Build a woodshed in the country. Not a complicated instruction on how to build a woodcutter with your own hands

Shed or build a woodshed with your own hands, providing stored firewood optimal conditions. It's about last version and the features of the construction of this building will be discussed.

Choose a place

The convenience of its use depends on the correct placement of the building, therefore, when choosing a place for a woodcutter, consider all the nuances. The structure should not be located in the most visible place and interfere with movement around the site. For a woodcutter designed for a large amount of fuel, take care of the convenience of approaching it by car, otherwise it will be a difficult task to move the brought firewood to the storage place.

Big woodcutter

If firewood is used to heat the house, they are placed near it. The fuel used in the preparation of a barbecue or kindling a bath, respectively, is stored closer to the listed buildings. There are no special requirements regarding the terrain, but fit places with high humidity Not recommended.

Drawing up a drawing of the site with the designation of all buildings on it, including the future woodcutter, will help not to be mistaken with the location. Based on the scheme and the existing free space for construction, it will be easier to decide on optimal view buildings.

Type of woodcutter

The simplest construction of a woodshed is an extension to the house, which has two walls, a roof and a base raised above the ground. Such a structure is stable and saves on material due to the absence of a rear wall at the point of contact with the main building.

The second option is a separate building. It can look like a full-fledged firewood shed with a door, or it can be made in the form of a canopy with three walls.

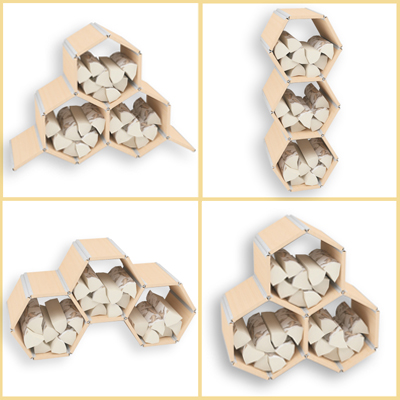

not for storage a large number logs, portable woodsheds are convenient. You can make them from old barrels, pallets, metal rods and even vines.

Wood shed

Wood shed The main purpose of a firewood shed is to protect fuel from moisture and dampness, therefore, almost any materials that can provide suitable conditions. The most commonly used board, metal, profiled sheet, there are also structures made of timber, logs and polycarbonate. A good solution would be to line the woodshed in the same style with other yard buildings.

Choosing a drawing

The drawing of the structure will help to accurately calculate the amount the right materials and facilitate the construction process. When choosing the right type of woodcutter, start from the need for fuel. If you plan to consume a small amount of firewood (up to 3 m³), a design in the form of a canopy or a small shed with a door is suitable, and for large volumes it is recommended to make a woodshed consisting of several sections.

Construction scheme

Construction scheme To determine the need for firewood, keep in mind that a house of 100 m² with furnace heating in the cold season, about 2 m³ of well-dried pine firewood is required (they are considered dry after a year of storage from the moment of sawing). Fresh firewood will need 2 times more. In the storage it is desirable to have a supply of fuel for 2 seasons, taking into account heating and additional costs (barbecue, sauna).

Selection of materials

Wood - best material for construction

Wood - best material for construction Before you build a woodcutter, you will need to decide on the materials for construction and purchase them. If the structure is stationary, the list of necessary items will include:

- supports (from timber or metal);

- corrugated board, slate or metal roof tiles;

- wooden beams;

- everything for cooking concrete mix(cement, sand, gravel);

- nails and screws;

- metal corners.

Boards are suitable for wall cladding, sheet metal, you can lay them out of cinder block or brick. If you have recently completed the construction of a house and there are unnecessary leftover materials, it is more economical to use them.

Selection of tools

To build a woodcutter standing on supports, you will need a tool for earthworks- a drill, a shovel, as well as for woodworking - a saw, a planer, an electric jigsaw. If the skin is metal, you should get a grinder. In addition to the above, auxiliary equipment is useful:

- ladder;

- container for mixing cement;

- hammer;

- drill with a mixing nozzle;

- pliers;

- twine;

- measuring tool (tape measure, building level).

Preparation for work

Antiseptic treatment

Antiseptic treatment Preparation for construction includes pre-treatment of wood and clearing the site at the location of the building. Processing means impregnation with antiseptic and water-repellent compounds, which is necessary to extend the life of materials.

Then the selected part of the yard is freed from weeds, shrubs and tree roots, if any, and proceed to the construction of the foundation. The base is made of a columnar or tape type. You should also take care of logs made of bricks or cinder blocks (the minimum height for them is 7-10 cm), laid on top of the foundation, so that the building is raised above the ground.

Stationary woodcutter

Consider how to build a stationary firewood shed standing on a columnar foundation with your own hands. The first stage is digging holes for supports. Pits are made with a garden drill or a shovel, while their depth should allow the posts to be installed no higher than the freezing level of the soil. Otherwise, when the soil swells, the building will warp.

Sand with crushed stone is poured at the bottom of the pits, foundation piles from a bar (with a diameter of 20 cm or more) are installed on top and poured with concrete. The correctness of their installation is checked by a level and a twine stretched between the supports. The purpose of this check is to make sure that the posts are in line and fixed vertically.

Important! To make the roof sloping, supporting pillars do different heights. The minimum height difference between the front and rear piles is 15 cm.

The next stage is the connection of the front and rear supports. To do this, the timber (15 cm in diameter) is fixed with long self-tapping screws to the poles at a level of 10 cm above the ground, reinforcing the junctions with metal corners. In the same way, the upper strapping is done. Then the upper and lower logs are fixed and a vertical frame is installed.

Connecting a beam with corners

Connecting a beam with corners If the design provides for a door, two more vertical racks of timber are inserted at the opening site, on which it will be hung. The horizontal surface of the woodshed is sheathed with a standard floorboard, leaving small gaps for air circulation. The walls are performed in the same way, using the same board or slab (side part of the log).

The roof is covered with corrugated board or slate. You can save money and make it from a slab, like walls, but in this case, roofing material or ondulin must be laid on top, fixing it with nails with stainless steel gaskets.

For a woodcutter with a door, it is advisable to make a visor over the entrance. The material for it can be wide board, planted on self-tapping screws and additionally fixed with two side supports.

The finished structure is painted or varnished. This is not necessary, but will provide additional protection to the material and decorate the building.

Wall variant

An economical option of how to make a woodcutter is an extension to a house or a utility block. This building is usually placed near the northern wall of the building so that the firewood is not constantly under the sun.

The construction of a wall-mounted woodcutter is similar to the technology of building a stationary structure. The only difference is the roof, the arrangement of which must be given Special attention. Due to the specifics of the location during precipitation, water from the roof of the main building will drain onto the extension, therefore, to prevent moisture stagnation, the roof of the woodshed is made flat. In this case, the slope should be directed away from the wall.

Woodshed combined with the house

Woodshed combined with the house Portable version

For those who do not need a lot of firewood or want to always have a supply of logs near the barbecue area or by the fireplace, and the stationary woodcutter is far away, a portable design will be convenient. There are many originals for sale. ready-made options made of wood and metal, but a self-made portable woodcutter is no worse, and when connected to fantasy work, it can turn out even more interesting. And it will definitely cost less.

One option is to use the old wooden barrel, which is in almost any household.

New life old barrel

New life old barrel The sequence of work is as follows:

- We put the markup on the barrel. Its central part with one of the hoops remains intact, and the sides are cut off with a jigsaw so that it looks like a basket with a handle.

- The saw cuts are sanded.

- The remaining hoop is fixed with screws or bolts.

- Two figured parts for the legs are cut out of the board.

- In each of the parts, two holes are drilled on the sides, into which the skinned cuttings are inserted. This will be the stand.

- The details are varnished or stained, and the portable woodcutter is ready.

And those who are familiar with the basics of weaving can make a small firewood shed from a vine. For this you will need wooden slats, flexible wire and wicker. A rectangle is knocked together from the rails, which will become the base. Then, on its opposite sides, holes are drilled every 3 cm and thick branches of the vine are inserted into them, they will serve as the basis for weaving.

Woodcutter from a vine

Woodcutter from a vine In the middle of the rack frame, a wire is attached and a handle is formed from it. Further, the main rods are bent and braided with thinner ones. Take the diagram below as the basis for the pattern. At the end of the work, the wire handle is also braided with rods and the ends of the wire are carefully masked.

Having an idea of how to build a woodshed with your own hands, keeping firewood dry is not difficult. By choosing the right design, you will also be able to appreciate the advantages of such storage and be sure of the safety of fuel at any time of the year.

On the personal plot there are no unimportant buildings - the convenience and style of this space are made up of little things. So you can store firewood for the winter by approaching the process creatively - by arranging a beautiful firewood shed from available materials. Participants offer interesting design solutions that you can use.

In the old days, not only a building for storing firewood was called a woodcutter, but also a trader in this common type of fuel. Special attention was paid to the preparation of firewood, proverbs, sayings and sayings were composed: “Hunting to amuse is not chopping firewood”, “How does the winter know that the poor have no firewood”, “The firewood was burning hot, it was parko in the bathhouse; there was no firewood - and everything was gone", "A lazy husband has no firewood in the yard."

forum member dim-dim decided to make a neat woodshed and finds out how open the design should be:

- Of course, the woodcutter must be ventilated. But I don't want the rain to pour down the side. Maybe close the walls with polycarbonate?

denforever:

- If you make the woodshed too open, in winter the snow will cover the wood. Personally, this is how it is with me, and when you dig up firewood and bring it into the house, a puddle flows.

Shaitan:

- The firewood itself is often brought raw, only sawn and split - they need to dry out. I will do the woodcutter for myself like this: a metal frame covered with a chain-link. Under the roof - a place for birch brooms. concrete base(easier to sweep). Gate with a lock (from hooligans). Cheap and cheerful, it is blown, but it does not get wet, plus bark beetles from firewood do not eat metal.

Bark beetles are a serious reason to think about where it is better to arrange a woodcutter. Many homeowners and summer residents, in order not to go far, store firewood close to the wall of the house or bathhouse.

Megapon:

- I would not make a woodshed next to existing buildings, so as not to rack my brains later on how to get rid of grinder beetles, ants and other insects that live in firewood.

Shaitan:

- Fact! Insects will eventually move from. The best way- a separate woodshed.

forum member OlegCheb he built his free-standing woodcutter in three days from materials left over from the construction of a house and a bathhouse. As a support, he used six concrete blocks 200x400x600 - the ground was previously excavated in the places of their installation; covered, spilled with water and packed with sand. On the concrete blocks the forum participant laid roofing material and laid the bottom trim of round timber with a diameter of 120 mm. Then the solid owner mounted the racks and top harness from 100 mm timber, installed rafters and crate. The roof of the woodshed is covered with ondulin.

As a material for the walls, a 30 mm board was used, which previously served as a formwork during the construction of the foundation of the bath. It was a pity to throw it away, and OlegCheb beat off the concrete with a hammer, and then cleaned the corner grinder with petal disk. The builder put the same board on bars 40x80 mm and 20x30 mm, from which he made the door. So that the building does not look dull, the forum member mounted the walls according to the chess principle, through a 40x40 mm beam: one board was hemmed in front, the other in the back. To give color, the tree was covered with rosewood stain. That's what came out of it:

But this one, a little more open, wooden woodshed in chocolate white color scheme appeared on the forum member's site numis :

With oblique rain, water gets on the outermost logs, but thanks to ventilation, they dry out quickly.

Member of our forum lancen his storage for firewood ... weaved. The material for the original woodcutter was the flexible branches of trees. The owner also uses the building as temporary storage for tools.

Members of the forum advise to determine the size of the firewood shed based on the imported volume of firewood and the space that already stale logs will occupy. You will be heated with dry wood, and fresh wood will wait for their turn and lose excess moisture. For convenience, the firewood shed can be divided into sections.

In order not to walk with a bunch of firewood in the dark, it is also important to provide lighting for the woodshed. Some members of the forum additionally install lights with a motion sensor outside the building. They turn on automatically, and the owner no longer needs to go back to turn off the light.

Woodcutter or woodpile?

Or maybe not bother building a woodcutter, and put firewood in a woodpile right on the ground, experimenting with the shape of the structure for beauty?

Stacks in the form of haystacks in the Pyukhtitsky Dormition Monastery. Kuremäe village, Estonia

– Woodpile on the ground is good for those who have a large consumption of firewood. And who has a small one - it is better to lay it higher so that it does not rot, - says the participant of the forum Hel .

Some members of the forum use open woodpile only in the summer, and in the fall they put the dried firewood into the barn. It remains to choose which of the options for storing firewood suits you best.

You can read the advice of members of the forum on how to build a beautiful firewood shed in our forum. Learn about overhaul old woodshed is possible. In it is told about properties of different wood fuel. You can read about making a wood splitter with your own hands.

- a place of unity with nature. A real open hearth is built on the street, it heats up a little to the side, warms the soul in the house, and helps to cook in the kitchen. Therefore, firewood is vital on your own site.

They need to be stored somewhere, placed, carried somewhere. In solving these problems, firewood for summer cottages helps. This is not an easy stationary structure, which serves to store the total supply of fuel. But also special devices that allow you to neatly and aesthetically organize the storage area for firewood near each firebox.

For each type of firewood, you need to use your own materials. Their choice depends on the size of the structure, capacity, mobility, as well as where it will be located.

Anyone who is at least a little familiar with the construction business, carpentry or knows how to use welding machine. The main thing here, as in any business, desire.

An example of a combined firewood

An example of a combined firewood Outdoor firewood

The largest of all existing structures. Its main task is to create optimal conditions for storing a large amount of firewood. This means protecting them from precipitation, the harmful effects of moisture, creating a well-ventilated space, as well as ensuring that firewood is neatly stored and easily accessible at any time.

Most often, a street firewood shed is a small detached barn. But a creative approach to the design of the woodpile is also possible.

To create a simple wooden firewood rack, you will need to perform the following steps.

The firewood itself is ready. However, before starting operation, it is necessary to figure out on what basis the firewood will be laid. Their direct contact with the ground is highly undesirable. Can be used as a layer construction pallets. Or build a similar design from improvised materials. For the manufacture of a metal firewood rack, a lattice base welded from reinforcement will be an excellent solution.

Now you can start laying firewood. There is more than one way to correctly place the logs, which does not just give the firewood an aesthetic appearance, but also allows the firewood to dry, which means that it is better to burn later. In addition, a blank wall of firewood can be decorated by creating a whole picture or scene from logs.

Original firewood in the form of an owl

Original firewood in the form of an owl Firewood for a bath

Most often it is also street fixed structure. But unlike the general storage, the firewood for the bath is much smaller and is located in the immediate vicinity of the entrance. It makes no sense to build the same massive barn. The local canopy should contain as many logs as necessary for several full-fledged fires, just so as not to run once again with armfuls of firewood from a remote storage to a bath and back.

You can make a woodcutter in the country in the form of a small wall canopy. It should contain logs arranged in one row, to a height no greater than human height. And in length to be as long as the wall of the bath, convenient for its location, allows.

An example of a firewood rack made along the wall of the main building

An example of a firewood rack made along the wall of the main building It is not necessary to prepare a massive base, however, it is necessary to mark the corners of the firewood with bars or metal rods by driving them into the ground. Fill the sides with boards, slats or fasten a chain-link mesh. If desired, you can get by with just two corners of the base, and instead of two more, use the wall of the bath, and attach directly to it.

When the walls are ready, go to. It will also be single-sided, but this time the water flow will occur on the front wall. To do this, you need to attach either a metal corner or wooden block. Fix the second similar element on the racks - it should be located below. Now we collect a symbolic crate and mount any roofing material.

Shed roof on woodshed

Shed roof on woodshed Despite the fact that the firewood under such a canopy will not be for long, it is not worth stacking it directly on the ground. To do this, it is worth putting construction pallets on the bottom or assembling a bottom crate, where to place the logs.

As practice shows, some firewood is stored under a canopy or in. But in such places there should be natural ventilation. The real owners build a firewood storage as a separate building.

How to build a woodcutter with your own hands is of interest to many. Simple Tips specialists will help to cope with the construction of the structure, even for those who have never built. Moreover, it is possible to build a structure not only from new materials, but also from used ones. For example, old chopped windows can become an amazing woodcutter, you just have to put a little work and imagination into them.

Choosing a place for a woodcutter

The first thing to do is to correctly determine the place of construction. When choosing a place to build a woodcutter, you should be guided by rationality. The building for storing fossil fuels should not be in sight, because it is not a building that is the focal point of the courtyard. But at the same time, it is recommended to have it close to home. Remember that firewood will have to be carried, and this is not such an easy physical labor. At the same time, it’s great when there is an entrance to the woodcutter. With this approach, the delivery of fuel to the storage site will not be difficult.

If you do not heat the house with the help, the fuel storage place must be located near the bathhouse. This kind of construction should be convenient, and firewood will always be at hand.

To select the “right” place to build a woodshed, draw a site plan. This will allow you to better plan the construction and determine the most suitable location. It is worth giving preference to the hills. Experts do not recommend building a firewood shed in the lowlands, as moisture accumulates there, and this firewood is useless.

A firewood shed can be erected as a separate structure, but very often it is made as an extension to a house, bathhouse or barn. It depends on your personal priorities, the size of the plot, your imagination. Simple designs allow you to build an amazingly beautiful structure.

Choosing the type of woodcutter

After the place for the construction is determined, you can proceed to the choice of the type of structure. At this stage of planning, it is necessary to determine the size of the structure, depending on how much firewood will have to be stored throughout the year. The first thing to do at this stage of construction is to decide on the budget and whether you will build an outbuilding from new or improvised materials. Exists great amount types of woodsheds, because everything here depends on the imagination and capabilities of the owner of the site and his family members:

- . This is the most simple design storage facilities for natural fuels. It has three walls, a canopy roof and a floor. An excellent option when building a canopy is a raised floor that will not pull moisture from the ground. The canopy can be built as a separate building or as an extension to or a house.

- As. This very elegant design with a door allows for proper storage of firewood and has beautiful view. Such a woodcutter will perfectly complement the courtyard ensemble. It can be built as a separate building or as an economic unit.

- Open type. These structures have a presentable appearance and externally fit into any interior. woodcutter open type consists of two walls and a raised floor. Many attach a roof to it to prevent precipitation.

- Barn. In fact, this is an ordinary economic structure, only smaller. Such a structure also has an insignificant foundation. It can be equipped.

A do-it-yourself woodcutter, whose photo is presented on the Internet, can have the most different forms. This building does not belong to capital construction and is being built very quickly.

Materials for construction: do-it-yourself woodcutter

When building a firewood shed, the most different materials. Most often, a tree is used for such purposes. The woodsheds from those yards look very nice, where everything is decorated in a single natural style. The most important thing is that the firewood shed in the country, made with your own hands, protects the fuel from precipitation and has natural ventilation.

Very often used in the construction of a woodshed. With this installation, special attention should be paid to the ventilation system. To do this, leave gaps between the logs.

They look elegant and unique. Such a firewood shed is not built in large dimensions. It looks especially sophisticated in the recreation area, where it is located outdoor fireplace or barbecue grill.

You can also build a firewood shed from improvised materials. Imagine a little and see how you build a structure. As practice shows, the construction of such a building does not require certain materials. The main thing is to create a natural ventilation system.

Before proceeding with the construction, it is worth determining the budget, because you can build a firewood shed of any design. The construction of a storage for firewood depends on the money spent.

Ready-made woodsheds - a simple construction solution

Today on the market building materials you can buy ready-made firewood sheds of any type and design. This the best solution for those who don't own free time for construction or simply does not want to engage in the construction of structures. On sale there is also a chic firewood shed made of timber, which looks like a gazebo, and an exclusive forged firewood shed, made manually, and the construction of polymers. The choice is great in a variety of shapes, models and colors.

Necessary materials and tools for the construction of a woodshed

Before you start building, you need to create a clear drawing. The sketch will allow you to quickly build a woodshed, especially if shelves for storing things are planned in it. A do-it-yourself firewood shed, the drawings of which are presented on the site, allows you to conveniently store firewood. The drawing clearly shows the dimensions of the building and the entire construction process. Next, you should purchase or prepare tools for construction. For such work, you will definitely need a drill to create holes for the pillars, a hacksaw and a hammer for working with wood.

It is worth remembering that appearance storage depends on the quality of stacking logs. If the firewood is placed randomly, it will not work to create harmony, no matter how hard you try. Therefore, logs should be laid carefully. The layout method is determined by each according to his personal requirements and desires.

Decorating a woodcutter is limited only by your imagination. Forged details are perfect for decoration. They are ideally combined with any materials. If you have a fireplace in your house, then you can complement the interior with a small forged woodcutter, which is located directly next to the firebox. Such a mini woodcutter will decorate and.

A firewood shed is a simple structure that greatly helps to conserve firewood. Experts advise harvesting logs immediately for several years. Such a supply will not be excessive, but will allow you to feel confident, because each person uses the barbecue, heats the stove or fireplace. Well, a place to store firewood will always help keep natural fuel dry.

A firewood shed is a special free-standing structure designed for warehousing and storing firewood. The choice of material and method of manufacturing a firewood shed is determined by the budget set for this building and the requirements that future owner presents to him. The most common structures are made of boards on a simple frame of vertical wooden posts covered with a shed roof.

What should be a lumberjack?

The main requirement that a design for storing firewood must meet is effective protection wood fuel from water coming in the form of precipitation. Since rain or snow in most cases falls vertically on the surface of the earth, it will be quite enough for a woodcutter to install shed roof. Such a roof collects the bulk of sedimentary water and guarantees the safety of firewood for several months until it is used.

The design of a woodshed is necessarily carried out taking into account how often and in what quantity firewood is used. If wood fuel is taken from a storage place for daily needs 1-2 times a day, then access to firewood should be free and the size of the building itself should correspond to the amount planned to be stored.

For example, in a GAZ-53 car, in the common people “Lawn”, the dimensions of the body are 3600x2200x600 mm, and when laying in bulk with a slide, it fits at least 6.3 cubic meters already chopped wood. The next section contains drawings indicating the exact dimensions of possible buildings: they can be used to more accurately calculate the amount of material that each structure can accommodate.

As far as wall construction is concerned, the requirements for the level of protection they provide will depend on several factors. First, you should take into account the weather conditions in a particular region. For a dry climate with little rainfall, and simple canopy without enclosing structures around the perimeter. If rains in a certain area are a regular phenomenon, then it is better to take care of making light walls from horizontally packed boards with small gaps.

Regarding the frame of the woodcutter, its strength is also determined by climatic characteristics and terrain. If the site often blows strong wind, then the structure must be equipped not only with walls that protect firewood from slanting rain, but also with a reliable frame that can guarantee the stability of the building even in very windy weather.

Depending on the level of complexity of each structural element, the woodcutter may look different. It is made as an ordinary mushroom with a circular roof, as a canopy, resting with one edge on the wall of a house, garage or other building on the site, or as a small shed with light walls and columnar foundation minimal complexity.

Woodcutter drawings

Let us first consider the drawings of a woodcutter of a classical design in the form of a small free-standing covered frame with lattice walls.

The detailed technology of its construction will be described in the next section, and here, using the indicated dimensions, you can calculate the approximate amount of firewood that can be stored under the roof of such a building.

The next woodcutter has compact dimensions of 1800x472x2015 mm. It is suitable for storing a small supply of firewood for a summer house or a bath.

The rear wall is made in one piece and can be turned to the windy side, from which slanting rain flows are most often observed.

For the most convenient approach to firewood and simple laying of the material, the design in the form of a fungus, located below, is well suited.

more complete and detailed drawing with an indication of each specific element of the building is available under the spoiler.

The disadvantage of such a woodcutter is the complete exposure of wood fuel from rain from the side of the walls. Manufacturing of this type buildings will be acceptable only in areas with low rainfall.

A small woodshed that can be used to temporarily store a small supply of firewood. It would be appropriate to place it near the barbecue, fireplace or stove so that wood fuel is always at hand.

How to make a woodcutter with your own hands?

The technology for building such a small firewood storage is quite simple. The first step is the construction of the base, in this case, small foundation blocks. With the same success, on such a foundation, you can take cubes made of several standard bricks fastened with mortar.

The installation procedure begins with digging a shallow hole. Then sand 10 cm thick is poured into it, after which it is compacted, spilled with water and compacted again.

The next stage is the placement of foundation supports in prepared places with the alignment of the entire structure on one level. Each block must be covered with roofing material or special durable waterproofing material for guard wooden frame from groundwater intrusion.

Next, a wooden strapping is made around the perimeter of a bar of 50x100 mm and installation cross beams floors of the same material. Then vertical racks of the frame and transverse ceiling beams along the perimeter. Racks are fixed with special jibs in the lower corners of the structure to give it strength and stability.

The photo shows how simple enough is made rafter system roof, and on top of it a crate of regular board inches for laying the roofing layer of metal tiles. Final stage- sheathing of gables of the roof and exterior finish walls made of boards with gaps for ventilation.