The program cutting logs on the disk sawmill. Sawing with maximum profit! Collapse Breed Optimization Program Increase

For the processing of logs on the ribbon panel, it is necessary to adhere to the adopted technology. Thus, you can get the maximum amount of quality materials - boards and timber. But it should be previously familiar with the basic rules of cutting.

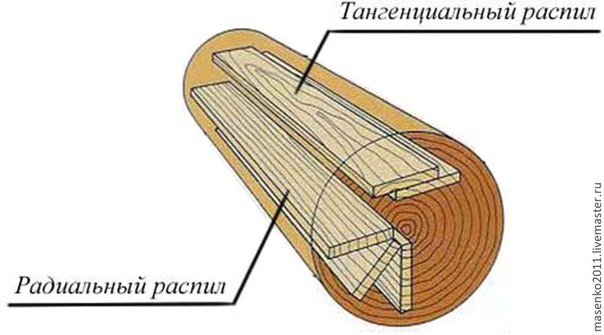

Types of saws of wood

At the first stage, the logs are formed. For this, two parties do sections. In some cases, processing is performed from four sides. There is a preliminary map of the tape cutting of the workpiece, which indicates the dimensions of the components.

The determining parameter when choosing a scheme is the direction of the processing of the log. In particular, the movement of the cutting edge relative to the annual rings. According to this, lumber of various qualities are formed, possessing unique external species. Not only their aesthetic qualities depends on this, but also the price.

Distinguish the following types of saws:

- tangential. The incision is performed on tangentially relative to the annual rings. As a result, there are oblong patterns in the form of arches, rings;

- radial. It requires perpendicular processing for annual rings. A feature is a uniform drawing;

- transverse. Processing occurs across the fibers, the cutting pattern is a smooth cut of annual rings;

- rustic. It can be done at any angle, contains a certain number of bitch, swamp or other defects similar to them.

Often in the woodworking industry used waste ribbon sawing logs - a horn. On the one hand, a flat plane, and the other remains untreated.

To compile the most accurate cutting, it is recommended to use special programs. They take into account not only the dimensions of the source material, but also the wood.

Sawing on a sawmaker with a log rotation 180 °

To form a maximum number of boards, it is recommended to use the technology at which some ribbon processing processes rotate 180 °. This allows you to achieve the maximum number of sawn timber with various types of saws.

The processing principle is to perform the initial cuts along the edges of the logs at an angle of 90 ° relative to each other. They will serve as a basis for further tape cutting. Works are carried out on the equipment with the vertical location of the cutting elements. The diameter of the trunk should be at least 26 centimeters.

Phased procedure for performing work.

- Face treatment with cut crumpled part. As a result, two boards are obtained.

- Turning blanks 90 °. Crop is performed from the opposite part. The number of products varies from 3 to 4.

- Return 90 °. The main part of the source material is processed. Depending on the planned, 7-8 blanks may turn out.

Despite all his positive traitsThis method has one significant drawback - low speed production. It is recommended to apply on the equipment, which provides a block of automatic change in the position of the log regarding the cutting part of the machine.

The detailed scheme is most often used for the manufacture of rustic boards to which reduced quality requirements are presented.

Sawing on a sawtur with a log of 90 °

For the manufacture of tangential and radial boards, it is recommended to use another technique. It consists in planned log ribbon processing with simultaneous analysis of defects. Thus, you can get products of the required quality.

After removal, the billet is placed on the feeding machine of the sawing machine. Then you need to perform the following steps.

- Removal of the primary neck. It is performed until the base width is 110-115 mm.

- Remove unedged Board Thick about 28 mm.

- If the number of defects on the surface exceeds the required level, the material turn is performed 90 °. With a sufficient high quality of the board, the following is sliced.

- Repeat operation.

Such a technique is applicable to machining installations that have one cutting surface or there is a function of temporary dismantling the rest.

At enough large quantities Defects can not postpone the workpiece, and to process it with a reversal by 180 °.

The above-described ribbon processing technique can be applied to create any configurations of wooden products. Often the core area is used to form a bar, and the rest of the parts are for the manufacture of boards. But there may be exceptions - it all depends on the required form of blanks.

The quality of the work affects the current state of the sawmills, the sharpening level saw and the processing speed. These factors must be taken into account before the start of the manufacturing process. If necessary, prevention or repair of equipment is performed.

The video material shows the sawing method of logs on a homemade belt panel:

When sawing the forest, it is important to immediately calculate what consumption will be, as it will have an impact on the cost of sawn timber. Output finished products May be different. It all depends on how quality the forest is used whether measures to optimize cutting are applied. There are special measures to increase the efficiency of work, make the output better, and the quality of sawing is higher. Before sawing, it is necessary to calculate everything. It is not as difficult as it may seem, but the flow rate of the round forest will be optimal, profitable for obtaining an excellent result.

How to increase the efficiency of cutting

In order for the lumber output to be significant, it is necessary to use special measures to increase the efficiency of the process:

- The calculation should be carried out only when using special programs, manually it will have a low performance, the percentage of marriage will be large.

- Pre-rounding must be sorted so that the processing is carried out correctly.

- For cutting it is necessary to apply high quality equipment. Otherwise, the amount of waste will be large, and the quality of the resulting lumber will become low.

- It is best to first cut a wide sawn timber, the treatment of narrow leaves more time.

- The logs are not recommended to take long.

- Before work, configure the equipment.

The output of finished lumber may be different. It must be remembered that at the first stage the boards are obtained, then they are sorted. As a result, the percentage decreases even more, for example, for deciduous breeds, it can be only 10-20%.

How to optimize the cutting

To make the output of sawn goods above, the cutting process must be optimized. This applies primarily to those billets that are significant curvature. To cut a round forest curve, you need to perform a number of actions:

- First, only a suitable forest is selected for work. If there are rotes, seedlings, cracks on the ends on the remaining logs, then it is necessary to reflect some sites.

- If a rotten core is detected during operation, then it can be carefully removed, after which it is possible to cut the remaining part. This will avoid large losses, get boards with a length of 1 m with the necessary quality.

- It is recommended to use logs with large diameterso that the output percentage was higher. The coefficient can be 1.48-2.1, but it all depends on the diameter, the quality of the roundabout, sorting, equipment. For framework workshops, such a coefficient will be 1.48-1.6, and for lines with milling equipment - 1.6 for a large forest. With a diameter of the rounder from 12 cm, the coefficient may exceed the mark of 2.1.

Waste volume after sawing

To make the finished board with a great percentage, it is necessary to prepare everything correctly, work should be carried out only in accordance with technology. Round wood coniferous and hardwood gives a different way out. In the latter case, the volume is less, even if used special accessories. The cutting of sawing is considered more convenient, since she has a straight line, and the log has a larger diameter. The coniferous forest is not as susceptible to rotten, so marriage is less. For deciduous breeds, 2 technologies are usually used:

- with the help of the belt panel on the Z75, Z63;

- in the collapse, when a semicircular is cut into the core of the material, passed through a multi-step machine.

The volume in the belt sawmill is 40-50%. When using the technology into the collapse, the output is different, it can be increased to 70%, but the costs of such work are higher. If a round forest is to be cut, the length of which is 3 m, then you can see that the percentage of marriage is quite large, and the remaining material requires processing. This concerns the bulk of the bulk of 22x105 (110, 115) x3000 mm. There are a lot of such marriage options. For example, it can be wormworm, which is no longer suitable for most works.

After sorting the volume of hardwood material, which refers to a variety of 0-2 will be only 20-30% of the amount that is obtained after sawing. This means that from total mass Hurried round forest The output of the normal board will be only 10-20%. The remaining materials mainly go on firewood. The coniferous rounding the output will be different, but attention should be paid to which the average values \u200b\u200bof the resulting volume are observed.

Lumber output

To access the lumber is optimal, it is necessary to take into account numerous conditions. For correctly calculations, you can consider an example of the release of round wood. The data was obtained on the real experience of specialists and in the indicators of the pilots. This makes it possible to compare the percentage ratio, calculate the optimal averages.

Softwood has the following way out:

- For unedged boards and other umbered materials during sawing, the yield will be 70%. This is the number of material obtained during processing, the amount of waste will be 30%.

- For edged material when using pylomas at 63, 65, 75, there will be a smaller output of sawn timber, in total in the area of \u200b\u200b45%. W. ribbon Pylorars The output is usually up to 55-60% of the finished material. If you use the effectiveness to improve efficiency, then 70% can be achieved, although it requires extensive experience.

- From the disk sawmill, it is possible to obtain a sawn timber in an amount of 70-75%, although it may be 80-75% when using efficiency methods. But you need experience.

According to GOST 8486-86, for a grade of 0-3 percentage of output, without taking into account the sorting, is approximately 70%.

Another 30% can be left to the rejection of the finished material. The material being discarded is not discarded, it is used to make other types of sawn timber, which allow for a certain marriage.

At the round forest of hardwood, another percentage of exit is observed:

- Unedged material - 60%.

- At the edged - up to 35-40%, since the curvature of the source forest of hardwood is usually large.

The output can be enhanced, for this applies additional equipment. It can be a special multi-step machine, an edge cutting machine, a subgrile machine. In this case, it turns out the output of the lumber to increase by about 20%. The percentage given is based on the data on obtaining a grade board of 0-4. When sorting varieties 0-1, the percentage of sawn timber is 10%. To obtain a cube of the finished edging material from hardwood, it is necessary to break 10 cubes of the original round forest.

The output of sawn timber from the round forest may be different. It all depends on the starting breed of wood used by the sawmills. Special measures to increase efficiency allow you to get a greater percentage than it is possible, but for this you should have some work experience.

The sawmilling of the forest is a cycle of actions using a variety of technologies, aimed at obtaining lumber, suitable for further use in industry. The processivity and labor cost of the process depend on the selected method of processing roundabout, as well as the time of year.

Tools and equipment

The production of trunks and large size of the branch are in production. All material is divided into groups of thickness and the presence of a crust. Often, forest processing enterprises have shops near the workpiece, in which machines for initial wood treatment are installed.

Handicraft forest

Last stage ham the forest can be used on the ceiling device or as a skate bar in the corresponding interior, or as a reference device during construction.

Industrial scope of forest

If another version of the use of wood is scheduled, cutting is carried out, the following segments are carried out at the output:

- unedged and semi-cut (rough material, from which the bases of the floor, walls or ceiling are assembled);

- edged (designed for the cleaning floor).

Colot can carry out an exit organization that has the whole required tool.

Map of sawing wood

The rational use of the material is ensured by correspondence with the sawing card. This allows you to reduce the cost due to waste, the percentage of which the card can be significantly reduced. The applied tool and types of woodworking equipment depend on the volume, desired quality And the size of the finished lumber.

Most often used circular saw and various machines:

- circular to the disk saw allows accurate cuts of various orientation. Suitable for both professional and home use, perfectly copes with a circulation diameter above average;

- chainsaw;

- machines for pure lifting of the bark;

- sawing on the belt sawmaker makes it possible to process dense logs, it is considered the most popular, since the output gives qualitative material and a small amount of waste;

- disk machine.: production of a two-way timber and unedged boards;

- the frame sawmate does not need the foundation, the technology with its use allows you to install equipment in the immediate vicinity of the deforestation;

- tonomer processed universal machines, exit gives high-quality building materials even from low-grade whips;

- the sawing of a round forest on a large woodworking company should be made with the largest lumber different from other special quality and accurate sizes. For this purpose, install special lines designed for sawing.

The sawmaker receives a bar and a cutting board due to the cut of a log up to 7m and a diameter of 15-80cm along the longitudinal line. Circular saw has one or more disks, processes different diameter Forests, respectively, their number.

If at home it is necessary to handle a small volume of wood, then you can use the usual chainsaw.

Wood cutting

Before choosing a tool, you need to decide on the view of the saw, focusing on the annual rings of the log. Several types of types are distinguished:

- radial (radius);

- tangential (spoke parallel to one radius concerns annual rings);

- fibers are located in parallel relative to the cutting produced.

Among the methods of sawing, the one that is most suitable for a particular case is selected:

- Called. Forest sawing in this way for deciduous trees with a small thickness of the barrel, is considered the simplest processing. Exit: Unedged elements and hill.

- If there is another forest machine, that is, the ability to cut up to 65% of the material to exit the same in the width of the edged boards. First, a two-toned timber and boards are peeling off, and then some amount of edged lumber is obtained from the bar.

- Specific methods - sector and segment sawing. The number of elements in the first method varies from 4 to 8, and depends on the thickness of the barrel. After separation from each sector, elements on a tangential or radial line are written. The second method begins with the exit of the bar from the central part, and the boards are written out of the side segments in the tangential direction.

- For individual cutting wood, a circular method is suitable. It is based on the rotation of the log on the longitudinal line 90 ° after each scaled board. This makes it possible to monitor the quality of the wood and timely remove the affected areas of the trunk.

Handmade: Application Chainsaw

For home cutting several trunks, it is impractical to acquire a tool, the cost of which is at times exceeds the price of finished products. If there is a necessary skill, then more efficiently and cheaper to do all necessary work ordinary chainsaw, or chain equipment operating from electricity. Of course, such work requires much more physical costs and time, but the price of the issue is significantly reduced.

Work on garden plot Requires trimming of fruit trees, and it is also possible to additionally produce material for household buildings, without resorting to the services of specialists, so that any preservation will prefer to buy chainsaw. Most often for the house are harvested coniferous breedsWith the cut of which this tool is perfectly coping. Due to the smooth trunks, it is easier to schedule the lines of the cut, which increases the speed of work. Professionals, by the way, most often use precisely a chainsaw, since it is more powerful and use it anywhere, regardless of the presence of a deforestation or sawing power sources.

To work by the chainsaw on the loop logs, it will take such a device as the nozzle on the saw, as well as the guides of the cutting and fixers of the base-barrel. The nozzle in the form of a frame is attached to the tool so that the ability to regulate the distance between the chain and the framework itself. It is done to get ready-made lumber, different in thickness. You can take the role of the guide or the desired length profile, or a flat wooden bar with sufficient rigidity. A special chain is selected on the tool, designed to cut the trunk along. Its difference from the rest consists of teeth, sharpened at a certain angle.

Before you start work, it is necessary not only to prepare the entire necessary tool. Regardless of whether the woodworking machine is intended for the treatment of the trunk or manual fixture, First of all, you need to get acquainted with the cutting card. This is done in order to minimize the percentage of waste, and increase the yield of useful products.

The first thing you need to bother with a longitudinal cut is the uniform density of the finished boards. For this, the competent saw driver sends a tool from the east side of the log on Western, or in the opposite direction. This is explained by greater density of rounding in its northern part than in South.

Next, the chainsaw is removed with a hill from two sides in such a way as to get a two-toned timber. It, in turn, is cut in accordance with the cutting scheme chosen at the beginning of work. The output gives an unedged board. If a certain percentage of vices is present in the trunk, it is possible circular cuts with a rotation of the trunk at a right angle or 180 °.

The amount of finished material, the price of cutting

Output useful material With coniferous and hardwood differs in percentage ratio. For sawn timber obtained from coniferous trees, the following indicators are characterized:

- provided that the operation is carried out by a professional, and a disk sawmill is used, the percentage of finished forest will be highest (80-85%);

- edged material that gives machines is an average of 55-70%;

- unedged board when the chainsaw leaves up to 30% of the waste.

The numbers are shown without the finished refrigerated forest, the number of which can reach 30%. However, such a material goes to products that make a certain marriage.

Deficious rounder gives 60% of the finished umbered forest and about 40% of the edged. This is explained by the initial curvature rounder. You can increase the amount of products obtained: for this it will require woodworking machines of various focus. A certain kind of device can increase the amount of sawnwood by 10-20%. About 10 cubes of deciduous rounding will be needed on one lumber cube. The price for installing additional equipment will pay off the cost of the finished forest. Special lines give a greater volume, but their use is advisable only on a large plot. The average price of sawing sawmills on a conventional sawmaker will be approximately 150-180 rubles per cubic meter of boards.

Card sawing

The sawing card is the calculation of the optimal amount of the finished lumber from one log. It can be calculated independently for each specifically log diameter, and you can use a computer program that significantly facilitating the calculation, and the price of which is quite accessible.

Either the source can be the usual reference book on the sawmill. As a result, the table is obtained, which is taken as the basis. The sawmill must always be focused on its data, to obtain more Lumber of any wood breed.

Calculation of optimal cutting logs using excel programs. For each sawmill, it is important to minimize raw material waste. The profitability of the production log was significantly dependent on this.

An example of calculating the crucified construction logs in Excel

The program for calculating the breakdown of the log will be useful to small entrepreneurs ready to create your business for the production of rounded logs and construction buildings

Some logs comes on the cut, 10 meters long each. The sawmill was concluded for the supply of raw materials from wood in such a quantity:

- 100 logs 5 meters;

- 200 logs 4 meters;

- 300 logs 3 meters.

What will be the optimal number of logs that should be cut to fulfill contract conditions? In other words, how to cut the boards with a minimum amount of production waste?

Solution of the task for cutting logs

To compile a solution model, you must define all possible options Cutting the logs long 10 meters each on 3-, 4- and 5-meter segments, taking into account the length of waste. The result of such calculations is the identification of 6 options for cutting:

- 2 bars 5m (0m waste).

- 2 BROUSE 5M + 4M (1M Waste).

- 2 bars 5m + 3m (2M waste).

- 3 bars 3m + 3m + 4m (0m waste).

- 2 bars 4m (2m waste).

- 3 BROUSE 3M (1M Waste).

Under the condition of the problem x i, they are collected by the method of І. Then the scheme will be true:

F \u003d x 1 + x 2 + x 3 + x 4 + x 5 + x 6 \u003d\u003e min

You can make such a system:

The next step will be the preparation of the table Microsoft Excel.which will contain the source conditions of the task.

To calculate the left part of the limit and the target function, appropriate formulas are introduced. Cells J3: J5 float these formulas:

And in the B8 cell, enter the formula: \u003d amounts (B7: G7).

Next is filled by the form of the "Solution Search" modules and "Solution Parameters". To do this, go to the B8 cell and use the Tool on the Data tab - "Analysis" - "Solution Solution". If this tab does not have this tool, then read the instructions.