How to make a garage gate with a wicket with your own hands. Swing gates with built-in wicket

Garage operation is not limited to parking. Frequent visits may be related to the presence of a basement or workshop. It is very inconvenient to open a completely heavy structure every time. It is much more practical to install a garage door with a wicket. The design features and the ability to remake existing gates will be discussed further.

Features of doors with a wicket

You can appreciate the advantages of a gate with a wicket at any time when there is no need to use the machine. The design is especially relevant in winter period... There are two reasons for this:

- There is no need to clear snow drifts in front of a metal gate.

- Open at sub-zero temperatures A garage padlock can be tricky. There is usually a built-in lock on the gate, and it is much easier to deal with it.

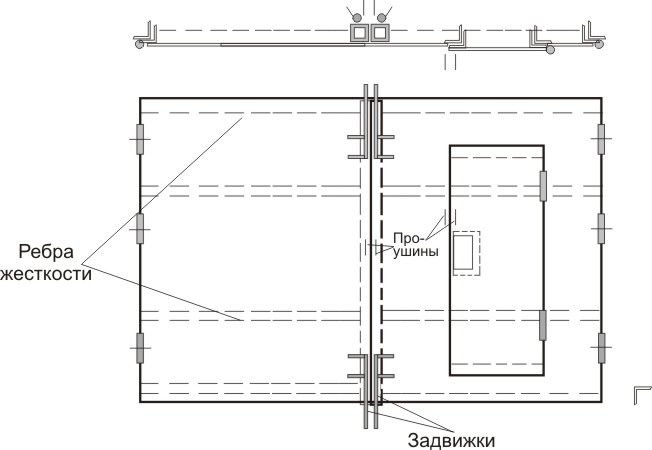

Wicket door garage doors significantly reduces the rigidity of the structure, so the installation of additional reinforcement is required. For this, the drawing of the garage door needs improvement, it is necessary to provide for the presence of vertical and horizontal beams. It is optimal when the reinforcement elements match the dimensions of the gate.

Another important point when creating or upgrading a circuit metal gate- the presence of beams on both sides of the wicket, both from the side of the lock and from the side of the hinges. You should not reduce your vigilance at the stage of equipping the wicket with a lock. In terms of its reliability, it should not be inferior to the level of locks for garage doors.

Comment! The equipment of the wicket is inextricably linked with the installation additional elements constructions. Accordingly, this entails an increase in overall weight. Therefore, in order to facilitate the process of opening and closing, it is worth considering in advance which hinges are best suited.

An interesting example of a garage with a wicket is the photo below:

Variety of designs

There are several models of gates with a wicket. After examining possible ways arrangement, it will be easier to decide on a suitable garage structure. There are three options for the location of the wicket in the sash:

- Traditionally, the additional entrance is equipped according to the principle when the gate is locked in the area of the garage door joint.

- Practicality is possessed by the model in which the wicket is cut out in the middle of the sash. Among the advantages - the rigidity of the garage door structure suffers least of all, and on the contrary, it becomes easier to close it.

- Only occasionally can you find metal garage doors, on which the wicket is located in the area of the hinges. When you need to open the sash, additional door the garage must be closed.

In addition to the space on the sash, the opening direction is also different. The classic version involves opening outward. But if the garage is free, you can design a wicket opening inward.

Another area for creativity is the installation of locks. Sometimes it is difficult to understand from garage doors how they close. The secret is simple - metal structure equipped with automatic locks with remote control.

Attention! Such a protection system provides for control over the state of charge, otherwise the garage door will simply not be able to open.

As you can see, when starting to create a drawing, there is something to think about:

- location of the gate;

- opening direction;

- the presence of beams that enhance rigidity;

- what locks to embed;

- concealment system;

- spare autopsy options;

- reliability of hinges that can withstand the significant weight of the garage door.

Measurements and drawing creation

Before drawing up a drawing, it is necessary to determine optimal sizes garage doors. The main parameters are selected taking into account the following requirements:

- The minimum width of the opening is repelled by the dimensions of the car and exceeds them by 0.3 m on each side. A larger value contributes to a convenient entry, a smaller value creates the risk of damage to the car.

- The opening width is limited by the dimensions of the garage. There must be a gap of at least 0.8 m from the gate to the wall perpendicular to the entrance.

- For a passenger car, a garage door height within 2.0-2.2 m is sufficient.Owners of minibuses should take care of a higher opening, about 2.5 m.

When starting to create a drawing, keep in mind that the garage door leaves are smaller than the internal dimensions of the frame. A small gap facilitates easy opening of the structure.

You can create a drawing yourself from scratch or use ready-made scheme by changing the individual parameters according to your own measurements.

Advice! For work, it is convenient to have several sketches describing individual elements garage doors.

The creation of the drawing begins with drawing the frame. It can consist of two identical elements - external and internal parts, which are interconnected by jumpers. Another option is shown in the photo, when a single frame is equipped with special fasteners for mounting.

Then they begin to draw the frame for the sashes. These drawing take into account all the nuances, from the location of the wicket and reinforcement beams, to the point of installation of hinges, locks and handles. An example of a competent drawing is given below:

Do not forget about the gaps between the leaf frame and the garage door frame, these millimeters play very important role during the operation of the metal structure.

Based on the existing drawing, a calculation of the need for materials is made. The following set is considered the most suitable:

- the frame of the garage door is formed from a steel angle 65 mm thick;

- the frame for the shutters has a lower power; a metal corner with a cross section of 50 mm or a profile pipe of similar parameters is suitable for it;

- it is accepted to sheathe the structure of garage doors with a wicket with sheet steel, minimum thickness starts at 2 mm.

The thicker the material is taken, the more durable the garage doors are, but their weight also grows proportionally. We can talk about a reliable design when the steel thickness exceeds 3 mm. If the garage is not intended for parking an expensive car, but serves only for household purposes, light corrugated board can be used as a door trim.

Attachment nuances and protection measures

Summing up the weight of all elements of the garage structure with a wicket, it should be understood that the result will be impressive. Therefore, you should take care of the unhindered opening of the gate. The structure is mounted on hinges; bearings are capable of facilitating their movement.

The location of the hinges also matters. The external fastening is not reliable, it is much more practical to put the hinges from the inside. If the hinges are outside, additional protective measures must be considered to prevent the garage door from falling over when trying to cut the hinges.

An important point in arranging a gate for a garage with your own hands is the selection of locks. According to their design features and the installation method of the locking system is:

- built-in (embedded);

- hinged;

- overhead;

- sliding.

Important! Not only the lock deserves attention, but also the method of attachment to the garage door. For safety reasons, the fixation points from the inside should not be visible from the outside.

An invoice or mortise protective mechanism is considered an actual option. Therefore, if a gate with a wicket is equipped with a hinged copy, it is better to replace it with an improved model.

Modernization of finished garage doors

As the owner of a garage where the gates are not equipped with a wicket, it is not at all necessary to change them to a new design. The defect is quite realistic to fix. The main steps in the process of equipping a ready-made garage door with a wicket:

- The casing is dismantled. For this, the welding tacks are cut off with a grinder, if necessary, the seams are removed with a hammer and chisel.

- A box for a gate is being prepared from a metal corner.

- An opening is cut on the skin according to the drawing.

- The frame of the wicket door is connected to the cut-out paneling of the garage door.

- The remaining steel cladding is attached to the sash frame.

- Hinges are welded onto the sash and the wicket, after which the wicket is installed on the garage door.

- You can proceed to the installation of locking mechanisms.

The opening made will greatly simplify the task of getting inside the garage without the need to use a car. This is especially useful if the room is used as a workshop or for storing household items.

The presence of a wicket involves the installation of additional reinforcement beams. You should also carefully select the locks, otherwise the strength of the steel will not save you from theft. The locking system must be equally reliable on the garage door and the wicket itself. Find out the details of how to make a wicket door in a garage door video:

Today, one in three people in the world owns a car. But it's not enough to buy it, the main thing is to think over a place for storing it. You can use guarded parking lots, but it would be better to have a garage, especially if a person lives in a private house. It is not difficult to build a garage, but here are the gates to choose, and perhaps you should make them yourself. Garage doors with a wicket can be different types: swing, roller shutters, roller shutters, lifting, sliding.

Varieties of garage doors

A few years ago, swing gates made of wood were most often installed to protect the garage, but now everything has changed dramatically. The variety of models is huge, each person will be able to find the option that he will like in all parameters and characteristics. Each has its own pros and cons, and you need to know about them before deciding on a particular option:

- Lifting rotary models... As already mentioned, most of the gate models have appeared recently, for example, a model that rises during opening, and then hides in an area under the ceiling. In this case, the opening occurs automatically, you just have to press a button on the control panel. The hinge-link mechanism and guides are taken as the basis for this type. The main advantage of this type is that they take up a minimum of space. But this type of gate is best installed in heated garages.

- Swing. This type has been known for a long time. These types are used everywhere, very often they can also be found to protect a summer cottage, a private lady, ancillary and industrial premises. Swing gates with forged elements anyone can create with their own hands, because they consist of doors, hinges and a short one, which is installed in the opening.

- Rollback options. These models have appeared for a relatively long time, they are very convenient and practical. The sliding gates consist of one sash, which opens to one side, moving along the guide with the help of wheels. But this model is not always possible to install in a garage, and all because you need to have enough space in the front wall. That is why they can often be found installed in industrial and hangar rooms.

- Roller shutters. This type of gate is considered one of the most relevant today. Roller shutters can be found not only on garage doors, but also on production and warehouses... Roller shutters are safety, protection from dirt and cold thanks to rubber seals. You can open or close the roller shutters using the remote control. Long service life and many other advantages make them popular.

- Sectional lifting. The device of this model consists of sections, which, when opened, gradually hide in the area under the ceiling. They are based on a chain guide and a mechanism with springs. Such lifting gates allow you to significantly save space, and if they are still installed with seals for automatic garage doors, you can make the room warm.

- Rolled. The device of this type is simple, but roll-up doors will not always help to reliably protect the garage if it is not installed in a protected area. Roll models can be easily made with your own hands in stores today you can buy everything you need for this.

- Rolling gates. They can rarely be found in garages. Rolling garage doors are not considered very reliable. This type is made of practical aluminum plates, which, when opened, are folded into a special box that is installed under the ceiling. Roller shutter models are advised to be installed in garages only if they are in a guarded parking lot and are heated.

How to make the right choice?

Currently, you can buy any type of garage door, but the price for them is not always acceptable. If you have at least minimal skills in working with the tool, then you can make them yourself, including roller shutters, lifting and sectional ones. Before choosing a specific model, you need to take into account their capabilities: climatic conditions, the presence of space for opening. Considering the climate of our country, metal swing models are chosen.

Lifting models have an aesthetic appearance, but they will not be able to protect from the cold. Most often they have severe frosts the mechanism freezes, and it will be problematic to open them. It is better to install them in places where there is heating.

Garage door drawing

So, it's not difficult to make swing gate models with your own hands, the main thing is to make correct drawing given its size.

Width must be 60 cm wider than vehicle width. This distance is quite enough for a car to enter, but if possible, it can be made wider, which will allow you to enter and exit the garage without problems, but the maximum width should be no more than 5 meters. Most often, the drawing is drawn with a door width of 2.5-3 meters.

When a drawing is drawn up, the height is also taken into account, which also depends on the size of the car, usually the standard is 2-2.2 meters, and if the transport is higher, then you can make 2.5 meters, for example, for a minibus.

When drawing a drawing, they calculate the amount of material, and you need to immediately make a choice: metal or wooden gate... The structure consists of a frame that frames the entrance and two hinged leaves. The frame can be made from a 65 mm steel corner, and the frame can be made from a steel profile or corner. After it is sheathed with metal, the thickness of which is 2-3 mm. But it is better to choose external and reinforced hinges for swing gates. All materials are calculated based on the drawn up drawing.

When gates are installed, for example, metal or wooden swing gates, many people are faced with such a problem as opening a large sash, and only now they remember that they did not foresee a wicket. Roller shutters, roll-up or sliding models can be moved a little and go inside, and to enter a garage with swing gates, you need to open one of the doors. But if you need a wicket, then it can be done after installing the doors. And this is exactly what we will tell you about.

How to make a wicket?

So, it is not at all difficult to cut the gate into the garage door with your own hands, which are already installed and functioning. DIY manufacturing scheme is simple and accessible to everyone.

First of all, you need to take into account the fact of what the gate is made of, because you will need to modify the finished device, which means that you need to remove inner lining and make a cutout in it.

So, using the example of a gate made of corrugated board, we will tell you how to make a wicket in them.

To work you will need tools:

- Grinder, with it you can cut metal.

- Welding machine. It will help to increase the rigidity of the gate and make the wicket itself.

- Screwdriver. All fasteners - self-tapping screws in our case, it is better to tighten with a screwdriver.

- And you will also need to stock up on a level, tape measure and a pencil.

Wicket construction made of shaped pipe- this is the best choice... A profile pipe is a very strong material, moreover, its price is low and its weight is low, which is very important for manufacturing.

First, you need to decide exactly which of the doors the gate will be located in. After that, you should remove all the casing. Then make the markings for the future wicket, its dimensions are better to be made standard. It is better to measure the opening in the sash a little more, while taking into account the width of the material. After everything is measured, you can cut the opening, but it is better to cut it when the sash is removed.

The next step is to unfasten and tighten the opening. To do this, pieces of a profile pipe must be welded to the frame, while observing all dimensions of the future opening.

When the opening is ready, you can proceed to the gate itself. It is necessary to cut the pipe to size and weld it to each other along the perimeter, it is imperative to take into account the stiffeners and guides for sheathing. During assembly, it is imperative to use a corner, keeping the angles of 90 degrees is very important during manufacturing.

After both structures are ready, you can start welding the hinges. But first, decide in which direction the gate will open - outward or inward. The location of the hinges will depend on this. Next, you need to install a locking device, if provided, install the casing and put the sash in place.

It is not at all difficult to make a gate with your own hands; roller shutters or roller shutters can also be equipped with a door. But the device of a wicket in roll-up models or roller shutters will require more effort and time.

Fence gate - very important element fencing. You can make it yourself from a metal profile. For this, the sections of the profile are welded together. For beauty, an arc is welded to the door frame, and for strength - two transverse struts made of metal shaped pipes.

When the frame of the gate is ready, it is necessary to embed a lock into it. When working, use:

- soldering iron;

- hammer;

- grinder.

The finished frame of the gate will need to be marked. For this to metal profile apply a lock and outline its outline with chalk. Then, using a grinder, four horizontal slots are made along the outlined lines, two slots each on the outer and inner sides of the frame.

Preparing the end plates for the protective box

A hammer is used to make holes for the lock. With its help, the sections of the metal cut by the grinder are folded back. Then they are removed with metal scissors.

You should be able to through hole under the gate lock.

Insert into this hole. It is fixed to the frame of the gate with metal rivets.

In order to hide its internal details, decorative metal plates are used. The holes for the keyhole and the door handle are marked on them.

To do this, attach one of the decorative plates to the lock and mark all the holes with chalk. An awl and a drill with a feather drill are used to drill holes. After one plate is ready, you can attach a second to it and make a duplicate.

Assembling the protective box

Once the end plates are ready, you can start assembling the protective box. For this to inside the frame of the wicket is welded to the "p" -shaped part. It is necessary in order to hide the castle.

With the help of a grinder, holes are cut in the "p" -shaped part for the crossbar. To mark the hole, you need to make three full turns with the key. Then the crossbar is circled with chalk and a hole is cut with a grinder along the outlined lines.

Then the end plates are welded to the box. This completes the assembly of the protective box.

At the final stage, you can trim the edges of the decorative plates using a grinder, cutting off the protruding parts.

After completing the assembly of the protective box, screw it into the lock for the wicket door handles... The frame of the gate is completely ready, it remains to sheathe it with slate or any other material.

Sectional doors have long occupied their niche in the arrangement of garages of private houses, as well as in the equipment of industrial and commercial premises. The hinged sections, when opened, rise along the guides up to the ceiling, without taking up much space. The popularity of such designs lies not only in the ease of opening, but also in enhanced protection from hacking.

A rigid frame made of aluminum profiles, high-quality automation enhance security for the entire building and do not give a chance to thieves. For convenience, many design organizations propose to cut a wicket into the sectional door and thereby relieve the general opening mechanisms. This gives additional functionality even large size gate and brings the whole building to the established norms fire safety.

Dimensions (edit)

For sectional doors there are no generally accepted standards in size, so they are often installed in hangars, garages, warehouses, car washes, car services. On request, you can make any gate and block even a huge wide opening.

The advantages of a sectional door:

- saving space in front of the room;

- enhanced protection against burglary;

- high sound insulation and thermal insulation;

- close any openings.

Opening methods:

- Manually, using a spring mechanism.

- With the help of automation.

An economical option for garages can be manually opened using a spring mechanism. This system can easily lift even large, heavy gates without requiring additional funds.

But it is better to install a modern electric drive on the structure, and not only on the sectional doors, but also on the embedded wicket, thereby ensuring its quick and safe opening.

Modern sectional door models offer a variety of finishes:

- From sandwich panels (with microwave, paneling, corrugation finishing).

- From a panoramic canvas.

The finishing of sectional doors made of sandwich panels is the most common type of structure that provides high thermal insulation and sound insulation from the outside world. Various patterns and unique wood or orange embossing of the panels help to easily blend into general form buildings and even decorate the facade.

Various coloring according to the RAL catalog will complement the possibilities of such a material, as well as diversify design projects.

To relieve appearance of such products, the canvas can be completed with acrylic windows, letting in a lot of daylight inside the room.

Typically, these techniques are used to decorate car dealerships and car washes, modeling not only their individual appearance, but also the practicality of the buildings themselves.

Sectional doors with a wicket door fit easily even into modern architecture city due to the variety of colors and panel finishes. Quick installation, safety in work, ease of operation will not make you regret once made the right choice.