group of fire preserves | G4 |

| Operating temperature range, ° C | -50 +75 |

Nutrified by moisture during the rainy season of the soil during freezing increases in size, rises and damages the canvas. Prevents the emergence of this phenomenon of the insulation, since when using it, the soil freezes very little, or does not freeze at all. The strongest plates of this material do not change their geometric sizes and operational characteristics throughout the entire length of service.

"Penoplex 45" loads are not afraid

"Penoplex 45" loads are not afraid Dimensions of packaging material thickness 20, 30, 50 and 100 mm

Producers of these products produce insulation in the form of plates of 600 * 1200 or 600 * 2400 mm. Sometimes the width can be 580 mm. Sheets are completed in packaging, the number of plates in it differently and depends on the thickness of the extruded polystyrene foam. Depending on the purpose of use, the thickness of the polystyrene can vary. In one packing of the material with a thickness of 20 mm contains 20 plates, 30 mm - 14 pcs., 50 mm - 8pm., 100 mm - 4 pcs. In practice, it is useful to know the amount of material in the package in the area, which is presented in the table below.

Insulation in construction is given separate graph. For each object, its material is selected to be used for these purposes. One of the universal is the penplex. It is used everywhere. Why did he gain such popularity? Thanks to what technical characteristics does he win from his competitors? This is what article is devoted.

History of appearance

Penoplex is a material that is obtained by extrusion. Its appearance was impossible without appropriate equipment. For the first time, such a machine appeared in the US for more than fifty years ago. As a result of several experiments, it was possible to come exactly to the sight that the penplex is today. In fact, the word "PESEROPLEX" became the name of the nine from the name of the manufacturer "Penopeles". It is he who is the leader of the production of this material in Russia since 1998. The production process itself is quite simple, but requires complex equipment.

The insulation of the fastener is polystyrene granules. They are melted under the influence of temperature to a homogeneous liquid mass. The process occurs at 140 ° Celsius. After that, substances are added to the resulting mass, which, when heated, begins to highlight gases. The latter and create foam inside the polystyrene mass. Bubbles are not bursting and not pop up, but remain in the melt. During this stage, additional substances are introduced, which, for example, increase the resistance to open fire, without giving the finished product to focus, but only melts. Other additives serve antioxidants. Their task is to extend the service life of the finished product under the influence of various factors, in particular, the air containing oxygen.

Mandatory are antistics in the insulation of Penoplex. The fact is that during the installation on sheets, a large amount of static energy can accumulate, which can harm electrically appliances. After the complete readiness of the solution, it is squeezed through a special molding hole in the extruder. The generated elements fall on the conveyor and are moving on. The final product is only 2% consisting of polystyrene and additives, the remaining volume occupy gases that were formed from catalysts. At the same time, the size of the bubbles is correct due to the formation of pressure. Below is a video about the production of inferno.

Specifications

Knowledge of the technical characteristics of the fastener will provide an opportunity to apply it in the correct manner when insulation of various parts of the building. It is important to know how much the insulation is the Painoplex is able to withstand moisture, ensure noise insulation or interact with other construction materials.

Gigroscopic

Gigroscopicity is an indicator that reveals the ability of some substance to absorb moisture. If the insulation has a high meaning, then it can not be used in rooms or conditions of high humidity. After water absorbing, he will lose its properties and fungus may appear in it. Insulation Penoplex is characterized by a minimum hygroscopic rate. An experiment was carried out during which, a piece of polystyrene was lowered into the water completely. He stayed in a vessel for a month. After weighing the control sample, it was revealed that it still absorbs moisture. It amounted to 0.6% of the total mass of the piece of polyems. At the same time, the moisture did not get inside the sheet. It is simply impossible. All granules are clogged and not in contact with each other, so water can not accumulate them. And the percentage of weight, which was recruited due to the fall of water into damaged bubbles, which remained after cutting the inferno.

Thermal conductivity

The thermal conductivity is one of the main indicators that pay attention to insulating material. For example, oak, which was sipped across the fibers, it is 0.1 W × m × k. This is a pretty good indicator, which allows without any difficulty to build structures from a rounded log without additional insulation. In the fastener, this figure is 0.03 W × m × K, which is three times lower than that of oak. In a pair with minimal absorption of water, insulation Penoplex becomes perfect material for the insulation of buildings or foundations that are constantly in a wet environment.

Parp permeability

Parry permeability is a certain feature of materials to carry out gas exchange. It is mandatory in order to inside the room there was a healthy atmosphere. The ability of material to vapor permeability is explained by its porous structure. The process of vapor permeability depends on the partial pressure, which may not depend on the atmospheric. Polyplex has a vapor permeability indicator very low. This means that it is impossible to perform insulation of rooms from the inside. This will definitely lead to the fact that the fungus will begin between the wall and the penplex, which will cause trouble as building materials and the health of the owners. Mounting Penoplex is only outside and mandatory is the laying of vaporizolation. But this is a positive point for refrigeration or heating equipment. Insulation Penoplex is able to maintain heat or cold for quite a large period of time.

Ecology

During the production of fasteners, substances are not used, which in time are capable of giving emissions, which would be harmful to humans. It is true that in the process of manufacturing fusions, freons involve, but this is not the discharge of the elements that destroy the ozone layer or when heated becomes toxic. Perhaps, for someone, the argument will be that the insulation Penoplex is used in the bath at the research station in Antarctica.

Spray

Almost all materials that are used for insulation are well burning. This concerns only polymers and does not apply to the stone wad. Various types of polyplex are in varying degrees are susceptible to burning. Those who have anti-public adversions can simply melt. But there is an insulation of the penplex free from the flames. Such insulation Painoplex burns well. This distinguishes not only carbon dioxide, but also other substances that can harm human health. But this harm does not exceed in its indicators the one who can cause such last-minute materials like wood, plastic, MDF and others. With a thermal reaction, a syntic acid is not distinguished, so such a statement can be considered a myth.

Chemical stability

Before covering the insulation of Painopyx to any makeup, you need to know exactly how they will interact. For the most part, the insulation Penoplex is perfectly tolerated the neighborhood with construction materials and not only. These include various types of alcohols and paints that are diluted with alcohol. If there are no different types of pools near the inferno, it is not worth worrying. It perfectly transfers their impact without any damage. Outside the risk zone is also alkalis, ammonia, natural gas, cement solutions and vegetable fats.

In the risk zone there are paints on an oil basis, which are able to destroy the insulation of the Penoplex. Benzole, xylene and derivatives will not leave hope to insulation. Watching the use of esters next to such insulation. Does not tolerate the neighborhood insulation with all kinds of liquid fuel, so if there is a desire to wash off the paint or other substance, it is better to do it as far as possible from polystyrene foam.

Life time

The service life of the material is most often determined by its resistance to temperature drops. For this, the insulation is arranged extreme conditions. In them, he has to froze and return to the state of zero again. Some building materials after 30 such drops are simply scattered into powder. Extruded expanded polystyrene was able to transfer several hundred such procedures. The average service life of the insulation would be set at 50 years. But this is not the limit. During tests, insulating material was also exposed to other factors that are an integral part of its daily exploitation.

Mechanical impact

Thanks to the structure of the material, the insulation of the Penoplex perfectly transfers mechanical loads. This is explained by the resistance of the walls of bubbles, which is thicker. With a significant physical force, the Penoplex may progress, but will subsequently restore its shape. This makes it possible to apply insulation even under the tracks, where bandwidth exceeds a thousand cars per day. Depending on the density, the stability of the insulation to the exposure to compression may be varied.

Varieties of Polymplax

The manufacturer of the insulation of Penoplex has several solutions in its arsenal, which are suitable for the insulation of specific sections of the structure or other surfaces. One of them is the insulation of the Penoplex for the foundation. With modern construction, the insulation of the basement is mandatory. In order to suit this type of polystyrene foam. It is also called the penplex 35. In this type of insulation there are no additives that guarantee attenuation, so it is a fire-hazardous material, but it is not so critical, because the fire almost never starts with the foundation. The thermal conductivity of this subspecies of the insulation is 0.03 W × m × k.

The most common and versatile is the insulation of the Penoplex, which is used for wall decoration. They can also warm the floor and foundation. In the manufacturer's catalog, it is so "wall". He came to replace the insulation with an index 31, which has antipyrin additives. They prevent the burning of the insulation, reducing it to the drain. The thermal conductivity is also 0.03 W × m × k, but the density is slightly lower than that of the foundation and maximum is 32 kg / m 3. A separate type of insulation is designed for the insulation of the roof. It has the same thermal conductivity as the two previous places of polyplex, but the density is slightly higher than that of the wall and is 33 kg / m 3. Such insulation Painoplex will provide additional sound insulation with a metal flooring.

The insulation of road surfaces is also not a problem for fasteners. For this, there is a insulation with an index 45. Its density reaches 47 kg / m 3. Such a heater has the highest degree of sustainability to the compression effort. Even the take-off stripes on the teeth such a penplex. Another universal type of insulation, which comes with a thickness of a leaf of 20 mm, is "comfort". Insulation can be used for walls, balconies, saunas and other purposes. Standard dimensions of all types of fasteners are 120 by 60 cm.

conclusions

As can be seen, the manufacturer of Penopelex has prepared an excellent product line, which has become an undisputed leader among insulation. Many began to copy the technical process of production and a large number of purely domestic analogues appeared.

No construction today do without using insulation. For each type of tasks, it is trying to choose exactly the one that will serve as longer as possible. One of the leaders is the penplex. Penoplex 35 GK / m 3 is used even for the insulation of the tracks. But why many prefer to use this material? It will help to understand the understanding of its features, as well as the size of the sheets that are on sale.

What the insulation is

In fact, Penoplex is the name of the Russian firm, which is engaged in the release of this insulation. It makes it for quite a long time - for 28 years. The correct name of the material is extruded expanded polystyrene. He starts his story a little more than half a century ago in the military industry. It was for the purposes of defense structures that this insulation was developed by the American company. Due to its unique properties regarding thermal conductivity, as well as absorbing moisture, it was used for rescue rafts. After that, extruded expanded polystyrene was used in refrigerators. Only from the 50s, he received special recognition in the construction sector. Many are confused by the penplex with conventional foam, but there are certain differences between them.

Structure

Polystone production is a rather complicated process. To complete all stages, there will be such components:

- lemon acid;

- crushed perlite;

- zinc stearate powder or barium;

- polystyrene;

- bicarbonate of soda;

- additive in the form of tetrabromparasylol.

It all starts with polystyrene granules. For the manufacture of fasteners, they are placed in a peculiar autoclave, where the temperature can reach 140 °. Granules form a homogeneous mass in which the poroforms add. The latter contribute to the emergence of small bubbles with gas in the liquid. It is they who give fastening its unique properties. The resulting foam under pressure passes through the molding holes and falls on the transport ribbon, where the processing ends and the polystraction is attached to the form of sheets. The number of bubbles with gases reaches 98 percent from the entire material area. That is why the insulation is light and has a low thermal conductivity.

In the process of production of fasteners, the foam can be mixed by various components that determine where those or other sheets will be used. Substances that provide fire safety are called antipirens. The air contains oxygen in itself, which is capable of oxidizing materials, resulting in disrepair, therefore antioxidants are added to the Penoplex. During the installation of fasteners and during operation, static electricity can accumulate, which can be dangerous for various devices, so special substances are added that remove such a charge. Another number of additives increases the stability of the inflow to ultraviolet rays.

Positive and negative sides

Given the facts that were given above on the production of fasteners, it is possible to distinguish its positive parties. They are:

- low weight;

- ease of installation;

- moisture resistance;

- resistance to temperature drops;

- high mechanical strength;

- simplicity of interaction with finishing materials;

- simplicity of giving the required form;

- service life of up to 50 years;

- environmental Safety.

Mount the sheets of the polymplast can be independently. They are low weight, so they are easy to lift them. Even with constant finding the insulation in the water, it does not absorb it. This means that the Penoplex remains resistant to a large zamorrow-tanning cycle. Due to its bubble structure, the Penoplex has good strength characteristics that exclude its jurisdiction. Extruded polystyrene foam is very simple in processing. You can cut it with an ordinary stationery or construction sheet. If special forms are required, then you can take advantage of tungsten floss. With proper appeal, the penplex is ready to last up to 50 years. With all this, sheets are resistant to open fire. They melt, but do not ignite. There is a material and its shortcomings:

- practically zero vapor permeability;

- favorite insects and rodents;

- sensitivity to solvents;

- sensitivity to UV rays.

The poor vapor permeability of expanded polystyrene is pushing the idea that it is possible to use it only for outdoor decoration. Otherwise, the moisture will accumulate, which will lead to the development of fungus and mold. When insulation, the penplex should take care of the proper finish. The fact is that inside insulation there may be some types of ants, which will reduce its strength and lead it into disrepair. Rodents are able to organize dwellings inside sheets of the fasteners, creating an unpleasant noise. Installation work should not be combined with paint or with rust removal. Penoplex is destroyed under the influence of various solvents. It is not recommended to leave the insulation without finishing for a long time. Ultraviolet rays destroy his shell, and it begins to crumble.

Types of Penoperance

It was described above that various types of insulation are used for their own purposes. In this case, the size of the sheet may differ depending on the application. The thickness of the individual plates will also be different. They can be combined to achieve the best result.

Comfort

This material is universal. It can be used for insulation of various parts of the building. Often the insulation is used to reduce heat loss through balconies and loggias. Sheet thickness is usually indicated immediately in the marking. For example, if 20 mm is needed, then it is necessary to purchase comfort 20. Such thickness will be sufficient for additional heat insulation of the floor or ceiling. For insulation of walls, the polyplex is most often used. This is the maximum thickness for a subspecies of comfort. Length and width of sheets that are on sale is 120 × 60 cm.

Foundation

This type of sheets is used to insulate the foundation and the ground floor of the building. In some areas there will be enough to use a 20 mm polyplex. The maximum thickness of the sheets of this subspecies is also 100 mm. At the same time, the maximum density reaches 33 GK / m 3. The size of individual parts also has parameters 120 × 60 cm. Due to this, you can quickly cover extensive surface area. A distinctive feature of this subspecies is the absence of an antipyrin additive, which is designed to reduce flammability. It is placed in a tie for a warm floor, for the insulation of garden tracks or beds. Such a sheet insulation will be the perfect option for the basement and cellar.

Penoplex 45.

This type of leaf insulation is used for wider goals. The maximum value of its density can reach 47 GK / m 3. This indicator allows you to apply even a 30 mm polyplex for the insulation of the site on which the car will be located. The size of the sheet is standard for all products. Sheet material was developed for stacking under runway and high-length bandwidth. This avoids the destructive effects on the asphalt during frosts and thaws.

Roof

The process of insulation of the roof is mandatory during construction. This makes it possible to save the heat that rises up. For these purposes, this type of sheet fastener was developed. It is used with any roofing flooring. Thanks to its peculiarities, Painnessyx practically does not add the roof weight, so the rafter system will not suffer. Roofing polystyrene foam under the brand ROOF has additional fire resistance, which is very important. For high-quality insulation in areas with moderate winters, where the temperature does not fall below zero enough and 50 mm. Standard sheets will have to be confused under the required that will depend on the distance between the rafyles.

Note! Penoplex 10 mm is not available, the minimum thickness of the sheets begins from 2 cm.

Wall

This type of polyplex is an analogue of the insulation "Comfort". He has additives from substances that reduce burning, which is important for the wall material. Sheet insulation reduces heat loss almost 45%. It is produced with a thickness of 20 mm, but the ideal choice for insulation the wall will be 100 mm. The size of one sheet and packaging is standard 120 × 60 cm. Due to its density, the sheets perfectly withstand mechanical exposures, which is very important for the walls. After all, they can most often hook children or masters during carrying various materials. Montage video can be viewed below.

Conclusion

As can be seen, the leaf insulation of Penoplex is an ideal solution for any tasks. It can even withstand extreme conditions. In a pair with waterproofing, the sheets of insulation of the fastener will prevent the adhesion of the basements and garages under the house.

Currently, there are quite a few different thermal insulation materials. One of them is the insulation of the Penoplex technical characteristics of which fully comply with the highest requirements for thermal insulation of almost any elements of the building.

Modern technologies using non-toxic components make it possible to produce lightweight and convenient insulation in the installation. "Penopeleks" is made by extrusion using various chemical additives, so it is impossible to unconditionally name the material is completely environmentally friendly.

The technical and operational characteristics of Plenoplex clearly show that it is today one of the most effective heat insulating materials. And the parameters of this insulation should be considered steadfast.

What "Penopeleks"?

"Penopeleks" is, in fact, extruded expanded polystyrene foam, which is an improved form of a long time ago of all known foam.

The first installation for the manufacture of this material appeared more than half a century ago in the USA. The production process of the PR is as follows: polystyrene granules are sent to a special chamber, where, in the process of manufacturing the work maker, they are melted and foams with the use of poroforms under the influence of high temperatures. As a result, it turns out a magnificent thick foam, similar to whipped cream, which is squeezed with a smooth layer of the installed thickness of the extruder, and then enters the conveyor belt and is cut into separate panels. The whole process AD is in closed mode, and you can see only finished products.

Prices for Penopelex

penopelex

Polystyrene foaming occurs by adding poroforms to it - chemical compounds, when the heating of which is the active separation of gaseous products - carbon dioxide, nitrogen and others, which are foaming polystyrene mass. The composition of the poroform composition for the manufacture of extruded expanded polystyrene can include the following substances:

Preparation of composition and its forming occur at a temperature of 130-140 ° C at a speed of up to 60 kg / h. In this way, not only Penopelex, but also Tekhoplex, Extrol and other domestic and imported insulation are produced.

In the form of additives to such materials used light stabilizing Substances, antioxidants, antipyrins, modifiers, antistics and other components.

- Antioxidants are added in the extrusion process - they prevent heat-oxidation during processing and quick destruction during storage and operation of the insulation.

- Antipirens reduce the flammability of the material or make it quite non-combustible.

- Other additives protect the material from the aggressive exposure to the external environment.

Porous structure of "Penoplax"

When the extruded polystyrene foam is frozen inside it, an air layer is preserved, evenly distributed over the entire structure of the material. Therefore, the finished insulation has a homogeneous porous structure with small cells with a size of 0.1 to 0.3 mm, filled with air (gas). Each of them is isolated from another, which ensures the highest indicators of thermal resistance and strength of the material.

You may be interested in information about how it is done.

Technical and operational characteristics " Penoplax»

The main characteristics of the material are shown in the table:

| Physical and mechanical Properties | Technical norms | unit of measurement | Type 31. | Type 31S. | Type35 | Type 45S. | Type 45. |

|---|---|---|---|---|---|---|---|

| Density | GOST 17177-94 | kg / m3. | from 28 to 32 | from 28 to 32 | from 28 to 38 | from 35 to 40 | from 40.1 to 47 |

| Compressive strength of 10% of linear deformation, not less | GOST 17177-94 | MPa (kgf / cm2) | 0,20 (2) | 0,20 (2) | 0,25 (2,5) | 0,41 (4,1) | 0,5 (5) |

| Elastic modulus | Soyuz Dornia | MPa | - | - | 15 | 18 | 18 |

| Strength time with statistical bend | GOST 17177-94 | MPa | 0.25 | 0.25 | 0,4-0,7 | 0,4-0,7 | 0,4-0,7 |

| Water absorption for 24 hours no more | GOST 17177-94 | % by volume | 0.4 | 0.4 | 0.4 | 0.4 | 0.2 |

| Fire resistance category | SNIP 21-01-97 | group | G1. | G4 | G1. | G4 | G4 |

| Thermal conductivity coefficient at (25 ± 5) ° C | GOST 7076-99 | W / m² × os | 0.03 | 0.03 | 0.03 | 0.03 | 0.03 |

| Parry permeability coefficient | GOST 25898-83 | mg / m × h × pa | 0.008 | 0.008 | 0.007 | 0.007 | 0.007 |

| Standard dimensions | |||||||

| Width | TU 5767 - 006 - 56925804 - 2007 | mM. | 600 | ||||

| Length | 1200 | 1200 | 1200 | 2400 | 2400 | ||

| Thickness | 30, 40, 50, 60, 80, 100 | 30, 40, 50, 60, 80,100 | 20, 30, 40, 50, 60, 80, 100 | 40, 50, 60, 80,100 | 40, 50, 60, 80,100 | ||

| Soundproofing partition (GLC-Penoplex (50mm) -Gl) R W | GOST 27296-87 | dB | 41 | 41 | 41 | - | - |

| Index improvement of structural noise insulation with 20-30 mm plate thickness in floor design | GOST 16297-80 | dB | 23 | 23 | 23 | - | - |

| Temperature range of operation | T. | oS. | From - 50 to + 75 | ||||

| Durability | Niizf Moscow test report № 132-1 of 29.10.01 | years | Manufacturer guarantees 50 years | ||||

As can be seen, several varieties of "Penoplax" are produced, which are designed for a specific scope. Therefore, plates of material have retail density and a certain range of standard sizes. The insulation is easy to install, it is easy, perfectly cut into the desired size. All this allows the process of thermal insulation of the elements of the building independently.

Plates of "Penoplas" are very convenient in the installation

The table is given "dry numbers", but it costs each of the parameters to consider in more detail.

- Coefficient t.evitation

"Penopelex" has a low thermal conductivity: this parameter is one of the lowest among all modern insulation, about 0.03. The thermal conductivity of the material remains almost unchanged with the differences in humidity or ambient temperature (oscillations do not exceed 0.001 ÷ 0.003 W / m² × ° FROM). Therefore, Penopelex is suitable for external and internal thermal insulation - they are also produced by overlaps, basements and foundations, and it does not require additional external protection with moisture-resistant materials.

- Gigroscopic

If the insulation is excessively hygroscopic, that is, actively absorbs moisture, it loses not only most of its heat insulating properties, but also becomes less durable. Therefore, this parameter is especially important for materials intended for insulation. And it is necessary to pay special attention when purchasing. However, when buying a high-quality "Penoplax" for this parameter is not necessary to worry.

To make sure the reliability of Plenoplex in this regard, numerous tests were carried out, during which the slab was completely immersed in water for a month. As a result, it turned out that the plate absorbed moisture just 0.6% of the total volume. Moreover, the process of the ITTOVA passed only throughout the first 10 days after immersion, and the moisture penetrated only into the external layer insulation that It was damaged by a cut. The inner part of it remained absolutely dry. This factor indicates the reliability of insulation with the help of Polynecks of any part of the structure.

- Parp permeability

This type of polystyrene foam, as Polyoplex, is perfectly opposed to evaporation. The stove having a thickness of 20 mm has vapor permeability comparable to the rubberoid layer. Therefore, using this insulating material, additional vaporizolation is required, which significantly reduces the costs of all at home or a separate part of it. However, in some cases, low vapor permeability will, rather, the disadvantage - Penopelex will not allow to provide a natural steam exchange, that is, the wall will not "breathe."

- Resistance to compression

Thanks to the technology of production by the extrusion method, Penopelex has a homogeneous structure, and the uniform distribution of the smallest cells increases the strength and reliability of the material. It is able to withstand heavy loads, so it is great for insulation not only walls and ceilings, but also floors. At high loads, only minor surface changes in the form of dents remain, the depth of which can be only 0.5 ÷ 1 mm.

- Ecology

According to technological standards, Penopelex is conceived as an environmentally friendly material. However, not all manufacturers adhere to these requirements, including insecure components for the human body. Therefore, substances that stimulate the development of certain diseases begin the development of certain diseases in time. Much depends on the installation of material on walls - retreat From technology can make a "penplex" source of danger to human health.

Qualitative material must be self-tapping, that is, spread the flame even when exposed to open fire. Unfortunately, not all materials behave in this way - some of them are not only burning, but also melted, turning into a burning fluent mass, besides a large amount of caustic and extremely toxic burning smoke.

In appearance, it is difficult to determine the quality of products, so before purchasing a large batch of material, it is worth buying one plate and carry out various outdoor experiments over it. Making sure that the insulation corresponds to all the characteristics assigned to it, you can buy the required number of panels.

In addition, it must be said that in the market - an abundance of low-line fakes made with a violation of the technological process. This material is especially dangerous, as it is unknown, as it can be tested under extraordinary circumstances.

- Lifetime

Since the insulation is used for outer insulation, during testing it is subjected to multiple freezing and thawing - these procedures indicate the number of cycles of the use of material under conditions of large temperature differences. Experiments are carried out until damage from external influence on the material. It is the number of weathered cycles and determines the service life of the insulation.

The experiments carried out in Niizf showed that Penopelex is able to serve without losing its initial qualities, about 50 years. Usually such a warranty is given with a reserve, which means that the specified period no limit.

In the process of testing, the material is exposed not only to temperature drops, but also to all sorts of atmospheric influences, such as increased humidity, ultraviolet rays, strong wind load.

Again, you need to remind about the good faith of the manufacturer - the material will be operated without problems. The specified period will be operated if all the established rules for its manufacture will be followed.

- Heater resistance to chemical exposure

Using Penopelex in construction, you need to know which substances are able to destroy the insulation, and which - what is harmonized with him. Mainly mineral chemical compositions that are used in construction practice are not harmful to this material, but some organic substances cause it softening or melting.

In order not to encounter similar troubles while working, it is better to prepare in advance and eliminate substances containing such components from the process of insulation.

Substances incompatible with Penopelex include:

- Sophisticated and ethers: ethyl acetate and methyl acetate solvents and diethyl ether.

- Toluene, benzene, xylene and hydrocarbons like them.

- Formaldehyde and formalin.

- Diesel fuel, kerosene, gasoline.

- Ketones - acetone, methyl ethyl ketone.

- Coal tar.

- Oil paints.

- Polyesters that are used as epoxy resin hardeners.

It is worth listed and those compositions that will not harm "Penoplas":

- Various alcohols and substances based on them, including paints.

- All kinds of acids (inorganic and organic).

- Bleaching powder.

- Salt solutions.

- Water and paint based on it.

- Alkali.

- Ammonia, propane, butane.

- Freons.

- Carbon dioxide and oxygen.

- Cement-based solutions.

- Vegetable and animal oils, as well as paraffins.

In addition, it can be noted that Penopelex has a high biostostility - it is not subject to rotting and decomposition.

Marking "Plenoplex"

Earlier in the marking in the first place was the letter, and then came the numbers, for example, M35 and M45. The modern designation is as indicated in the table presented above, that is, 31.31c, 35, 45 and 45c.

- Penoplex 31 has a sufficiently low indicators of compression strength, so it is not used in areas where high load is assumed. Most often it is used for the insulation of tanks and various pipelines.

- Material having labeled 31c is also not distinguished by high strength and is intended for insulation of inner walls. Its difference from 31 lies in a higher degree of flammability of the material.

- Penopelex 35 has sufficiently high strength and good thermal insulation qualities, therefore it is considered universal. They insulate walls, foundations, floors and pipes.

- Penopelex 45 is used to insulate the take-off stripes, the arrangement of the road surface, the thermal insulation of deep foundations, floors in industrial workshops and other rooms with a large dynamic load. The density of this material allows you to withstand elevated loads, and its water resistance does not give coatings to deform when temperature drops.

- 45FROM It has approximate to "Penopele" - 45 characteristics for strength and thermal insulation, but the insulation with this marking is usually chosen to fasten on the walls of industrial premises with large volumes.

Along with digital marking, there is another line, in which the characteristics of Plenoplex are as close as possible to its operational purpose.

Sometimes marking is carried out somewhat differently, and it is much easier to figure it out.

- Penoplex - Wall has a density within 25 ÷ 32 kg / m³ and is intended for fixing on on rifted and interior walls, as well as for the insulation of partitions and basements, which increases the energy saving and the quality of sound insulation of the structure.

"Penopelex" for wall insulation

If the insulation is carried out outside the building, then after fixing the insulation and sealing the seams between the plates, on top of the Plenoplex, it is recommended to apply plaster or bind it with one of the facade materials, such as lining, siding or decorative tiles.

- "Penopelex - foundation" has a density of 29 ÷ 33 kg / m³ and is used for the insulation of foundations and surfaces in the basement. The material is fairly tight and water vehicles, since it is designed for insulation of these elements of buildings. It also uses it for thermal insulation of septic plates that have not too much baptity, and there is a risk of their freezing.

- "Penopelex - Roofing" is produced for the insulation of terry, or flat roofs. In addition, it is suitable for insulation of the attic overlap. The density of this material grade is 28 ÷ 33 kg / m³, so it is sufficiently light and will not give a large load on the rafter system.

- Penoplex - Comfort has a density of 25 ÷ 35 kg / m³ and is used for the insulation of walls of apartments, balconies and loggias, as well as surfaces in private houses and such premises with high humidity, like baths and saunas. The density of the material is small, but it is quite enough for residential buildings, as it will not be exposed to extensive loads.

- "Penopelex - 45" has a density of 35 ÷ 47 kg / m3 and its purpose has already been considered above. But besides this, it is used to insulate the floors of garages and flat roofs, on which sports fields and even parking are organized.

Basics of insulation technology "Penopelex"

So that the insulation fully coped with the tasks assigned to it, it is necessary to comply with the technology of its installation on certain elements of the structure.

Wall insulation Outside

From the right installation of "Plenoplex" on the walls outside will depend not only the preservation of heat in the premises of the house, but also the health of its tenants. Unfortunately, in violation of technology to save money. Egoe builders enshrine insulation only on special fastening - Dowels With wide hats, which are called "fungi". This installation will not only wipe the walls, but also will contribute to the occurrence of molds or colonies of fungus, which can grow and penetrate the inside of the wall material. This occurs because due to the loose fit of the insulation material to the wall, the dew point is shifted. Therefore, if the decision has already decided to warm up, then it is worth doing this in all the rules.

- The first thing to start work is from the preparation of surfaces for the installation of Penoplax. The wall should be cleaned from the old plaster, dirt and dust. It is then driven by antifungal solutions.

If obvious deformations or irregularities are detected after cleaning the surfaces, they need to be aligned with layers of plaster, otherwise the plates will be loosened to the wall. After the wall is aligned and sucked, it should be rebuilt again.

- "Penopeleks" begin to install from the bottom of the wall, and in order for the first row to get up perfectly exactly, a M-shaped starting profile is fixed on a blank line, which will neatly stand up plates of insulating material .

- Next, there is an installation of the first row of the material on the wall. Plates are fixed on the surface with special adhesive solutions that are applied directly on the stove. After that, it is well pressed against the wall.

Installation of "Penoplex" is made according to the scheme of brickwork, and the gaps should remain between the plates. If they still remain, they must be filled with mounting foam after drying the main glue.

- Next, after the plates are glued, they must be fixed with plastic dowels - "fungi". To do this, in the wall right through the insulation, the holes are drilled in which part of the dowel is installed hat then a plastic nail is driven into it. Such mounts will need 5 ÷ 6 pieces per m², if necessary, their number can be increased. The fasteners hats should be on the same level with the surface of the insulation, that is, shut into it on the thickness of the cap.

- After that, it is recommended to strengthen the angles with perforated metal corners. This must be done because the material on the angular parts of the house is damaged primarily.

- Further, the surface reinforcement is underway. In order for the plastering solution to have a good clutch with plates of insulationFor them you need to walk sandpaper with large grain.

Then the plaster-adhesive composition on a cement basis is applied to the surface from the top of the wall, to which the reinforcing fiberglass mesh is fixed. It is well recalculated and removed into the first layer applied on the plates.

Reinforcement of the wall over "Penoplax"

- The first layer with the reinforcement grid should be good and only after that the second leveling plaster layer is applied. It is well aligned, and if it is planned to be covered with paint, it is brought to a smooth state with putty compositions.

If relief plastering will be applied to the surface, or the decorative tile will be laid, the ideal smoothness of the surface is not needed - sufficiently high-quality alignment.

Wall insulation balcony or loggia

The insulation of the inner walls, as well as or the balcony, is made in the same way as the outer, but the balcony surfaces when insulation have their own characteristics.

The junctions of the glued and fixed insulation must be closed with a foil tape or walk on them by mounting foam.

Next, when the cold bridges remain, you can fasten another layer of foil insulation on top and close the walls with clapboard or plasterboard. Another option is to apply finishing plaster on top of the Plenoplex.

Perhaps you will be interested in information on how to produce

Video - an example of the insulation of the balcony " Penopelex»

Heavy insulation roofing

The process of insulation of the roof occurs at the construction stage or during reconstruction.

1 - masturbation.

2 - doom.

3 - vapor insulation membrane.

4 - "Penopeleks".

5 - a rafter foot.

6 - windproof film.

7 - a counterclaim.

8 - Roofing.

In the presented version, the whole "pie" is stacked on a dumping trim, fixed by the attic room, to which a vapor insulation membrane is laid.

- Between the rafting feet is mounted "Penopelex". If gaps remain between these elements, they must be filled with mounting foam.

- Then the insulating layer is closed with windproof film.

- From above, the sling is fixed by a counterclaim on which the roofing material is laid.

With the insulation of the attic overlap of Penopelex, they laid between the beams on the dumping trim, linked from the premises of the house. "Pie" is drawn up on the same principle as roofing insulation, that is, vaporizolation, "Penopelex", waterproofing film, a boardwalk of an attic floor.

Thermal insulation of concrete floor

Due to high density, this insulation can be passed onto the concrete surface of the floor in the apartment, for example, under a laminate or parquet board.

A glue mass is applied to the purified and primed floor, which is glued to the "Plenoplex" plates, having fasteners and spikes. This method will help not only insulate, but also soundproof Room, as well as level the floor surface.

Laying plates "Penoplax" on the floor

Another option for insulation of Paul Penopelex can be its installation between the lag attached to the floor. This is how heat insulation is produced when it is planned to be placed on top of it. Such a method is usually used in a private house, since the ceilings height is limited to 2700 mm, and the floor insulation layer will reduce this parameter by another 80 ÷ 100 mm.

You may be interested in information on how to choose inside the house at the cottage

Domestic analogues of the material

If Penopelex is a patented insulation brand, then other analogues of such material are developed by Russian technologists based on existing compositions.

Technoplex

This domestic insulation is intended for installation on any surfaces of the private house, as well as well suited under the "Warm floor" system. A technoplex produced on nanotechnology, using graphite, which is able to reduce the thermal conductivity of the insulation and increase the strength of the plates.

Packaging "Technoplex"

This material, unlike Penoplax, has a gray-silver color, but meets all the necessary requirements for the first.

Technoplex is made in the form of plates having a thickness of 100.50,40,30 and 20 mm. The plates have butt grooves and spikes that allow them to assemble them into a single coating that does not have gaps - it avoids the formation of cold bridges.

After mounting the "technoplex" on the insulated surface, it should be closed with decorative material, since the ultraviolet rays act fairly detrimental.

« Polyspen "

Another analogue of Penoplax is the insulation of the domestic production "Polyspen". This material is produced in three versions, which differ in technical characteristics - the coefficient of thermal conductivity, compressive strength and flavoring:

- "Polyspen 45"

- "Polyspen 35"

- "Polyspen Standard"

The figures included in the marking determine the density of the insulation - this is 45 kg / m³ and 35 kg / m³.

"Polyoplaks" worthy competitor is also "Polyspen"

The complex of ingredients included in the material is included with antipyrins that significantly reduce the flammability of the insulation.

- Polyspen 35 is used for insulation and sound insulation of the bearing walls of the building, as well as for internal partitions.

- "Polyspen 45" is suitable for thermal insulation of floors in a house or garage, as well as for road surfaces, which drops large loads - its density allows them to be delicately withstand.

- Polyspen Standard is excellent for insulation of premises, where it is especially necessary for such quality as a reduced flammability is a "warm floor" system, garage floors, attic floors.

Plates are produced in 100, 80, 60, 60, 50, 40, 30 mm thick, so you can choose that option that is suitable for a specific section of insulation.

In conclusion, I would like to say that it is better to purchase heat-insulating material in specialized stores capable of presenting a quality certificate for realized products. By buying it on the "wild" markets, you can easily run into fake. Therefore, it is not necessary to take risks, because, saving a penny, you can subsequently pay our own health. And more - wherever the material is purchased, it is recommended to first spend the test test by purchasing one stove. When contact with open fire

0