We are building a porch of concrete. How to properly pour a concrete porch with your own hands: the choice of material and manufacturing technology

Country house, Vacation home, a cottage cannot be imagined without a beautiful comfortable porch with a canopy to protect from the scorching rays of the sun, cold drops of rain and snow. Can be done exterior decoration buildings in the modern style but without a porch it would be a normal building. Before making a concrete porch with your own hands, we recommend that you read this article. We will tell you how to pour concrete correctly and describe all the stages of work.

Our article is for those who wish to decorate their home lasting beautiful porch built by our own efforts without hiring specialists. We propose to consider a universal reinforced concrete structure that can be finished with any building material, in full accordance with the style of home decoration. For decoration, clinker tiles or porcelain stoneware matched in color and style are perfect.

Tools and building materials

When planning to build a porch of concrete, you need to prepare:

- medium fraction sand;

- crushed stone;

- concrete;

- plywood sheets, dry boards;

- nails with a wide head;

- fittings;

- shovel;

- concrete mixer;

- tape measure, spatula, level, meter;

- metal wire, broken brick.

Soil preparation and design calculation

You have a porch, but it is badly destroyed and does not look very aesthetically pleasing. To erect a new structure, it is necessary to carry out a number of works:

- Completely break down the old porch and clear the area of debris.

- Measure the distance from the ground to the threshold - the height of the porch. Knowing the height and having decided on the number of steps, calculate the height of the steps.

- The minimum dimensions of the platform at the door are calculated based on the width of the doorway. The width of the platform is equal to the width of the doorway plus 15 cm. The depth of the platform should not be less than a meter.

Foundation and site preparation

The porch area can be different sizes... If desired, such a platform can be built to the length of the entire wall of the house. By configuration, it can be rectangular, square or semicircular. It all depends on your personal preference.

A pit must be dug along the perimeter of the projected porch. The depth of the pit depends on the level groundwater, but not less than 50 cm. With a layer of 20 cm you need to fill in the rubble, level it. Then add sand 10 cm, thoroughly tamp and fill well with water.

It's time to start waterproofing your foundation. To do this, you can use a thick film or roofing material. Install fittings and start cooking concrete mortar... Usually a crushed stone - sand - cement ratio of 3: 3: 1 is used. Now you need to fill the foundation, level it and let it gain strength for several days.

Note! The strength of the foundation will increase with the use of reinforcement, and waterproofing will help to avoid destruction of the structure from the effects of surface water.

Formwork installation

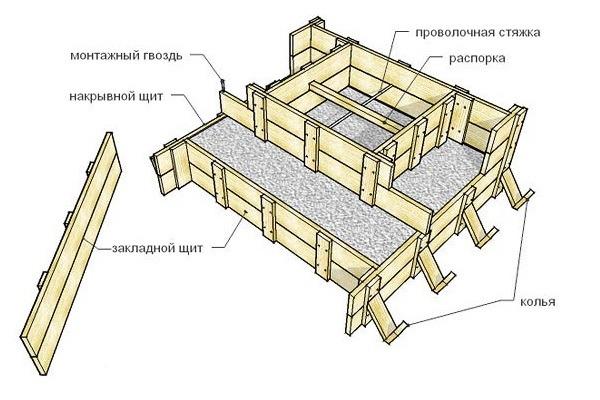

The quality of the future steps of the constructed porch depends on the quality of the installed formwork. Add 30 cm to the porch height. This will be the height of your plywood formwork. If plywood sheets are not available, you can use sturdy planks or metal sheets... On the sheets of formwork, you need to draw steps and treads at an angle of 90 degrees, and then a platform and treads with a slope at the rate of 30 cm in depth, a slope of 5 mm. Now draw the steps with a 15 degree slope.

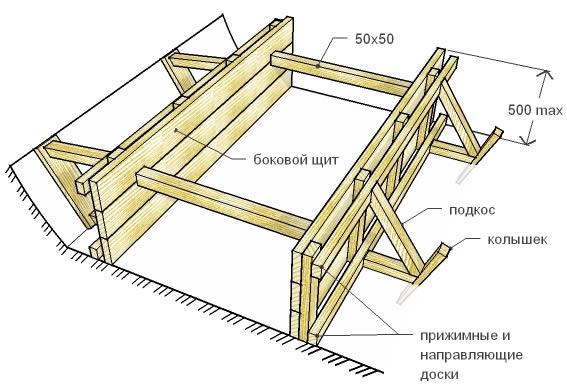

Stiffeners must be attached to the side parts of the formwork. The prepared shields must be installed one centimeter away from the building. To prevent the shields from spreading when laying the concrete, make spacers: for this, at a distance of 45 cm from the groove prepared under the steps, drive the stakes into the ground by 20 cm. Place spacers between the stakes and the formwork.

The installation of the formwork continues by installing boards with a length equal to the width of the steps. The edges of the boards at the bottom should be sloped, which will make it possible to make the concrete pouring evenly. Fasten the boards using wide-headed nails to the formwork. This completes the work with the formwork.

Place a vapor barrier on the base before pouring the concrete. Apply roofing material to the foundation of the building and apply a layer of sealant. The formwork inside must be lubricated with a special lubricant so that the laid concrete solution does not stick to the boards or plywood.

Making steps

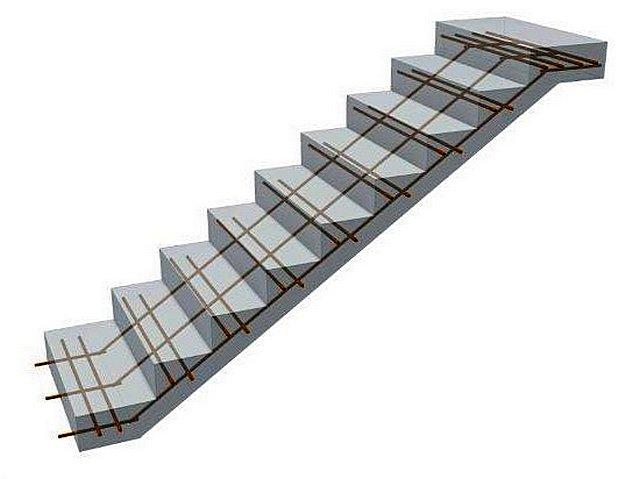

The erected concrete porch will be much stronger and more durable if you install the reinforcement, previously cut into the desired pieces. Reinforcing stakes are connected to each other by wire. In addition to reinforcement, broken brick and stones can be put in each layer, which will save on the volume of concrete and make the structure even stronger.

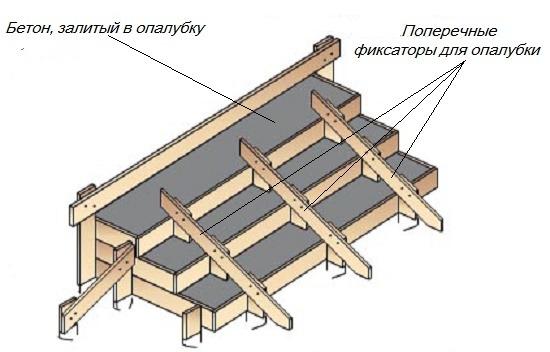

It is better to use a concrete mixer to prepare the concrete solution. Concrete is laid down the steps. Work starts from the bottom step.

Note! The concrete must be placed as soon as the batch is finished in order to maintain all its strength characteristics.

Each poured layer must be carefully compacted, trying to remove all voids. It is necessary to be very careful, as the resulting voids will lead to rapid destruction of the structure. If the aggregate protrudes above the level of the mortar, you need to gently tamp it inward with a shovel or trowel. Using a level, check the quality of the concrete placement.

After filling the first layer, let it dry well and only then start working on the next one. The work should be completed by laying the top step-platform with concrete. The formwork must stand for seven days. At this stage, the work on the manufacture of the porch is completed.

Finishing

You can leave the porch with steps as it is - this is the easiest option.

You can immediately lay out pebble patterns on the surface during the laying of concrete. True, this method will slightly increase the duration of the work.

Most often, the option of finishing concrete steps and porch with clinker tiles, which has a special anti-slip coating, is used, which is very important in wet weather or in winter.

Note! It is important to choose a single style solution buildings and a new porch.

Little country house don't need a big pompous porch. It will look ridiculous.

Porcelain stoneware will be an excellent decoration. The most important condition is to observe the combination of porch decoration with the overall design of the building.

What porch would look beautiful without railings and a beautiful visor? If the stairs are short, the railings can be omitted. When elderly people live in the house, it is advisable to install the railings even with five steps. The material for the railing is used in different ways, and here the general design of the building plays the main role in the choice.

In order to comfortably climb into the house, you need to make a porch. It can consist of one or two steps, or it can be at a decent height - it all depends on the basement of the house. In any case, the structure must be strong, therefore, before filling the porch, the site should be cleared of all unnecessary things - the old porch (if any), debris, grass, young growth of nearby trees. Construction technology begins with this.

Preparatory process

To build a comfortable porch in a private house, you should calculate the dimensions of the entire structure, prepare the site, and you can begin to build the foundation. The latter must be present, albeit small. And if the soil on which the house stands is clay, the pit under the foundation is pulled out deep enough (up to 70 cm) and strengthened with a mixture of sand and gravel. They are laid on the bottom, forming a kind of pillow, and only then they form the main foundation for the porch of a private house.

With dense soil, a hole 30-35 cm deep is enough. A porch made of concrete should be comfortable and safe - the site should be leveled, and only high-quality materials should be used. Since this structure will be constantly exposed to temperature changes and the influence of precipitation, it must also be especially durable, therefore the process of creating a porch is an exact adherence to technology and calculation.

Types of concrete porch

In addition to the size, you should also decide on the shape. It can be rectangular, square, round, oval. You can also attach a trapezoidal concrete porch to the house. It all depends on the taste of the owners and their imagination. But you need to make sure that the shape is in harmony with the overall appearance of the facade, otherwise it will look alien. A porch with a staircase can be located either on the side or on the front facade of the house (by the way, you can make several entrances, but then the process of building the porch will take a little longer).

Concrete is an excellent choice of material for creating a porch. It can be faced with stone, tiles, even wood and is stronger than other materials. It is not so difficult to create a monolithic concrete porch with your own hands if you follow the technology, but some nuances should be taken into account.

If the staircase is designed higher than 5 steps, you should leave holes for future railings even at the stage of concrete hardening. The same goes for the canopy - the supports for it are installed during the manufacture of the porch.

Design

- the width of the porch is made more than the door by 3-5 cm in each direction;

- and the height of the porch should not reach about 5 cm to the door frame;

- the pit for the foundation will be even slightly wider than the site - by 4-5 cm (this is an allowance for the thickness of the boards for the formwork);

- you also need to count very carefully. It should be at least 30 cm - designed for an average foot size. And the height of the steps is about 20 cm. With a larger one, it will be difficult for children and people in old age to climb into the house;

- the upper platform is convenient with a width of 80-100 cm;

- the ladder should be made inclined - 30-45 degrees is quite enough. So the ascent will be comfortable, and the water after precipitation will not linger;

- the width of the staircase itself can be equal to the size of the upper platform - 80-100 cm.

Calculation of materials for the porch

At this stage of construction, you should find quality materials for assembly, pouring, reinforcement and so on.

You will need:

- Formwork boards.

- Reinforcement mesh.

- Crushed stone and sand.

- Cement brand M400, and better M500.

- Waterproofing materials.

- Water.

- Fittings (screws and corners).

You can also take ready-made concrete. But by mixing it with your own hands (more precisely with a concrete mixer) and controlling the number of components, you can achieve best quality... To receive good solution you should mix 1 part of cement with 2 parts of sand, but crushed stone needs 3.5 parts of the cement norm. For 1 cubic meter of concrete, about 190 kg of M400 cement will be needed. Therefore, in order to calculate the amount of material, you need to understand how many cubes ready-mixed concrete will be needed for filling. And do not forget about the layer of rubble and sand at the depth of the foundation.

As for the reinforcement, it is believed that at least 2 rods should be consumed for each step. Most often, they take material with a cell size of 10x10 cm. It fits best into the formwork. For reinforcement calculations, it is worth measuring the quadrature of the lowest step and multiplying this figure by the number of steps.

The boards will be used to create the formwork. For each tier, that is, steps, you should take 3 boards about 2 cm thick.Do not take too dry material - it will crack under the pressure of concrete. Frame blocks for the porch, it should be fastened together with self-tapping screws, and the corners will help to install them evenly. The latter are needed only for a square or rectangular porch.

Design features

If the foundation is deep, you can scatter any non-combustible debris along the bottom - foam blocks, broken brick, even glass. But from above, all this is covered with an even layer of a mixture of sand and gravel.

The armature should be cut into pieces in advance. the right size, it is laid not on the bottom, but on single-standing gas blocks or bricks - so it is all evenly covered with mortar and the concrete porch will be stronger.

Formwork on all sides can be additionally reinforced with pieces of timber or thick boards. The material for the formwork should be lubricated from the inside. special composition- then it will be easier to clean it upon completion of construction work.

The concrete solution is sometimes supplemented with various additives, which give the required level of plasticity, make it frost and water resistant.

If a porch with steps is attached to an already erected house, it is necessary to leave a gap of about 10 cm between them. This is done so as not to damage the foundation of the house in case of possible deformation and create the so-called " expansion joint". A wooden shield can be laid in this space and filled with glass wool.

Design advantages

- The main advantage is that you can make a concrete porch device with your own hands. If you correctly calculate the amount of materials, follow the technology and do not save on quality, it will be durable and beautiful.

- Materials for the arrangement need the most common, which can be easily bought. They are not a deficit.

- Such a porch can be easily made original, since it can be revetted with stone, tiles, wood, and other materials. You can also use a mixed version.

- The end result is relatively inexpensive. You can choose the shape and size.

Cons of construction

Sometimes the porch quickly begins to collapse - crumbling, settling, loosening. This means that in the process of pouring its technology was violated. The porch of the house should be properly filled. As an option, a low-quality material came across, so you need to pay special attention to its quality.

Making the foundation

To make the porch foundation easier and faster to fill, in addition to materials, you need small concrete mixer... The solution must be developed within about an hour and a half after its manufacture, then it will harden and crumble.

The reinforcement rods are cut into pieces of the required size and fastened together with a wire. So concrete staircase the porch turns out to be durable and does not disintegrate over time. The finished porch steps can be additionally secured with corners.

You need to dig a hole according to the size of the foundation with an allowance of 2 cm from each side. Next, crushed stone with a layer thickness of 7-10 cm is placed on the bottom (you can add any construction waste to save material). The same layer of sand is laid on top, carefully tamping it. Sometimes sheets of roofing material are also placed on the sand. The site should be flat. This is followed by gas blocks, reinforcement and finally concrete.

Site preparation

It is thoroughly cleaned of everything superfluous - garbage, bushes, grass. If we do the foundation with our own hands, we dig a hole 30 cm deep (if the soil is strong enough). In case of doubtful soil, the depth of the foundation should be deeper. Waterproofing and leveling of the site with sand and gravel are required. Pegs for the future formwork should be hammered along the perimeter of the site.

How to prepare concrete?

It is a mixture of cement, sand, and crushed stone in certain proportions. All this is poured into a concrete mixer and water is added. The consistency of the concrete should be doughy - not spilled, but not too dry. It should be easy to spread with a shovel and tamp. Sometimes concrete is supplemented with special additives to improve its technical properties.

Reinforcement principles

The consumption of reinforcement for a medium-sized porch is about 160 meters. Its thickness should be at least 10-12 centimeters. Reinforcement is the binding of reinforcement with wire in a specific configuration. You cannot save on its quality, like other materials. At the edges, pieces of reinforcement should be left under the future railings.

Installation of a concrete porch

After preparing all the components, as well as the area under the porch, you can begin to install it. To know exactly how to make a concrete porch with your own hands, you can watch a training video or work with experienced craftsmen.

The weather should be clear and moderately warm. You should go through all the stages one by one, without missing anything. 6-7 days after the end of the work, you can start finishing the porch.

We install the formwork

Boards for it are installed around the perimeter of the pit and secured with spacers. They should be wider than future steps due to the fact that part of it will go into the depth of the pit. The formwork for the porch is placed directly, fastened with self-tapping screws and, if necessary, corners. Stiffeners will also be needed - they strengthen the sidewalls.

If only dry boards are available, they should be moistened with water. The form of the formwork must exactly follow the outline. A trapezoidal concrete porch with your own hands is more difficult to create than a rectangular one, but it looks much more spectacular.

On concrete blocks or another support of at least 5 cm in height, reinforcement rods are laid, cut as needed. They are tied together with wire, preferably steel. Make sure that the fittings are not corroded.

Mortar creation

It requires a cement grade of at least 400. The solution is strong enough. Cement is mixed with sand and crushed stone in proportions of 1: 2: 3.5, respectively. Then water is added for the required viscosity of the solution. The mixture is thoroughly mixed in a concrete mixer and after that it is considered ready. It should have a uniform, fairly plastic consistency.

Before making a concrete porch with your own hands, you should think about and check everything. Directly to concreting, you need to start fully armed, because after it there is already little that can be fixed. After the pit has been dug, a layer of sand and gravel is filled in, reinforcement and formwork are installed, concrete mix can be poured.

It must be tamped in the process of pouring the steps, carefully spreading it with a shovel over the pit. It is imperative to get rid of air bubbles that appear in the solution. It is better to place the stirrer as close as possible to the pouring point. We fill the porch of concrete layer by layer: leave the first layer to harden a little, then the second, third, and so on according to the number of steps follow. At the end, we cover the finished structure with tarpaulin or roofing felt.

Concrete porch cladding

For finishing concrete porch you should first clean it up to smoothness, you can manually, you can use special devices. After that, it is painted, revetted with stone, tiles or wood. Color, shape and type of surface facing material everyone chooses independently.

Clinker tiles look great, besides, they also do not slip. Many people opt for porcelain stoneware tiles. The veneering process is the same in both cases. The surface of the tile is smeared special glue and snuggles against the desired section of the porch. When the cladding is finished, cruciform spacers are inserted into the seams to prevent the tile from slipping. Then they are taken out, and the seams are rubbed special mixture... On this, the device of the concrete porch can be considered complete.

Final step-by-step instructions

So, in order to properly fill the porch with concrete, you need to do the following:

- Clear the place.

- Dig a pit.

- Install the formwork.

- Make waterproofing, fill the bottom with rubble and sand, you can build debris, compact.

- Make sure that the surface of the concrete floor is even, cover it with pieces of roofing material.

- Install gas blocks, lay the prepared fittings on them, tie the rods with wire.

- Repeat all steps starting from the formwork by the number of steps.

- Fill all the steps with concrete solution in stages.

- Cover the finished structure with roofing felt or tarpaulin.

- After a week, you can remove and clean the surface.

- Make the cladding to your liking.

The result is one of the most beautiful structures - a do-it-yourself porch that you can be proud of.

After completion of construction country house, a summer residence or a modern cottage, you should worry about building a porch. This task should be taken seriously. It is important not only to reliably protect the entrance from the effects of precipitation and sun rays using a canopy, but also to provide an attractive appearance, reliability, strength and durability input structure... You can build a concrete porch with your own hands in a limited time with the help of timely prepared materials. It is important to be guided by the working project and adhere to the construction technology.

Let's note the main advantages of a concrete porch:

- The concrete porch has long term operation;

- Concrete is not prone to decay and the formation of corrosion, it retains its physical characteristics for some time;

- The presence of reinforcement makes concrete more durable;

- Impact ultraviolet rays protect the porch from defects;

- Possibility of building different types of porch;

- The construction of the porch is carried out from sand, cement, gravel and water;

- Concrete is fire-resistant compared to timber construction;

- Wide possibilities of facing the porch. You can use any kind of tiles and natural stones. And you can leave everything as it is, just varnish the surface. In any case, you get a beautiful and durable porch.

I would also like to note that the porch does not have to be immediately revetted from concrete. You can even wait until next season. How will it be possible to make sure that they have erected a reliable structure with their own hands?

Disadvantages of self-concreting porch

Inspired by the dream of independent work, it is worth considering the fact that concreting is a multifaceted process, and for beginners in this business it is also difficult. There is so much to consider in order to end up with a truly reliable design.

Concrete is like a capricious child - you do not know how to find an approach to him and what is better for him - not to see a "docile disposition" and "ideal obedience" in the future.

Therefore, before making a concrete porch, consider the main mistakes and shortcomings during its concreting:

- A low-quality cement grade and an insufficient strength class of the finished concrete can lead to defects - cracks, delamination, chips.

- Lack of waterproofing. Without waterproofing components, the structure begins to actively absorb moisture, which destroys and leads to freezing of the structure. The lower step is often destroyed, which is actively getting wet.

- The leveling screed and plastering of the steps is carried out after the completion of the concreting, usually after a few days - the gross mistake. We are waiting for 28 days and only after this period has passed, you can carry out the finishing. It is also important that the leveling layer is stable.

- The base of the structure is made without reinforcement. Without reinforcement, the porch will begin to split into separate components in the event of subsidence and uneven precipitation. And in general, concrete without reinforcement will not last long.

- Tying the porch to the foundation is done seamlessly. There is a risk of cracks between the two structures if the porch rests strongly on the foundation.

Self-preparation of the mixture, direct concreting of the porch requires special skills. Therefore, if you have not previously made a high-quality solution with your own hands, then it is best to purchase it.

This reduces the risk of getting a low quality structure to a minimum. At the same time, the price of the final design will not rise much.

What are the entrance groups with a concrete porch

The concrete porch is only part of the total, which are classified into several categories:

- One of the simplest and convenient views is a metal-plastic hinged door. metal-plastic door and a canopy.

Attention! In this case, there is no need to build a porch.

It is important to consider some factors, for example, landscaping the area near front door... To give the facade more original view, it is necessary to choose a uniform color contrasting range.

- Warm entry group with a terrace is considered a more practical form interior design... The terrace is a free area where you can grow green plants.

- The entrance lobby for shops should be more functional. For this group, doors with a swing and sliding view... The main thing is that the temperature is comfortable from the inside.

- Entrance groups for a country house have good protective functions. In these constructions there is warm vestibule with powerful doors.

- Entrance groups for cafes and restaurants are more in demand. They pay special attention to design solutions.

- For office and banking groups, glass structures are suitable. They are more open and do not obscure the look.

As you can see, the construction of a concrete porch is versatile and suitable for any object. It remains only to take into account the nuances and "pump your database" regarding concreting.

Simple concrete porch

Our small instruction, answering the question of how to make a porch from concrete quickly, easily and economically, presents a project of a simple structure that is flush with the ground.

This solution is universal - perfect for beginners in this business, and experienced craftsmen can show imagination and make it interesting due to unusual finishes.

For carrying out it may be required:

- Concrete solution of the M100 - M200 brand, it is prepared independently, or bought.

- Refined sand with a specific consistency of components.

- Gravel or crushed stone with a medium fraction.

- Steel reinforcement with a diameter of 10 - 12 mm.

- Binding wires that hold the components of the carcass together.

- Bars made of wood, for the frame.

- Shaped boards. Plywood, metal sheets.

- Deep vibrator. Without him in such works - just nowhere. If the mixture is badly compacted, there is a high risk of rejection of the finished structure.

- Screws and nails that hold the formwork components together.

Instruments:

- Concrete mixer or container for manual mixing of concrete. If there is none, you can spread the films on the ground on it and carry out all the work.

- Shovel.

- Vibrating compactor, ramming the poured mortar.

- Bulgarian.

- Saw for cutting beams and boards.

- The building level will help to carry out control operations.

Concrete porch erection technology

Let's take a look at how to build a concrete porch yourself. Since this is a serious extension to residential building, then you first need to familiarize yourself with technological aspects its construction, the rules for preparing the foundation.

Please note: work on the construction of a veranda requires special attention and control at all stages.

As with any structure, you should first develop an extension project. The veranda can be erected together with the house, or attached to an already finished structure.

The veranda consists of a platform and steps. Building codes and rules for constructing a concrete porch will help determine their dimensions. The height of the extension should correspond to the distance from the ground to the bottom of the threshold. To determine the width of the staircase, you should know that for one person to pass through, an opening 0.8 m wide is required, and in order for two people to separate on the staircase, it should be no more than 1 m.

To prevent precipitation from accumulating on the site, it is built at an angle of 26-45 degrees. For its safe use, the site must have a depth of at least 1 m.

Depending on the height, the extension may have steps. Their number should be unpaired, so it will be more convenient to climb them. For comfortable use of the stairs, a step width of 25 cm will be sufficient, with a height of 12-20 cm.

Attention: if a concrete porch for a house, the construction technology of which is described below, is attached to the house, then it should be 50 mm below the threshold of the door so as not to interfere with its opening.

Having calculated all the necessary dimensions, you should draw up a sketch - a project of a porch of a private house made of concrete. It will be easier to carry out further work with it.

Work order

The construction of a concrete porch takes place in several stages:

- clearing and preparation of the site for construction;

- calculation of the size of the structure;

- manufacturing and installation of formwork;

- pouring concrete.

Preparatory work - site clearance

First you need to clear the area for the extension. A pit should be dug under the foundation (a hole about 30 cm deep, which in width will exceed the dimensions of the foundation by 2.5 cm).

Attention: a shallow foundation is being built under the concrete porch. Its depth should be 20-30 cm below the level of soil freezing.

Then, at its bottom, a substrate of sand and crushed stone is made. A layer of sand (about 10 cm) is tamped first, followed by a layer of rubble (5 centimeters).

Note: a substrate is needed for, as well as strengthening its base. It should extend beyond the perimeter of the foundation by 10 cm.

If the foundation is located in the zone of groundwater, they should be diverted.

Installation of formwork under the foundation

After the formation of the pillow, you can proceed directly to the manufacture of the concrete porch itself. Like any structure, it needs a frame - formwork. It must be a stable base that can support the weight of the concrete to be poured. It is a box structure consisting of edged boards, OSB-boards, plywood and fully corresponds to the appearance of the future concrete porch.

How to make porch formwork? For its construction, they take strong boards, at least 2 cm thick and about 20 cm wide.

Attention: do not take boards that are too dry - they can crack.

How to set up the formwork? In height, it should be 30 cm higher than the height of the concrete porch, since its lower part enters the ground. Then the side formwork brushes, the location of the risers and treads are outlined. To form their frame, boards of the required width are used. The details of the formwork are connected to each other and fixed with spacers. This ensures the strength of the entire structure.

The sides of the formwork should be reinforced with stiffeners. It is possible to additionally perform strapping with reinforcement - reinforcement. To do this, lay the reinforcement with a step of 20 cm according to a previously drawn up sketch.

Spacers are made between the stiffeners and the formwork. Then all this is covered with a 10 cm layer of soil and well compacted. When the formwork for the porch made of concrete is ready, we fill it with a concrete mixture (preferably grade M200 (B15) with a frost resistance factor of F150, which will ensure the reliability of the structure). It can be prepared by hand or mixed in a concrete mixer.

How to properly fill the porch of the house? Pouring is performed starting from the bottom step. The loaf is leveled with a shovel. After pouring each step, cover it wooden shield... This will protect the structure from drying out and waterlogging.

Advice: Concreting the porch is best done by adjusting the concrete mixer directly to the place of work.

If in the future a canopy is installed over the concrete porch, then support pillars for it it is better to install it at the stage of formwork installation. To securely fix the base for the visor, it is poured with concrete.

Concrete surface to be decorative finishing, must dry completely in the formwork for not a week. In the warm season, in order to avoid drying out of the concrete, it is periodically moistened with water. After its complete drying, the formwork is removed. To do this, the boards are tapped with a hammer so that they fall behind the concrete base.

The formwork should be removed gradually and carefully so as not to damage the concrete base.

When the formwork is removed, the porch surface must be sanded. Rough roughness can be removed with a stiff steel brush. It can also be done using an electric tool with a special grinding attachment.

How to finish

External cladding concrete structure allows you to improve its aesthetic perception and provide harmonious combination with the exterior of the building.

In the absence of financial resources, you can skip decorating, and after pouring, limit yourself to the following activities:

- lay pebbles on the concrete surface;

- create a texture that simulates a tile or stone.

Thinking about cladding options, it is advisable to determine a general finishing solution that ensures the unity of the style of the constructed span with the building. After all, concrete in pure form not particularly attractive.

As finishing material can be used:

- clinker tiles, on the surface of which there is an anti-slip coating. This is relevant in winter time and rainy weather;

- porcelain stoneware with an original texture. The material ensures the presentability of the erected structure;

- natural stone or its artificial analogue. Stone cladding leads in appearance among other types of cladding.

Important elements for an attractive look are:

- original visor;

- stylish railings.

For lovers of a creative approach, a huge field of activity opens up here, an opportunity is provided to realize artistic taste and imagination. In this case, the porch should harmoniously fit into the overall design of the building. Among a variety of materials, it is widely used for facing works tiles, which must be chosen taking into account a number of requirements.

Main characteristics:

- the presence of a rough surface;

- frost-resistant version.

The concrete porch looks original with the combined finishing of the steps, which provides for:

- plain finishing of the horizontal surface with clinker tiles;

- cladding vertical surfaces tiles with ornaments, similar in color.

Performing work on facing a concrete surface with tiles can be done on your own, following the sequence of operations:

- Clear concrete surface from dust, remove dirt.

- Treat the concrete with an adhesion promoter.

- Apply special adhesive to concrete and tiles.

- Fix tightly clinker tiles, protecting it from shifting.

- Ensure equal space between tiles using cross-braces.

- Grout the formed joints with a special compound.

Summing up

Despite the seeming simplicity of the structure, the construction of a concrete porch requires a serious approach and compliance with technological requirements. The recommendations of the specialists outlined in the material of the article will help answer the question of how to make a concrete porch with your own hands. Self-production will provide savings in money and will improve the skills of performing various construction operations. It is important to use high-quality materials, perform calculations correctly and follow the technology.

It can be made of various building materials. If we talk about strength, then concrete is an excellent material that, if observed the right technology will last for more than a dozen years. Moreover, you can make such a structure with your own hands. How to do concrete ring will be discussed in this article.

We can say that the porch is the business card of the owner of the house. Therefore, its construction must be approached with all responsibility. You can make a porch both at the stage of building a house and after its completion. The main thing that affects the quality of the porch, adherence to technology. V otherwise sooner or later, it may begin to deform or crack. And just the same, in order to prevent this, we will consider the details of the technology in this article.

Concrete construction has a number of advantages, here are some of them:

- Unlike other materials, a concrete porch has a long service life.

- Concrete does not rot, does not corrode and after a while does not lose its physical characteristics.

- To increase the strength, reinforcement is installed in the concrete body.

- Under the influence of ultraviolet rays, such a porch will not deteriorate in any way.

- The ability to build a porch yourself different shapes... There are no boundaries and rules here. Therefore, everyone can use their imagination.

- For the manufacture of a concrete porch, all available building materials are used - sand, cement, gravel and water.

- Unlike wooden structure, concrete is not subject to fire.

- Such a porch can be tiled, natural stone and so on. As a result, you can get a beautiful appearance.

As you can see, there are many positive sides the material used to construct the entrance to the house. Now is the time to consider the possible forms and design of the porch with concrete steps.

A porch made of concrete can be made of the following forms:

- round;

- trapezoidal;

- rectangular;

- square.

The choice of one form or another directly depends on the size and type of construction.

Concerning design features porch, then there are such types:

- closed;

- open;

- veranda-shaped.

Also, a railing must be installed on the porch, making the entire structure not only safe, but also making the appearance aesthetic and complete.

Concerning finishing, then a lot depends on own desire, as well as on the features of the structure of the building. Also, your financial capabilities play a significant role. After making all the calculations and making the design, you can start work.

The first step is to make a project of the structure, which will accurately indicate the shape of the porch. The size / number of steps also plays an important role. The steps should be comfortable for people of different ages.

The stairs to the porch should not be narrow. Otherwise, when walking intensively, inconvenience will be created.

So, when planning the manufacture of a porch, several important factors which are given below:

- The staircase should have a width of at least 0.85 m. This will allow you to move freely. Of course, if space permits, make a staircase bigger size.

- The angle of inclination of the stairs should have a maximum value of 5 °. If the slope is too steep, the descent will be too steep and therefore unsafe.

- An odd number of steps is preferred.

- One step should be no more than 180 mm.

- Overhang of one step over another is allowed more than 30 mm.

- The difference between the door and the upper platform should be no more than 50 mm.

- The size of the platform must be sufficient for the door to open freely.

You can make a porch in two ways:

- Buy ready-made concrete.

- Prepare the concrete mixture yourself.

If we speak for the first option, then this is the simplest method, but quite expensive. This concrete has several advantages. For example, there is no air in it, the mass is delivered homogeneous, after hardening the concrete has high characteristics. But if we talk about the cost, then it is much higher than the cost of self-prepared concrete.

You can use a concrete mixer to prepare the concrete. At the same time, the quality of the mixture will be no worse than the imported one. For the manufacture of concrete, it is recommended to use M400 cement. In addition, you need to worry about the availability of the following materials and tools:

- cement M400;

- sand;

- crushed stone;

- reinforcement Ø65 mm.

- wire for reinforcement bundles;

- formwork boards;

- bars;

- roofing material;

- nails.

As for the tool, the following set is required here:

- Bulgarian;

- puncher;

- manual vibrator;

- concrete mixer;

- shovel;

- kneading container;

- bucket;

- hammer;

- roulette;

- building level;

- rule.

Having prepared everything you need, you can start to get started.

Starting to make a porch, it is worth remembering 3 important rules:

- The height of the porch should match the height of the foundation of the house.

- Make mutual reinforcement by making the porch part of the foundation of the house.

- Make high-quality waterproofing.

Having a ready-made project, you can make an approximate consumption of building materials in advance. For example, knowing the area of the foundation, you can determine the required volume concrete mix... To determine the area, you need to make the following measurements: multiply the width, height and length of the future structure. This also applies to the stairs.

- So, first of all, you need to dig the foundation for the porch. The depth of the foundation must be equal to the depth of the building foundation. A layer is laid on the bottom of the trench sand pillow... It must be tamped well. To do this, after filling, slightly moisten it with water and tamp it with appropriate equipment.

- The next step will be the manufacture of the formwork. During the construction process, be sure to monitor the evenness of the entire structure. For this, you can use the building level. Also, the formwork must be well anchored. Otherwise, under the pressure of concrete, it can crumble.

- When the formwork is ready, the reinforcement can be made. The fittings are connected with a wire. Directly at the place of the foundation of the house, make holes and drive reinforcement in them. This will allow the structure to be connected to the house. When performing reinforcement, the step between the wires should be 10 cm.

After completing all preparatory work, you can start concreting.

Apply waterproofing to the foundation, for example, roofing material. When pouring concrete, use a vibrator. If such equipment is not available, then you can simply take a rail and pierce the poured concrete with active up / down movements. This will remove all air bubbles from the concrete body.

In parallel with this process, it is necessary to build steps for the porch. There are also some subtleties here:

- When arranging the risers and treads, set a right angle.

- For the construction of the formwork, it is necessary to install stiffeners.

- The slope of the treads should be around 6 mm. This will allow the water to drain off the surface quickly.

- A layer of waterproofing must be placed on the bottom of the formwork.

If the steps are round in shape, then for the formwork you will need to use plywood with a thickness of 30 mm.

The steps also need to be reinforced. The armature also connects to the foundation of a porch or house. This will prevent cracks from shrinking the building. In the end, it remains to pour concrete on the steps and porch. The site must be leveled with a rule.

Check the porch and steps for evenness several times. This will save the material for their finishing in the future.

When the concrete is dry, the formwork can be dismantled. This must be done carefully. After that, it was time for the final finishing. For this, you can use all kinds of Construction Materials, for example:

- fake diamond;

- a natural stone;

- porcelain stoneware;

- clinker tiles.

The final choice depends entirely on your preference. You can also choose the color of the finish that will fully match the exterior of the facade of the house. Accordingly, the material installation technology also depends on the choice of finishing material.

This is the principle behind the installation of a concrete porch. If you have your own experience, then share it by leaving comments at the end of this article.

Video

The video provided tells you more about making a concrete porch:

Schemes

On the diagrams, you can find many ideas and examples of how to build your own concrete porch:

There are many materials for making a porch. Among them are wood, metal, stone. However, the most durable and durable is the concrete porch. The procedure for its manufacture is characterized by certain difficulties and requires a large number time, but the result is worth it. We will consider how to make a porch of concrete further.

Concrete porch: advantages and characteristics

The porch is a visiting card of every home; the process of its construction should be carried out at the stage of construction of the house itself. Although sometimes, the porch is built later.

At self-erection porch, you must strictly follow all technologies and recommendations, since an improperly made porch can destroy the foundation, lead to deformation or cracking of the walls, and the subsidence of the house.

The choice of concrete as the main material for the construction of the porch has the following advantages:

- long service life, which is much higher than products made of metal, stone or wood;

- concrete does not corrode, does not rot and does not lose its physical characteristics under the influence of atmospheric precipitation;

- the use of reinforcement can significantly improve the strength characteristics of the porch;

- the concrete porch is resistant to mechanical stress, abrasion, ultraviolet radiation;

- imagination, in the process of making a concrete porch is limitless, it is possible to construct undulating steps, arcuate ledges, etc.;

- for the manufacture of this kind of porch, you will need sand, gravel, cement and water, these materials are absolutely accessible and inexpensive;

- fire safety is also a very important advantage of a concrete porch, because, unlike a wooden one, such a porch is not prone to burning and spreading fire;

- the option of finishing the concrete porch with tiles, natural or piece stone is possible, which will significantly improve its attractiveness appearance.

Concrete porch device: porch types

In relation to the shape of the steps, a concrete porch is:

- trapezoidal;

- round;

- square;

- rectangular.

The shape of the porch directly depends on its type, size, shape of the house and other individual characteristics. In relation to the structural components, the porch is:

- veranda-shaped;

- open;

- closed.

In addition, a railing is installed on the porch, which makes its appearance more complete and aesthetically pleasing.

The final appearance of the porch directly depends on the individual characteristics of the building, the preferences of its owners, as well as on financial investments. The initial stage of manufacturing a porch involves designing it, which we will talk about further.

How to make a concrete porch with your own hands: designing a porch

Before buying materials and tools that will be needed in the work, you should initially decide on the type and shape of the porch being made. Concrete steps for a porch should be of such a size that it is convenient to stand on them. In addition, the stairs should not be too narrow, as the porch goes down and up every day.

When making a porch from concrete, the following parameters should be taken into account:

- the minimum value of the width of the staircase is 85 cm, thus, it will be comfortable for one person to move along it, if the opening allows you to build a staircase of a larger size, then use this opportunity;

- the maximum angle of inclination of the ladder is forty-five degrees, if it is exceeded, the ladder will be too steep for descent, there is a risk of injury during its operation;

- try to choose an odd number of steps;

- the optimal height of one step is 18 cm;

- the value of the overhang of the steps above each other should not be more than three centimeters;

- the difference between the upper platform and the door should not be more than five centimeters;

- the size of the area in front of the entrance to the house should be such as to ensure optimal opening of the front door.

We build a porch of concrete: the choice of materials and tools

The procedure for making concrete for pouring a porch can be carried out in two ways:

- purchase of ready-made concrete mix;

- independent preparation of it.

The first option is more expensive, but it has certain advantages. Factory-prepared concrete has better adhesion to the surface, there are no air bubbles, after hardening, it has a higher strength and good performance characteristics... However, the cost of this solution is an order of magnitude higher than that of a composition prepared with one's own hands.

Using a concrete mixer, you can prepare a solution of good quality, which will also have good technical characteristics... In the manufacture of factory concrete, it is enough to purchase cement of grade 100 or 200, and in the process of using a concrete mixer, it is necessary to use cement grade not lower than 400.

In order to carry out the construction of a porch made of concrete, you will need:

- purchased concrete or cement grade not lower than 400 for the preparation of concrete;

- sand and gravel for concrete mortar, in the case of its own preparation;

- reinforcing rods, the diameter of which is about 65 mm;

- wire for tying reinforcement;

- boards from which it is necessary to build the formwork;

- beams, the frame part of the formwork will be based on them;

- nails;

- roofing material.

As tools for performing work, you should prepare:

- puncher;

- grinder for cutting reinforcement;

- manual vibrator, which will compact the concrete;

- shovel;

- concrete mixer, in the case of self-preparation of concrete mortar;

- bucket;

- the container in which the mixture will be kneaded;

- hammer;

- roulette;

- level;

- a board for leveling concrete.

Do-it-yourself concrete porch: the beginning of construction work

In the process of making a concrete porch, it is imperative to adhere to three basic principles:

- the height of the foundation of the porch must be identical to the height of the foundation of the building, near which it is being constructed;

- mutual reinforcement will help to connect the building with the porch into a single integral structure;

- to increase the duration of the operation of the porch, it should be carefully waterproofed at the base.

Work on the porch should start with its design. To do this, you should use a ready-made project, develop it yourself, or ask for help from specialists. Each of these options has certain disadvantages and advantages. The use of a ready-made project will reduce the cost of hiring a specialist, the porch will turn out to be of high quality and well-planned. However, in finished project not taken into account individual characteristics buildings.

Self-design of the porch allows you to build a structure that will meet all the individual preferences of the owners. However, to complete the project, tremendous experience and the ability to carry out calculations are required. In the presence of the slightest mistakes, there is a risk of damage to the entire structure, not only of the porch, but also of the house.

Contacting specialists is the most optimal, but at the same time expensive option... Such a porch will be clearly designed according to your individual preferences and characteristics of the house. In addition, specialists will accurately carry out all the calculations and help to achieve a result in obtaining a high-quality and aesthetically attractive porch. The choice of this or that option remains with the owners of the house.

The design process is followed by the calculation process. the required amount materials with which the porch will be built. To calculate the amount of concrete solution, you should find out the area of the foundation. Measure its width, height and length, multiply the values obtained, the resulting number will be the volume of concrete that will be required for pouring. The same should be done with the stairs, calculate the volume of one step and multiply it by the number of steps.

When choosing reinforcement, it should be borne in mind that the standard length is 12 m. Calculate the total length of the reinforcing rods that will fit on the porch and divide the resulting value by 12. As a result, you get the number of rods needed to complete the reinforcement. Tip: On the porch project, you should also indicate the location of the reinforcement, thus simplifying the procedure for calculating the reinforcement and its laying.

To equip a crushed stone pillow, you should measure the length and width of the warp on which it will be fitted. Further, the resulting value is multiplied by 0.05 m, the result obtained will be the volume of crushed stone required for arranging the pillow. The same procedure is carried out with sand, however, sand will be required 10 cm, that is, you need to multiply by 0.1 m.

Advice: All obtained values should be multiplied by 10, 15% to compensate for unplanned costs.

Concrete porch photo:

The field of project development should proceed to the direct preparation of the base under the porch. If you have an old porch, you should take care of its destruction and removal of all the garbage that remained as a result of this process. In addition, there should be no vegetation on the site.

The next stage involves digging a foundation pit for the porch. The foundation should be as deep as the foundation of the building itself. A cushion of sand and gravel is arranged in the pit. The sand layer should be gradually moistened with water and well compacted using special equipment.

After that, you should build a formwork from boards and beams, keep an eye on the evenness of the entire structure, since the shape of the porch will depend on it. In addition, a poorly assembled formwork will lead to the destruction of the integrity of the entire structure. Use self-tapping screws and anchor bolts to fix the boards together.

The next stage in the manufacture of the porch involves its reinforcement. In order to reinforce the surface, you will need reinforcing rods with a diameter of about 6-8 cm. To connect the rods to each other, you need a wire. Please note that holes are also made in the wall of the building, with the help of which the porch reinforcement is connected to the house, so the structure will turn out to be holistic and unified.

The spacing between the wires is about 100 mm, the reinforcement should rise 200 mm above the foundation. After the completion of the reinforcement, the process of pouring the porch with concrete follows. We will talk about this further.

How to pour concrete porch: technology

A layer of waterproofing is laid on top of the foundation; it is best to use roofing material or a special Pvc film... Before that, the porch is filled with a previously prepared mortar based on cement and sand, in a ratio of 1: 4. In addition, it is imperative to use a vibrator in your work. This device will help improve the adhesion of the concrete solution to the surface and rid the mixture of air bubbles that impair its quality.

Depending on the drawing, a formwork should be installed to fill the steps. There are certain subtleties in this process:

- for arranging treads and steps, the formwork is installed strictly at right angles;

- please note that stiffeners are required for formwork;

- the slope for treads is about 0.6 cm, so it will be possible to provide a stack for water when it rains;

- the formwork for a semicircular porch made of concrete should be made of plywood, minimum thickness which is 3 cm;

- at the bottom of the formwork, a roofing material waterproofing should be installed.

After the installation of the formwork and the installation of waterproofing, the process of reinforcing the steps is carried out. The reinforcement of the steps must also be connected to the house in order for the structure to be as complete as possible.

Tip: The optimal step size is 25 cm wide and 20 cm high.

How to build a concrete porch: processing a finished porch

You have already learned how to make a porch of concrete with your own hands, however, in order to improve the attractiveness of the appearance of this structure, you should also work a lot.

For finishing a concrete porch, materials are used in the form:

- piece stone;

- natural stone;

- clinker tiles;

- porcelain stoneware.

The choice of this or that type of material depends on the individual preferences of the owners of the house. In addition, it should be remembered that the porch should be in harmony with the overall style of the building.

After finishing the porch, a railing is installed on it, if the number of steps on it is more than three. To prevent precipitation from entering the front door, it is recommended to install a visor. There are a lot of options for its construction - brick, piece stone, metal, wood, polycarbonate.

Flowers, figurines, additional accessories are installed on the porch that increase its aesthetic appeal and delight guests who come to the house.