How to paint the PVC panels in the bathroom. PVC painting and ABS plastic

Now in fashion wall and ceiling panels From plastic. Many residential owners use them as a finishing material. But not everyone is satisfied with the proposed color palette, so the question often arises: how to paint the PVC panels and is it possible to paint them at all?

Given the huge range paintwork materials In the sales market, pick up the paint on the plastic will not be a special problem for the user. But before proceeding with painting, you need to decide on the color that the homeowner is most promoted in the interior of the room. As a rule, acrylic compositions are made under pastel, medium and saturated tones.

Before painting plastic panels, it is necessary to prepare the surface to paint, prepare materials and tools that include:

- Purifier for plastic panels;

- Cotton fabric without a pile;

- Special paint for plastic;

- Protective gloves and respirator.

It is best to treat the surface with high-quality and inexpensive cleaner. On the plastic there may be traces of lubricant, which is covered in manufacturing. With the help of the cleaner, the material manages to degrease, remove dust, statistical electricity. This means is applied to the fabric without a pile. It is treated with the surface of the plastic. Cleaning the surface, you need to wait until it dries, but only then you can paint.

Many believe that the panels can be painted with a roller or brush. This is an erroneous opinion: as an instrument for applying paint can only be used the paintopult, and paint plastic - by spraying.

On video: PVC and MDF panels.

What kind of paint can be used?

Not every paint is kept on plastic panels. Therefore, for such a material there are special species compositions. Today, you can get the paint of the desired shade without difficulty. Choosing paint for plastic, you need to consider the conditions under which staining will be carried out. It's one thing when it comes to internal painting works, and the other, if they are held outside.

If you choose decorative materials, you should know what they are used for decorative decorationsAnd for their application there are special stencils. Technological compositions are intended for reliable protection Surfaces from damage and wear.

To avoid problems in working with paints, you need to strictly choose those materials that are intended for PVC panels. Painting allows you to extend the life of plastic and make it decorating the interior design.

Often plastic are painted with polyurethane water paint, the durability of which is verified in practice. In order for the layer of painting was more durable and served longer, a varnish is applied on top of the dried composition. Drying can be performed by natural or enforced way.

To date, polyurethane-acrylic water dispersions are also used for painting plastic surfaces. Such colorful materials are painted windows, doors, panels, other pVC products. You can list the following advantages of using such dyes:

- these are environmentally friendly paintwork materials, which contains non-solvents;

- the coating applied to such paint serves as an excellent decorative decoration;

- coverage is steadily for deformations and pollution;

- such paints are water repellent.

Acrylic paint for plastic panels will quickly dry. So if for some reason the color of plastic finishing materials The owner does not suit, they can be painted with acrylic composition. A large range of colors allows you to choose a material under the interior design of any room.

Polyurethane acrylic LKMs are resistant to pollution, impact of atmospheric phenomena, elastic and environmentally safe to use. They do not have a sharp smell, are easily cleaned of dirt and dust, have a water-repellent composition. The service life of such a coating is long. The only drawback of this material is the complexity of application.

Choosing paint, you need to pay attention to the composition and instruction, because a good product Must get dry no later than twelve hours. It should be focused on hardness, degree of repulsion from the surface, learn about the presence of organic compounds in the paint.

It is also necessary to pay attention to the manufacturers of paints and varnishes. Acrylic paints are considered harmless, and after their application, a coating is obtained, an externally resembling the surface of plastic panels. As for the water-emulsion analogs, they are not suitable for painting plastic, because they will simply flock from it.

Features of staining

Knowing how you can paint plastic panels, how to prepare them for this, which technicrafts for this use, you can proceed to the painting process. Pay attention to the following principles:

- Painting works need to start an hour after paint tinting.

- Before starting staining, it is required to determine the viscosity of the composition and, if necessary, breed the paint with clean water.

- Paint is applied exclusively to the paintopult.

Following the instructions how to paint the panels, you can achieve an excellent result. In the process of work, it is necessary to cover the adjacent film with the surface panels so that paint material does not spray.

It is necessary to select the optimal parameters of the collapse, the diameter of the nozzle of the pistol and the working pressure, as well as to monitor the thickness of the layer. Spray the dye need a layer of 6 mm. The thinner the coating, the faster it dries.

Light plastic can be painted in one layer, and the dark is better to cover the paint twice. For drying paint, the temperature in the room should be at least twenty degrees of heat. Check if the panels were dry, it is necessary not earlier than six hours later. If the color of the panels does not suit, it is better to paint them with acrylic composition.

You can paint I. oil colorsHowever, they are distinguished by a sharp smell. But they can be applied with brush or roller. Just for a while you have to leave the room in which such paint was used. If there are no practical skills in the performance of such work, it is better to charge the painting of plastic panels experienced in painting to specialists who will fulfill painting quickly and efficiently. The quality of the painted panels and the interior design of the room in which they are installed are dependent on the quality of the painting.

What experts say (2 video)

PVC panels of different colors (20 photos)

MDF panel is construction materialdesigned for finish finish Premises, facing facades of cabinet furniture or walls, it is made of low or medium thick chips from wood chips. Data details are considered environmentally friendly. pure element finishes, since they are not used synthetic adhesive compositions, and the natural wood resin is used, which reliably fixes all the layers of the product and forms a single integer. The MDF panels have an average and low density, depending on the number of layers and wood composition. Over time, during the operation of these parts, their surface can get scratches, the coating loses the gloss or has defects, as a result, the integrity of the entire panel is violated, and the appearance of the entire finish becomes unsightly. In this case, any owner faces the question: how to update the facade of the panel without changing them completely?

MDF panels on the wall

This article describes the possibility of painting such products such as MDF wall panels, is it possible to paint the MDF, as well as the process of conducting such work at home.

There are a number of reasons for which the painting of MDF panels may be needed, they include:

- Mechanical surface damage as a result of hitting a sharp object or other material. The top layer of the MDF panel consists of laminated or simple paper with paint applied to it, when exposed to it a solid object, a film is rupture, which shaves the core of the entire product;

- Burning paint, loss of color brightness. This deformation is obtained from exposure. ultraviolet rays and atmospheric air, which contains a small amount of moisture. Over time, the coating becomes matte, loses shine and initial View;

- The temperature differences also negatively affect the outer state of the MDF panel surface, since the internal structure consists of wood, which absorbs moisture from the atmosphere and is inflated throughout the area. During the increase in the temperature of the MDF dries and at the same time can crack, besides the glue contained in the panel, the moisture loses its abilities, which leads to detachment of paper, lamination and chips.

MDF and Water

These causes of deformations lead to an unsightly view of the entire surface and violate the overall wall design. In the event of these defects, you can paint the MDF panels, after having done a number of preparatory procedures, but it is worth understanding that the painting of the parts with their own hands at home brings a result that differs from paint processing in production.

The process of painting MDF panels

Before answering the question, how to paint the MDF panels, you need to figure out the composition of this product. The MDF plate, wall or facade, consists of several layers of compressed paper and sawdust, laminated with transparent or color film from the front side. Most often upper layer It is subject to damage and wear, so when planning, update MDF needs to be prepared the specified types of coatings.

In order to prepare the MDF panel at home, you will need:

- Sandpaper to prepare the surface and removal of gloss or varnish;

- Solvent for degreasing the surface from glue and liquid residues;

- Dry rag or other fabric without a pile.

These materials are necessary for pre-processing MDF panels under painting and sealing cracks and scratches on the laminate.

Printing MDF panel

All work should be carried out in accordance with the algorithm of actions. At the first stage, it is necessary to stick the panel with grinding paper with a shallow fraction, this can be done manually or using a pneumatic tool. It is important to comply with lacquer removal technology, prevent overheating of the surface or the formation of large rinks on the laminate. A fibustarity surface is under a decorative film, so when sanding it is necessary to closely monitor the thickness of the upper layer so as not to erase it through. After this procedure, the coating will stop glistening and will become rough, slightly looting.

Next, you need to clean all the cracks and chips from dirt and dust, and also clean their edges. All irregularities, if necessary, are maintained by a special putty, which forms a single whole with the basis of the panel, it should also be aligned with sandpaper.

After the surface is processed and aligned, it is necessary to wipe it with a dry cloth and degrease the chemical solvent, which displaces and evaporate all the water, wash dust and dirt.

At the next stage, the top coating of special paint is carried out, it has a grainy texture and can be applied using compressed air or a simple tassel. It can cover the surface into several layers, with intermediate grinding, until the required smoothness is reached.

Next, the main paint is prepared, and it is mixed and thoroughly mixed so that all the elements are mixed with each other. You can paint the paint panel of the MDF, manually or a special pneumatic gun, but this requires compressor installation and moisture-water separator. The composition is applied with smooth movements in two layers: the first - across the main direction, the second - along the entire length of the part. Thus, the formation of inclusions and inks of paint is prevented.

The final step will be the processing of the upper paper-wood layer of the panel with a transparent varnish. This procedure It is not necessary, but after it has the surface of the MDF, the product becomes a glossy, its upper layer seems to be updated, and the appearance of the entire structure is restored.

For your information. It is important to observe the intervals of the drying of the elements between the layers of the soil, paint and varnish, since otherwise they will be folded and cracking, they will have to carry out all the work.

Use of kraskopulture

How to paint and update MDF panels

For MDF panels, you can use an alkyd or acrylic enamel, but when choosing paint it is worth considering the type of primer, the operating conditions of the panels, as well as the composition of the upper layer. If it is laminated paper with a synthetic, weakly absorbent film, then it will be advisable to use acrylic or water-dispersion enamel. These materials are environmentally friendly and perfectly suitable for interior painting indoors, while the surface of the panel will be updated, as well as additionally protected from moisture of the aggressive external environment.

Thus, when compliance with the entire staining technology, it is possible to paint the MDF panels, it becomes completely solved at home.

Video

Is it possible to paint the MDF panels or facades? Such a process is possible. But it requires compliance with certain conditions that make up the choice of materials, preparatory work, main stages and final strokes. Painting MDF panels - the task that every one can do. The only thing that is important to consider is not all the paints are suitable for this purpose, but those that are suitable are not suiced.

Pros and cons painting MDF

MDF painting is most often for two reasons:

- need to protect material from negative factors ambient;

- decorative goal - I want to change the color MDF plate Or improve its appearance.

Regardless of the cause of painting, it has several advantages:

- The painted element becomes resistant to high temperatures. This means that when using the MDF panel in the kitchen, it will be possible to put hot dishes on it.

- Presence in paint special additives allows you to get facades original design: Pearl, pearls, metallic.

- As a rule, paints intended for MDF do not have harmful chemical substances. This is a big plus, especially if the material staining is planned to be carried out at home.

- And finally, painting products allows you to significantly extend their service life.

Of course, the coloring of the MDF is not devoid of deficiencies, from which the following can be distinguished:

- high price, compared with film coating;

- the ability to burn out the color under direct exposure to sunlight.

What materials use?

Since MDF is a material that consists of wood fibers, it can be painted and ordinary paints on wood. However, to get a really high-quality result and uniform staining, you will need special compositions, among which:

- polyurethane-based primer;

- paint (also polyurethane);

- varnish for MDF (if necessary).

Polyurethane enamel does not have volatile components in its composition, it can be used both for internal and outdoor work.

Staining technology

Process coloring MDF. Color polyurethane enamel includes several stages:

- grinding;

- primer;

- directly painting;

- drying.

Grinding

For good adhesion paint coating It is necessary to polish the processed products, be it facades or wall panels. To do this is used:

- dry sandpaper;

- scotch-Bright is a soft abrasive of small graininess;

- grinding machines under ground.

If the product is small, then the sandpaper on the foam-based gradation of the P220-P280 is used.

For flat surfaces, 700 series grinding mats are used with fine-grained abrasive. The same materials will help remove the surplus of the soil, fill risks before painting.

This surface is preparing, directly to which paint will be applied. After stripping, the surface needs to be deguted with antisilicone.

Shpaklevka

MDF is preparing for painting carefully, here alone is not separated by grinding. If there are visible flaws (cracks, dents), the surface in these areas should be sharpened, thereby align the surface.

An acrylic putty for the tree is best suited for shtclosure, to apply and smooth it with a special rubber spatula.

Primer

For flat products it is better to use a universal white polyurethane soil LBR30. The content in it of a large amount of resin gives a minimal tendency to shrink. Suitable for matte and glossy finish. For the latter, where each defect is visible on the surface, the requirements for the preparation of the order is higher. Best result It gives the use of polyester soils.

Before painting the panel, you need to prepare them thoroughly. Originally make a working mixture. For this you need to take:

- lBR 30 - 100 weights soil;

- hardener LNB 77 - 40 weight parts;

- diluent LZC 1051 - 10 weight parts.

All of these components need to be mixed between themselves and apply the first layer of soil into the stained surface with a gun with a top tank. The diameter of the nozzle is 1.8 mm, air pressure is 2-3 atmosphere. The material consumption must be 120 g per 1 m2. The optimal thickness of the resulting film 120 microns. So that the shrinkage process completely completed, the soil should be dried within 12 hours.

Before painting the product, it will need to once again handle abrasive. For gloss, an emery tool with smaller grain is used. After that, the surface will be prepared, and you can apply paint for MDF panels.

On video: primer and grinding MDF.

Painting

Painting the wall panels can be tasted, roller or paint. The room temperature should be about + 20 ° C, air humidity - in the range of 50-80%. You can paint matte or glossy enamel. But initially you need to prepare work formulations. For matte enamel take:

- 100 weights of enamel;

- 50 weights of the hardener;

- 30 weight parts of the diluent.

For glossy enamel, 70 pieces of the hardener are taken. The remaining components in the same quantity. For gloss, you should always use a slow diluent, which will provide good spreading.

Painting MDF panels should be made in a relatively spacious room, if it is internal structures (for example, facades or wall elements). The house from the outside should be fermented in the warm season. Emality consumption should be approximately 150g / m2. Fiberglass stove of medium density or MDF completely dries in 24 hours.

To obtain a gloss, polishing should be performed after 3 days. By this time, all polymerization processes will be completed. With the help of special additives on the surface of the product, you can create the effects of pearl, metallic, obtain corrugated waves.

Wet

You can paint the MDF panels alkyd or polyurethane enamel, as well as powder mixtures. Wet technology It implies the use of a sprayer with appropriate pressure. If the paint is applied in two layers, intermediate grinding is necessary. The thickness of the layers is not more than 120 microns.

Coloring surfaces should be free from small garbage, dust, insects. In the case of their hit, it is necessary to eliminate in a timely manner, using the T-type Tool. The flowing surfaces formed on the painted surface after drying are eliminated by the stationery knife or emery fine-grained paper.

Powder

Is it possible to paint the MDF in a different way? Yes, there are special powder mixtures that are applied on working surface Sprayer. After that, the product is subjected to high temperatures until the paint is completely melted. This method provides for the preparation of a practically perfect smooth surface.

The technology of powder staining involves sputtering dry microscopic particles to the surface.

Drying

Painting MDF panels can be any method. Completes any technological process of decoration drying. It is carried out in compliance with some conditions:

- air ambient air no more than 50 ° C;

- relative humidity less than 80%.

The duration of the final stage depends on the conditions of the environment. It can be from 5 hours to days. The painted MDF plate will dry faster at lower temperature and humidity indicators.

No matter what you can paint wall panels, compliance with stages, conditions technological process All will get saturated color, smooth surface, will save time, costs. It is better to automate all the work using special paint equipment for this.

How to paint MDF (2 video)

What will take for work (20 photos)

Painting MDF plates is a very time-consuming procedure that will require compliance with technology and a variety of rules. Immediately it is worth noting that such work is stretched for a long time, not one week may take place. In any case, everything can be done independently, while getting the necessary decorative surface.

Why do it?

Many wonder: is it possible to paint the MDF at home, and why is it necessary? The first part of the question will be affirmative. Indeed, you can paint the panel with your own hands. But you should immediately make a reservation: if there is no paint chamberThe result is not always perfect. And the coloring procedure is necessary for the following reasons:

- Covered paint elements become more resistant to high temperatures and humidity. Therefore, they are allowed to be used in the kitchen and in the bathroom, where they can perform various roles.

- By decorating, it is possible to diversify the dull interior, refresh the look of the room. The shade is chosen on the basis of the designer ideas.

- Painting panels from MDF is also needed in order to extend their service life.

Painting MDF allows not only to diversify the boring interior, but also to extend the life of the product

Painting MDF allows not only to diversify the boring interior, but also to extend the life of the product

Of course, this option has some drawbacks. For example, this procedure is sometimes much more expensive than using decorative films. In addition, the surface becomes prone to fading.

Choosing materials for staining

In principle, all paints for MDF are selected taking into account the composition of the material. And this is, first of all, a small wood fraction, which means that paint solutions for wood are suitable for work. But to obtain a really high-quality coating, it is advisable to apply special mixtures.

When choosing materials for painting MDFs, it is worth paying attention not only to color, but also the purpose of the paint

Polyurethane enamel

To give preference to this material follows for the following reasons:

- The coating is obtained by wear-resistant, withstanding the effects of household chemicals.

- The solution does not have an unpleasant odor, which allows you to carry out work in cramped home conditions.

- The mixture is allowed using a sprayer, roller and tassels.

- Painting MDF enamel is made independently, such a procedure does not require professional skills.

Naturally, choosing this material, pay attention to the manufacturer. It should be a well-known brand that is sold in specialized stores. By purchasing the goods of an unknown manufacturer, the likelihood of getting fake is great.

Tip! If there is no possibility to choose a polyurethane composition, then pay attention to alkyd enamels and paints (oil and acrylic).

Choosing paint, you need to pay attention to the manufacturer

Varnish

Thus, the question of how to paint the MDF panel is no longer a problem. But another dilemma occurs - the surface needs additional protection, how can this be done?

Indeed, to increase the resistance to mechanical effects, protect against chemical compounds - use varnish. And for such a work, a two-component polyurethane composition, which possesses all the desired parameters is especially well suited.

Painting Stages and Technology

The procedure for painting MDF with their own hands is carried out in several stages. They can be divided as follows:

- Grinding.

- Putty.

- Padding.

- Staining.

- Lacrification (patination).

Execution of each stage - serves as a key to the fact that the result is as conceived.

Grinding

Work begin with surface grinding. This is a rather time-consuming event that needs to be accurately.

The panels are grouped by sandpaper with grainy from 120 to 240 units. The process is performed in several stages and different materials. It is necessary to do everything very carefully, without lingering for a long time in one site. This procedure is carried out in order to remove small irregularities, as well as remove a small pile that is covered with the entire surface.

MDF grinding procedure allows you to get rid of small irregularities on the surface of the plate

On a note! If on facial side There are milling sites, they are better not to touch them. The likelihood is the likely that sandpaper is smoothing the angles of the pattern.

Shpalian

The film of the MDF under painting is aiming a goal - to correct the existing flaws of the panel. It happens that when grinding or due to improper storage, cracks or dents appear on the surface. To hide them, put a shit. Of course, if there are no such problems, then this stage is missing.

The technology itself looks like this: the acrylic mixture is neatly applied to the desired area and leveled with a rubber spatula. After drying, it is defined.

Padding

The priming of the surface of the MDF plate is better to perform with the help of a collapse, then the primer layer falls uniformly

This stage is mandatory. It is conventionally divided into two processes:

- Application of the first layer of primer

- This is done with the help of spray, so you prepare the room and place to work. It is better to close the remaining items with cellophane film.

- The mixture is sprayed over the entire surface of the panel with a uniform layer. This is done in order to raise the remaining pile and reduce the absorption of basic materials.

- Next, when the stove dries off, it is subjected to grinding with shallow sandpaper.

- Coating by the second layer

- The second layer is applied to secure the result and remove the remaining flaws.

- Drying should take about a day, after which, painted with the primer panel is stuffed.

Coloring

Is it possible to paint the MDF with a brush and roller? Yes, but it should be done very carefully. The likelihood is great that there will be divorces and drows on the surface. Therefore, it is best to use the paintopult.

The technology itself resembles priming. The paint is applied in several layers, each of which is pre-dried. It is important to achieve an excellent result, so the mixture is starting to spray from millillated areas to the edges, and then pass along and diagonally. Much more convenient to paint the smooth panels.

For painting MDF, you can use brushes and rollers, but to obtain a uniform layer it is better to use the paintopult

On a note! In order to understand the time of drying out the solution and its quantity in detail, it is necessary to carefully examine the manufacturer's instructions. And also select the desired mode of operation for the sprayer.

If you want under the old

If a desire appears to give the surface a more expressive appearance, it is a bit of it, then resort to patination. It is advisable to do when there are pictures and patterns.

The patina is applied in this way:

- at the selected area, a sponge dipped in the mixture is passed;

- leave until complete drying;

- painted plot of grinding;

- embed to the end stage.

The effect of artificial formation can be created independently, resorting to the patination of the surface.

Lakovka

The procedure is performed according to the instructions:

- Varnish prepare for use.

- The first layer is applied at the rate of about 150 grams per square meter.

- Having waited when the first layer will dry well, impose a new layer.

- Repeat the drying process.

- Start the final grinding. First, on the surface passes sandpaper with large grain, then use smaller. To avoid rolling lumps, the site is sprayed with water.

- The panel is left for several days (from 4 to 7) and are polished. To do this, it is better to apply the power tool.

There are many tips on how to paint the MDF. The main thing is to follow the clear plan and follow accuracy.

The corridor will trim the MDF panels under the light tree from the floor to the ceiling. The thickness of the panels is about 5 mm, which is not observed from above, it looks like a conventional paper-cardboard layer on top. They laid a little hands, decided to wash the wet sponge for the dishes, rub there from a dozen times and the dotter to a light spot in the middle of the wall, right if he stopped, and then the week is still in a pair of places

The first idea to cover the entire corridor of the whole corridor, you can darken a little color, it is not fundamentally. I tend to paint the roller. How to take advantage of the men, so that the loss places crushed and the general color to keep it possible. Maybe varnish with a tint. Can I coat MDF? I myself do not understand how I did it.

Thanks for the advice and all happy New Year.

Before painting plastic with your own hands, you need to choose, based on its structure. After all, this material is quite different.

After choosing paint, it is important to properly apply the coating, because it should look and be durable. And it can be done in several versions. Also on video and photos you can see the most difficult moments of doing this work.

How to paint plastic correctly, will depend on its characteristics. But in any case, high-quality surface preparation should be made.

The paint does not keep so well on the PVC surface. Therefore, preparation is quite serious. Coloring plastic, like staining of any other surfaces, has its own characteristics.

ATTENTION: Painting is better done with the help of a spray gun. In this case, the coating can be applied most evenly.

For convenience, we will analyze the entire process in steps:

- At the beginning of work it is necessary to make sure that there are no contaminants on the surface. The processed surface must necessarily be dry and clean.

- Before starting color, plastics must be covered with a special primer for plastic with high adhesive properties. It can be purchased in paint and varnish, construction and auto shops. Apply primer with spraying (using spraying device) or wiping. After processing, the product must dry completely.

- In order for the coloring procedure to be comfortable, and the grip between plastic and paint was as strong as possible, a number of conditions must be observed:

- The ambient temperature should be more than 18 degrees, and humidity indicators should not exceed 80%;

- The temperature of the stained surface, paint and snap should be approximately the same.

- Plastic staining passes into one layer, the thickness of which is 60-120 microns. If the layer is thinner, then the wear resistance of such a coating will be very low. A layer thickness above 120 μm will significantly increase the time of complete drying, which can worsen the appearance of the painted product.

- Recommended drying temperature of plastic surfaces 18-60 degrees, more specific temperature range, as the time of the drying itself directly depend on the thickness of the painting layer. For example, a layer of 80-120 microns with room temperature And the standard humidity of 40-50% will dry in 8-10 hours, and at a temperature of 50 degrees and relative humidity of 65%, the drying period will be reduced to 3 hours. The surface of polyamides and polypropylenes at an air temperature of 100 degrees will dry in 20 minutes.

- Polymerization (final drying) of the painted surface is terminated only by 5-7 days. However, with a layer thickness, more than 120 microns, low ambient temperatures and high humidity, polymerization time can increase significantly. Before the end of the polymerization, the painted plastic is undesirable to expose low temperatures and high humidity.

Plastic Coloring at Home

With your own hands, the coating will be significantly cheaper than the price of specialists. Consider how painting plastic at home.

In order to quality to paint the plastic surface yourself, we will need:

- Aerosol enamel paint on plastic or enamel for plastic;

- Acrylic aerosol varnish for the final surface treatment (it happens matte and glossy);

- Hand protection, eyes and respiratory (gloves, mask, safety glasses);

- Polyethylene film (in order to cover the surrounding items);

- Malyary Scotch;

- Means for cleaning plastic (water, rags, brush, detergent);

- Solvent (for example, White Spirit);

- Grinding paper with abrasion up to 180 microns.

What kind of paint use?

What paint can be painted plastic now consider in more detail. It is necessary to approach the choice of paint with a special scrupulousness, since the type of paint and the features of its interaction with the surface has a direct impact on the final result.

So:

- For products made of mild plastics, it is necessary to use enamel with an increased content of elasticity and plasticity. And universal acrylic enamel and enamel are suitable for products from solid plastics.

- In our case, acrylic paint on plastic is best suited, which can be purchased in any construction and paint stores.

ATTENTION: Also when buying should be borne in mind that there are two forms of release such as paint: aerosol (in bells) and liquid (in buckets).

- It will be most convenient for us to take advantage of the aerosol paint enamel, because It has good adhesion, easy to use and dries quickly. If you need the most homogeneous distribution of enamel on the surface, you can purchase a specialized tip for aerosol cylinders, allowing manually adjusting the degree of paint spraying.

ATTENTION: Plastic products with labels PS (polystyrene), PC (polycarbonate) and PE (polyethylene) are not painted!

- We will finally fix the paint with the help of acrylic aerosol varnish.

If you work with a new surface or use liquid paint, then you will also need a primer for plastic, for example, "ETEX" from TM Ticcury. - If you are going to paint the old plastic, then there will be a surface grinding.

The process of coloring aerosol paint

Conditionally the full process of staining of the plastic product can be divided into 6 steps:

| Cleaning the product |

|

| Surface degreasing | Degreasing is an important stage of pre-processing of products under painting, since no paint material closes with a bold surface. To delete old paint and degrease the surface of the stained product, it must be thoroughly treated with a solvent. After processing, the working surface must be carefully flushed and dried. |

| Surface grinding | Grinding is needed in order to increase the roughness of the painted surface and facilitate its adhesion with paint.

|

| Decoration |

|

| Coloring | Features of surface coloring aerosol paint:

The number of layers is directly due to the quality of paint and the degree of surface preparation to staining; When using any aerosol paints, do not forget about protective facilities For eye and respiratory organs. |

| Varnish, fixing the result | After a complete drying of the painted product, it usually occurs in 25-30 minutes, treat it with an aerosol varnish. The principle of processing is the same as when applying paint. Prepandable product dry. |

The process of staining with liquid paint

An alternative way to paint, is staining using liquid paint and brush. Painting brush has both pros and cons.

The main disadvantage of this method of staining is a long drying time, during which the deposition of dust / dirt should be allowed to the treated surface. Since at home it is impossible to do this, such a coloring method is applied only in cases where perfect coating not necessary.

In many ways, this process repeats the above method:

- Cleaning the product.

- Degreasing the surface.

- Grinding. At this stage, the processing of the product of the primer is added, which will significantly increase the adhesive properties of the plastic surface and improve its grip with paint. After processing the primer plastic, it is necessary to dry within a few minutes.

- Staining.

Painting brush has a number of their special, which must be considered if you want to get a good result:

- Paint-enamel should be applied with a thin layer, continuously pressing the brush to the surface;

- When the paint is set, do not immerse the brush in it completely;

- During the dyeing, it should be carefully monitoring the angle of applying paint, it should not change;

- First, apply enamel wide stripes, and then delete it. This will make it possible to fill all the surface roughness and achieve the most uniform coating.

Lacquering, fixing the result. Consider that Varnish in this case should also be applied after the surface of the product surface is completely drying, in the case of liquid paint This period is quite lengthy. Do not forget that the aerosol varnish is driving much faster than the usual one. Drying time of ordinary varnish is about 2-2.5 hours.

How to paint plastic, you now know and the instruction will not allow you to allow you to make mistakes.

The main reason to change the colors of plastic is to give it a harmonious view with the interior of the room or external species building. At the moment there are more than 2000 shades that allow it to do. One thing remains to properly apply the paint on the plastic panels.

In the photo - staining plastic windows

The material during operation also turns yellow due to sunlight, losing its original appearance. In addition, physical properties are violated. In this case, staining will protect the PVC plastic from such influences.

Tip: Want to protect metal elements in the apartment from corrosion, for this it is used by the electrically conductive paint Zinga, which can prevent moisture to their surface.

PVC dyes in granules

Technology

Coloring of plastic PVC profiles with a water-based polyurethane acrylic system has a number of advantages:

- fast and high-quality surface preparation;

- drying occurs in a short time at room temperature;

- a set of hardness at a temperature of 20 ° C - from 8 h;

- manual and automatic spraying;

- large spectrum decorative possibilities - texture "under the tree", mother of pearl, metallic.

Acrylic paint for PVC panels

Preparation

Below will look at the stage of manufacturing color profiles from plastic. And the most important stage will prepare products for painting.

You must make sure that there are no dirt, silicone, fat spots and other substances on the surface, which will become an obstacle to the good plastic adhesion with paint.

For this there is a small instruction:

- remove with a dry napkin or compressed air dust, lines of chips and crumbs;

- pour the rag with a special cleaner intended for polystyrene;

- declaring and clean your own hands the surface of the product from the residues of lubricant and dirt, while removing static stress;

- wait 5-10 minutes. until the cleaner evaporates from the plastic surface.

Tip: Use special activator cleaners for this PVC. This liquid also creates micropores on the surface, helping the adhesion of materials among themselves.

Paint for PVC plastic and internal works

Another way that will help achieve good adhesion - PVC grinding, and then his priming. However, this process is more laborious and requires some skills.

Tip: Does not suit the price of professional painters, shall hold the case yourself.

Choose paint

Remember that if you do not polish and primed a piece of plastic, you must acquire only those paints that are specifically designed for PVC staining.

- Select a hue. To do this, you can use the catalogs of NCS, RAL or Monicolor, where so much big choiceWhat to find the appropriate color will not make problems.

- Determine what items, and in what quantity it will be necessary to paint. This will give the opportunity to calculate the paint volume on certain square.

- Make a tinting to the required shade at least 60 minutes before the start of work. Tinted paint will occur by a special recipe with the addition of pigments. The selected shade will be as close as possible to the color in the directory. There are ate the ability to control the viscosity using the VIS-6 viscometer and adjust, the ate is necessary, its addition to the pre-purified water.

Paint for products from solid PVC

Coloring

The process should be made in one layer at room temperature without prior applying of primer. When using a sprayer, the coating will be better.

Also paint can be applied with a brush or roller. It dries about 8 hours, depending on the temperature, but it is possible to use it completely only after 72 hours.

Tip: If necessary, you can apply the second layer, but only when the previous one is completely drying.

If you use a pistol for staining, make sure that the temperature of the paint, it and plastic corresponds to the work room - not lower than 18 ° C, the humidity should not exceed 80%. It should also be dry and clean. It is recommended to apply 2-2.5 atmospheres, the nozzle size is 1.6-1.8 mm.

The desired film thickness is at least 60 μm, otherwise it will affect the tensile strength with the basis. With a layer thickness more than 120 microns, drying time will increase and this will affect the decorativeness of the coating.

Tip: Indoors have enough items that may suffer during a fire. To protect them, use modern flame retardant paints on metal polystyl, which are diluted with water.

Polyurethane paint PVC

How to dry

The drying of the painted surfaces from the ABS plastic occurs at a temperature greater than 40 ° C. They should be placed in a heated dryer no later than 5-10 minutes after staining.

They eaten the thickness of the wet film will be 80-120 microns, the temperature is 50 ° C and the relative humidity of 65%, the drying will continue for about 2-3 hours. It is not necessary to immediately check the degree of adhesion, it is better to wait 24 hours, full polymerization occurs in 5-7 days.

Remember that drying time due to the high thickness of the wet layer, lower temperature, large dimensions of the product and high humidity drying can significantly increase.

When stored finished products From plastic, they must be protected by film or paper, protect against friction and shocks along the painted surface. Also, they should not be subjected to a long exposure to moisture and negative temperatures to complete polymerization.

Output

From the article it became clear that staining plastic PVC And the ABS is an easy. It is only necessary to carefully clean the surface from any contamination, decide on the color and required amount of material (find out as well as paint old parquet Alone).

You can apply it convenient for yourself by spraying or roller with a tassel. Drying the first to produce at room temperature, the second at 40 or more degrees.

Video in this article will help you find additional information on this topic.

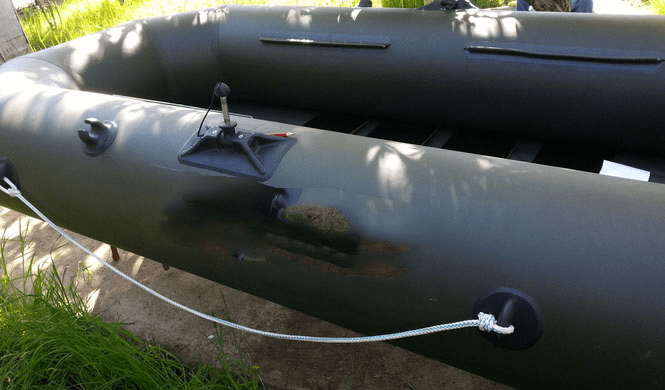

The need to restore or repaint a decorative coating on plastic parts and facing from PVC is much more frequent than it may seem at first glance. It can be the surface of metal-plastic windows of the veranda, household equipment, a soft inflatable boat, plastic body elements by car and even protective covers of fabric. Polychlorvinyl plastic paint is not difficult, but under one condition, if there is a special PVC paint.

Complexity in coloring how to paint polychlorvinyl

For staining of plastic, acrylic or acrylurean paint for PVC profile is used. As a rule, due to a high gloss or a specific "fatty", paraffinous texture of the PVC surface, the usual acrylic paint on the plastic lies very badly, rolls up with drops. Even the classic increase in the increase in adhesion paint with applying artificial roughness does not improve the adhesion with the base.

Therefore, before trying to put paint on the frame of windows or attachments from plastics, it will take a solid preparation of the PVC surface:

- On the eve of the use of paint, the PVC surface is cleaned from dust and dirt with soap water and washed with clean water so that there are no traces left. Ideally, the detergent for PVC details is best suitable, but an aqueous solution of isopropyl alcohol can also be used;

- The surface is treated with a special solvent-activator that improves sticking or adhesion of paint to smooth PVC profile;

- If the staining uses acrylic paint on a water basis, PVC plastic can be slightly moistened from the manual pulverizer, and then apply a paint material with a brush or by painting.

Important! It should be borne in mind that the quality of the painted surface depends primarily on temperature and humidity. The higher the ambient temperature, the better the clutch, and above the speed of the drying.

After about a couple of hours, the PVC applied at a temperature of 20-23 about the paint will cease to stick to the hands, and after 26-40 hours, the drying process of the painted surface will be completely complete.

Water soluble acrylic paints allow the painted surface of PVC most different colors And shades. According to the paint manufacturers, the Tinting Installation, with which the toning and the color adjustment is performed, more than 2 thousand color compositions can be issued.

Technology of dyeing household items from PVC

The high quality of the surface in the surface can be obtained only if we use specially developed tools for painting surfaces from polychlorvinyl to any modification. More simple materialsFor example, the frames and cladding of metal-plastic windows can even be painted with acrylic materials, but to obtain an exemplary glossy surface, paint will require a paint containing modifiers and polyurethane varnish.

Therefore, to obtain high-quality perfectly smooth textures from PVC most often use:

- Polyurethane paints and varnish compositions of FEYCO AG, Switzerland;

- Acrylic urethane paints "Paliplast RP BASE" used for industrial painting of PVC plastic.

For your information! Painting compositions "Paliplast" are produced on both water and lacquer-based.

Despite the fact that, after drying, the water-fused compositions "Paliplast" are not washed off with water and withstand the multiple washings of windows and frames, periodically it is necessary to restore the protective layer with varnish, for example, "Paliplast RP 022 Varnish".

Staining plastic surfaces PVC at home

The most popular treatment procedure of polyvinyl chloride plastics is the painting frames of metal-plastic windows. Not everyone likes white color The standard PVC cladding, or the owners want to make windows of their store or salon more expressive, in any case, the windows of the windows do not represent any particular difficulties if you use materials for PVC "Paliplast RP Base".

It will only be necessary to stick the window, slopes, glass and rubber compactor frames with a polyethylene film with a painted tape, and can be stained by the method described above. The easiest way to put paint on PVC profile Tassel or roller, but the best quality is obtained when using collapse low pressure. The viscosity of the paint is small, but the presence of mineral fillers can sometimes lead to blocking the nozzle or poor spraying, so the paint solution must be cleaned from the films and mix thoroughly.

More complex is painting decorative and protective elements from PVC plastic on the car. Most often it is moldings and lining inside the interior of the machine. The size of the details is small, so it is best to use aerosol packaging for PVC plastic staining. The composition includes an activator and solvent, providing good adhesion to plastic and rooted drying of the applied layer.

Color small details From PVC, you can with a preliminary dismantle from the car, and directly inside the car. In the latter case, it will be necessary to install a fan to make an aerosol flow from the cabin and make a apron from polyethylene filmwhich will close the space around the painted part of PVC.

Full-size parts from polyvinyl chloride must be dismantled, clear from dust with alcohol or a tool for washing windows, and after that an aerosol with thin layers, 50-70 microns thick.

Complex options for painting PVC plastic

To large parts of the body kit or spoilers, paint can be applied using a sprayer or collapse. Initially, it will be necessary to perform surface matting with thick paper and micron-size abrasive powder. Next, plastic is thoroughly washed and dried.

Before applying paint, the surface will be required to wipe the PVC napkin moistened with solvent "P646" and can be painted. If the thing is very thin and soft, then the first layer is better to perform a polyurethane varnish "Feyco", after which you can apply required amount layers of paint.

In the same way, you can paint polychlorvinyl pipes, framework frames, even glass and furniture. To increase the adhesion of paints to an absolutely smooth and inert glass surface, FEYCO offers to add a special reagent "Fey (N) Vetro ZUSATZ 501 to the paint. Polyurethane I. epoxy compositions It is possible to paint metal enough, stone, plastic, wooden surfacesAt the same time, the quality of the clutch is significantly higher than that of acrylic and water-dispersion materials.

Separately, it is necessary to mention the painting of soft PVC fabrics, such as covers or an inflatable boat housing. Most polyurethane paints It can be used for dense PVC tissues under one condition. Staining is performed using a barrier sublayer from a solvent in a solvent in proportion 1: 3 of the "Feyco UniversalPrimer 2159" soil, with the addition of "Fey (N) Vetro ZUSATZ 501". The sublaw is applied with a thin layer of 20-25 microns with a thin layer. Subsequent staining is performed by conventional polyurethane paints.

If there is no special desire to look for optimal recipes for staining soft tissues, the barrier layer can be done using aerosol paint for cars.

Conclusion

Polyvinyl chloride staining is not a sufficient task, if you use correctly selected materials. Given the high durability of PVC plastic, the demand for special paints for decor or repair is only increasing, so the technology of staining is improved, and, apparently, in the near future, the problem from PVC painting is finally solved.