Heating bastard bastard. Heating and cooking furnace "Baby": design and project with a friend

If the building is conceived country housemost comfortable for comfortable accommodation in it, then without small oven It usually does not do, especially if it is planned to use it most of the year. The lack of experience in furnace work should not stop the owners who want to put the furnace on their own. Just need to choose the appropriate, not particularly complex option, whose design is simple and understandable.

In addition, for a large heating structure, which has an intricate configuration of internal channels, as a rule, in the country house, simply lacks the place. Consider and uncomplicated performed options that are suitable for a small house, and for a beginner bit – in short, the stove laying is simply and practical.

To easier it was to decide on a suitable model, it is necessary to highlight several conditions that are important for right choice. Well, then, consider several options, stopping on the optimal area and configuration of the premises of the house.

General requirements for brick furnaces

The conditions that the selected design should correspond directly will affect the quality of the heating of the house, so you should not neglect the information on which, on the contrary, it is worth paying close attention. These factors include:

- The sizes of the furnace design must correspond to the area to which it is installed, since the heat transfer depends entirely on this parameter.

- In addition, it is necessary to choose the correct shape of the furnace structure. The side walls of the oven, warming up, give a greater amount of heat, while the indicator of the front and rear walls is lower than 3 ÷ 4 times. Therefore, if you need to heat two rooms at once, it is necessary to choose a narrow and long furnace, which can be embedded in the wall between the rooms.

For the efficiency of heating, the T-shaped version of the furnace is often installed. It can only be designed for heating or perform two functions if the model is selected in which the cooktop is provided. Such a furnace is able to heat up to four rooms having a small area.

- The following condition that is important to consider is the location of the building inside the house, it should be as rational as possible. So that the furnace was functional, worked as a device for heating and cooking, it must be installed so that the cooking plate goes to the side of the kitchen, and one or both side walls looked into the living rooms.

- Choosing a furnace, it is very important to take into account its heat transfer - this parameter must correspond not only to the area of \u200b\u200bthe rooms, but also their location and the number of external walls. Determine the choice of furnace on the area of \u200b\u200bits surfaces, depending on the features of the room, this table will help:

| Room Square, m² | Not an angular room inside the house | Single angle room | Outdoor room | Parishion |

|---|---|---|---|---|

| Surface furnace leaving m² | ||||

| 8 | 1.25 | 1.95 | 2.1 | 3.4 |

| 10 | 1.5 | 2.4 | 2.6 | 4.5 |

| 15 | 2.3 | 3.4 | 3.9 | 6 |

| 20 | 3.2 | 4.2 | 4.6 | - |

| 25 | 4.6 | 6.9 | 7.8 | - |

- Do not need to be reinsured and choose for small house Massive oven, so how to warm it, it will take a lot of time and a sufficiently large amount of fuel, with all the fact that a significant part of the heat generated is simply "thrown into the pipe". In addition, small designs sometimes work even more efficiently than structures that occupy half the room, as the heat transfer depends largely on internal design Furnaces, and not only from its massiveness.

- Any, even the most heatary oven, will be ineffective if the house is not insulated, since all the heat generated by it will go through the walls, windows and overlaps. There will be a very large amount of fuel in these to maintain the temperature in the rooms at an acceptable level.

If it is planned to save on fuel, getting high-quality heating, you should warm the building well and choose a cap of the furnace, which, thanks to the numerous channels, will hold the heat transferred to the living space for a long time.

How to choose the right place for the furnace?

The location of the furnace in the house is determined in advance, even before it is built, in the preparation of the project, it is possible to establish a heating structure in the right area, where heat from its walls will be rationally distributed throughout the house. In addition, it is much easier to equip the foundation for the furnace to build the house, and in terms of work. You must immediately say that the foundation for the furnace must be installed separately from the foundation of the house, that is, there should be a distance of at least 150 mm between their walls. Otherwise, when shrinking (and it will definitely be uneven for different in the mass and area of \u200b\u200bthe structure), one of the foundations can begin to collapse, and the walls installed on it are deformed.

- If there are several rooms in the house, the furnace must be installed so that it is located at the crossroads of the walls separating the house on the rooms. But, since the foundations of buildings should not come into contact with each other, interior walls We will have to do light, without foundations. This variant is presented on the above scheme.

- In some cases, the owners of the house prefer to install a stove near the entrance from the street, since the thermal radiation from the walls creates an excellent veil from cold streams.

- The placement of the flue hatch near the entrance door will save from excess garbage in residential roomsSince they do not have to make firewood or other fuel. However, installing the stove in such a way, it is necessary to arrange the firebox door so that it is impossible to burn it.

- The walls of the heating structure should not be adjusted to the walls of the house closely, that is, it is necessary to provide free access to any of them, as they require periodic control for security purposes, and the internal channels of the furnace are cleaning the cameras. Sometimes the furnace is part of the wall of the house, in this case there is a reliable heat metering between it and the ends of the partition.

- If the furnace is installed in the already built house, then, planning its location, it is necessary to provide that the chimney pipe falls between the beams attic overlapwhich should be at a distance from it at least 150 mm, with the creation of thermal insulation "gasket" filled with heat-resistant material. For this, most often around the pipe fix the metal box, which is filled with a grain fraction, mineral wool, vermiculite, or just sand.

- The playground in front of the furnace is stove must be styled by heat-resistant material - it can be a metal sheet or a ceramic tile.

You may be interested in information about what is

Models simple on the design of small brick stoves

Brick ovens of small sizes do not lose their relevance today. And this is despite the emerged alternative heating options, as many of these new products are too expensive, while others are inaccessible in country conditions. The traditional stove for Russian homes or will help out in any situations - it will warm up, and cook cooks. Therefore, if gas is not supplied to the house, and the electricity is often disconnected or just want to save on it, it is worth choosing a furnace, the design of which includes a cooking panel. Knowing about the demand of models of small sizes, engineers have developed quite a lot of their options. Some of them will be discussed below.

Oven "Kroch"

The name of the model "Kroch" in itself speaks of the size of this furnace, and it is suitable for a residential building with any square. Moreover, when the design is properly installed, it is quite capable of dropping not one, but two rooms and the kitchen. For dacha house This compact stove will be the perfect option, as it is able to create in it in spring and autumn, as well as in crude or cold weather in summer.

This stove is called "Cooking", because it is easy to design, and with a serious approach may well be built even a novice master. The furnace has very small sizes, only 640 × 770 mm at the base, so it will be suitable for small roomwhere it is decided for it to highlight the corner.

The designer of the furnace A. Sushkov successfully combined compactness, elegance and functionality in it, so "Kroch" will perfectly fit out not only in the cottage room, but also will decorate its cozy interior of the private house. This furnace is designed for heating one or two rooms with an area of \u200b\u200b18 ÷ 20 m², and has the following characteristics:

| Furnace parameters | Numeric values \u200b\u200bof parameters |

|---|---|

| Width and Length Based | 3 × 2.5 bricks or 640 × 770 mm |

| The height of the design to the pipe | 2030 mm |

| Weight of the furnace | 1260-1280 kg |

| The depth of the furnace | 746 mm |

| Kpd. | Up to 70-75% |

| Heat transfer at one-time furnace | 1760 W. |

| With a three-sided firebox | 2940 W. |

| Cooking panel | SingleForch |

The designer well thought out the rationality of the furnace, so it gives excellent heat transfer for its small size. In the process of the furnace of this model, its lower section is heated, and the "cap", which is in the upper part, retains the highlighted heat and slows down its chimney care. The furnace is equipped with a "summer" stroke, which allows you to heat only the hob, without heating the entire design, which is especially important in the warm season. "Krocha" has three design options, which differ in each other by the arrangement of the cooking plate relative to the furnace, but most often used improved and most convenient type, in which the stove and the furnace are located on the one hand. Such a location is convenient because the furnace can be installed in such a way that the furnace and stove will be in the kitchen, and two other walls, if you integrate them into the partition, heat the two rooms through the wall from the kitchen room.

In order for the furnace to serve as long as possible and was safe, its fuel chamber is laid out with fire-resistant chamotte brick. Such walls are withstanding not only wood heat, but also that fuel as coal, briquettes and peat.

To the level of the stove oven has smooth walls, and above the heat door, under hobster stove, throughout the perimeter of the structure, a protruding forward by 30 ÷ 35 mm is laid out, a series that shares the design into two departments: the upper, air-gas and lower - fuel. In the top of the furnace there are channels for circulation of heated air. They contribute to the highest possible retention of heat in the furnace, without letting it go to the pipe immediately.

In theory of the developer, this furnace should be equipped with a firing door with refractory glass, through which flames are perfectly visible. Therefore, if the "kroch" desires can be used as a small fireplace. Such a door may well be replaced by a conventional cast-iron option.

Since the furnace has a small size around the perimeter, it will require less consumables for it.

| Size in mm | Number, pcs. | |

|---|---|---|

| Shamotny Brick Sha-8 | 21 | |

| Red brick (without chimney pipe | 352 | |

| Figured (Rounded) Red Brick | 124 | |

| 350 × 250. | 1 | |

| Glass fire door In the cast iron frame (DP-308-1C) | 210 × 250. | 1 |

| Cast iron puff door | 140 × 140. | 1 |

| 410 × 340. | 1 | |

| Metal sheet for flooring before furnace | 500 × 700. | 1 |

| Smaller valve | 130 × 250. | 1 |

| Steel corner | 40 × 40 × 5 × 520 | 4 |

Compact model furnace - "Baby"

The main advantages of the model is its small size, component of 505 × 760 mm at the base. Well, a small weight, only 360 ÷ 365 kg, allows you to install construction to a strong ferricsolated wooden floor. A small furnace has a relatively thin walls, so, heating, quickly begins to give heat into the room in which a comfortable temperature is created in a short period.

When laying this model, the oven is important to consider one point - in the first lower row of the back wall, the middle brick must be left free, that is, to lay it without a solution. It is necessary to do so that after completing the masonry, the brick could be pulled out and clean the bottom part of the furnace from the fallen solution. In addition, the resulting hole will help dry faster ready design. Then, the brick can be installed in the place already per solution.

If the furnace is planned to be installed on a wooden or concrete floor, then a heat-resistant layer is laid before masonry. Usually it is used for this asbestos sheet with a thickness of 5 mm, which is closed from above with a metal sheet or referenced and an additional solid layer. brick masonry. In addition, it is necessary to remember that the metal sheet must be necessarily accumulated before the furnace or the ceramic floor tile.

First protood finished furnace It is necessary to carry out light fuel - it may be paper or straw. After the furnace is droplet, its doors and valve open for ventilating and final drying, which should be carried out at least 7 ÷ 9 days.

After drying, the oven is recommended to bother. The question arises: . The smoke layer will immediately appear on the layer, in the event that small gaps remained between the solution and bricks. Smoke will leave black or gray stripes on the whitewash, which will reach from the defective suture. With the appearance of such traces, the seam, from which they proceed, it is necessary to completely clean from the frozen solution and fill out a new one, but more carefully and neatly.

You may be interested in information on how to do with step-by-step instructions.

If you plan to produce decorative finish The outer walls of the "babies", then you can start it only after two or three months of operation of the furnace.

The chimney of this model has such a design that it can be removed into the street in three ways:

- Having lifted the brick masonry of the chimney to the ceiling, bring it through the attic and roof of the house;

- By imagining the steel pipe and connecting it with a native chimney;

- The battered tube can be removed through the wall, pre-secure the hole of its passage by heat-resistant material.

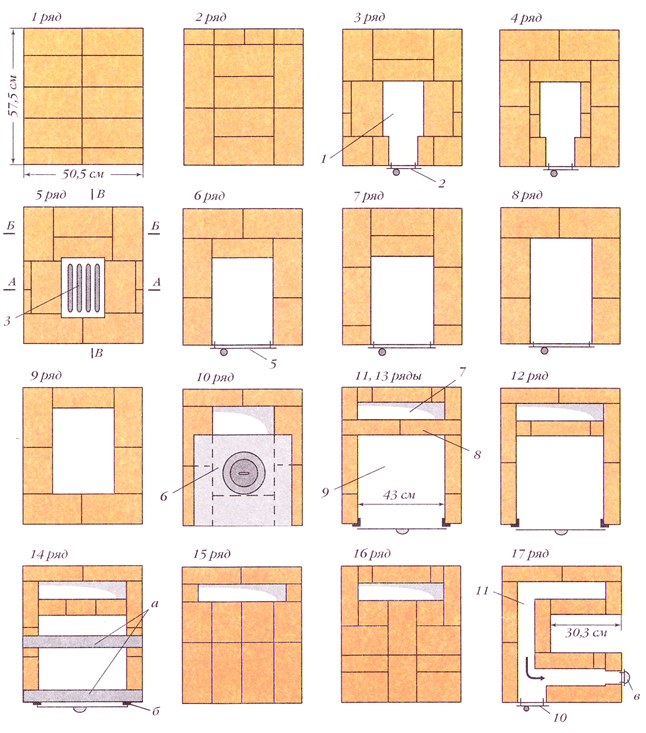

This scheme will help to figure out the design of this model. brick ovenSince it looks well viewed by the number of rows and the configuration of chimney channels.

The main characteristics of the stove "Baby" are as follows:

| Furnace parameters | Numeric values \u200b\u200bof parameters |

|---|---|

| Width and Length Based | 505 × 760 mm |

| The height of the design to the pipe | 725 mm |

| Weight of the furnace | 360 ÷ 370 kg |

| The depth of the furnace | 737 mm |

| Chimney Channel Size | 100 × 100 mm |

| Kpd. | Up to 70-75% |

| Heat Pot. | 1210 W. |

| Cooking panel | singleForch |

To build the stove "Baby", the following materials and finished elements will be required (if you do not take into account the chimney pipe):

| Name of materials and components | Size in mm | Number, pcs. |

|---|---|---|

| Chamotte Brick Sha-8 for firebox | 37 | |

| Red brick | 62 | |

| Cast iron puff door | 140 × 140. | 1 |

| Cast iron cooker | 210 × 250. | 1 |

| Single-mounted cast iron plate | 410 × 340. | 1 |

| Grid grater grate | 350 × 200. | 1 |

| Smaller valve | 130 × 250. | 1 |

| 550 × 800. | 1 |

Prices chamotted brick

chamotted brick

It is necessary to note that this model is easily improved, despite its compactness. To its design, some masters managed to add a brass cabinet and a water heating tank. In such a configuration, the "baby" can be used as a bath oven.

Perhaps you will be interested in information about what is mini

Heating stove with a small base area

This mini-furnace model has only one, heating function. It can be used to install in the country in the event that, besides it, an electrical or gas stove is provided for cooking, and there is no need for a cooking panel. Otherwise, its installation will be irrational.

She is suitable for a private house, in which you need to drop two neighboring rooms, by building the stove into the wall between them.

The advantage of this model can be safely called its compactness and high heat transfer. The side walls of the oven have a sufficiently large area, therefore, heating, they will become a kind of "battery" in the size of the size of the mixture, which quickly and efficiently transmit heat into the room. The total heat transfer from this model is about 2000 W, and 210 W accounts for the front and rear wall of them, and on the side - 895 watts.

Heating furnace is more complex internal structureconsisting of several channels that provide excellent heat transfer from the walls. Since the furnace has a decent height, then the material for it will need more.

The characteristics of this model of the mini-furnace consist of the following parameters:

In this case, the design of the furnace, as well as the structure of the "crumbs", can be divided into two departments: the upper - gas feeding, and the lower - flue. The upper part of the furnace is "Cap", consists of vertical channels, interconnected horizontal. Thanks to this feature, warm air longer delayed inside the structure, having warmed the entire area of \u200b\u200bits side walls.

To build this model, the materials listed in this table will be required:

| Name of materials and components | Size in mm | Number, pcs. |

|---|---|---|

| Red brick | 260 | |

| Chamotte Brick Sha-8 for a filling department | 130 | |

| Grid grater grate | 250 × 400. | 1 |

| Cast iron puff door | 140 × 200. | 1 |

| Cast iron cooker | 200 × 300. | 1 |

| Clean doors | 140 × 200. | 2 |

| Smaller valve | 130 × 310. | 2 |

| Ruberoid leaf for waterproofing | 1000 × 600. | 2 |

| Metal sheet for flooring under the furnace and in front of the furnace | 500 × 700. | 1 |

For simplicity of work, the wizards use special schemes-coaches to which it is necessary to navigate, performing the masonry of each row.

Prices for smoking valves

smaller valves

This scheme-order shows the masonry of the furnace from the first to the twelfth row. The construction can be conducted on the equipped foundation or on the prepared hydroelectric concrete semi. Since the design is sufficiently massive and bulky in height, install it on the wooden floor will not work.

- Ruberoid stacked under the masonry in two layers, and to simplify the alignment of the first row, waterproofing material You can draw in chalk using a long ruler, the boundary of the base.

- By producing a masonry of the first row, it is impossible to forget that the horizontality and verticality of the walls of the furnace will depend on its quality and accuracy. Therefore, before starting work, you must prepare control instruments - plumbing and building level. Some masters practice and stretch the horizontal cords for each of the rows.

- As you can see in the diagram, the door is mounted on the second row, it is formed a chimney vertical channel.

- On the fifth row of the masonry, an installation of a grate grid is made, which will block the confusion chamber and denotes the bottom of the cooler camera. Starting with the fifth and ending the 15th adjustment, the masonry is performed by chamoten brick.

- On the sixth row, in front of the grate grid, it is installed and fixed with a wire cooker.

Prices for rubberoid

ruberoid

- The following scheme represents the order, starting from the 13th and ending the 24th nearby. It shows the gradual formation of vertical channels and the furnace chamber, so it is very important to produce masonry in accordance with the scheme. Otherwise, all work can be spoiled, and it will have to redo it.

- After completing the masonry of the fifteenth row and the walls of the sixteenth, the clay-cement mixture is laid in the resulting space, and the cleaning chamber door is installed. Next, up to 25 rows, the masonry is made according to the order scheme.

- The bottom of the second cleaning chamber is drawn up on the 25th row. To do this, on top of the brick masonry of the 24th row is laid out a layer of clay-sand mixture. Then mounted the door of the camera cleaner.

- On the 28th and 32nd rows, two smoking valves are stacked, with which you can adjust the craving.

- The remaining rows are stacked according to the scheme, and with the 35th row begins the masonry of the chimney pipe.

Heating-cooking "Swedie" - a detailed description of the furnace masonry

General description and necessary materials

The final section will be presented a fairly popular model of the Furnace - "Swedish". It is chosen for detailed descriptionSince, with ease of design and compact size, it is multifunctional and very comfortable in operation.

This version of the heating and a cooking furnace has a good location of all functional elements - they are placed on one face of the structure. Therefore, such a "Swede" is usually installed in such a way that the cooking plate, oven, drying niches, and, of course, the coil chamber went aside the kitchen, and an even rear brick wall, which greatly warms up during the firebox - in the living room.

The dimensions of this design are 1020 × 885 × 2030 mm, with a capacity of 2750 kcal / hour, so the furnace is able to heat one or two rooms with an area of \u200b\u200bup to 30 square meters. m.

The presented option "Swedes" was created for certain operating conditions. So, it was created for heating country house, 4000 × 7000 mm, erected from silicate brick or blocks. However, this model is suitable for houses with other sizes, which the parameters of its heat transfer are indicated.

- Firewood, as well as other types of solid fuel can be used as fuel for this furnace.

- This model uses only the inner lining of the furnace chamber and regions located near it. Therefore, chamoten brick will not disturb the aesthetic species of the facade of the furnace made of high-quality red bricks. The external finish is not provided.

- So that the furnace was effective and corresponded to the characteristics of the heat transfer, its walls should be relatively thick (in the Pollipich), so the installation of bricks on spoons is not allowed.

- In this design laying drying chamber obligatory.

If it is decided to take advantage of this development, it is worth considering the table essential materials And calculate their cost for your area of \u200b\u200bresidence.

Perhaps you will be interested in information about how best to use when erecting fireplaces and stoves.

Table of materials that are necessary for the construction of the heating and cooking "Swede":

| Name of materials and components | Size (mm) | Quantity (pcs.) |

|---|---|---|

| Red full-length chimney brick (excluding the height of the pipe) | 250 × 120 × 60 | 551 |

| Shamal refractory brick sh-8 | 250 × 124 × 65 | 31 |

| Door for confused | 140 × 250. | 1 |

| Fire door | 210 × 250. | 1 |

| Doors for cleaning cameras | 140 × 140. | 3 |

| Oven | 450 × 250 × 290 | 1 |

| Cast iron cooking two-air cooker | 410 × 710. | 1 |

| Colonnik. | 200 × 300. | 1 |

| Smaller valve | 130 × 250. | 1 |

| Steaming valve | 130 × 130. | 1 |

| Steel corner | 45 × 45 × 5 × 1020 | 1 |

| Steel strip | 45 × 45 × 5 × 700 | 1 |

| Steel strip | 45 × 45 × 5 × 905 | 5 |

| Steel strip | 50 × 5 × 650 | 2 |

| Shelf for dryer | 190 × 340. | 1 |

| Metal sheet overlap of drying chambers | 800 × 905 × 0.5 ÷ 1 | 1 |

| Metal sheet prestope | 500 × 700 × 1.5 ÷ 2 | 1 |

| Asbestos sheet or twine for laying between brick and metal elements. | 5mm thick | 1 |

Step-by-step instructions for masonry heating and cooking "Swede"

| Illustration | Description of the Procedure for conducting work |

|---|---|

| The first solid row consisting of 28 red bricks must have a perfectly smooth surface and straight angles, as it is the basis for which all other vertical and horizontal planes and rows will be oriented. |

| The second row is laid out of 28 ½ red bricks, also solid masonry, but its drawing has several other configuration. This moment must be taken into account, conducting work, because the seams between the lower first row masonry should not coincide with the seams between the bricks of the upper second row. In other words, bricks are reported to be laid in disintegration, with seams overlap. |

| The third row begins the formation of a lower warm-up camera, which will be located under the oven, and pissed. Vertical smoke channels begin to form. After laying out a row, leave peculiar windows to install the doors of recumminers for vertical channels, and also pissed the bottom warm-up cameras. After completing the installation on the installation of this series, cast-iron doors are fixed in the windows. After that, work is performed inside the design - two integers and two three-fourth bricks are mounted on spoons. Moreover, the brick installed in the right vertical channel is shredding an angle for more unimpeded air circulation. In addition, the fourth part of the refractory chamotte brick is installed in the first chimney - in the figure it is highlighted in yellow. For the masonry of this row, ½ chamotte brick and 14½ red. |

| Fourth row. At this stage, channels and cameras continue to be formed, according to the scheme, and the chimney channels remain united. For a number it will take ½ chamotte brick and 14½ red. |

| When working on the fifth, the previously installed doors overlap. The side walls of the bottom of the coil chamber are laid out with chamoten brick. Moreover, in a brick that will be laid on the sides, it is necessary to cut steps for laying a grate grid. The second and third vertical channels remain combined, but are separated with the right first channel. To install this row, you need to prepare 8 chamotte and 16 red bricks. |

| The sixth row is laid out in the drawing. At this stage of the second and third smoke channels are divided into each other, and now three separate channels should form in the back of the furnace. The basis under the oven and the inner walls of the fuel is laid out with chamoten brick - it is installed on spoons. Wall between niche for oven And the fuel chamber is erected from Quarters of chamotte brick. Next is the mounting stage of the furnace, also left for her window between bricks. The door frame needs to be overtaken asbestos, so that the compensation gap remains between it and brick to expand the metal when heated it. Temporarily door can be pushed by stacks of loose bricks until it is fixed tightly the next rows of masonry. In addition to the door, a glass cabinet is installed, also tested to asbestos. For laying this series and internal arrangement Niche will need 13 red and 3½ chamotte bricks. |

| For greater clarity, this picture shows the sixth row installed box oven. |

| The seventh row continues to form the chamber of the furnace and the oven - the inner lining is carried out fire-resistant, and the outer masonry is red brick. Chamotted brick is installed on spoons, red to bed (plafhmy). For work it will take 13 red and 4 chammed bricks. |

| On the eighth row, the first chimney canal is separated from the camera, where the root of the oven, chamoten bricks. The rest of the masonry comes along the presented scheme, and it uses 5 chamotte and 13 red bricks. |

| Ninth row. At this stage, the door of the furnace chamber is overlapped with bricks. The remaining works are made according to the scheme shown, and for them you need to prepare 5 chamotte and 13½ red bricks. |

| On the tenth row of masonry overlap the oven. The wall between the brass cabinet and the furnace is not laid out. IN refractory brick, installed on the inner perimeter of the front of the furnace, a step 10 × 10 mm is cut, designed to lay the cast-iron hob. For this row, 4½ chamotte and 15 red bricks will be required. |

| Having tenth row, on a step, carved in chamotone brick, throughout the perimeter indoor space Locked asbestos cord. Then, the cooking plate itself is mounted - it must be located on the same level with the outer walls of the furnace, built of red bricks. Before the stove stove, on the front wall, the steel corner is mounted (45 × 45 × 1020 mm), designed to protect brick corner from damage I. general strengthening row. |

| The walls of the cooking chamber are formed on the 11th row. The gap, which formed between the hob and the right wall of the furnace, is laid by brick, which is mounted across the masonry of 10 rows. To work, you need to prepare 16 pieces of red bricks. |

| For the 12th row, 15 red bricks will be required - the masonry passes through the submitted scheme. |

| The 13th and 14th rows are laid out according to the definition scheme. For the 13th row, it will take 15½, and for the 14th - 14½ bricks. Here you need to take into account that the seams between the bricks of the lower row should be blocked with a whole brick, and therefore the 14th row will have a different pattern from the 13th. |

| The 15th and 16th rows also stacked according to the search scheme. It is necessary to prepare for them: for the 15th row - 16, and for the 16th - 14½ red bricks. |

| After completing the masonry of the 16th row, the cooking chamber must be overlapped with three steel corners with a size of 45 × 45 × 905 mm. In the middle part of the space above the camera, two corners are stacked, vertical walls to each other, and one corner at the end of the chamber. In addition to them, a 45 × 45 × 700 mm strip is overlapped by the front of the camera. These elements form a reliable support for overlapping the chamber with bricks, so the corners must be laid at a distance of 255 mm from each other. |

| The masonry of the 17th row consists of 25½ bricks, which overlap the space of the hob. Moreover, in the left left corner of the overlap, a hole for extracting vapors from a cooking chamber is left - its size should be a pollipich. In addition to overlapping, the laying of vertical channels continues. |

| The 18th line is laid out almost solid, but exhaust and vertical channels remain open. It will take 25 bricks for work. |

| After that, a steel corner of 45 × 45 × 905 mm is installed on the front edge of the masonry. This element is designed to strengthen the overlap of the exhaust chamber window, as it should withstand two rows of top masonry. |

| On the 19th row, small and large drying niches begin to form, as well as the continuation of the ventilation channel intended for the removal of vapors from the cooking bottom chamber. The work goes according to the scheme, and for laying you need to prepare 16 red bricks. |

| The 20th row also consists of 16 bricks and mounted according to the scheme shown. |

| The 21st row consists of 16½ red bricks. It is laid out according to the scheme shown. |

| The 22nd row is laid out of 16 red bricks. |

| After laying out the 22nd row, a metal plate is mounted on a small drying chamber with a size of 190 × 340 mm, which will perform the role of a heated shelf. |

| 23rd row. At this stage, the walls of chimney channels and drying cameras continue to rise. On a brick, stacked above the steam channel, a cutout is made, which will be mounted by a valve, adjusting the heating of the hob. The next step on the prepared landing place is stacked, having a size of 140 × 140 mm. For this row you need to prepare 17 red bricks. |

| The 24th row is overlapping the ventilation valve, as well as the combination of the first and second chimney channels. To work on this, it takes 15½ bricks. |

| On the 25th row, the three vertical channels are combined into one. For this number it is necessary to prepare 15½ red bricks. |

| The 26th row consists of 16½ bricks and stacked on the demonstrated scheme. |

| Further, on the same 26th row, the drying chambers overlap the steel corner having a size of 45 × 45 × 905 mm, and two steel stripes in size of 50 × 5 × 650 mm. The corner stacked on the front side of the drying chambers is intended to increase the stiffness of the structure, as well as, along with steel stripes - to create the base under the overlapping chamber of the steel sheet. |

| From above steel stripes and angle, metal sheet of 800 × 905 mm is settled. It overlaps the surface of the chambers and vertical ventilation canalsIn addition to one chimney channel, which will go smoke from all other channels. A chimney pipe will be erected over it. |

| On the 27th row on top metal sheet Complete solid brickwork. It should be in frontimeter of the cross section of the furnace by 25 mm. For laying this row, 32 bricks will be required. |

| The 28th row completely overlaps the previous one and stands out for its limits by another 25 mm. The chimney hole remains open. To calculate this series, 37 red bricks will need. |

| For the 29th row, 26½ red bricks will be required. They are laid out with an indentoceration of 50 mm from the edge of the previous row, in essence, leading it to the size of the perimeter of the furnace. |

| The 30th row of masonry of the furnace is already the first series of chimney naval tube. The series consists of 5 red bricks. In the upper part of the side bricks stacked in this series, a step 10 × 10 mm is cut - it will serve planting Moz For chimney valve, in size of 250 × 130 mm. Further, the flax solution is mounted and the frame of the gate. |

| The 31st row is the second series of chimney. It overlaps the edges of the chimney valve, thus fixing it from above. The series also consists of 5 bricks. The above will work on the construction of the chimney pipe. |

On the lower circuit with a context of the design of this furnace, the direction of circulation of fuel combustion products is shown. It is clearly clear that hot gases, thanks to the vertical channels, cover the entire surface of the furnace, heating it, and from a well-hot surface heat is effectively transmitted to the heated room.

The oven "Baby" shown in Fig. 1, -Nemick, compact, economical and convenient for garden warmed house. If desired, the furnace can be made above, laid between the 18th and 19th rows of the same rows. The ovens arranged cooking and two drying chambers: lower and top. The lower drying chamber is closed and located on the right side of the furnace over the slab overlap. Four hooks made of thick wire laying in the laying of its overlap (hanging threads with mushrooms or fruits on them).

You can install the thermometer on the camera door. In this drying chamber, a constant temperature is held for a long time. The door of the chamber is attached on a frame from metal corners. Instead of door, you can install a L-shaped valve. The hooks, if necessary, replace the wire of the P-shaped or support type of shelters for the baking sheets. The top dryer is open, but you can also put a damper. To do this, in the overlap, the metal plate is deserted, deepening it in front of 1-1.5 cm so that the flap can be put with a slope. The walls of the drying cameras are unwanted, you just need to lure the seams.

Fig. 1a. Furnace "Baby" (front view): a - cooking chamber; b - drying chamber; B - holes with a diameter of 7 mm in the door of the drying chamber; g - thermometer; d - self-duct

Fig. 1b. Furnace "Baby" (rear view)

The design of the oven is simple and with small skills to build it easy, but for an inexperienced master it is considered complex. The furnace can be folded under any solid fuelBut as coal, peat and kizyaki allocate a lot of smoke, then the furnace due to the scoring of hot gas supplies needs to be cleaned annually.

Fig. 1B. The oven "Baby", cuts on aa, bb and in-in: a - drying chamber; B - laying back wall ladder (with protrusions)

The furnace is put on a solid (monolithic) foundation. From the 3rd row lay out pissed 1

with a window in which the door is installed 2.

The 5th nearby overlap the window with the door. Top of the 5th row install a grate grid 3.

Before starting the masonry of the 6th row, it is necessary to think about how to put the rear wall, as the grate grille can be shorter or longer. The wall can be placed from the lattice or from a brick thickness of 12 cm, as shown on the section of the in-in dotted line 4

It is possible to lay the wall laying with a ladder (see fig. 1b). To do this, from the upper wall going on the edge, the same protrusions should be made to the grate grid in four rows. In our case, every protrusion is about 4 cm. In the 6th row, the flue door is installed 5.

Having placed in the 6-8rd row of the furnace, the 9th nearby is overlapped with a flue door and fix the overlap of the 10th nearby. Now you need to overlap the slab 6

firework and to make gas from the furnace, make a fire 7,

the size of which should be within 7-7.2 cm. To do this, first it is more convenient to make the back wall, which is installed on the edge. After that, lay the stove over the furnace so that it does not reach the back wall and the distance from it to the plate was at least 11.5-12 cm (this is necessary for the back of the back the opportunity to make Hylo 7

and install the partition 8,

separating Higho 7

and coming from him gas duct from the cooking chamber 9).

The plate is put straight on the solution without a groove. It should be noted that the standard plate having two holes is large for this furnace, so it is shortened to desired size (Cropped, leaving a smaller hole) and put flush over the furnace with the front wall. On the 10th row in front of the cooking chamber, the frame with doors is installed. Rama is fixed with wire or plates. The fastening wire is bred under the side walls of the furnace. Do it like this: one hand is stretched with one hand, the other put the brick walls on it and so that the door does not weaken, bend the wire up close to laigned brick. The frame in the upper part can be tied up with the side walls, but with the laying of overlap. In the case of contacting the corners of the frame with a stove, they pump up the part that concerns the stove. On top of the frame in the 15th row, the woor chamber is overlapping in iron plates or corners installed on the 14th row (see section of the B-B and general type of furnace). Before performing the overlap, the 14th row is first customized in height, that is, weave so that the upper 15th row lay down without a subsidence with the side walls. The 16th series is fixed by two previous rows and fasten the masonry with the back wall, and also set the frame with the door for the drying chamber designed for a small amount of products or herbs, and cleaning the cleaning door 10.

The 17th row throughout the perimeter is put on the edge. In the middle of the 17th and 18th rows, the nozzle for samovar is pushed. The 18th overlap the cleaning door. If necessary, the brick over the door is squeeze. As a result of the masonry of the 17-19th rows, a drying chamber is formed, the size of which is limited to the size of the gas pipe, the width of which should be 7-7.2 cm. In the 18th row, the gas pipe is overlap, due to which the left wall of the furnace with a drying chamber is fastened window 11

for an additional passage of gases and faster heating of the left wall and the bottom of the drying chamber. In the 19th row again overlap the gas - as a result of which the window is formed 12

and small gas pipe 13

for heating the front wall and drying chamber. On top of the overlap fasten the front wall with a drying chamber with a wire is not thick for 4 mm, bent on both sides. The 20th row is placed around the perimeter on the edge to the drying chamber, and the overlap over the drying chamber is laying on the cry, making it so that the size of the gas pipes at the walls still accounted for 7-7.2 cm. In the seams of overlapping laid hooks 14

from thick wire (if it is very thick, then in the brick cut down for her grooves-deepening). The 21st row is put on the cry on the ribbon to the edge on the edge, which was performed in the 20th row. After that, it is aligned with the top of the masonry - pose. In this row, shy, expanding the gas pipe from 7-7.2 to 13 cm (see section of the B-B). Top 21 -to row set two valves 15,

after which the 22nd row is put, which fixes the valves. In the 23rd row begins to spread gas in the middle of the furnace 16

and in the left wall one more (open) drying chamber 17.

In the 23rd and 24rd rows lay the cleaning window and install the cleaning door 18.

In the 24th and 25th rows make out the size of the square gas 16.

After that, inside the gas doc on the diagonal will not decrease. 25th Night overlap the back and middle part of the gas 16,

leaving only a hole for the output of the gases (the size of the opening must correspond to the size of the pipeline of the pipe). In the same row, the corner or plate is preserved for overlapping the top of the drying chamber.

Fig. 1g. The oven "Baby". Coaches (ranks 1-17): a - iron plates; b - door frame; B - Self Poll

In three-hardt 19

overlapping cleaning door 18,

they make the shy of the protrusion hanging over the gas duct, so that it does not interfere with the movement of gases going down (they will hit it, which is undesirable). As a result of the masonry, the entire 25th row will have an entrance of the eaves around the furnace, with the exception of the three-steppe 19,

which is laying with the front wall of the furnace, forming a break in the cornily. In the 26th row above this three-hard speed, there will be a cornice of two ingestion (measurement - an open pit of the cornice in the 25th row). The 26th nearby overlap the small drying chamber. 27th next to the masonry of the furnace - it is pushed with its walls. From the 28th row, the pipe laying is beginning and on top of this row laid a valve 20.

Fig. 1d. The oven "Baby". Coachings (ranks 18-29): a - fastening wire; B - Iron Corner

The furnace works like this. Fuel is laid in the furnace, open a valve 20

in a pipe and a valve 15

over the norannel nozzle. In this position, the gas from the furnace rise up, reaching the other valve 15

near the rear wall. This valve is closed, and the gases go through the windows to the left wall, make a turn and above the cooking chamber (see orders from the 17th to the 20th row) fall to the front wall. Since the furnace is small and gas ducts without partitions, they serve as guides for gases, so gases from the left wall, as if they do not reach the top of the furnace. But it is known that warm air is lighter than cold, so over time it will rise up and heats up the masonry.

If it is necessary to reduce the heat transfer of the furnace, then you can use the summer gas duct, which is well visible on the context of the in-c. He although a little, but still reduce the heat transfer of the furnace. To do this, open a valve 20

in a pipe and a valve 15

near the rear wall. Then gases will go from the firebox through the valve 15

in gas pipe 16

and through the valve 20

in the pipe. During operation in this embodiment, only the rear wall of the furnace will be heated and one of the walls of the lower and upper drying chambers will be heated; The rest of the furnace will remain cold.

To work yourself, you need to open a valve at any time. 20

in a pipe and a valve 15

over the norannel nozzle. Gaza from Samovar will go straight into the pipe.

For masonry, the furnace will be required (pcs.): Brick red - 250, stove cast iron 41 × 39cm - 1, flipping door 21 × 25 cm - 1, door for podded 14x 14 cm - 1. Cleaning door 14 × 14 cm - 2, gate 13 × 13 cm - 1, valve with holes 12 × 23 cm - 2, frame with door for a cooking chamber 37 × 43 cm - 1, frame for a drying chamber 17 × 37.5 cm - 1, metal corner 4-5 cm wide and a length of 50 cm - 2, a metal plate is 58 cm long - 1, a grain grille 17 × 25.5 cm - 1, nozzle for samovar - 1.

The heating of the country house is one of the most important moments Comfortable recovery of country housing. However, due to the short pastime there, it is impractical to invest a huge amount of money in equipment central heating. In this case, the small brick stove of the baby is yours best choice. Having preference this option, You can save money and at the same time improve the comfort of the room. Once the oven played a central role in the arrangement of the house. The real Russian man appreciates, understands the advantages and indispensability of the furnace in a country house.

Baby Furnace Features

Baby has a long list of advantages, the main among which can be called: low cost Buildings, simplicity of design, high heat transfer. The compact size will make it easily finding the location of the new furnace without redevelopment at home. Brick oven with their own hands can serve as a fireplace in a separate room, where it is necessary to increase the level of comfort.

Wood, stone coal and anthracite can be used as fuel. The device has excellent heat transfer capable of only one furnace to warm the room to 35 square meters. Meters or two adjacent rooms with a total area of \u200b\u200bup to 50 square meters. meters. The furnace can be melt even low-quality wood remaining after spring cleaning or garden work.

Due to the simplicity of the design, such a furnace is easy to build with your own hands and even modify depending on the emerging needs. For example, it is possible to add an exhaust, oven and additional surfaces for cooking food. Some cast-iron coatings, fire-resistant bricks, and it turns out not only an inexpensive type of heating, but also a cooking furnace for giving.

The heating and cooking furnace of the baby has the following parameters:

- height - 210 cm;

- the base is 63 x 50.5 cm;

- dimensions of the chimney section - 130 x 130 mm;

- mass - 1260 kg.

Preparation for work

In order to build a heating and cooking oven with your own hands, first of all, you need to spend preparatory work. Should be made up detailed schema Works and adhere to a clear sequence of actions. For example, first of all, you need to find location for the future furnace. Think, where exactly in the house the heating is most of all. The furnace is better to place away from the outer walls of the house, otherwise the air will be heated on the street, and this is inexpedient at all. Moreover, the installation should be made on a distance safe from the walls, at least 25 cm. In this case, besides compliance fire safetyThe circulation of air around the heating surfaces of the furnace will be improved and the efficiency of heating will increase. However, it is desirable to prepare the walls and the floor next to the future oven fire-resistant materials.

It should be taken into account that the chimney of the furnace should not touch the roof overlaps of the house, as this can lead to a fire. Minimum distance between chimney and wooden overlaps There must be more than 25 cm. Some developers to enhance fire safety fill empty space around the chimney of burlap impregnated clay.

Materials required for work

- Ceramic brick - 200 pcs.

- Chamotted brick - 80 pcs.

- Fine-marked sand.

- Fire-clay.

- Doors for firebox and pissed.

- Metal sheet for firebox.

- 2 valves.

- Cement (brands not lower than M300).

- Cast iron stove with burners.

- Metal sheet 50x50 cm on the floor before furnace.

May be needed additional materials, such as fittings, waterproofing and foil for the construction of the foundation.

Also do not do without the following tools:

- level;

- roulette;

- line;

- trowel;

- kirk's hammer.

Benefits and simplicity buildings

After the place is selected for the future furnace, tools and materials are prepared, it is time to do the foundation. Thanks to a relatively short weight, the baby does not always need the foundation. If the floor on which the oven stands, strong enough and will withstand the load in one and a half tons, then it is quite possible to do without the foundation.

Foundation - the basis of the reliability of the furnace

Kotlovan for the foundation is worth doing at least 80 x 65 cm. The formwork is installed in the kitty, the bottom is covered with rubberoid, after which concrete is poured. For the strength of the foundation before the fill, it is better to additionally install the reinforcement grid. The foundation must be below the floor level by 30 cm. To improve heating Qualities The foundation is consumed by waterproofing, as well as a foil facing the mirror side up.

Before continuing the building of the baby, the foundation must be provided by about 25 days to dry completely and strengthen.

Work scheme - laying order

The brick furnace brick furnace looks like this:

- Two initial solid levels of bricks are laid out on clay solution. The initial rows finally equalize the base of the furnace, so you should carefully check the laying at each stage of work.

- The door is installed and the base of the chimney canal.

- The chimney canal overlaps in the center so that two channels remain on the sides.

- The inner surface pissed overlapped with a grain.

- The base of the flue separation is laid and the heat door is installed.

- The door of the fuel department is covered. At the same stage, a window of the chamber of the furnace in the rear furnace canal is formed.

- Next, the cooking panel is installed.

- The walls of the cooking department are laid out.

- A horizontal furnace canal is created, and a window for a clear hatch is generated in the rear wall.

- The horizontal channel overlaps. A metallic tape is installed above the cooking department.

- Another layer is laid out on top of the horizontal channel. The same row covers a metal tape.

- The last horizontal furnace canal overlaps with an outline output.

- The transition to the chimney is laid out, and the formation of the chimney structure begins.

- The chimney is laid out.

It should be remembered that during the masonry process at each stage it is necessary to check the operation. You also need to draw a dressing one second or one fourth brick.

The construction of the chamber of the furnace should be performed only from fire-resistant types of bricks. Installation of metal sheet on the floor is required before the flue compartment flap.

The masonry of the baby's furnace may well independently fulfill one person in less than a day. Before using a new furnace, it is advisable to give a solution to completely dry. On the first day you need to melt the furnace with a small amount of paper and chips, but so that the temperature reaches high level. Such a procedure is desirable to repeat twice a day during the week. After that, the new furnace will be ready for use.

close ×

To equip the house with high-quality heating design, it is not necessary to have specialized skills and knowledge. A simple and accessible option to each owner is a furnace-baby, requires a minimum of time and attachments. In the article, we will look at all the stages of the construction of such a furnace with their own hands.

Brick babber furnace is a compact mini-fireplace that can be placed on a small area of \u200b\u200b0.4 square meters. meter. She has the most simple design in which the fuel cap replaces the entire system of standard for heating stoves. She does not need an additional foundation, and the total heating area can reach up to 35 square meters. meters.

Brick Baby Oven

Baby brick stove does not need large quantities high quality fuel. For its work, the most ordinary firewood, anthracite, coal or other materials is fairly common. It can easily replace the bourgear for the cottage and at the same time be at times functional. If you add a cast-iron slab to the main design, it turns out not just a heating furnace, but also cooking.

But the main advantage of such a design can be considered a high masonry rate. One day is enough for detailed projects. This time is enough to build and start to make the oven paper and sins. True, it will be possible to throw the lamps no earlier than it will dry masonry solutionOtherwise there is a risk of cracking.

What materials are needed

To build a brick oven with your own hands for heating a country or other room, you need to stock materials such as a set of materials and tools.

- Chimney red brick - it is durable and easily cuts the grinder will be used as a base, but not suitable as a facial material. It will take 60 pcs.

- Chamotte brick - is a refractory and only view of the brick, it will be necessary for masonry in the furnace part, as it will be subject to direct influence Fire. Number -37 pcs.

- Clay solution - will be used to fasten the masonry. 20 liters

- Standing door.

- The door for the furnace can be both metal and glass.

- The grate grille - will support a layer of solid fuel.

- Cast iron stove hard.

- One metal gate.

Heating-boilers-baby

Heating-boilers-baby Instruments

- Trowel. For applying a solution. It will also be possible to remove excess.

- Hammer - Kirk. For cutting bricks.

- Level. To control the horizontal masonry.

- Rule. There is a level.

- Plumb. With the help of it is monitored by verticals.

- Roulette. Can be replaced with an iron meter for measurements.

How to build yourself

Baby furnace with their own hands is built in stages. First you need to decide on the location of the furnace and proceed to the formation of the foundation. To do this, the litter is spinning at the selected place, a polyethylene or other adhesive base can perform as it. It is necessary to pour a centimeter layer of ordinary sand to it. Next you can start the laying.

Order

1 row. 12 pieces of brick lay out on the prepared sand, bonding is not required. Bricks are covered with a layer of solution, right there to fastened the doors for ponds in Asbest.

2 row. It is laid out on top of the first layer.

3 row. Smooth brick is used. The grille is put on top, it must subsequently be located above the confusion.

4 row. Masonry is made by an edge, and in the chimney there is a partition. When laying the back wall, it is not required to use a solution, bricks should slightly perform on the outdoor side. You can start the installation of the door for the furnace, pre-wrapped in several layers of asbestos. It is necessary to wrap up with the way that the door should be unimpeded.

5 row. This series must be placed on the contour of the previous one.

6 row. Mason edge. Chimney need to wipe with a wet rag.

7 row. Like 5 row, the plastle is stacked, you need to start with a three-wayway.

8 row. Top is placed two bricks, which closes the door. For this series, it will take a brick in a beveled form, it will serve as a kind of canopy.

9 row. Must be with a displacement with the calculation to support the open state of the door. Previously, moisturized asbestos must be laid.

10 row. From it begins the formation chimney. It builds up expanding back. Taking into account the design of the crumb furnace, it is necessary to remember that the installation of a brick support pipe is impossible due to the displaced center of gravity of the entire furnace.

11 row. Go to the installation of the valve, compacted asbestos, lubricated clay.

The next step will be the extraction of groissing bricks and cleaning the nose of chimney from garbage.

Baby furnace with their own hands is practically ready to produce bliss. To subsequently, the oven is not yellowed into the mixture it is necessary to add blue and milk.

The furnace of this type is a compact design, conveniently equipped in the house of any type, ranging from the country house - and ending with residential year-round.

Baby is created from ecologically pure Materials, such as red ceramic brick Or refractory chamotte brick. Baby prototype is a modernized stove-Swede, thanks to its constructive features, easy to modify; Catching prototypes are much less likely.

This is what the stove looks like a baby.

From its prototype, the babber stove from the brick retains the height - the depth and width are easily varying values.

Tools for the construction of the furnace should be prepared before the construction

To create this furnace manually, the following tools and materials will be needed.:

- 210 red bricks or 76 refractory chamoten;

- clay ordinary or chammed;

- sand;

- the doors are coat, confused, 2 cleaners, 2 truck valves;

- ruberoid in the amount of 2 sheets;

- metal premium sheet.

Now you can proceed with detailed consideration of the construction of the babes and its advantages.

Pluses of such a type of furnace

The baby, which, in essence, the mini-fireplace, occupies the minimum for a heating furnace area - only 0.4 square meters. meter. She has simple design, to collect that, under the power of any newness, and instead whole system Heating channels in it functions fuel cap.

The furnace of this type does not require a powerful additional foundation.But with ease capable of heating the room to 35 square meters. meters. To achieve this effect in the offseason, it can be trampled only once a day, and in the cold season - 2 times a day.

The babber furnace is economical and can use for its work both firewood and anthracite, coal and other types of fillings.

If the future brick oven of the baby will be treated exclusively to firewood, in its construction you can use a red brick, but only the brick and fireproof is suitable for the construction of the camera and fireboxes.

Baby furnace with their own hands

Before starting the immediate construction of the furnace, it is possible to consider its location - excluded as an adjuncing to two external Walls Buildings and location of it in the center of the room - in view of the unreasonable thermal loss and inefficient distribution of heated air.

Baby requires not a powerful, but good additional foundation. In the case of the presence of water heating or electric heating, the whole screed rises - in the absence of a grinder under the floor with diamond disk The floor rectangle is cut around the perimeter of the future oven.

A hole of a depth of 350 mm is digging, which has the most aligned edges. In her falls asleep sand pillow The height of 70 mm, which, after pouring, the water is left to its drying for several days.

The rebar is created from twelve rod with a 100-millimeter step, welded in two layers of crosswise. Following the maximum lattice identical to her. Both are bonded by reinforcement rods in the joints of the joints - and they are welded along it.

In the manufacturing process concrete solution Only Cement M300 will be able to provide optimally durable foundation for baby. The flooded foundation must be finished 50 mm to the level of the floor in order to avoid the occurrence of the cold air in the lower part of the underground.

Facilities Masonry Babe Furnace

To build the masonry of the baby personally, in addition to bricks and runners, there will be such materials as: steel strip, water-clay-sand solution, trowel, level and foil.

To prevent heat from leaving under the floor of the building, the foundation of the future oven is covered with foil.

- On the set of 1 and 2 rows of bricks after the masonry of each of them the level necessarily monitors their location. This is required due to the small area of \u200b\u200bthe stove itself, and therefore the correct pressure distribution on each carrying brick element.

- On 3 row with front face Vacifected pushed having dimensions twice already flopping. A window is inserted into it in 4 rows. The inner surface pissed overlapped with a grain.

- 5 row representing a circular masonry fixing all constructive elements and metal.

- 6 Row forms a fire window and a firebox, which the door is installed on the 7th row.

- 8 row overlaps the furnace with a steel strip located from the facade side.

- From 9 to 11 row is dialing with a circular masonry.

- From 12 to 14 rows, the rear wall turns "on the side", the masonry goes to the expansion of two small grooves.

- On the masonry of 15 rows on the back and side wall, an extended vertical well is formed; The center puts the main support brick, the basis of the future column. The laying continues 16 row, on which the columns are laid out by two perpendicular steel stripes.

- The 17th row separates all the formed wells from each other, receiving 4 oblongs - along the walls - and 1 central square.

- From 18 - and in 22 rows are similar masonry.

- On 23 row, the wells formed "g" - like a similarity, in the next row - too.

- On the 25 row side wells closed with bricks. From 26 to 28 - external laying dimensions are compared with the size of the pipe.

- The flap is made on the 29 row, and from the next row, the formation and output of the chimney pipe occurs.

Thus, it is absolutely easy to perform the construction of a baby's oven with their own hands..

Recommended for watching video on masonry furnaces with your own hands: