Induction boilers heating scheme. Is it worth buying an induction electric boiler for heating at home? Review of the expert about the induction boiler heating

The process of housing heating is one of the most important for any person. When building a house, overhaul, updating the pipeline is very important to accurately decide on the source of heating. If the homeowner lives in a gasified area, then there will be no extra questions with the choice of the heating boiler. Gas device - optimal solution, available at high quality level and cost.

It is more difficult for those people, the house-building of which is located in places remote from gas supply lines, and the purchase of cylinders occurs with interruptions. In such a situation, it logically pay attention to the electric induction boiler heating. User feedback and opinion of independent experts will provide us with an invaluable service in learning and choosing a device.

First acquaintance with heat generator

Based on the title, it becomes clear that the principle of electromagnetic induction is based on its work. What is his essence? Let's try to skip the current through the coil of thick wire. A strong electromagnetic field is immediately formed around the device. If you put inside the ferromagnet (attractive metal), it will warm very quickly.

The simplest heating is a wire coil with a dielectric tube, inside which is located a steel rod. Bypowing from electrical network Device, we get the heating of the core. It remains only to connect the resulting coil to the heat trap and will be primitive heating system.

In other words, electrical energy produces an electromagnetic field, the waves of which are heated by a metal base. And from it, the high temperature is transmitted to the coolant (water or antifreeze). Intensive heating of the fluid creates convection streams. Their power is quite enough for productive work A small heating circuit. In systems with a large length of the pipeline, it is recommended to install a circulation pump.

Internally

Structurally induction heating is a transformer enclosed in a welded metal sheath. The casing is the heat insulating layer. The coil is located in a separate compartment, hermetically surrounded from the workspace. Such an accommodation is safe because it completely eliminates contact with the coolant. The core consists of thin steel tubes with a toroidal winding.

Please note that the heating boiler from induction tile It does not have any fundamentally different from traditional heat generators equipped with Tanni. Its constructive features provide uninterrupted highly efficient operation of the heating system for a very long period of time.

Long operation of the heating system is ensured constructive featurewhich differs induction boiler heating. User feedback indicates that such aggregates are equally perfectly operating at any frequency of current. That is, instruments can be powered not only from the household electrical network, but also from high-frequency converters. Built-in sensors are capable of reacting to voltage drops and control the heating indicators.

Heping induction boilers: reviews and complaints

Insufficiency of information about the device and principles of the action of heat generators creates many questions. By contacting the specialized store, you can sometimes hear the positive characteristics that are awarded induction boilers Heating. Reviews of trading managers are often distinguished by a debris, because there are no ideal devices in the world.

Intention to the existing shortcomings, sellers can mislead potential buyers. To objectively disassemble the situation, consider the most common assertions.

Basic theses

Innovative development

In reality electromagnetic induction As a physical phenomenon was discovered by Michael Faraday, in the XIX century. And furnaces based on induction plates It has long been used for steel smelting. That is, there were no new technologies invented, and modern boilers work on a long time ago.

Profitable purchase

We are assured that up to 30% of electricity can save induction heating boiler. Reviews of authoritative specialists express incomplete agreement with this thesis.

First, any heating device all incoming electric energy Transforms to thermal. In this case, the efficiency will not necessarily be high, because the dispersion of heated air flows can occur unevenly.

Secondly, the heating rate of the coolant depends on efficient work Heating appliance. No matter how we did not want this, but the facts confirm the large amount of electricity that the induction heating boiler consumes. Reviews of any person, at least a little familiar with the laws of physics, agree with the obvious fact: to receive one kilowatt heat you need to spend the same amount of electricity.

Thirdly, some of the heat obtained isted. For the sake of justice it is worth noting that she still remains in the house, and does not fly into the pipe.

Thus, a high economy of the device can be considered somewhat relative.

Durability

We are assured that induction is capable of uninterrupted work For thirty-forty years. And that the reliability of the devices is much higher than other varieties of electric boilers. We will analyze this statement more.

First, induction devices are incapable of mechanical wear. They lack moving parts, so there is simply nothing to break.

Secondly, the coil's copper winding is capable of listening long enough. Even damage to the isolation will not harm it.

Third, the steel core, despite the sufficient thickness (about 7 mm) and the fortress of the main material, still gradually collapses. The constant heating change with cooled is noticeably reflected on the strength of the rod. But the negative process is too stretched over time, therefore, before the full failure of the core can pass for more than one year.

Fourth, on duration and trouble-free operation heating device The quality of transistors has influence. It is from them that the induction heating boilers will be perfectly perfect. Reviews of grateful owners confirm the fact of a decade guarantee. In practice, cases are noted when heat generators worked without failures of more than thirty years.

The listed arguments unanimously recognize the actual durability of induction boilers. This dignity especially convincingly looks against the background with the Tanni, which requires the replacement of the inner parts after several years of operation. There are no cases when the heating elements do not even produce their resource.

Invariability of work parameters

Furnaces that have the basis of heating elements gradually lose the power due to the formation of scale on bench. The induction boilers of heating are significantly different from them: specifications Here remain unchanged throughout the long-term exploitation. Let's try to figure it out, is it true this statement.

Great influence of scale reduction in boilers with Tanni is somewhat exaggerated. The fact is that the limestone falls does not differ in the high level of thermal insulation. In addition, in the closed ring of water, it is impossible to form a large layer of scale.

In induction devices, the formation of layers is completely excluded. Even if the core comes in contact with the liquid coolant, it will still not turn lime raid. Deposits are simply physically able to hold on the surface of the rod due to its constant vibration under the influence electromagnetic field. In addition, water bubbles are constantly formed on a hot core, which destroyably affect any scale.

Thus, the statement about the invariance of the technical characteristics in induction devices is quite fair. As for the Tannic boilers, here the thesis is not completely truthful.

Silent job

Trade agents are in a hurry to assure us in the fact that induction instruments do not publish any sounds when turned on. Is it really?

In any electrical heating devices there are no sound oscillations. An insignificant noise level can create additional devices - circulating pumps. The modern market suggests big choice Forced operation devices, among which can be found completely silent. So, the statements of sellers can be considered valid.

Compactity

A small segment of a pipe with a wedged wire - this is exactly what an induction heating boiler looks like. Reviews of the heating instrument owners confirm the possibility of the disposition of the device in any rooms.

Safety

It is absolutely safe to argue that the heat generator is absolutely safe. In the event of a leakage of the coolant heating of the core still will continue. If you do not turn off the device, it will be melted very quickly. In order to eliminate such situations, you need to take care when installing additional devicewhich automatically disables the system operation in case of unforeseen circumstances. It is obvious that the safety of all electric boilers is at the same level.

Is it possible to make an induction heating boiler with their own hands

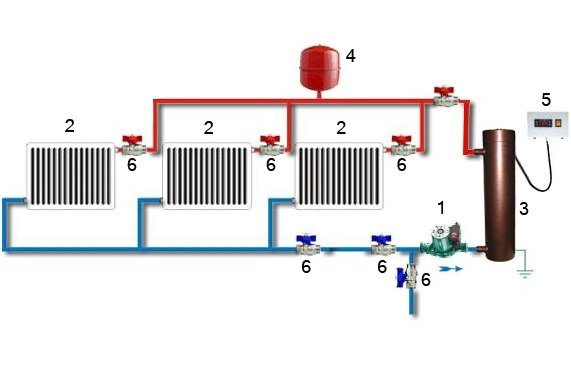

The need to obtain inexpensive and efficient heating at home with minimal cost For the arrangement of the heating system, pushes many consumers to the thought of doing independently by the manufacture of equipment. Having read carefully with the workers and constructive principles Devices, you can collect homemade induction boiler heating. The main assistant in the case will be a schematic image of the heating strapping, which must be constantly kept near himself, referring and specifying the installation on it.

For home, you will not need a high power device. So, for heating room at 100 square meters It is enough to make a boiler for 10 kW. It is able to provide in rooms temperatures at 20 degrees. You can buy an electronic programmer of working modes to the homemade boiler. With it, you can plan the work of the induction device for a week ahead. It is also possible to control the temperature regime at a distance.

Where to begin

Getting started, you need to prepare necessary materials and suitable tools. For the convenience of manufacture, it is desirable to prepare a welding machine inverter type. With it, there will be a compound of seams in the generator body and the attachment of pipelines. Also in the heating circuit device will require a high-frequency converter (inverter).

Materials may need:

- segments of steel stainless wire or rods 50 mm long and a diameter of about 7 mm - material for heating in a magnetic field;

- segment of a plastic thick-walled pipe with an inner diameter of up to 50 mm - the base for the boiler housing;

- copper enameled wire - the main element of heating;

- adapters - connecting fasteners;

- metal mesh - barrier between the coil and walls of the case.

Prepare everything you need, we begin to make an induction boiler of heating with your own hands.

Installation of a simple scheme

To improve the safety of the homemade heat generator, it is advisable to exeter open areas Coils. Choosing a material to protect the copper wire, it is necessary to take into account its electric and thermal conductivity.

The considered scheme of the induction boiler made by personally, costs the manufacturer inexpensively and is able to significantly increase the heating rate of water in the heating system. The disadvantages can be classified as a small size of the equipment and a non-clear appearance.

Second Mounting Boiler

You can try to make a heating device of high power. Its device will be somewhat more expensive than the first option, but afterwards all expenses will fully pay off excellent quality and high performance.

The design of the complicated model is welded connection Two pipes, outwardly resembling a bagel. The resulting part will simultaneously serve as a core and a heating element. Copper winding directly on the housing of the boiler provides high level Performance with the preservation of compactness and small weight of the device. Feed and tapped nozzles are welded directly to the inductor. Thus, water heating will occur as a result of the contact of the coolant with a copper winding.

Features you need to take into account when the boiler device.

- Such an induction device can be integrated only in the closed heating circuitWorking on forced circulation coolant.

- Only plastic materials should be used in the pipeline system.

- The induction instrument should be placed in the room so that the distance from it to the nearest walls and items is at least 300 mm. From the floor and the ceiling, the boiler must be removed by 800-1000mm.

Time-consuming installation process induction scheme As a result, wrapped with high-quality warming at home. The homemade heating device will serve you at least two decades, without having any concerns.

Induction boiler SAV - famous brand of industrial production apparatus

One of the varieties of factory devices can be considered an induction boiler heating SAV.. The furnace is a pipeline system with an integrated inductor. The manufacturer of heat generators is the Volgograd Research Company Velbit.

SAV thermogenerators are successfully used in several types of systems:

- autonomous heating;

- combined scheme;

- backup heating;

- hot water supply;

- maintaining specified temperature mode technological processesoperated in flow and chamber reactors.

It is noteworthy that the SAV heating induction boiler shows high performance in automated heat supply systems controlled remotely. Industrial production of electric installations of three classes with power ranges is adjusted: 2.5-10 kW, 15-60 kW, 100-150 kW.

Wine generators type wine

The vortex induction heating boiler (WIN) is intended for heating and hot water supply of residential buildings of private buildings, country houses and commercial and public facilities. Depending on the size of the power, the heaters of two species are produced: single-phase and three-phase. More powerful models can be successfully used in the devices of the heating system of industrial enterprises.

Let's summarize

Induction heating boilers in Ukraine began to use even in the late eighties of the last century industrial enterprises. The development of household options began approximately in the middle of the nineties. Over the past decades electrical heaters We repeatedly changed, upgrading and improving.

To date, induction devices constitute a worthy competition with gas and belated boilers. The trading network offers many models that differ in technical parameters and cost. The price of household appliances begins from 25 thousand rubles. It is much more expensive - over 100 thousand. Making a thermogenerating apparatus with your own hands will allow you to significantly reduce the cost of living home heating.

To date, induction boilers are considered indispensable for the heating of a private house: energy prices are growing continuously. Modernization of already existing generators does not always give the expected result, so new methods of heating are interested in many.

How does an induction boiler

Induction boiler in its essence is a plurality of tubes with a tip representing the inductor. The principle of operation of such a device is to transform electricity into an electromagnetic field. When the device's core is heated, excessive heat transmission is transmitted by the carrier, in the role of which almost any liquids can act: water, antifreeze (based on ethylene glycol) or oil. Such a choice is especially important for districts with large drops temperatures where the abnormally cold temperature periods are not uncommon.

Induction heaters are more expensive than shadow, however, the payback in severe temperature conditions occurs at times faster. The frequent operation of the Tan leads to relatively rapid combustion, the heat transfer is seriously reduced due to the scale. For example, a layer thickness of 0.5 mm reduces heat transfer by approximately 10%, and over time, this indicator is only increasing. The power of the shadow mechanism falls by 40% in four years of use, while the last generations of induction boilers are energy-saving. Such aggregates reduce the cost of operation by 30% and above.

Interesting! When heating the room in 200 square meters, the efficiency of the induction boiler of heating in five years will decrease by 0%, and the percentage of the effectiveness of the bypass heater is 3 times.

Types of electrical induction boilers

Before choosing an induction boiler for heating, you should familiarize yourself with its varieties and features. On the modern market Two options are offered - for heating and hot water supply SAV. and Wine (vortex induction):

- On the inductor itself sAV converters There is a current having a frequency 50Hz. As a secondary winding and heat exchanger of such boilers, a closed chain of pipes filled with heat carrier. The induction current very quickly heats the coolant in the interweaving of pipes, which allows you to maximize the capacity of the boiler. Boilers are powered by 220V and 380V power grid. Installation SAV highlights the thermal energy of 2100 kcal / hour and is able to heat the room with an area of \u200b\u200b25-30 sq.m. Price in the configuration with the automatic block - in the area of \u200b\u200b30 thousand rubles.

- Induction boilers Wine They differ from the first group by the fact that the current is already transformed into high-frequency on the primary winding, due to which the overall tension of magnetic fields grows significantly. Corps I. interior The boiler is made of a special alloy provoking substantial heating. In such a design, not only the totality of pipes is acting as a heat exchanger, but all cabinet parts. The guilts are able to allocate up to 2500 kcal / hour to warm the area of \u200b\u200babout 30-40 sq.m. The price bundled with the automation unit, circular pump and reinforcement - approximately 36-38 thousand rubles.

Induction boiler do it yourself

At the present time of savings, everyone seeks to find a more rational way of investing funds, and is no exception to this rule. You can save money by making an induction node yourself. This will require a global redevelopment of the house and special knowledge - sufficiently minimal skills and elementary familiarization with the structure of the heater.

More simple models  Induction aggregates are arranged on the principle of an inductor coil consisting of two windings - primary and secondary. In the primary winding, electricity is converted into a vortex stream, the secondary represents heating element And the shell of the boiler, through which heat is produced. The housing is a core, an outer contour, electrical insulation and thermal insulation.

Induction aggregates are arranged on the principle of an inductor coil consisting of two windings - primary and secondary. In the primary winding, electricity is converted into a vortex stream, the secondary represents heating element And the shell of the boiler, through which heat is produced. The housing is a core, an outer contour, electrical insulation and thermal insulation.

For self-assembling induction boiler, the following materials will be required:

- Professional tool;

- Copper and steel wire pieces with a diameter of up to 7 mm;

- Pipe of plastic thick-walled;

- Metal grid;

- Welding machine inverter type.

Plastic tube having an inner diameter of 50mm is used not only as an induction coil, but also as a thermal conductory. Slices of steel wire are placed in the electromagnetic field, which are pre-cut into pieces of 50-70 mm. Special adapters serve to connect the mechanism with the system of pipes, where, on the one hand, the heat carrier is enters cold, and on the other hand, it is heated under the influence of induction.

Important! For independent manufacture Induction boiler The first adapter is necessarily joined by welding, and the second can be treated on the thread.

The internal space of the tube is filled with sliced \u200b\u200bslices of wires, after which the design is reliably closed on both sides. For the manufacture of an induction coil on the plastic case, about 100 turns of copper wire are wound up, and the distance between them should be the same. After assembling the homemade inductor, it is installed and connecting it to the heating system.

Attention! To make the use of the boiler absolutely safe, all visible sections of the copper wire should be isolated suitable materials with high heat and electrical conductivity.

Comparison of prices for induction boilers heating

In the modern market of thermal units, devices of an induction type of brands are presented: SAV, WIN, Miratron. Russian manufacturers Offer models with the following characteristics and approximate prices.

People are spoiled by civilization and do not think of existence without its goods. These are undoubtedly related to the heating of buildings. Heating systems are constantly being improved and becoming increasingly efficient and convenient for use.

But this is not enough. Agree, it is quite good that the heating equipment is also economical. And this desire is quite feasible - you can make an induction heating boiler with your own hands. It is capable not only to provide the necessary level of heating of the room, but also highly economically spent energy resources.

Moreover, such equipment, if desired, will bring even a novice master. And how to do it properly and what materials are needed for manufacture - we will analyze these questions in detail in our article. We will first consider the device and the principle of operation of the equipment, as well as the advantages of its use.

Before you do an independent assembly of an induction boiler, it is necessary to deal with its device and the principle of work. And only understanding these moments you can start making homemade.

How does an induction boiler work?

To understand how the induction equipment works, you need to get acquainted with the principle of its action. Therefore, let's remember the school course of physics.

When through the conductive material passes electricityHe highlights heat. At the same time, the amount of heat obtained will be directly proportional to the voltage and strength of the current. This regularity was opened by Joule and Lenz, in honor of which the physical law is named.

Gallery of images

However, induction boilers, although they work from electricity, are quite economical.

Gallery of images

On the plastic pipe With segments of metal wire inside carefully wounds copper wire

Only after that you can test a new device. It must necessarily have a liquid.

If you turn on the induction boiler "On the dry", the plastic housing is melted from high temperature. This will lead to partial destruction of the heating system, which is unacceptable.

Another important moment – competent arrangement Grounding the heating device, without which its safe operation is impossible.

Features of the vortex induction boiler

With the principle of work of the induction heating device, we are already familiar. There is its variety: a vortex induction boiler or wines, acting somewhat differently.

Distinctive features of wine

Like an induction analogue, it works from high-frequency voltage, so it is necessarily equipped with an inverter. The feature of the wine device lies in the fact that the secondary winding is missing.

Its role is performed by all metal details of the device. They are mandatory made from materials that show ferromagnetic properties. Thus, when a current comes on the primary winding of the device, the electromagnetic field strength increases sharply.

It in turn generates a current, the strength of which is rapidly increasing. The vortex currents provoke magnetization, as a result of which all ferromagnetic surfaces are very fast, almost instantly, heated.

The vortex devices are compact enough, but due to the use of metal, their weight is great. This gives an additional advantage, since all the massive elements of the housing take part in the heat exchange. Thus, the aggregate efficiency is approaching 100%.

This feature of the device must be taken into account if it is decided to independently make wine boiler. It can only be made of metal, plastic should not be used.

Unusual Induction Device Model

This modification of the induction boiler may seem very unusual, however, it is quite eligible for existence.

Moreover, the practice shows that such a device is much more economical than a standard bean boiler. There will be about 1.8-2.5 kW for heating the standard "treshki" per hour, while the electrocoon will spend at least 6 kW.

In the manufacture of homemade induction boilers for winding on the core, only a special winding copper wire is used.

Actually, the boiler is a heat exchanger embedded into the heating system, which heats up from the induction electrolycot.

An important link design is a heat exchanger, it must be compact, reliable and, if possible, cheap. Calculations show that for heating apartments area of \u200b\u200babout 50 square meters. M will be enough device operating with 40 liters of coolant.

That is, you will need a flat metal tank, the dimensions of which vary in the range of 50x600x500 mm. Such a container can be made independently, welding from profile pipes 50x50.

Works are performed in the following sequence:

- The pipe 50x50 is cut into segments of 600 mm long. In total, it should get 9-10 pieces.

- The resulting segments are welded one to another on the principle of "wall to the wall" so that a solid row of pipes turns out.

- Two more segments are cut from the pipe so that their length is equal to the width of the resulting workpiece.

- From both obtained fragments of the pipe, one wall is cut off.

- The item is installed cut part on the pipes cooked together so that it turns out a blank resembling a collector. The fragment is welded to the heat exchanger.

- Similarly, the second segment of the pipe from the opposite side is set.

- In the opposite diagonally, the heat exchanger sections are boiled pipes for connecting to the heating system.

- The design is carefully colaried, because it must be completely sealed.

The heat exchanger is ready, it can be installed in place and lead the source of heat under it. Practice shows that it is best to install such a system in the bathroom by performing vertical installation.

The heat exchanger is welded into the heating system, and the tile is located between it and the wall.

Homemade masters claim that if you connect an inverter to such a device, its power consumption will significantly decrease.

After reading the instructions, the manufacture of homemade boilers seems to be a complex and dangerous occupation? Do you doubt that homemade will save energy to heal the heat carrier in the heating system? In this case, the purchase of a ready-made heating unit will be the best solution.

On our site there useful materials The choice of the best electrocotel and the rating of the most popular among customers models. We also recommend familiarizing with the features of energy consumption calculations by the boiler and other options. electric heating in the House:

To buy such a device in the store will have to spend a significant amount, so homemade craftsmen learned to make them independently.

Do you use homemade induction boiler as a heating device? Share your photo of your homemade and assembly recommendations in the Comment Block.

Or maybe you are just going to do the manufacture of the boiler and you have unsolved questions left after reading our article? Feel free to ask them - we will try to help you.

Induction heating boilers Recently appeared on sale and immediately composed competition with the usual electric motors with Tan. For similar sizes and power consumption, induction heaters are able to warm up the system much faster, in addition, they can operate in low quality coolant systems and less frequently require maintenance. Applying knowledge in electrical engineering and smelting, you can make an induction heating boiler with your own hands.

The basis of the action of induction boilers and other heating devices of this type is the ability of conductive materials to heat up under the action of vortex currents created as a result of electromagnetic induction.

The source of induction is a high-frequency alternating current passing along the primary winding of the heating device made in the form of a coil. The heating element placed inside the coil plays the role of a secondary short-circuited winding. It occurs in the conversion of electromagnetic energy to thermal.

Vortex currents occur and industrial frequency 50 Hz, but the effectiveness of the heater will be low, and the operation of the device will be accompanied by a strong hum and vibration. With increasing frequency up to 10 kHz and the above noise disappears, the vibration becomes imperceptible, and the heating is enhanced.

Device

The industrial induction boiler consists of a core whose role is played by a heat exchanger around which a toroidal winding is wound connected to a high-frequency converter. When the current winding is passed, an alternating electromagnetic field is created, as a result of which the vortex currents occur through the core.

The industrial induction boiler consists of a core whose role is played by a heat exchanger around which a toroidal winding is wound connected to a high-frequency converter. When the current winding is passed, an alternating electromagnetic field is created, as a result of which the vortex currents occur through the core.

The winding is connected to a high-frequency converter, in which the signal from the control unit creates the current frequency. Modern boilers have a high level of automation that allows not only to create the optimal heating mode of the coolant, but also disconnect the device in case of an emergency.

Inside the heat exchanger core is a coolant. Under the influence of vortex currents it heats up to high temperatures. Due to the difference between the temperature of the coolant at the inlet and at the outlet, from the boiler circulation of the coolant over the system is continuously, even without connecting the pump. Therefore, induction boilers can be used in systems with forced and natural circulation.

The coolant can be both water and antifreeze, toosol, oil. The quality of the fluid does not matter: the constant vibration of the system is irrelevant by a person makes it impossible to precipitate the scale and other impurities on the walls of the thermal circuit.

Outer shell - Metal case equipped with a thermal and electrical insulation system.

Form of boiler It may be any, as well as the method of its installation: due to the absence of a tank inside the boiler, its sizes are usually small, and the mass does not exceed 50 kg.

The induction boiler can not even be briefly included in the work without filling the system with the coolant! A boiler overheating and failure of its elements will occur!Advantages:

- High efficiency. Most manufacturers call 95-98% figures;

- A large selection of models of different power on a single-phase voltage ~ 220 V or three-phase ~ 380 V;

- Rapid heating system of heating at startup;

- Can work with any coolant;

- The contour, according to which the coolant is passed inside the boiler, is absolutely sealed, which eliminates leaks and associated malfunctions;

- Long work without the formation of scale and deposits. It is this phenomenon with time that reduces the effectiveness of the boilers with Tanes and serves as a frequent cause of their breakage due to overheating of the heating elements;

- The service life declared by manufacturers - from 25 to 30 years.

No heaters and disadvantages, The most significant of which is a high price. This factor usually encourages the maternity owner to assemble a homemade induction boiler made of primary materials and appliances. Despite the complexity of the processes occurring in the boilers of this type, it is possible to create a design that is not lagging behind the main parameters from the boiler of industrial manufacture, and make an induction boiler with their own hands.

Copper with a welding inverter

The design of such a homemade boiler is quite simple. The most difficult for self-fulfillment Block requiring knowledge of electronics and electrical engineering - high-frequency converter. Its function perfectly performs welding inverter Modern type capable of output signal with a frequency of 20-50 kHz.

The design of such a homemade boiler is quite simple. The most difficult for self-fulfillment Block requiring knowledge of electronics and electrical engineering - high-frequency converter. Its function perfectly performs welding inverter Modern type capable of output signal with a frequency of 20-50 kHz.

In addition, for installation will be required:

- copper wire in enamel insulation with a diameter of 1-1.5 mm;

- insulated wire with terminals for connecting the winding to the inverter;

- trimming stainless steel wire with a diameter of 3-5 mm, 5 cm long;

- small grid of stainless steel;

- section water pipe from sewed polyethylene or polypropylene for gVS systems and heating with a diameter of 50 mm and the thickness of the wall is 8.4 mm, the length is 1 m;

- adapters from pipes 50 mm on pipes involved in an existing or projected heating system, a tee for connecting the emergency valve and two ball valve;

- stripes of textolite for fastening winding;

- epoxy glue for the insulation winding;

- the housing of the homemade boiler, it can be made from the distribution metal or plastic cabinet, in which the inverter can be installed and fasten the heating element.

Sequence of assembly and installation of elements:

- On cut polypropylene pipe With a diameter of 50 mm using epoxy glue, 4 bands from a textolite width of 8-10 mm are fixed, retreating from the ends of the pipe from 70-100 mm. The winding will be wound on them. To secure extreme turns of the winding in the textolite you can make grooves.

- Washing 50-100 turns of copper wire in enamel isolation. The turns should be located approximately 0.3-0.6 mm at an equal distance. The exact amount of turns depends on the diameter of the wire used and its specific resistanceas well as the output parameters of the inverter.

- When installing a homemade boiler in a residential room, it is recommended to perform a toroidal winding to reduce the external electromagnetic field. The toroidal winding consists of the same number of arrogant turns, and the electromagnetic flows are mutually compensated and pass only by the inner contour.

- Inside the pipe from one end it is inserted with a grid of stainless steel and tightly stuffing it on the other side of stainless wire segments - it will be heated under the influence of vortex currents. It is recommended that the stainless steel is recommended to ensure that there is no corrosion destruction of the wire over time, but any conductive metal will be theoretically suitable, including wire-rod. The second end of the pipe is also closed with a grid.

- On both ends of pipes, polypropylene adapters are attacked by the diameter used in the heating system. They establish ball valves that allow to overlap the circulation and remove the heat exchanger for revision.

- From the side of the top output adapter, an emergency valve is installed to reset pressure.

Fracture with epoxy glue winding to ensure high-quality electrical insulation winding. The manufacture of adhesive is recommended to perform with a small retreat from the instruction, adding 10-15% less than a hardener. This will make isolation less fragile. - Fasten to the conclusions of the wire winding in isolation using crimping terminals. The second end of the wire must be equipped with terminals for connecting to the inverter. The diameter of the wires must withstand the maximum output current of the inverter.

- Install the heat exchanger in the cabinet, attaching it to the brackets from the heat-resistant non-conductive material. You can use textolit.

- Connect the heater to the system and fill it with water.

- Inverter put in the lower part of the cabinet. Connect terminals to it and include it in the network. Produce the start of the boiler and setting up the mode.

From induction tile

Induction boiler can also be made based on induction tiles. To do this, disassemble the heating element of the tile and use copper wire for winding on the core, manufactured by the method specified above.

Induction boiler can also be made based on induction tiles. To do this, disassemble the heating element of the tile and use copper wire for winding on the core, manufactured by the method specified above.

Tile control unit is used to power the resulting winding, exhibiting necessary power On the touch control panel.

However, this method has significant disadvantages:

- For the successful operation of such a homemade boiler, you need to calculate the parameters of the inductance of the newly assembled coil. They may not coincide with those on which the tile electronics is calculated, as a result of which the control unit may fail. For calculations, you need to have good knowledge in the field of electrical engineering and be able to understand the connection scheme;

- Most plate models are equipped with an automatic shutdown after 2-3 hours after the start of the burner. This will lead to regular shutdation of the boiler;

- Induction type tiles usually have no capacity of no more than 2.5 kW, so suitable only for alterations on low power boiler.

Errors in the device induction boiler from tile are shown in the video:

Simplest use of induction tile, eliminating disassembly of the device and installing a new scheme - to install a sealed stainless steel tank on it suitable size With input and outlet fitting and connecting it as a boiler in the heating system. With such a connection scheme, almost everyone can cope.

In the presence of required knowledge And the ability to understand the schemes can follow the example of the author of the video and collect a functional induction boiler from the tile, finishing its scheme.

Dry type heater

The principle of operation of the induction boiler involves the use of water or other liquid not only as a coolant, but also for cooling the core. But the heating of the secondary winding, the role of which in this device plays a pipe with water, will occur in the event that it consists only of metal.

The degree of heating in this case depends on the ratio of the power of the electromagnetic field created by the winding, and the mass of the core metal. Making calculations, you can create a dry induction heater do it yourself out metal pipes and copper winding, as shown in the video.

The use of an induction boiler costs cheaper than an ordinary electric unit with Tanans, and homemade design It will significantly reduce the cost of its installation. Similarly, you can collect a water heater flow-up To install in the country, pickup the device required.

Heating is an indispensable attribute of almost all country houses and cottages. After all, from how the heating system operates, the heat and comfort of home comfort depends largely.

On the modern market heating equipment The boilers of all sorts of modifications occupy a very wide niche. Everyone may choose an individual boiler unit depending on the possibilities and technical need.

However, it is worth noting that constant growth different species Fuel leads to the fact that many owners of households are beginning to think about what heating is to establish that it effectively hesitated the room, and at the same time there was an explicit savings of cash spent on the heating of the dwelling.

An induction heating can be alternative in this situation, which can rightly be considered a new technological thought.

In order to understand what we are talking about, we will discollect in detail all the important sides of this type of heating equipment in detail, and we will also describe what the principle of operation of this heating.

Design

The main element of this type of heating is the induction boiler.

This unit is a kind of electric water heater, which operates on the basis of electromagnetic induction.

The design of this electric boiler unit, as a rule, consists of the following main elements:

- outer housing, which is made of metal;

- internal node consisting of ferromagnetic pipes with winding;

- the insulating element, which is located between the housing and the inner node, simultaneously performs the function of insulation of light and heat.

Thus, the unique design of the induction unit allows it to be used for the heating of dwellings, heating the garage and various economic premises.

How does it work

The principle of operation of the boiler of this species lies in a number of following actions:

The principle of operation of the electric boiler of this species can be considered in the following figure.

Device induction heating system

The heating system of this type consists of the following elements:

Based on the above scheme, you can safely conclude: induction heating can be made with their own hands.

Main advantages and disadvantages

The heating system based on the induction boiler has a whole near positive momentsTo which can be attributed:

It is also worth indicating that induction heating has some drawbacks to which the following points can be attributed:

- induction boilers are installed only in closed heating systems;

- mandatory forced circulation;

- mandatory electrolyney equipment in 380V for bootloads with a capacity of more than 6 kW;

- if the coolant feed stops, the functioning of heating is automatically terminated.

And in conclusion I want to say that many reviews of induction heating owners say that it is enough practical way Heating of any types of buildings. And indeed it is! After all, the efficiency of the electric boiler of this species and excellent specifications do not cause any doubts.

See the video in which it describes in detail about the features and benefits of induction heating: