How to paint the PVC panels in the bathroom. Paint for PVC windows and panels - selection, consumption, reviews

Now in fashion wall and ceiling panels From plastic. Many owners of residential premises use them as finishing material. But not all satisfied color paletteTherefore, the question often arises: how to paint the PVC panels and is it possible to paint them at all?

Given the huge range paintwork materials In the sales market, pick up the paint on the plastic will not be a special problem for the user. But before proceeding with painting, you need to decide on the color that the homeowner is most promoted in the interior of the room. As a rule, acrylic compositions are made under pastel, medium and saturated tones.

Before painting plastic panels, it is necessary to prepare the surface to paint, prepare materials and tools that include:

- Purifier for plastic panels;

- Cotton fabric without a pile;

- Special paint for plastic;

- Protective gloves and respirator.

It is best to treat the surface with high-quality and inexpensive cleaner. On the plastic there may be traces of lubricant, which is covered in manufacturing. With the help of the cleaner, the material manages to degrease, remove dust, statistical electricity. This means is applied to the fabric without a pile. It is treated with the surface of the plastic. Cleaning the surface, you need to wait until it dries, but only then you can paint.

Many believe that the panels can be painted with a roller or brush. This is an erroneous opinion: as an instrument for applying paint can only be used the paintopult, and paint plastic - by spraying.

On video: PVC and MDF panels.

What kind of paint can be used?

Not every paint is kept on plastic panels. Therefore, for such a material there are special species compositions. Today, you can get the paint of the desired shade without difficulty. Choosing paint for plastic, you need to consider the conditions under which staining will be carried out. It's one thing when it comes to internal painting works, and the other, if they are held outside.

If you choose decorative materialsthen you should know what they are used for decorative decorationsAnd for their application there are special stencils. Technological compositions are intended for reliable protection Surfaces from damage and wear.

To avoid problems in working with paints, you need to strictly choose those materials that are intended for PVC panels. Painting allows you to extend the life of plastic and make it decorating the interior design.

Often plastic are painted with polyurethane water paint, the durability of which is verified in practice. In order for the layer of painting was more durable and served longer, a varnish is applied on top of the dried composition. Drying can be performed by natural or enforced way.

To date, polyurethane-acrylic water dispersions are also used for painting plastic surfaces. Such colorful materials are painted windows, doors, panels, other pVC products. You can list the following advantages of using such dyes:

- these are environmentally friendly paintwork materials, which contains non-solvents;

- the coating applied to such paint serves as an excellent decorative decoration;

- coverage is steadily for deformations and pollution;

- such paints are water repellent.

Acrylic paint for plastic panels quickly dries. So if for some reason the color of plastic finishing materials owner does not suit, they can be painted with acrylic composition. A large range of colors allows you to choose a material under the interior design of any room.

Polyurethane acrylic LKMs are resistant to pollution, impact of atmospheric phenomena, elastic and environmentally safe to use. They do not have a sharp smell, are easily cleaned of dirt and dust, have a water-repellent composition. The service life of such a coating is long. The only drawback of this material is the complexity of application.

Choosing paint, you need to pay attention to the composition and instruction, because a good product Must get dry no later than twelve hours. It should be focused on hardness, degree of repulsion from the surface, learn about the presence of organic compounds in the paint.

It is also necessary to pay attention to the manufacturers of paints and varnishes. Acrylic paints are considered harmless, and after their application, a coating is obtained, an externally resembling the surface of plastic panels. As for the water-emulsion analogs, they are not suitable for painting plastic, because they will simply flock from it.

Features of staining

Knowing how you can paint plastic panels, how to prepare them for this, which technicrafts for this use, you can proceed to the painting process. Pay attention to the following principles:

- Painting works need to start an hour after paint tinting.

- Before starting staining, it is required to determine the viscosity of the composition and, if necessary, breed the paint with clean water.

- Paint is applied exclusively to the paintopult.

Following the instructions how to paint the panels, you can achieve an excellent result. In the process of work, it is necessary to cover the adjacent film with the surface panels so that paint material does not spray.

It is necessary to select the optimal parameters of the collapse, the diameter of the nozzle of the pistol and the working pressure, as well as to monitor the thickness of the layer. Spray the dye need a layer of 6 mm. The thinner the coating, the faster it dries.

Light plastic can be painted in one layer, and the dark is better to cover the paint twice. For drying paint, the temperature in the room should be at least twenty degrees of heat. Check if the panels were dry, it is necessary not earlier than six hours later. If the color of the panels does not suit, it is better to paint them with acrylic composition.

You can paint I. oil colorsHowever, they are distinguished by a sharp smell. But they can be applied with brush or roller. Just for a while you have to leave the room in which such paint was used. If there are no practical skills in the performance of such work, it is better to charge the painting of plastic panels experienced in painting to specialists who will fulfill painting quickly and efficiently. The quality of the painted panels and the interior design of the room in which they are installed are dependent on the quality of the painting.

What experts say (2 video)

PVC panels of different colors (20 photos)

The urgency of the color replacement of plastic may occur due to the need to create harmonious design interior. Exists great amount Shades of paints for PVC windows. It is only necessary to choose your perfect option and get acquainted with the technology of painting material.

When maybe you need paint for PVC plastic? Material can burn from exposure sun ray, lose your primordial look. May be violated and physical properties. Staining protects plastic from any defects.

Choker selection

First you need to choose paint for PVC windows. If grinding and primer work is planned, the paint should be suitable for plastic.

In building stores, buyers provide special directories, with which you can easily find the tint without any problems. It is worth deciding with the required amount of paint, taking into account all repainted windows. Approximate consumption of PVC paint on 1m - 130 g. The coloring agent is better to buy with a small margin. But it is better to approximately calculate the painted area so that it does not have to interrupt repair work Due to the lack of a kole. In addition, the desired shade of paint for PVC plastic at that time in the warehouse may not be.

The paint must be prepared in advance, dilute, if necessary, and give it a little to stand. Only after that you can proceed to applying.

Preparation for work

- prepared surface quickly and without much effort;

- for room temperature The kel dries very quickly;

- at temperature mode, 20 ° C coating will dry about eight hours;

- staining can be performed in manual mode or using a sprayer;

- huge decorative opportunities: imitation of wood, pearl texture, metallic.

The surface must be prepared for painting. It is necessary to remove all the dirt, the remains of silicone, fat stains - all this can negatively affect the adhesion of plastic with a kelper.

- remove all dust, chips, crumbs;

- special plastic cleaner wipe the entire surface;

- degrease the surface from various dirt and lubrication;

- wake out a few minutes to complete surface drying and evaporation of the cleaner.

It is worth getting a special activator cleaner for PVC. It will not only prepare a coating, but also contributes to the clutch of materials.

It is possible to polish plastic and take care of its primer. But it will take significantly more time, in addition, certain skills are required in this work.

Stage of applying paint

Paint for PVC profile should be applied into one layer at room air temperature. Using the sprayer, you can perform all the work quality and faster. For applying the koller, it will fit a roller or brush. The latter is better to use for staining complex small details.

During the application of paint, it is necessary to monitor the uniformity of application and the absence of flutters. If it is decided to make painting on your own, it is better to abandon the tools that require a certain skill. It is worth staying on a painting brush or roller for staining a large area. If this method is selected, then temperature mode For dryshka plastic materials - From forty degrees.

During the work, Malar Scotch may need. It will prevent paints from entering the non-stainable surface and simplifies the work.

It takes about eight hours for drying, but it will take another 72 hours for complete consolidation. If necessary, apply a second layer, but only after drying the previous one. Careful drying is a prerequisite for plastic. Otherwise, the paint will not last long.

It is possible to make painting yourself if you adhere to all rules and recommendations. The main thing in this matter is accuracy and cheepingle.

Need to restore or repaint decorative coating On plastic parts and facing from PVC, it arises much more often than it may seem at first glance. It can be a metal surface plastic windows Veranda, household equipment, soft inflatable boat, plastic body elements on car and even protective covers of fabric. Polychlorvinyl plastic paint is not difficult, but under one condition, if there is a special PVC paint.

Complexity in coloring how to paint polychlorvinyl

For staining of plastic, acrylic or acrylurean paint for PVC profile is used. As a rule, due to a high gloss or a specific "fatty", paraffinous texture of the PVC surface, the usual acrylic paint on the plastic lies very badly, rolls up with drops. Even the classic increase in the increase in adhesion paint with applying artificial roughness does not improve the adhesion with the base.

Therefore, before trying to put paint on the frame of windows or attachments from plastics, it will take a solid preparation of the PVC surface:

- On the eve of the use of paint, the PVC surface is cleaned from dust and dirt with soap water and washed with clean water so that there are no traces left. Ideally suitable detergent for PVC parts, but you can use and water solution isopropyl alcohol;

- The surface is treated with a special solvent-activator that improves sticking or adhesion of paint to smooth PVC profile;

- If the staining uses acrylic paint on a water basis, PVC plastic can be slightly moistened from the manual pulverizer, and then apply a paint material with a brush or by painting.

Important! It should be borne in mind that the quality of the painted surface depends primarily on temperature and humidity. The higher the temperature ambientThe better the grip, and above the speed of the drying.

After about a couple of hours, the PVC applied at a temperature of 20-23 about the paint will cease to stick to the hands, and after 26-40 hours, the drying process of the painted surface will be completely complete.

Water soluble acrylic paints allow to obtain the painted PVC surface different colors And shades. According to the paint manufacturers, the Tinting Installation, with which the toning and the color adjustment is performed, more than 2 thousand color compositions can be issued.

Technology of dyeing household items from PVC

The high quality of the surface in the surface can be obtained only if we use specially developed tools for painting surfaces from polychlorvinyl to any modification. More simple materials, for example, frames and facing metal plastic windowsIt may even be painted with acrylic materials, but to obtain an exemplary glossy surface, the paint containing modifiers and polyurethane varnish will be required.

Therefore, to obtain high-quality perfectly smooth textures from PVC most often use:

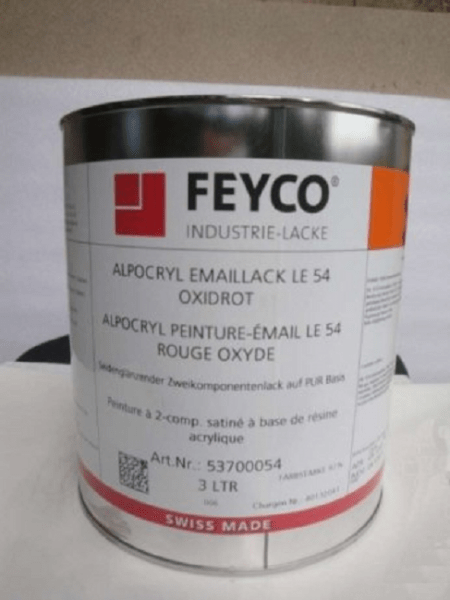

- Polyurethane paints and varnish compositions of FEYCO AG, Switzerland;

- Acrylic Urethane paints "Paliplast RP Base" used for industrial staining plastic PVC.

For your information! Painting compositions "Paliplast" are produced on both water and lacquer-based.

Despite the fact that, after drying, the water-fused compositions "Paliplast" are not washed off with water and withstand the multiple washings of windows and frames, periodically it is necessary to restore the protective layer with varnish, for example, "Paliplast RP 022 Varnish".

Staining plastic surfaces PVC at home

The most popular treatment procedure of polyvinyl chloride plastics is the painting frames of metal-plastic windows. Not everyone likes white color standard PVC. Facing, or the owners want to make windows of their store or salon more expressive, in any case, the windows of the windows do not represent any particular difficulties if used materials for PVC "Paliplast RP BASE".

It will only be necessary to stick the window, slopes, glass and rubber compactor frames with a polyethylene film with a painted tape, and can be stained by the method described above. The easiest way to apply paint on PVC profile with a tassel or roller, but best quality It turns out when using collapse low pressure. The viscosity of the paint is small, but the presence of mineral fillers can sometimes lead to blocking the nozzle or poor spraying, so the paint solution must be cleaned from the films and mix thoroughly.

More complex is painting decorative and protective elements from PVC plastic on the car. Most often it is moldings and lining inside the interior of the car. The size of the details is small, so it is best to use aerosol packaging for PVC plastic staining. The composition includes an activator and solvent, providing good adhesion to plastic and rooted drying of the applied layer.

Color small details From PVC, you can with a preliminary dismantle from the car, and directly inside the car. In the latter case, it will be necessary to install a fan to make an aerosol flow from the cabin and make a apron from polyethylene filmwhich will close the space around the painted part of PVC.

Full-size parts from polyvinyl chloride must be dismantled, clear from dust with alcohol or a tool for washing windows, and after that an aerosol with thin layers, 50-70 microns thick.

Complex options for painting PVC plastic

To large parts of the body kit or spoilers, paint can be applied using a sprayer or collapse. Initially, it will be necessary to perform surface matting with thick paper and micron-size abrasive powder. Next, plastic is thoroughly washed and dried.

Before applying paint, the surface will be required to wipe the PVC napkin moistened with solvent "P646" and can be painted. If the thing is very thin and soft, then the first layer is better to perform a polyurethane varnish "Feyco", after which you can apply required amount layers of paint.

In the same way, you can paint polychlorvinyl pipes, framework frames, even glass and furniture. To increase the adhesion of paints to an absolutely smooth and inert glass surface, FEYCO offers to add a special reagent "Fey (N) Vetro ZUSATZ 501 to the paint. Polyurethane I. epoxy compositions It is possible to paint metal enough, stone, plastic, wooden surfacesAt the same time, the quality of the clutch is significantly higher than that of acrylic and water-dispersion materials.

Separately, you should mention the painting of soft PVC fabrics, such as covers or housing inflatable boat. Most polyurethane paints It can be used for dense PVC tissues under one condition. Staining is performed using a barrier sublayer from a solvent in a solvent in proportion 1: 3 of the "Feyco UniversalPrimer 2159" soil, with the addition of "Fey (N) Vetro ZUSATZ 501". The sublaw is applied with a thin layer of 20-25 microns with a thin layer. Subsequent staining is performed by conventional polyurethane paints.

If there is no special desire to look for optimal recipes for staining soft tissues, the barrier layer can be done using aerosol paint for cars.

Conclusion

Polyvinyl chloride staining is not a sufficient task, if you use correctly selected materials. Given the high durability of PVC plastic, the demand for special paints for decor or repair is only increasing, so the technology of staining is improved, and, apparently, in the near future, the problem from PVC painting is finally solved.

There are situations where motorists and owners of houses or apartments are decided to change the usual interior and color of the room or car, as a result of which they will put an interesting question in front of them: how to paint plastic and what materials for this can be used?

Mobile plastic

As a rule, the technology of performing painting works for any surfaces remains the same. But except general requirements, there are also some subtleties, without which it is simply impossible to perform a high-quality finish. That is why such additional information should be adherent.

Species of paints for PVC products

Mobile plastic

Today, the market of paints and varnishes is a huge variety of paints, which can be qualitatively covered. pVC design. They can be both in the form of an aerosol and spray and the form of the usual paint for applying a brush or roller, which can be both matte and glossy or pearl.

Specifications suitable for plastic paints are shown in the table.

- Maraplan is a wonderful example for PVC works.

Finishing works of such paint are performed using a roller, sponge, brushes or sprayers. If such a plastic paint is applied at a temperature of 20 ° C., after 20 minutes, you can begin to apply the re-layer, and even after 4-5 hours, the product will be absolutely ready for use. Maraplan's paint is very resistant to the effects of ultraviolet rays, as well as durable to mechanical damage. But it is better not to expose the film with mechanical overload until the coating is completely drying.

- Rainbow-180 is an absolutely white glossy coating for PVC cloths.

Such paint on plastic is used to design windows, window sills, plinths and other hard plastic, which can be used for both exterior and for interior finishes. In addition to PVC, the aerosol is suitable and different surfaces, as well as putty and wood. You can work with such paint at 15-75 ° C, and the next layer can be applied after 1-2 hours. Such paint is great for outdoor decorations.

- Snowball - Enamel based acrylic for the decorative framing of hard PVC and other materials.

By advice experienced masters, apply such a coating is better in 2 layers. After applying the paint, the surface of the plastic will be matte after 5-15 hours, but to use this coat It is possible for outdoor, and for internal works.

- Amelight is a coating that is capable of dark or green in a dark room.

Pray plastic with your own hands

This paint is widely used for works on PVC, ABS, polystyrene and polypropylene. She has increased level Strength and weather resistance. Such paint has proven well when restoration of pots, furniture, souvenirs, window and door blocks using a sprayer or a dipping method from 1 to 3 layers, as indicated in the instruction manual of the material. Before entering painting workAlso in the process of their execution, paint all the time need to be mixed thoroughly, because the additives are prone to settlement, and the time for drying the finish varies in the range of 2-4 hours.

- Gamma - acrylic paint, is represented as an aerosol.

In the palette of such a finishing material there is about 25 shades that are applied to plastic, wood and steel, it is also well suited as a spray for applying graffiti. The decorative coating thus obtained will be atmospheric, have a deep color and muffled glitter. For achievement best result It is better to select a white foundation (if we are talking about a fluorescent version - this requirement is mandatory). Sometimes it is necessary to increase the contrast and strengthen the color to adjust the material in 2 layers, but re-apply the material is allowed only after 30 minutes, so that the lower coating has done properly dry.

It is also worth highlighting a separate category of paints, which includes chrome. Chrome are also called as "mirror paint" most appropriate in mechanical engineering. To apply chrome on the surface of the product, both an aerosol and a galvanic method, the difference will be practically imperceptible.

To date, such a finish, like chrome (especially in the form of an aerosol), is gaining more and more popularity. Chrome mirror features, fascinates the eye of passersby, so it loves to use Motto and car enthusiasts.

In addition to high strength, chromium withstands high temperature differences, and it is absolutely not important that it is used to apply an aerosol or painting was produced at the factory.

Chrome may have a gold or silver color, which can also be an interesting detail when making the interior of your apartment. In addition, chromium is characterized by excellent physical, chemical features and a democratic price.

How are painted work?

Before starting to paint work, the plastic should be pre-purified and dried, because it is allowed to paint only with a good level of adhesion, which will be achieved only on a skim and purified basis.

To prepare the surface and its purification, in no case use the usual solvents or long ago all familiar White spirit. Today, specialized compositions are presented on the market for plastic cleansing in a wide range.

Please note that not every plastic needs a primer, and sometimes it happens with accuracy, yes, on the contrary, it is impossible without it. To understand how to act you in specific situation, There are 2 simple check methods:

- Buoyancy

For such a check, it is worth taking a piece of plastic and lower it into the water. If he starts sinking, then the primer will not need. If the material on the contrary will lie on the surface of the water - without priming anywhere.

- Combustion

If, during arson, the material begins to smoke - the primer does not need to be applied, and if "purely" is burning - the imposition of the primer layer is inevitable.

If you need to paint not a new item, it may be that it will be eaten to span, for which the sandpaper will be required at number 320-400 and water to remove the slots and cracks.

Mobile plastic parts independently

When painting, the paint is applied to the surface with brushes, paint rollers on a woolen or mohair basis. Aerosols and sprays for small-scale production can also be used.

Often the need to paint plastic windows or doors in accordance with color gamut Interior, make less noticeable outdoor communications from PVC or simply protect material from burnout and destruction. This requires special PVC paint, which will be firmly held on the smooth surface of the material being processed.

Primary requirements

The main requirement to which such paint should correspond is high adhesion. Unlike wood, plastic has a smooth slippery surface and a very solid dense structure that does not give high level Clutch between materials.

Also, the coloring composition should have the following characteristics:

- water resistance;

- strength;

- resistance to mechanical influences;

- resistant to the effects of UV rays;

- preservation of color during the entire period of operation;

- absence in the composition of toxic and poisoning substances that may be released during heating;

- resistance to temperature differences;

- long service life;

- extensive color gamut;

- the possibility of giving the object of a specific texture.

An important role is also plays the ease of applying composition, since often the color of plastic windows is made with their own hands.

Polyurethane-acrylic composition

All these qualities have polyurethane-acrylic paint on a water basis for PVC. It is characterized by homogeneity of the coating, resistance to defect formation, high speed of drying, allows for self-taking. With it, it is possible to create textured effects using the introduction to the basic composition of special additives.

A wide color spectrum of such paint has more than 2000 shades. In addition to traditional tones, there are:

- nacre;

- metallic;

- composition with the addition of sequin.

In this case, PVC-profile painting will give the place or facade of the building originality and uniqueness.

Preparatory work

Before the windows, doors or other surface with your own hands, it should be carefully prepared. For this you need:

- Remove mosquito nets, Blinds, Curtains, Salves and other items that will interfere with work.

- Release the surface from mechanical pollution.

- Remove fat stains.

- Seal rubber seals and other construction scotch equipment accessories to avoid paint.

- Glasses should be closed with a plastic film.

For more effective cleaningDegreasing and removing static voltage You can use specialized activator cleaners for PVC. They are applied to the tissue napkin, which is wiped with the treated surface. After that, it is necessary to enable the solution to completely evaporate, which takes from 5 to 10 minutes, and only after that proceed to painting.

In case the surface has roughness, scratches and other irregularities, they must be sharpened, and then polished with shallow emery paper. In complete, you should cover the entire surface with a smooth layer of primer. With certain skills, it can be done with your own hands. But if there is no experience, it is better to resort to the services of professionals.

Application technology

Windows and other PVC products are painted with the help of a krash. Before pouring a polyurethane-acrylic paint into it, it is necessary to add a suitable color to it and stir thoroughly.

After opening the jar on the surface of the coloring composition, it is sometimes possible to detect a film that must be removed. It contains solid particles that do not dissolve with stirring and scoring the sprouting nozzle.

If the paint has been freezing, it should be thrown out, because after exposure negative temperatures She loses its properties.

For staining it is better to choose dry, but not very hot weather. It is impossible to carry out work at temperatures below +5.

The paint for windows is applied with a thin uniform layer with a thickness of 80 to 120 μm. At the same time, there is no need to pre-paint corners, faces and hard-to-reach areas. The composition is perfectly held and does not flow with vertical surfaces. The paint begins to stick tightly on the surface after 2-3 hours. But its full drying continues for another two days.

In industrial environments, a forced drying is used for two hours at a temperature plus 50.

Aerosols

For dyeing a small surface of PVC, you can use paint in an aerosol cylinder. This container is convenient because it reliably protects the contents from air from entering the air, therefore, it prevents the formation of the film on its surface.

To other advantages of this paint include:

- convenience during transportation;

- ability to dyeing hard to reach places and small details;

- no need to use additional tools;

- increased level of adhesion.

Most often, aerosol paint is used when painting parts from PVC in car salons.

Uniform paint application requires certain skills and experience, therefore it is necessary to practice a bit before proceeding to the coloring procedure.

Coating protection

Despite the fact that acrylic paints are well kept on the surface of PVC products, they can be additionally protected using a glossy lacquer for plastic having a water base. In addition to the protective, it performs the decorative function, giving the product shine.

This material can be used to process painted plastic window sills and windows in kitchens, where they are exposed to aggressive factors.

Varnish is applied using a brush and does not require certain skills. Therefore, these work is easy to implement with your own hands.

To protect the windowsill in the kitchen and pipes passing near open fire, which are also suitable, which are often used for metal surfaces.

Important moments

Purchasing paint for processing plastic windows, you must first calculate the right amount material. To do this, it is necessary to make measurements of the surface that will be processed. Accurate calculation will produce sellers consultants.

The cost of polyurethane-acrylic painting composition is sufficiently high. However, the small consumption of material and long term Services without additional treatments fully justifies costs.

When applying paint is the most an important factor is precise compliance with instructions. High ecological safety indicators of the presented paints for PVC make it possible to apply them in residential premises, children's and medical institutions, catering points.