What and how to build a simple bathhouse in the country? Budget sauna: how to get significant savings without losing comfort We build a sauna with our own hands a step-by-step demonstration of construction.

When hiring a construction team, the cost of construction will double, so if you have at least basic skills, it is better to start building a bath with your own hands. First of all, you need to decide on a building plan. You can create your own or use ready-made drawings and choose the design that is most suitable in size.

Building registration

No permission is required for the construction of ancillary premises on a private plot. However, after the completion of construction, the building must be registered with the BTI.

Regulated distance between buildings

Calculation of the amount of materials

Most often, baths are erected from solid or rounded coniferous logs, thick-walled timber, arbolite or brick. In recent years, foam concrete has also been used for construction. However, wood is considered the best material for it. Even in the hottest heated sauna, this environmentally friendly material will breathe easily and freely.

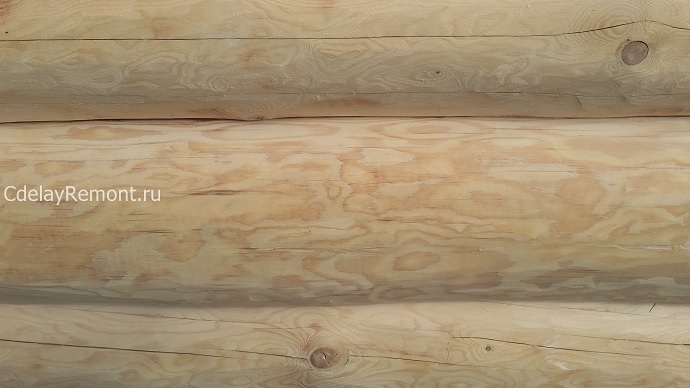

Rounded logs, regular and profiled beams

Construction of a bath from chopped, rounded logs and beams

Shrinkage of the building

Collect building from a bar preferably in winter. The fact is that in winter moisture freezes out more slowly, and the deformation of the material occurs more evenly. By the end of summer, the main subsidence is almost over, and finishing can already begin.

Erection of the foundation

If the groundwater in the selected area is deep enough, it makes sense to use an ordinary strip foundation. A pile or screw foundation is erected only when the waters are close.

Tape and pile foundations for a bath

Laying the first crown

1. The trim (first) crown, which is closest to the ground, needs reliable waterproofing. For this, 2-3 layers of roofing material or other material based on bitumen are laid between it and the base. On top of it, in the transverse direction, short slats of 15 mm, treated with an antiseptic, are placed, and only then the logs are laid out.

Direction of laying the battens

Corner connections of log cabins

The corners between adjacent walls can be connected in different ways in log cabins:

Corner connections of log cabins

Assembly of a log house

1. The logs should fit as closely as possible to each other. The seams between them are laid with a sealant: tow or jute. The gap between the flange and the foundation is additionally sealed with bricks, polyurethane foam, halves of logs or bars. You can also provide a fill multilevel foundation, which will prevent the appearance of cracks.

Foundation with different levels

Okosyachka for windows and grooves in window openings for her

Construction of a bath with your own hands in stages, video, photo

Therefore, if you have at least basic skills, it is better to start building a bath with your own hands.

DIY bath construction: step by step instructions

Before building a bath, you need to draw up a detailed step-by-step instruction for the work, which should take into account all the nuances of the technology for the construction of a bath complex.

The step-by-step instructions that are used in the construction of a bath can vary significantly depending on the materials used during installation and the characteristics of the soil at the site construction works.

In the process of building a bath complex, a variety of materials can be used for work. Depending on the type of foundation, for example, metal and asbestos-cement pipes can be used when laying a pillar foundation or cement-concrete mortar and metal reinforcement when erecting a strip foundation. The following building materials can be used for the construction of walls:

The most popular material used in the construction of the bath complex is timber. This material is also considered to be the most practical and convenient to work with.

The use of a bar allows you to significantly save money on the construction of the foundation. In the case of the construction of a bath complex from a bar, it is allowed to lay a light foundation. The use of a bar allows you to erect a building that practically does not shrink, and during the installation process, additional adjustment of structural elements is not required.

Building a bath using step-by-step instructions allows you to avoid almost all mistakes during the installation process and build an excellent bath complex with your own hands, without the involvement of outside specialists. Step-by-step instructions for building a bathhouse greatly facilitate the installation process, even for those homeowners who have minimal knowledge and skills in the field of construction.

Choosing a place for the construction of a bath complex

Choosing a place for the construction of a bath complex

The step-by-step instructions for the construction of a bath at the initial stage involves the selection of a place for work and preparation of the construction site. The ideal option is to choose a place for the construction of a bath even at the stage of planning the placement of objects on a private land plot. Very often, in the presence of a small plot, the bath complex has to be combined with some outbuildings, for example, such as a toilet and a summer kitchen. In some cases, the combination of a bath is carried out with a residential building. Bath complexes of this type are quite complex, and their development requires the involvement of professional designers of residential buildings.

When designing a structure and determining the place of its construction, it is necessary to take into account some natural factors that affect both the choice of the location of the site for construction and the layout of the bath complex:

- the level of occurrence of subsoil waters;

- determination of areas that are flooded during the onset of floods;

- location of a natural reservoir;

- prevailing wind direction and rainfall patterns;

The groundwater level is easy to determine on their own... For this purpose, it is necessary to dig holes at the corners of the location of the construction site with a depth of at least a meter and, after a while, check whether water has appeared in them or not. The level of occurrence of groundwater affects the choice of the type of foundation for the construction of a bath complex.

The best option for choosing a site for all construction and installation work is a hill located at a short distance from a natural reservoir.

High-rise construction avoids flooding when floods occur. The distance to the natural reservoir should not be less than 15 m, and in the absence of an elevated site, the distance to the reservoir should be at least 30 m.

In the process of choosing a site for construction, it should be provided that the distance to the border of the site from the construction site should be at least one meter. In addition, the site for the construction of a bathhouse should be located at a distance of 15 m from existing buildings.

Tools and building materials required for the construction of a bath

Tools and building materials required for the construction of a bath

Before building a bath, when developing step-by-step instructions after choosing a place for the construction of a structure, you should decide on the materials and tools necessary for carrying out construction work.

The most popular material is timber. It has a whole range of advantages. The most convenient to use is a type of timber - profiled timber. This material is resistant to deformation. When building a bath from a bar, you will need to prepare the following building materials:

- timber with a section of 15x15 for the installation of external walls;

- timber with a section of 15x10 for installation work on the erection of partitions inside the building;

- cement-concrete mortar for the construction of the foundation;

- reinforcement for reinforcing the foundation;

- building materials for waterproofing;

- crushed stone to create a blind area;

- timber for creating floor logs and floors;

- materials for insulation;

- materials for interior decoration;

- materials for creating steam and heat insulation;

- materials for roof installation.

The list of tools necessary in the process of work includes a shovel, a hacksaw for wood, an ax, a hand electric drill, a hammer, tools for laying an inter-crown insulation and a mallet.

Building a bath with your own hands

The next item in the step-by-step construction instructions for the construction of a bath complex is the construction work itself.

The entire range of required construction work can be divided into several stages. The main stages of construction are as follows:

- marking of the construction site and site preparation;

- laying the foundation;

- arrangement of the blind area;

- erection of the walls of the bath complex;

- floor installation;

- assembly of load-bearing roof structures;

- installation of roofing material;

- installation of hydro, steam and thermal insulation;

- assembly of communications in the premises;

- laying the floor;

- installation of finishing material.

It should be remembered that after the construction of the foundation foundation, it needs to be given time to gain maximum strength. When using a strip foundation, the period for gaining maximum strength with a cement-concrete mortar is 28 days.

Before proceeding with the installation of the walls, it is necessary to ensure the laying of high-quality waterproofing on the surface of the foundation between it and the first crown of the walls. High-quality waterproofing will significantly extend the service life of the building of the bath complex without major repairs.

After the completion of the installation of the walls of the building, the assembly and installation of the supporting roofing structures is carried out. The features of the roof supporting structure depend on the roof configuration.

When the roof is installed, they begin to install engineering communications and the floor in the premises, at the same stage, steam, hydro and thermal insulation is mounted.

Carrying out interior decoration and insulation of the bath complex

Carrying out interior decoration and insulation of the bath complex

Insulation of the ceiling of a small bath can be done in a flat way. For this, hardwood lumber is used. Boards up to 50 mm thick are sewn onto the floor, after which a layer of vapor barrier material is fixed on them. Foil-clad material is perfect for this purpose. On top of the vapor barrier layer, a layer of insulation is applied and fixed. Mineral wool can be used as insulation. After laying the mineral wool, it is closed with a protective layer of foil material. The last stage of work with the ceiling will be the installation of finishing materials.

If a beam of sufficient thickness was used during the construction of the bath complex, then you can do without installing a heater on the inside of the walls of the bath complex. In this case, before finishing, a layer of steam and waterproofing is strengthened on the walls of the bath, on which it is mounted finishing material... If the thickness of the timber is insufficient, then the insulation of the walls inside the bath is carried out in the same way as the insulation of the ceiling.

Insulation of the floor in the bath room can be carried out using expanded clay.

For finishing interior space bathing room it is best to use a lining made of wood that does not have structural defects. The material is fastened with small nails.

Compliance with their sequence in the process of construction work allows you to build a high-quality structure, which will delight the owner for a long time.

Affordable and step-by-step instruction for the construction of a bath

Step-by-step instructions for building a bath. This instruction will help you avoid problems when planning and building a bathhouse on your site.

Build a bath with your own hands

Do you want to build a bathhouse, but do not know what material is best to use to implement your idea? Then be sure to pay attention to the timber. A bath made of this material will be environmentally friendly, reliable and durable. At the same time, you can handle the construction of such a structure with your own hands.

Build a bath with your own hands

The advantages of building from a bar

There is absolutely nothing complicated in self-building a bath from a bar. This material has many advantages over its closest analogue - a rounded log (log house). Among the main advantages of the timber, the following points should be noted:

- all work on the construction and further decoration of a bath from a bar can be performed without the help of outside specialists;

- timber gives minimal shrinkage compared to all other wood-based materials;

- the construction of a bath from a bar will require a much more modest financial investment compared to most other popular materials;

- prefabricated timber may initially have fasteners and you will only have to assemble individual elements into a structure the right size like a constructor.

However, in order for a timber bath to fully manifest all its advantages and serve for the longest possible period, you must responsibly and competently approach the choice of building material.

What kind of timber can be used to build a bath?

The most important operational parameters of the finished steam room directly depend on the quality of the wood. First of all, pay attention that the logs are intact. No cracks or other defects are allowed. Even minor damage can lead to big troubles in the future, as a result of which the wood will rot and collapse.

Log and bar profiles

Make sure that there are no blue spots on the surface of the wood. Such defects indicate the presence of rot inside the material, the development of which, in most cases, is provoked by a variety of pathogens. It is impossible to use such material for the construction of a steam room and any other building.

There should be no noticeable traces of damage by beetles and other pests on the timber.

A high-quality timber has a perfectly flat and smooth surface. It is strongly recommended to refrain from buying material with distortions and any other damage - when laying the crowns, all deviations will clearly manifest themselves.

Bath building guide

Pre-compose yourself, order or find in open source bath project. Calculate the required amount of building materials for the project and start building a bath from a bar. Start by arranging the base.

The first stage is the foundation

The finished wooden steam room will have a relatively low weight, which makes it possible to abandon the arrangement of monolithic buried foundation structures. A timber structure will feel great on an ordinary strip or columnar foundation.

To equip the base of the tape type, dig a trench around the perimeter and under the walls of the future structure, fill the bottom of the pit with a sand and gravel mixture, lay a reinforcing mesh, install formwork and pour concrete. The optimal foundation depth is 70-100 cm. When choosing a specific depth, be guided by the soil freezing indicators for your region.

Strip foundation - erection procedure

The structure of a monolithic strip foundation

The foundation should rise above the ground by at least 50 cm - this will provide the necessary protection of the lower rims from excessive moisture.

Place sand and gravel strips within the perimeter of the base strip. In the future, you can fill them with concrete or build a wooden floor - choose a specific option at your discretion.

To arrange a columnar foundation, it is necessary to erect supports made of bricks or concreted asbestos pipes around the perimeter, in the corners and under the future inner walls of the bath. Under each such support, you should first equip a concrete "pillow". Place the posts in 150 cm increments.

The device of the supporting-column foundation

Regardless of the type of base chosen, it must be subject to additional reinforcement.

Features of a columnar foundation with a grillage

Varieties of schemes for constructing a columnar foundation

Let the concrete gain strength within 3-5 weeks and proceed with further work.

The second stage is waterproofing the foundation

Waterproofing the strip foundation with a special compound

Apply molten bitumen to the surface of the base, and on it - a layer of roofing material. Let the bitumen harden and repeat the operations done. As a result, you get a reliable two-layer moisture protection.

Before proceeding with further work, saturate all wooden elements antiseptic... Such processing should be carried out after the preparation of the cuts for fastening the beams, if such cuts were absent initially.

The third stage - the first crown

Start laying the first crown of the walls. To do this, first place slats up to 1.5 cm thick, pre-treated with an antiseptic, on the waterproofed base.Place the slats in steps of about 30 cm.

Laying the first crown from a bar

Place the first circle of beams on the slats. Thanks to the slats, contact of the timber with the bath foundation will be excluded. This will provide additional protection against wood decay and will significantly extend the life of the material.

Assembly diagram of the first crown of a log house for a house from a bar

Lay the first crown without securing it yet. Make sure that it is laid correctly and evenly using a square and a level.

Align the lower rim bars, if necessary, and then attach them to the foundation. There are several ways of fastening. The most optimal and frequently used method involves fixing the timber with anchor bolts.

However, developers quite often refuse to attach the lower beam to the foundation. In practice, the structure stands perfectly well without fixing the lower crown, supported by its own weight. The advantage of this solution is that in the future, if necessary, the bar of the lower crown can be replaced with much less effort.

Blow out the space between the first crown and the base with polyurethane foam.

Bath from a bar with your own hands

The fourth stage - the rest of the crowns

For laying out the walls of the bath is perfect wooden bar section 15x15 cm.

Cover the first crown of the bar with thermal insulation material. Jute or moss are traditionally used for insulation. You can also use tow. In the case of using moss or tow, the thermal insulation should be laid out with a 10 cm overlap along the edges. In the future, you will use the raised edges for caulking.

How a bathhouse is built from a bar

How a bathhouse is built from a bar

Lay the second crown of the timber and fix it with wooden dowels. Pre-drill the mounting holes of the appropriate diameter. Usually the length of one dowel is enough to fasten 2-3 rows of timber.

Lay out the walls to the required height. Every 3-4 rows, check the structure with a square and a building level. Place a seal between the rims.

How to assemble the walls of a log house

The two upper rims do not need to be fastened. The wood will shrink. Ceiling beams can only be installed after the wood has shrunk. To install the beams, the upper rims will need to be dismantled.

Fifth stage - door and window openings

How to make door and window openings

There are two options for arranging openings for mounting doors and installing windows.

In accordance with the first variant, the aforementioned holes are created after the completion of the construction of the log bath. To do this, you must first leave small gaps in the crowns in the places where doors and windows are installed. The dimensions of the gaps depend on the dimensions of the installed products.

Door and window openings

After the completion of the construction of the bath, you will simply have to make openings with a chainsaw for mounting doors and windows.

In accordance with the second method, openings for doors and windows must be left even during the construction of the bath. This option requires a more significant investment of time and effort. To accomplish the task, you will need to use special grooves and bars with end cuts.

Sixth stage - caulking

Leave the finished lumber box for "wintering" for 6-7 months. During this time, the wood will shrink sufficiently. For the period of "wintering" cover the timber with boards and slate.

If you used tow or moss as a mezhventsovy sealant, you can skip this step of the instructions - an additional caulk will most likely not be needed in your bar bath.

However, experts recommend that you still study the state of the structure. If you find noticeable gaps, be sure to caulk. To do this, twist the tow or moss into a bundle and insert the material into the gap, followed by compaction.

You can also use jute sealer to fill gaps. By most indicators, this material is superior to tow and moss, but it costs a little more.

Seventh stage - roof

The roof must become reliable protection your log bath. You can start arranging the roof structure only after the wood shrinks, otherwise the roof will lead and it will be significantly deformed.

First step. Place timber beams on top of the top wall rails.

Second step. Attach the rafter legs in 100 cm increments to the fixed beams. To connect the rafters in the ridge part of the roof, cut them at the required angle.

Installation of a gable roof for a bath

Third step. Nail a solid plank flooring to the rafters (if soft roll material will be used for finishing) or build a sheathing (if you plan to trim the roof with tiles, slate or other sheet material).

Methods for joining rafters

Fourth step. Install the final roof covering according to the instructions for the selected material.

How is the roof of the bathhouse made

Fifth step. Cover the ridge with galvanized iron. This will protect it from adverse environmental influences.

Sixth step. Sew up the gables of the roof with suitable materials at hand - clapboard, wooden board or siding. In this moment, focus on your individual preferences.

After finishing roofing works proceed with insulation and other insulation works, interior decoration and arrangement of the steam room in accordance with your project.

Build a bath with your own hands - step by step instructions!

Find out how to build a bath with your own hands. Detailed guide on the construction of a structure from a bar. Photo + video.

Baths have come to our days since ancient times. Back in the Scythian era, mobile heaters and special tents were very popular. And in our time, even with the advent of a shower and a bath, the Russian bath has not become less common. It is visited not only in order to get satisfaction, but also in order to cleanse the body of harmful substances, improve overall health and get rid of diseases.

Now there are the most different variants construction of a bath. It is popular to build a bathhouse from foam blocks with your own hands, from a bar, frame-panel materials, a log house, a rounded log.

Before starting work, the construction of a bathhouse may seem like a very difficult task to many, but when a detailed plan is drawn up, it turns out that phased construction do-it-yourself baths are nothing heavy. There is a lot of work, but if you correctly design the structure and carry out the work one after another (in stages), then over time you will be able to see your dream in reality.

As you know, the bath has tremendous benefits for human health. Regular visits to her can significantly increase the tone of the body and improve it, as well as get rid of some diseases. The complexity of the question is that if you do not have your own bath, you have to visit paid establishments. And this implies additional cash costs, you have to adjust to the schedule of her work, neglect the rules of personal hygiene, because you never know who steamed in it in front of you and how it was then removed. Of course, it all depends on the institution itself, but nevertheless these factors create certain discomfort for steam room lovers. In this regard, many have the idea of building their own bath.

Initially, this idea may seem unsuccessful, because a lot of work needs to be invested. But when the first elements begin to be erected, the do-it-yourself bathhouse, the phased construction of which will already be planned, will rise before the eyes of the dreaming in a ready-made way, which will serve as an incentive to continue the path to its goal.

DIY frame bath construction

Before starting construction frame bath with your own hands, you should decide on a project that is suitable for carrying out bath procedures, which means that it must ensure the conservation of heat in the walls of the bath. Then, after the construction of the frame, insulation work is performed.

A bath made of such material has a number of advantages. It heats up quickly and retains heat for a long time if a sufficient amount of insulation has been installed. The cost of frame materials is relatively low. This was the reason for the increase in popularity for this type of construction of baths.

Construction of a bath from a bar

Many people choose to build a bathhouse from a bar with their own hands, since the advantages of this material, to put it mildly, inspire confidence.

The raw materials for the material are ordinary trees, which means it is environmentally friendly. In addition, being in such a bath is very pleasant and useful.

The construction process, provided that the foundation is ready, takes a little time, such a bath will serve for many years.

Construction of a bath from a bar with your own hands on a turnkey basis in Krasnoyarsk.

As a rule, the building is divided into three sections: a room for a boy, washing and resting.

DIY construction of a wooden bathhouse from a log house

The material for construction is rounded logs, which are pre-processed and ready for delivery to the construction site.

Turnkey log bath

Usually, logs are purchased from manufacturers who number them. The task of the builders will be to put the logs in the correct order. The building can be erected according to both a standard and an individual project.

Bath construction plan

Before starting construction, it is necessary to draw up a plan for the future building, prepare drawings. To do this, you must first decide on the size, which depends on the area of the site allocated for construction. Then the dimensions of the rooms can be calculated.

A full-fledged bath includes a dressing room, rooms for a boyfriend and washing (combined or not).

In order to understand the stages of construction and draw up a plan, you can find materials on this topic on the net. You just need to enter a request, for example: we are building a bathhouse with our own hands, a phased display of construction. After reviewing the results, everything will become much clearer.

The main stages of building a bath

The step-by-step construction of a bath with your own hands implies the implementation of each new stage after the completion of the previous one. In this case, a seemingly complicated process will seem laborious, but easy.

To understand how to build a bathhouse with your own hands in stages, video from the Internet will help the best. Or you have a familiar builder who can show and suggest. In any case, starting work without first looking at what is being done and how is not worth it.

Preparing materials for building a bath with your own hands

The most popular are the baths built of wood. They have many advantages over structures built from other materials.

Logs and several lower rows can be made from oak, which will have a positive effect on the durability of the building. Further, four rows are laid out with logs from larch, and the last rows are from linden or white spruce.

To build a bath, you need to use the middle part of the trunk, which must be dry and sanded. As a rule, wood is prepared in winter, due to the fact that it is not as wet as in warm seasons and dries faster.

Preparation of the foundation for the bath

When the construction of a bath is carried out with your own hands, the foundation deserves special attention.

In order to choose what type of foundation to build, you need to determine the type of soil on the site.

Columnar (pile) foundation is constructed on a weak heaving soils... As a rule, the pillars are installed at the joints of the walls, both external and internal. If the distance between them is more than 2 meters, then another post should be installed in the middle. The installation depth should not be less than 1.5 m and protrude from the ground by another 30-40 cm.

The distance between the pillars is laid out with a brick, which goes about 25 cm into the ground.

On the heaving soil, a strip foundation is poured. To do this, you need to mark the area and dig a trench. Then fill the bottom with a layer of gravel and sand. After that, you need to erect the formwork, and pour concrete.

The depth of the trenches should be at least 40 cm, width - 30 cm. The foundation should protrude about 15 cm above the ground. When pouring, be sure to use fittings.

Bath foundation waterproofing

The next stage is the implementation of waterproofing and the construction of the basement. To do this, use a brick, roofing material, pipe, masonry mesh, masonry mortar and mastic.

Bath floor device

For the floor, you can use clay, earth, wood or concrete.

In different rooms of the bath, the floors should be at different heights. In the steam room, the floor is 15 cm higher than in the washing room, in which the floors are 3 cm lower than in the dressing room.

The most practical option is to build a concrete floor with a ceramic coating.

How to make a floor in a bath

Sewerage in the bath

To drain waste water from the bathhouse, you need to dig a well for it, a pit with a water seal and install pipes. All of this must be built in accordance with technology to ensure long-term trouble-free operation. Pipes need to be taken plastic, not iron.

Installation of a log house, a roof for a bath

If the bathhouse was made by professionals, then it must be laid according to the numbers indicated on the logs.

The construction of the roof of the bath with their own hands is carried out using rafters, which are lined with boards, and then upholstered with roofing materials.

How to build a roof on a bath

Sauna log caulking

Caulking is needed to seal the gaps between the logs and insulate the walls of the house. To do this, you need hemp hemp, wool felt, linseed tow, and red moss.

You can also take factory materials, which have their advantages in the form of resistance to fungus and moths.

Installing the stove in the bath

Sauna stoves can be made of brick, cast iron or steel. Depending on the type of heating, they are wood, electric, gas or liquid fuel.

Heater stoves are equipped with a special chamber in which stones of different weight are placed.

Installation of a stove for a bath, insulation of the ceiling and walls in a bath

Plumbing and electricity in the bath

Water, as a rule, is brought into the bath from a well or a well.

The supply of electricity practically does not differ from the supply to an ordinary house. It is only necessary that the characteristics of cables and devices comply with fire safety standards and be waterproof, as well as resistant to high humidity.

Internal finishing work in the bath

The partitions in the bathhouse are made of brick or wood.

The ceiling is made in two layers. The first, which is attached to the logs, is rough, the second is finishing.

The windows in the bath are set small and not very high.

Doors must open outward. The material for the manufacture of doors is a sheet pile board with a thickness of 40-50 mm.

Sauna shelves are made of linden, pine, aspen or poplar. There should be no knots, as they heat up more and can cause burns.

If someone is interested in "building a bath with their own hands video" that will show how this is done, on the Internet you can find without much difficulty and build yourself a building that you can only dream of

How to build a bath with your own hands in stages (Video instructions)

Complete step by step guide how to build a frame with your own hands from and to, wooden bath or a frame bath. Video from the masters and tips for warming baths

Hello, dear site visitors! We continue the cycle of articles from our readers In this article, the author shares personal experience on the construction of a log bath with your own hands. The construction is not finished yet, so we wish him every success! If you have any recommendations and questions for the author, you are welcome in the comments.

Part 1. Foundation

For the construction of the bath, I chose a relatively flat area with a slope of 20 cm on a six-meter stretch. First of all, after preliminary marking, I cut the fertile layer over the entire area of the future foundation. This is required to exclude the processes of decay of plant residues and other organic matter in the basement.

The site is dominated by sandy soil, so the best option would be 50 cm high from the base and 40 cm wide. The contour of the foundation is marked with ropes that are attached to the improvised corners of the inner and outer perimeter. To mark the perimeter, I took scraps of boards about 70 cm long and drove them into the ground, from above I screwed horizontal shelves with protruding screws for fastening the rope with self-tapping screws. It is better to choose a rope that is not prone to stretching, it will be easier to work with this.

In addition to the lengths of the sides of the future foundation, the diagonals between the corners must be verified, which must be equal to each other with a tolerance of plus / minus 3-4 cm. You can read more about how to mark the foundation in this article. Continue to remove the fertile layer and dig a trench to create a sand cushion.

As a result, we get a completely prepared "foundation pit", where the bottom of the trenches is almost horizontal (we check it with a building level). The depth of the trenches is 20 cm, from the soil level at the highest point of the plot 40 cm, in the lowest - 30 cm.

The dimensions of the foundation are determined by the center of the intersection of the logs. This will be the centerline. If the diameter of the logs is about 20-22 cm, then we retreat in both directions from the center line by 15-20 cm, respectively. This will be required to obtain the "shelves" for fixing the floor lags and rain tides. In addition, an error is practically excluded when the logs, due to miscalculations of the foundation, fall out or inward, "hovering" in the air.

The bath is connected to the strip foundation in order to exclude multidirectional shifts of the bath and the stove. The size of the oven platform was chosen 120 * 120 cm, as the average for the installation of metal ovens under brick lining.

We start laying sand in the trenches. At the same time, we moisten the sand and tamp it. Pour water until puddles appear, after the moisture is absorbed, we begin to ram. The process is repeated 3-4 times until your shoes leave marks on the compacted sand surface.

A day later, after the end of the work, we once again go through the entire base under the foundation with a rammer. Of course, you can use a simpler option and connect a rammer to work, this will not speed up the process much. I have the simplest option: a 100 mm bar, a 20x20 mm sole and a handle. The appearance of the finished base and manual ramming is shown below.

On top of the prepared site under the foundation, we pour a sand cushion to level the horizon and raise the site above the level of the site in order to exclude water from entering the foundation.

If you hire a concrete truck, then take care of additional reinforcement of the formwork with diagonal stops outside and inside the intended foundation. The pressure that is created when the mixture is supplied is capable of demolishing an insufficiently strong structure. The same applies to pouring the mixture from a concrete mixer. Only in this case, you need to strengthen the place where you will drain, or simply move the concrete mixer around the perimeter.

It is better to pour the entire volume of concrete in one go, so as not to get the effect of a layered cake. Cover the top of the foundation with a film that keeps our foundation wet in order to avoid cracks in the concrete. We periodically water the foundation with water, not letting it dry out.

After 7-10 days, we remove the formwork by unscrewing the self-tapping screws, which will also go into operation during the subsequent stages. The finished foundation looks like this. Layout: 2x6 meters - veranda; 4x4 meters - recreation room; 2x2 meters - washroom; 2x2 meters - steam room. The location of the ventilation holes is approximately 20 cm from the soil level, if necessary, you can buy plugs to close the holes in the winter.

The approximate amount and price of materials used in the construction of the foundation are shown in the table below.

Part 2. Installation of log house and roof

To bandage a 6x4 meter log house and a chopped veranda, you will need 25 bags of moss. When purchasing, make sure that the weight of the compacted moss bag is approximately 20 kg. The moss must be elastic, that is, it must have optimal moisture.

We use the "cuckoo flax" that we collect late autumn, when all living creatures leave for "wintering" in the soil and there is no risk of grabbing a snake with a bunch of moss. A small amount of sphagnum moss is allowed, which is shorter and crumbles when dry. If only sphagnum is fully used, then after a while it will simply fall out of the grooves.

The length of the strand of moss should be at least 30 cm, so that when caulking it is possible to curl the ends and ensure the sealing of the grooves. When drying, we sort the material, choosing branches, extraneous plants and cones from it. By the way, if the lump falls into the groove, then at a certain humidity it opens with such an effort, which is enough to lift the log and make a "cold bridge". This is how the installers of the log house did in the old days, and even now this situation is not rare if the owner “offends” money.

We install rolling logs. I have a small gap between the foundation and the log house, so I used half a log on one side and a 100 mm bar on the other.

We pierce the place of contact of the log with the roofing material with moss.

Errors were revealed that resulted in the reluctance of the cutters to do their job efficiently. The grooves were cut with a chainsaw, which made the gaps in the logs very large. Look, the edges of the grooves fit tightly to the body of the log, but in fact there is a void inside. Because of this, the amount of moss that will go to caulk increases greatly. And if you do the caulking yourself, and the "shabashniki" will only do the outer processing, no one will punch the insides.

| Material | Volume / quantity | Price |

|---|---|---|

| Edged fence board "inch" for the crate, 300 mm | 1 m 3 | 4500 rubles |

| Self-tapping screws for wood 50 mm | 2 Kg | 300 rubles |

| Moss | 25 bags | 6250 rubles |

| Log house | 1 piece | 72,000 rubles |

| Board 50 * 150 six meters | 14 pieces | 3600 rubles |

| Metal tile, thickness 0.5 mm, length 4.2 meters (optional ridge and windscreen) | 12 sheets | 31,000 rubles |

| Steam - Wind insulation | 1 roll | 800 rubles |

| Grooved board 20 mm | 1 m 3 | 8500 rubles |

| "Belinka" base | 2.5 liters | 400 rubles |

| "Belinka" glazing composition | 2.5 liters | 600 rubles |

| Total: | 127950 rubles | |

Part 3. Log caulking

The most simple, but tedious job of caulking a log house. We use a mallet, iron and wood caulk. Iron with a blade thickness of 3 mm and a width of 50 mm, wooden is made of hard wood (I have dry birch) and is a consumable.

Initial view of the groove.

We fill the moss into the groove with a construction trowel. Previously used a spatula, but it quickly failed and was not as elastic. Feel free to hammer in the groove completely. There is an opinion among ordinary people that there is no need to make the seams tight and uniform, they say, the temperature in the bath is enough to compensate for the losses. But judge for yourself, drafts in the steam room and the washing room will not add comfort and the consumption of firewood will be 2-3 times higher.

We hammer the resulting roller with a wooden caulk.

If necessary, if the groove is not tight enough, we make another roller of moss and punch it until we feel the hardness of the wood when struck with an iron caulk.

The final look of the buried groove.

To prevent the birds from dragging the moss and for aesthetics, we close the groove with a jute tape 100 mm wide, which will subsequently be treated with an impregnation and glazing composition to match the color of the log. Special "craftsmen" put logs only on one jute or flax, but this is unacceptable for a bath. If we have constant humidity in the house, then steam generation is welcome in the bath. Linen and jute absorb moisture, but do not dry out for a long time, the grooves rot and mold.

We get logs prepared for grinding.

We caulk the corners especially carefully in order to exclude the ingress of cold air into the bathhouse. The work, if you do not hire specialists, will cost you nothing. With the involvement of "shabashniki" - from 70 to 150 rubles per running meter.

Part 4. Grinding logs

So, the caulking is complete, the moss is tucked in and compacted in the grooves, we are starting to prepare the log house for painting. Currently, the logs look very unpresentable - traces from a planer, chips and pulled out chips. In addition, the logs are strongly "tanned" in the sun and under the influence of slanting rains, and some of the knots require picking and sealing with mastic.

The ends of the logs, which were damaged during storage and transportation, also require processing. Here is the most loose wood, respectively, there is a high probability of decay and further destruction of the log.

Log polishing tools:

- Bulgarian;

- flap emery wheel;

- soft brush from the mop;

- putty knife.

The grinder was used the cheapest - 1200 rubles, made in China. It is worth noting that it withstood all the tests with honor and remained operational even after passing 70 square meters of walls (we add to this the semicircular profile of the log). The only inconvenience is cleaning the stator, rotor and the inside of the grinder from wood dust. Of course, you can put a stocking on the instrument, but the incoming air is not enough for cooling. By the way, the work is very dusty and immediately stock up on glasses, closed on all sides, and respiratory protection - a respirator is enough. Working with a grinder requires utmost attention. High revs and the removed casing of protection can play a cruel joke with you. One has only to lose vigilance, intercept too quickly to the grinding wheel, and you are guaranteed injury. I walked twice over the same place on my hand — the glove to shreds and the skin torn to flesh.

The grinding wheel was used with grain 80. By testing and selection, I stopped at this value - grain 60 leaves too noticeable traces, and grain 100 clogs up very quickly. The approximate consumption of petal circles is 1 piece per 3 square meters. You can use the circle further, but the pace of work slows down, and you just get tired.

Attention, bonus! Accidentally found that if a circle is clogged with dust and resin to walk on the concrete of the foundation, then sandpaper is cleared and the circle is ready for work again.

In the absence of skill and when working with great care, you can sand 6-10 squares of the wall in a day. The rates of "shabashniki" fluctuate between 400-500 rubles per square meter, and plus they do not stand on ceremony with spending circles. Pay attention to resin pockets. If you expose such an area, then treat it with a solvent, otherwise this resin will then come out even through a layer of paint.

I started working from the smallest wall, the logs are being transformed before our eyes. Faced a problem that when machining grooves, the edge of the grinding wheel leaves cuts on the lower log. But with further processing, the cuts are well grinded, and there are no traces left.

Especially a lot of fiddling with corners, the high speed of the grinder and tightness slow down the process. Where the circle does not reach, you will have to switch to a slower processing method - a chisel.

When grinding wheel practically "sat down", we pass the ends of the logs. It is irrational to use a new circle for the ends - you will have to throw it out after a dozen logs.

We seal the ends with mastic on wood. At first I used the color "pine", but then I realized that it was more economical to use white, since it will be painted under it.

After polishing, an interesting structure of the wood appears, intricate patterns run throughout the log. The knots and irregularities of the log add a certain fundamentalness to the log bath, and I was even glad when I met especially knotty specimens.

To understand what the wall would look like after painting, I stopped and prepared the logs. For all the cumulative criteria (quality and price) I chose the composition under the Belinka brand. Pre-treated with Base, the drying time of which is 24 hours, and passed over the polished surface with the first layer of glazing composition No. 24 (rosewood). Agree, enchanting beauty! If you want to get a smooth surface to the touch, then after the first layer of the composition and its drying, go over the log by hand with a "zero" sandpaper. This is true on the railings and on the front of the bath, where guests love to hold their hand along the wall and appreciate the work of the master.

The drying time of the first layer is 12 hours, for fidelity I withstood the day and covered it with a second layer. A dark noble matte sheen appeared. Another trick is that after using the glazing composition, a little pigment remains at the bottom of the can. We dilute it with a solvent until it looks very pale and go over the second layer of the dried coating. The procedure can be done at any time after coating. The result is a surface that resembles an additionally waxed log. Very pretty.

Along the way, I processed the ends with a glazing compound No. 11 (white), which favorably sets off the work already done.

The result completely satisfied me, we continue the started grinding. Since you will do all the work yourself, the quality will be at the highest level. If the hired workers can ignore the flaws, then the master himself will torment himself even for the smallest oversight. For example, knowing that somewhere at the bottom of a log I missed a drink, like a criminal returning to a crime scene, I looked over and over again his "joint". Until he fixed it.

The log house is becoming more and more beautiful. Do not forget to clean the logs from dust with a brush after work.

The next photo shows the logs processed by the Base, and the ends, sealed with white mastic.

Having appreciated the color and texture of the painted logs, I realized that inside the veranda it would look a little darkish, and I conducted an experiment on coloring the logs with composition # 11 (white).

White paint preserves the texture of the polished log, and I decided to paint the veranda completely. Through the first layer, a slight yellowness of the pine appears, and there is no shine. Much like just bleached wood. But the second layer works wonders. There is shine and a certain completeness. By the way, buy "Belinka Lazur", as the white "Belinka Top Lazur" is intended for window frames and is much more expensive.

Now the bathhouse, with the exception of one wall, is covered in one layer and looks like a house with a negative Khokhloma painting. Pleases the top crossbeam is a gnarled Christmas tree that gives the structure the appearance of being in keeping with the natural style.

We continue the construction of the bathhouse and proceed to the stage of laying the floors on the veranda. There is a roof over the room, but the absence of a pediment (for the airiness of the structure) does not prevent the falling of oblique rain drops. In winter, snow blowing and its subsequent melting in the thaw are not excluded. Therefore, we will pay special attention to the preservation of boards and logs, as well as imparting water-repellent properties to the floor surface along with a good appearance.

Part 5. The floor of the veranda

Lags will serve as boards 50 * 150 placed on the edge. According to the universal formula, the thickness of the board is multiplied by a factor of 20, and we get the step between the lags, in my case, 1000 mm. But I decided to slightly strengthen the structure and placed the logs with a step of 600 mm. It turned out like this.

On the veranda (conventionally 2 meters by 6 meters) I bought 16 six-meter boards, taking into account the lag and a margin of one board. It cost me 4300 rubles and 500 rubles for delivery. Some boards have developed blue and mildew, which can be easily removed by sanding and bleaching. Worst of all, a few of the planks are affected by the woodworm beetle. Its larvae made several through holes, which I then sealed with mastic. Upon examination, I did not find any more living creatures and calmed down on that - after drying, the wood attracts them little, and treatment with an antiseptic and biocide will discourage the beetle from any desire to approach my veranda. I laid a vapor-permeable film on the ground inside the foundation so that no plant would have a chance to germinate inside the veranda. I marked and sawed the boards according to their location.

After that I took off the boards, numbered them according to their location, and started processing the logs. Used a vigorous antiseptic produced in Yaroslavl. I am a little familiar with the preparation of antiseptics and the composition of the purchased products inspired me with confidence. Wood preservation is declared at 45 years, subject to the impregnation technology. It is required to use 500 grams of solution per one square meter, i.e. apply the first layer, and after 1-2 hours the second. The antiseptic is yellow, so the coating is clearly visible. When dry, it becomes dark brown.

Next came the turn of processing the boards. Previously, on the surface located below and on the sides of the boards, I passed a petal emery wheel attached to the grinder to remove the pile. This ensures better absorption of the antiseptic. Then we grind face surface circle with 100 grain. I also used my long-suffering grinder of the lower price category. If you are afraid to make potholes and holes, then try to grind part of the board with a hammered wheel to gain a little experience. Remember to chamfer the edges of the board.

Attention, bonus! To keep the floor surface perfect to the touch and pleasant to the feet, walk over the sanded board with a mild soapy solution. Apply with brush or roller. When dry, the raised residual pile will become tough and can be easily knocked off with a sandpaper even in manual operation.

We lay the boards on logs with a gap of 4 mm. As a "reference" we take a regular nail, which we place vertically between the boards.

Since my boards have natural moisture, it may be somewhat drier, that is, the probability of warping during the drying process. That is why I decided to use screw nails instead of self-tapping screws for fastening. Self-tapping screws are weaker fasteners for lateral loads and may simply burst. Cover the nail head with mastic on wood so that there is no rust and spreading it onto the boards.

See the nail? And he is here!

In the process of laying the boards, I start processing them. I had the choice of using Alpina outdoor terrace oil or Belinka glazing compound as a coating. I liked the second option better. First, that oil, that Belinka Base penetrates deeply into the tree and protects it from moisture. Secondly, the tinting of oil and Belinka №24 are almost similar. Thirdly, the oil and glazing compound, which does not have high abrasion resistance, should be renewed every two years. And fourthly, Belinka is cheaper. A large flow of visitors is not planned on the veranda and the maximum load is walking in slippers or barefoot.

After the first layer of the Base has dried (24 hours), apply the second layer and let it dry for another day. And the climax comes - coating with a glazing composition Belinka No. 24. If you want more effect and shine on the floor, then get Top Lazur.

–––––– Six months have passed ––––––

Since my last story, the past has been quite a long time, and the construction of the bathhouse has gradually moved forward. Little by little, because you have to do everything yourself. I do not trust shabashniki. I contacted them twice (assembling a log house and installing a roof) and I am very dissatisfied with the result.

I looked at the bath from the side and decided that another pediment was needed to protect the veranda space from rain. He put the lining in different directions, leaving something like a window. There will be a stained glass window - polycarbonate with a pattern applied with special stained glass paints.

The fit of the boards to the pediment turned out to be quite tight, so I will do without an additional plinth, I will leave it as it is.

The pediment is painted in the same color as the bathhouse, a side board with a pretense of carving is installed. The cost of the work was: lining - 2500 rubles; self-tapping screws - 200 rubles; paint - 200 rubles; wind carved board - 800 rubles. I think that it is quite inexpensive for such a result.

Last year I didn’t have time to paint the roof lining, I only covered it with a base, and the temperature began to be below zero. Just the other day, having chosen a period without rains, I walked with two layers of white "Belinka". I liked the result, but I think to fix it with a third layer.

So, new season the construction of the bathhouse opened. In the fall, I managed to capture several fine days with a positive temperature, which finally allowed me to make a window and a door. Opening preparation technology is standard. We mark and cut out with the formation of a thorn on the log. For the window opening, I used a beam of 100 * 200, and for the window of the door, a beam of 100 * 250. At the sawmill they met me halfway and made two six-meter blanks for a special order. They took quite ridiculous money - about 2500 rubles with delivery.

On the spot, the timber was sawn into the required segments. The window opening turned out to be clean 50 * 50 centimeters, the door clean 70 * 160. So we will really implement the old commandment - bow to the bathhouse when you enter. The upper level of the threshold will be 15 centimeters from the floor to keep warm in winter. I cut a groove on the beam to fit the spike on the log, plus a centimeter in width in each direction. On a thorn I fixed a roll of insulation 20 centimeters wide, it seems flax, I no longer remember what I bought. The vertical bar went tight, and horizontal segments were used as spacers. The gap from the upper window to the log is about 3 cm, filled with moss. There is also moss under the threshold and the window sill, which, after installing all the components, was compacted to the state of almost a log.

On the window, a quarter is chosen for the convenience of installing plastic. Spacers are placed in the door, since deformation is possible during the natural drying of the timber.

What is planned. Plastic window with imitation of division into smaller windows. The photo shows my hooliganism, so to speak - instead of a window, I inserted foam and made the markings of the future product with an insulating tape.

The door is metal with insulation along the canvas and jambs. In the company where the doors are made, the director is a good friend of mine, we discussed all the details and, I hope, we will get a good product. On the door leaf there will be a wooden plate 1.5 centimeters thick. I will age the wood using the overlay, make an imitation of forged hinges and wooden crossbars. But this is in the future, and now he is engaged in the improvement of the veranda.

We have one master who makes tables and benches of fairly good quality and quite inexpensive. This headset cost me only 7.5 thousand rubles. By tradition, I covered it with Belinka base, glaze composition "Rosewood" and deck varnish from the same company.

Somewhere on the hundredth or two hundredth jump from the level of the veranda, I realized that I needed a porch. The plans were to make some kind of forged product with wooden steps, but for now I decided to confine myself to a temporary hut. Although the temporary house turned out to be quite nice and will still serve me until I get bored. On the sidewalls I used the logs that remained from sawing openings, on the steps a board 50 * 150. He laid stones from a nearby quarry on the base.

And now about the essentials. Firstly, I carry out the caulking inside the log house. The logs have already settled in place. What is possible - dried up, what is needed - led, what wanted - sat down to its permanent place. Accordingly, they appeared inside the cracks, which require careful sealing.

An external examination confirmed the good quality of the caulk. Nothing fell out, the birds didn’t misbehave, and the moss lay as planned. When sawing openings, the moss was packed into one dense and solid strip, it was even difficult to make out, but it was good to knock out the cracks with such strips. Made another caulk from birch. The scapula turned out to be wider and larger, a sledgehammer of two kilograms perfectly fit to it. Moss flies into the cracks with a whistle, and where the log is laid too tightly I use birch wedges. The process is long, but obligatory, if you do not want to bathe in felt boots in winter. Secondly, he audited the foundation. There are slight chips on the outside, but these sags during pouring and do not affect the quality. Nevertheless, if I have free time, I will plaster and cover facade paint... The manufacturer and color have not yet been chosen. Last year I put on ebb tides, which showed themselves well even with serious snow load... And, thirdly, I will count on the snow holders. When last year a crust formed on the roof after a freezing rain, and 50-60 centimeters of snow was thrown over it, there was a good surprise in the form of a huge dense snowdrift near the bathhouse after the first thaw.

Well, I'll tell you what I do to keep my bath warm and dry. A month ago I bought a metal stove from the Izistim company for 58,000 rubles. I chose for a long time, tediously, read all the reviews and realized that this is what I need. Its parameters can be found on the official website of the company, where a detailed description is given. While the stove is on the street in front of the bathhouse, 130 kg of metal still needs to figure out how to carefully drag it in, especially since I have no floors yet and 600 bricks are stacked on the ground. It turned out that these ovens are made literally at my side, respectively, I had the honor to communicate directly with the manufacturers, who really helped with advice and recommendations. The pipe is planned to stand next to a stainless sleeve. The construction will be about 5 meters. I ordered a stainless steel pipe with a wall thickness of 1 mm in the same place, in the Izistim company. Literally a week later I received an order. Laser welding, high quality and reasonable price. In terms of money, the pleasure was 11,500 full-weight rubles for a set of pipes of 5 meters. CRAFT firm.

IN full set includes a tee, a plug for cleaning the pipe from soot and removing condensate and the type of adapters with a platform that will rigidly fix the chimney in a brick pipe. The design on the right in the photo is a horizontal section of the pipe from the stove to the chimney. Heat-resistant stainless steel 4 mm thick, made in EasyStim for 4300 rubles.

Naturally, I did not go shopping and bought convection doors without leaving the checkout. Convenient locks, normal appearance and additional sheets of metal for fixing the products in the brick.

I bought a 150 grade Kostroma clay brick, which is enough for lining the furnace. The geometry of the brick is normal, if necessary, you can round off the edges to give the products a more interesting shape. If you want a more beautiful brick, then buy Vitebsk brand 200. Each brick cost me 25 rubles apiece.

I didn’t bother with clay, which needed to be mined somewhere else and prepared a solution, as I don’t have any special skills. I bought a ready-made mixture "The Makarovs Stove House" produced by Kostroma, Gzhel colors. They also have a white clay mixture for aesthetes. Pechnikov could not be found - everyone is busy. The cost from the craftsmen starts from 40 rubles for a brick for the lining and 60 rubles for a brick on the pipe. You can calculate the cost of the work yourself. I will do it myself, although the work will be delayed.

Part 6. Furnace

"And the battle begins again" - we continue the construction of the bathhouse and the improvement of the internal space. The heart of the bath is the oven. My wishes for the climate of the future steam room and the rest of the premises are extremely simple and unpretentious. Firstly, the legs and ears should be warm even in winter, and not bathe with a hard plus in the head area and at the same time in felt boots, so that your feet do not freeze. Secondly, the inertia of the sauna stove must be present in order to be able to stop heating and steam without running around for firewood, while constantly maintaining the desired temperature. It is advisable to keep warm in the bath for two or three days to dry the premises. And, thirdly, hot water should not boil in the steam room, but in the wash compartment in the portable tank.

As I already wrote, the Sochi stove from the Izistim company with a hinged heat exchanger for heating water was chosen.

The heat exchanger is equipped with inlet and outlet pipes with a diameter of one inch. The structure is intended for brick lining, which will simultaneously become a screen against hard infrared radiation emanating from metal and a heat accumulator. Before installation, it is required to heat the stove on the street in a gentle mode to burn the factory paint and eliminate the smell of burning when operating directly in the bath. A heat-resistant cord is laid on the door and the blower, which is necessary for sealing. Previously, this was not the case, but the company's managers listen to the recommendations of consumers through communication on the forum and make the necessary changes.

A cast iron grate is installed inside the combustion chamber. Additional metal sheets are welded on the sides and at the end of the chamber to reduce the effect of the flame on the walls of the furnace in order to avoid deformation.

For relative thrust, I installed a meter-long pipe and carried out the first tests of a metal bath stove. The draft even with such a stub of the pipe is quite good, only there is a slight intake of smoke from the door when it is opened and, accordingly, a small soot on the glass.

The foundation for the furnace is connected to the basement of the bath, reinforcement was carried out during the pouring. To begin with, the masonry leveled the surface with cement mortar so as not to damage the waterproofing. I put roofing material in two layers on the pedestal, on which I will begin to lay out the brick.

To rise above the floor level, and from the foundation it will be about 18-19 centimeters, we lay out the base under the oven three bricks high. There is a little trick. To save mortar and bricks, lay out a "well", and inside we simply place the worst brick and fill the remaining space with sand.

The sand will need to be slightly moistened and compacted so that it does not settle, but this is not necessary, the filling will not go anywhere.

Brick produced by Kostroma, costing 24 rubles apiece. The geometry is normal, there are chips at the corners and edges, so you have to choose on the front side of the oven. It pricks badly, it is better to cut it with a grinder. The oven mixture "Makarov's oven house" is used for the solution. The mortar sets quickly, holds the brick well, is easy to use. Bags of 25 kg, the cost is about 400 rubles apiece. One bag is designed for 60 bricks. The solution must be mixed with a powerful drill with a nozzle; it is unlikely that you can make a homogeneous mass with your hands. The mixture is well dried and you have to add a lot of water.

I “sealed” the upper row of bricks along the base of the furnace with mortar, I wanted to install the structure on metal nickels - the legs of the furnace, as it seemed to me, would push the brick. But it turned out that in this case, the neck with the door rises and a gap appears. Therefore, then I cleaned off the solution, refused the lining.

Immediately I tried on convection doors that will draw air from the relaxation room to the steam room for exchange. But, as it turned out later, they cannot be installed in this place, the decorative screen around the firebox will interfere.

The most difficult thing was to drag the stove into the bathhouse and not carry anything along the way. The 130 kg design aroused respect, and two tighter loaders had to be ordered. If for the first time a loader from the category of "legs and a cap" helped me to drag the stove to the bathhouse, then the masters really came here. They pushed me aside and in 10 minutes they hoisted the "piece of iron" to the place of operation.

I put a T-bend on the furnace to determine the root pipe. The picture shows a rear view, where "lambs" are located for removing the roof and subsequent cleaning of the pipe from soot, although the manufacturers assured me of its absence.

The root tube will run to the left of the kiln and will also stand on a foundation connected to a common belt. We continue laying with the formation of the pipe.

The pipe will be functional only after the entrance of the T-shaped segment, therefore we make its sides one and a half bricks, and we also fill the inner space with sand.

Inside the steam room, in the oven screen, we install two more convection doors, but of a large size. This is necessary to quickly warm up the room. We do not lay the top of the stove with bricks, we leave space for stones. When the convection doors are open, air is taken from the floor, passes near the furnace body and exits through the stones already heated. The air flow can be adjusted with a damper. The doors are hung from the side convenient for you.

I bought the doors from the Izistim company, they modernized the structure by adding a stainless steel box along the width of the brick. Now it has become convenient to put the doors, without additional fastening with wire. Small gaps are left along the perimeter (except for the bottom) of the doors, which compensate for the thermal expansion of the metal.

The root pipe, so that it passes between the rafters and does not take up much space, is located in line with the "face" of the stove screen. The T-piece goes a little to the side. In "Izistim" they made it for me with a margin. But, as it turned out, the size was the most suitable, as they say, do not subtract, do not add. A 4 mm stainless steel product cost 4,500 rubles.

It's time to hang up the heat exchanger. I bought galvanized corners, squeegees and couplings per inch, attached to overall design wrapping the thread with flax treated with heat-resistant sealant (red in the photo).

The brickwork reached the top of the firebox. We install a support corner 50 * 50 mm with a brick approach of 8-10 cm.Around the firebox, a thermal gap of about 2 cm.

The front side is almost finished, the convection doors are set higher than planned, but for air exchange it is even more convenient, the air coming from the relaxation room into the steam room will not overheat. Contact with a heated oven is minimal.

We slowly close the heat exchanger with masonry and make the outlets of the branch pipes for connection with the remote tank. The holes are not very neat and then I will cover with discs from of stainless steel or other decor that is not afraid of moisture. This is a wall in the washing room, it is planned to lay out bricks up to the ceiling.

The front of the stove is finished, the next row will be a “mantelpiece” so that hot air from the firebox does not go directly to the ceiling when it is opened, but has some obstacle. Yes, and you can put items of interior decoration on the shelf.

The wall in the washroom has been completed, and the pipe leads have been made. It remains to buy stainless pipes and make connections with a hinged tank.

It's time to drive the pipe. Masonry strapping from the side of the steam room. The T-piece is connected to the sleeve through a tee. A cover is installed at the bottom of the tee to drain condensate and clean the pipe from soot.

From the side of the steam room, the stove looks like this: the T-shaped adapter is covered by a brick screen from above. A corner 40 * 40 was taken as supports.

I will cover the cavity above the stove and the adapter with stones for decoration and evaporation of various incense, there is no other function for these stones. And perhaps I will close the pipe with a sheet of stainless steel iron to avoid harsh heat radiation from a highly heated metal.

We continue to build the pipe. In the place where the ceiling passes, we form a fluff in order to observe the fire-prevention distances from the "smoke" to the wooden structures. As expected, the front and side walls of the stove reached almost to the future ceiling.

The root pipe is calculated to run midway between the ceiling beams. And so it happened. The pipe has grown to the roof and it is time to make an opening.

And the "face" of the stove looks like this. Convection doors are located in one row with the pipe cleaning. It is still covered with clay, but you can already understand what I want.

Next, we prepare the roof for the passage of the pipe. From the inside, the roof was drilled at the corners of the future passage with a margin of one centimeter. With a grinder on the roof I sawed out metal tiles. I got a passage almost strictly in the center of the ridge, which is convenient for the subsequent closure of the hole from rain. And the snow will not put pressure on the brickwork.

First of all, we take out a sleeve from a stainless pipe into the opening, then we start laying.

You should not be content with just the level, you will have to run downward so that the pipe is visually even. "Otter", protection from rain is made almost in half a brick. And here is the pipe, until it is cleared of clay, takes its proper shape.

He cleaned the pipe of clay and covered it with three layers of varnish for exterior work on stone and brick. Each layer hardens in about four parts at a temperature of + 200 ° C. The result is a wet stone effect and pore sealing. The temperature in the furnace head will approximately correspond to the outside air, if only a little warmer, therefore the varnish is frost-resistant, withstanding sudden temperature changes. The result is the effect of a wet stone and sealing the pores on the brick and seams, which will protect the material from washing out.

Around the pipe, I covered it with material that remained from the manufacture of ebb tides. Approach to the brick about 1 centimeter under the "otter". The very first rains showed the effectiveness of the design.

Firstly, clean the oven from clay. Do not use water. This will only rub the mortar inside the brick and will not be able to get rid of the stains. If you do not want to spoil the outer part of the brick, then please be patient, with rags and brushes. You can use fine sandpaper.

Secondly, cover the oven with heat-resistant varnish, it is enough to use the composition up to 1500 ° C, you will no longer warm up the screen if you wish.

And thirdly, put an umbrella on the pipe in order to avoid precipitation from getting inside.

Little trick: to prepare the solution, take rainwater, thus you can avoid salty stains on the bricks when the clay dries.

And, I will be happy to answer all your questions, since the report from the scene is far from complete and you may be interested in some of the nuances. We will help, take a photo, show.

To be continued! (No ratings yet)

It is not an easy task to build a bathhouse from a log house, however, the construction technology, the choice of materials and even the exact sequence of actions have long been known and worked out by many craftsmen. This material explains all the key points that will help in the construction of a log bath: from laying the foundation to interior decoration.

The steam bath has been known since the time of the Scythians, who carried with them special bath tents and camp stoves. And in the 21st century, the Russian bath did not become a kind of archaism, having successfully withstood the age-old competition with bathrooms and showers. Get rid of many ailments, remove from the body harmful substances accumulated in urban everyday life, to give the body a full rest - all this is achieved when visiting the bathhouse for more than one and a half thousand years.

Which construction is preferable, how to choose a place for its placement, how it generally works - you will find answers to many "bath" questions in this article.

Place and layout of the bath

One of the important additions to the bath itself at all times was a reservoir with fresh water located nearby - in the absence of another source of water supply, water was taken from it. A special charm in the proximity of such a reservoir lies in the possibility of contrasting ablution - after steaming in a Russian bathhouse, run out of it and plunge into the cool water of the reservoir. In addition, the natural reservoir made it possible to quickly cope with the fire of the bath, which occurred quite often due to irregularities in the design of the stove.

Today, there is no special need to link a summer cottage bath to a natural reservoir, but it is still convenient if it is located near, say, an artificial reservoir - the final decision always remains with the owner of the summer cottage.

The main criteria for choosing a place for a bath: distance from the road, the presence of a natural or artificial fence from outside spectators (dense bushes, tree crowns, a fence, outbuildings), a fire distance from the main residential building of at least 15 meters.

The main rooms of the bath are the dressing room, washing room and steam room (the last two rooms can be combined into one). The size of the dressing room is determined at the rate of 1.4 m 2 for each bather, the size of the washing room is 1.2 m 2 per person. In addition, the dressing room should have a place for furniture (locker for clothes, benches for sitting) and for storing fuel (box for coal or firewood). In the washroom, you will need a place for containers with hot and cold water, stoves and a place for sun loungers.

For example, for a small family (no more than 4 people) a bathhouse of the following sizes is suitable: external size - 4x4 m; dressing room - 1.5x2.4 m; washing room - 2x2 m; steam room - 2x1.5 m. True, in a bath of this size you can't really turn around - but it also takes up little space.

In general, the size of the bath is directly related to the size of the area that can be allocated for it. If the site is significant, then the bathhouse can be expanded by adding a shower cabin, recreation rooms, etc.

In temperate and cold climatic zones, it will be correct if the entrance to the bath is located in the south, and the window openings are on the west (south-west) side of it. This location of the entrance will greatly simplify the use of the bathhouse in the winter season, since the snowdrifts on the south side melt faster, and the direction of the windows will allow to illuminate its premises with sunlight for a longer time.

Bath construction - stages

There are several of them:

- Procurement of basic materials.

- Selection and laying of the foundation.

- Creation of the foundation for the heater-stove (if necessary).

- Floor creation and sewerage system baths.

- Assembly of the bathhouse.

- Roof construction.

- Formation of a blind area along the perimeter.

- Caulking the walls of the bath.

- Masonry or installation of a stove, installation of a chimney.

- Electricity and water supply for the bath.

- Installation of doors and installation of shelves.

Preparation of basic materials for the bath

The classic and most successful construction material for a Russian bath was and will be wood - wood easily copes with waterlogging of bath rooms, diverting excess moisture out.