Potbelly stove from a pipe with your own hands drawings. Diy potbelly stove - basic types, drawings and connection diagrams (100 photos)

Potbelly stove - perfect solution in conditions when it is necessary to provide heating of small-sized premises (garage, utility room, bath heating), spending a minimum amount of money. It allows you to save money by using materials that almost everyone has, as well as the ease of making it yourself. Next, we will consider what you can make a potbelly stove and give specific drawings.

What tool is needed?

Regardless of the selected drawing or design features potbelly stoves, to carry out work on its manufacture, in addition to materials, you need to prepare the following tools and equipment:

- Hammer.

- Bulgarian.

- Welding.

- Drill.

- Drill.

- Brush.

- Chisel.

- Pliers.

- Roulette.

It is understood that each of the listed tools is designed to work with metals.

Choosing a type and starting work

Getting started:

- According to the given dimensions, it is necessary to cut out the elements from the sheet, from which the furnace will be made. Try to clean cut edges as much as possible.

- A part is being prepared for attaching the components of the stove - a pipe with holes.

- The parts of the upper tank are prepared for the installation of the chimney. To do this, you need, according to the data shown in the drawing, to make a hole offset to the left in relation to the cent. Also, at the bottom of the tank, another hole is made (shifted to the right) - it is intended for installing a connecting pipe.

- The constituent parts are welded to each other and a finished tank is obtained.

- The lower tank is welded in the same way. Only a hole is being made to install the pipe in the center. You also need to make another hole with a slight offset - processing will be poured into it. A special sliding cover is made over the filling hole.

- The lower tank is attached to the upper one (they are welded to the connecting pipe). The structure should be strengthened using brackets.

- Do not forget to weld the legs to the lower tank.

- To increase the service life, the oven is cleaned and painted.

You attach a potbelly stove to the chimney and try to heat the garage. To do this, pour fuel into the lower tank and set it on fire. When it flares up, the recycling hole needs to be closed with a sliding lid.

Important: Use special heat-resistant paints to paint the structure.

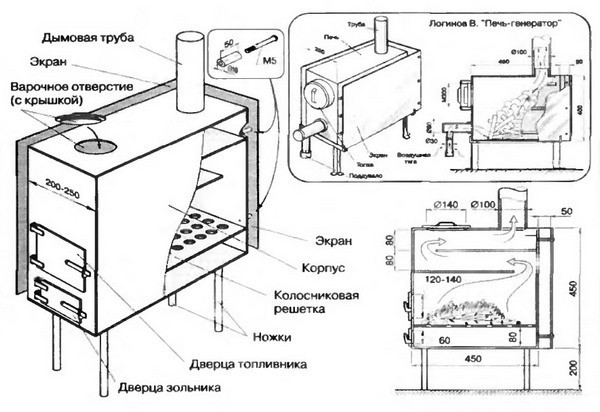

Rectangular stove on the wood

This option is suitable when you need to heat the garage or sauna rooms intended for relaxation.

The features of the model, the manufacture of which we will describe with our own hands, lies in the high heat transfer and the possibility of adjusting the traction force.

Our oven will measure 45x45x80. These dimensions are enough to heat an average room. Long wood will fit into it and is easy to move.

In this case, we will not give a specific drawing, and will try to explain it in words as much as possible. Before starting work, we buy:

- Steel 3-4 mm thick. A sheet one and a half by two meters will be enough.

- A piece of pipe. Choose from a diameter of 90 to 100 mm. Length: 0.4 m.

- Rebar 16 mm. You need exactly 6.2 m.

- Five kilograms of electrodes.

- Four door hinges.

- A rod of steel, half a meter long and about 10 mm in diameter.

- Seven meters of corner with 40 mm shelf. The walls should be 5 mm thick.

When everything you need is prepared, we start working with our own hands in the following sequence:

- Future walls of the structure are cut from the sheets.

- The corner is welded in such a way that a frame is obtained. When performing this and the first point, you need to remember the above dimensions of the stove (45x45x80).

- The reinforcement is cut and welded to the frame at 2 cm intervals.

- The finished frame is scalded with tin.

- Along the diameter of the smooth bar in the section of the pipe that will be the chimney, you need to make 2 holes. The pipe is welded to the frame (before that, you need to make a hole under it).

- A curved bar is inserted into the chimney holes. It must have the shape right angle... A round piece of tin is welded to it, slightly smaller in size than the inner diameter of the chimney - it will be used for adjustment.

- The potbelly stove must have doors. They are cut straight out of the body. Loops are welded onto the removed piece of metal, with which they are attached to the furnace.

- Bolts and handles are installed on the doors, which can be made by any comfortable view... The main thing is that they guarantee the maximum fixation of the door (if you do not want to burn the garage).

- When the work is finished, you can check the result of the work with your own hands and start heating the garage.

Important: To ensure traction, the doors are fastened so that there are small gaps.

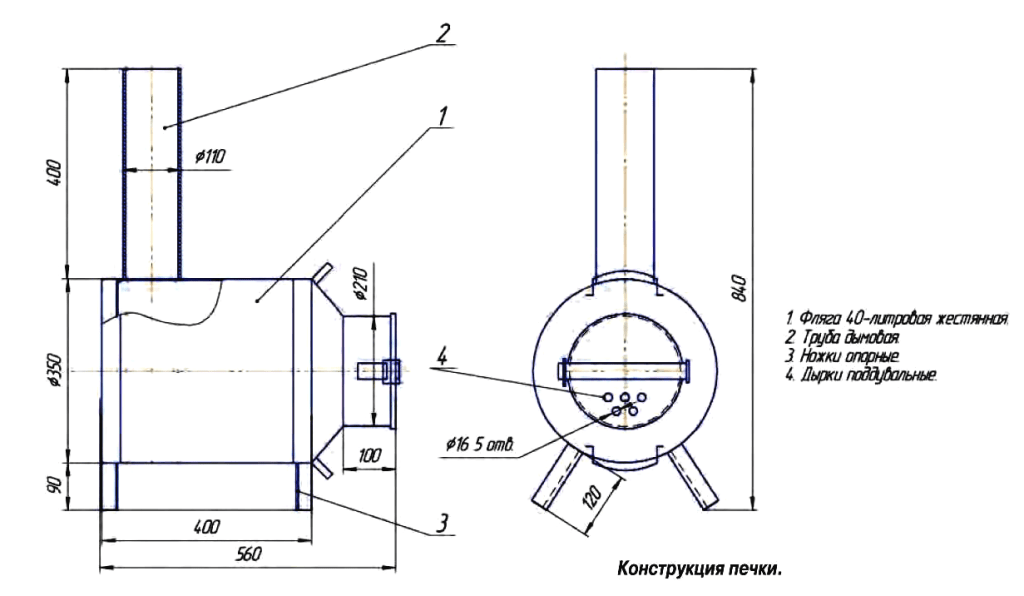

Potbelly stove from a pipe

This option implies the simplicity of doing the work with your own hands and aesthetic appearance, which will allow heating not only the garage, but also small rooms in the country.

Work algorithm:

- The pipe is taken and cut to the desired length.

- 2 holes are cut in the side part: for the ash pan and the firebox. The distance between them is approximately 15 cm.

- The cut pieces of metal will serve as doors. Their size is increased by welding metal strips on top. You also need to immediately install the handles that secure the door.

- Corner brackets are welded inside the future stove (they will hold a grate, welded with your own hands from fittings or bought in a store).

- The grate is being installed.

- In the circle of metal that will close the pipe opening (the upper part of the stove), you need to make a hole to fix the pipe (chimney).

- The bottom and top of the stove are brewed.

- The pipe is welded.

- The hinges are welded and the doors are installed.

- The furnace in the places of welding joints is cleaned and painted with a special paint.

- The last stage is the connection to the chimney brought out of the room.

If everything is done correctly, the potbelly stove will be able to completely heat the garage or other small room.

Oven from a can

A potbelly stove can be made from any old can. For this you need:

- The can.

- A piece of pipe.

- Rebar or wire.

Getting started:

- On the canister installed in a horizontal position, mark the location of the rectangular blower. It should be placed under the cover.

- Cut out a hole for the chimney. It can be in the bottom or in the wall.

- Making a grate. It is easier to make it from steel wire, which, when bent, is brought into the middle of the future stove and straightened. It is necessary to arrange the zigzag in such a way that it is most convenient to fill the stove with firewood.

- We attach the legs.

- We weld on the chimney.

The design implies a minimum of manufacturing costs and you do not need to have professional skills to complete the work. With its help, you can safely heat the garage and other utility rooms.

Gas cylinder oven

If you have lying around on your site gas bottle- use it to create a potbelly stove.

Sequence of work:

- Cut off the tap and plug the hole.

- Cut a hole in the bottom for the door. Doors are made from the resulting piece of the bottom, by scalding it with a strip of metal.

- A lock-handle is attached to the door and they are mounted on the cylinder using hinges that are welded.

- In that part of the cylinder, which will be the bottom, you need to make a grate. To do this, it is enough to make holes.

- A tin box is welded under the holes in the bottom, into which soot and waste will fall. Doors also need to be made in the front of the box - they will be used to adjust the draft.

- The stove must be lifted off the ground using the legs. An ordinary pipe is suitable for their manufacture.

- A chimney is welded into the upper part of the cylinder.

- If necessary, a hob can be arranged on the surface of the structure.

Such a stove will heat a garage or a small house in the country.

A potbelly stove is a fairly simple device for heating rooms. When carrying out work, remember that the oven should not only warm up, but also meet the minimum requirements for fire safety.

The stove-stove is a faithful companion of summer residents, security guards, and those who like to repair cars in their own garage. Owners of small private houses also often use this option heating as the most economical and mobile.

Such a stove is quite capable of heating a small room in a matter of minutes, and thanks to modern design solutions, she will not spoil the interior at all country house... Almost everyone who sets themselves such a goal can make a potbelly stove with their own hands. We will look at how to do this in this article.

Tools for the job

In order to make heater took you a minimum amount of time, you need to prepare the following tools:

Welding machine (not less than 200A)

Welding electrodes and protective mask

Bulgarian

Detachable and grinding wheels for metal

Slag hammer

Metal brush

Pliers, simple hammer, chisel

Drill with drills

Measuring device(tape measure, meter)

What are homemade potbelly stoves?

Appearance and specifications stove stoves can be different. For each premises will do its own stove, which can both heat it up and harmoniously fit into the interior. The future of the stove can be based on sheets of metal or applied already ready product: metal pipe medium-sized barrel, gas cylinder or tank. In any case, the wall thickness should not be less than 3-5 mm.

Appearance and specifications stove stoves can be different. For each premises will do its own stove, which can both heat it up and harmoniously fit into the interior. The future of the stove can be based on sheets of metal or applied already ready product: metal pipe medium-sized barrel, gas cylinder or tank. In any case, the wall thickness should not be less than 3-5 mm.

If you need to heat the garage, then almost any option will do, since such a stove only requires heating a small room. For the potbelly stove, which will be in the house, the aesthetic side is also important - the appearance of the unit, therefore it is better to refuse some options right away. An important point is also the type of fuel that is used

Do-it-yourself potbelly stove for working off

This is an option that is just not suitable for heating residential premises. Due to the pungent smell that is emitted during the combustion of oil waste, it is not very pleasant to be in such a room for a long time. Even if a good hood works, all things in the house will be saturated with this specific "aroma". This stove is perfect for heating a garage and other non-residential premises.

To make it, you will need a 4-5 mm metal sheet, which will be cut into pieces, and a chimney pipe. All elements of the stove are cut out using a grinder. The edges of the pieces are trimmed. Before cutting, it is necessary to make the correct marking of all parts, according to the drawing.

To make it, you will need a 4-5 mm metal sheet, which will be cut into pieces, and a chimney pipe. All elements of the stove are cut out using a grinder. The edges of the pieces are trimmed. Before cutting, it is necessary to make the correct marking of all parts, according to the drawing.

In the pipe of the required length, round holes... This pipe is designed to connect the upper and lower potbelly stove tanks. It is also necessary to drill two round holes in the upper tank: one for the chimney pipe (top left), the other for the connecting pipe (bottom right). The lower tank of the stove is done in the same way, only a cutout for the pipe is made in the center of the container. For filling fuel, it is necessary to provide a filler neck, which is equipped with a sliding cover.

The lower part of the tank is made flat, four or three legs are welded onto it. In order to prevent the lower and upper parts from loosening, they are reinforced with additional stiffening brackets. Welds it is necessary to thoroughly clean, and cover the furnace with high-temperature enamel, which will protect the metal from rust.

How does such an oven work?

The potbelly stove produces heat as follows: a long thin stick or curled paper ignites the used oil in the lower container. When the mining has caught fire, the filler cap should be closed. Combustion air will flow through a pipe that is connected to the top tank. Rising up, hot air heats the top of the stove to a high temperature. It gets so hot that you can even heat the kettle on it.

Such a stove - perfect option for the garage, since it successfully heats a small area, and used materials for the firebox will always be found by car owners.

Stove stove from a pipe or barrel

If you are planning to construct a heater from a pipe or barrel, you need to choose a suitable diameter. It directly depends on the size of the room that needs to be provided with heat.

A potbelly stove from a barrel can also be used in a living room, provided that it is made accurately and correctly. This type is most popular for heating country houses.

Two are cut in the barrel rectangular holes, which will be connected to the firebox and ash pan. The cut pieces are used for the doors. They are cut out before the right size, framed with strips of metal and attach handles and a latch to such impromptu doors.

Two are cut in the barrel rectangular holes, which will be connected to the firebox and ash pan. The cut pieces are used for the doors. They are cut out before the right size, framed with strips of metal and attach handles and a latch to such impromptu doors.

Inside the barrel (pipe), two angle-shaped brackets are welded. These are grate holders, which are located just below the doors. As a grate, you can use welded fittings or buy a ready-made one in a store.

A piece of pipe is welded tightly, and supports are welded to its lower part. A hole for the chimney is cut out on top of the pipe, into which the pipe is inserted and welded.

Only then are the doors installed. They are attached to door hinges and install the latch hook, having measured the desired level in advance.

To make the stove aesthetically pleasing, it is necessary to thoroughly clean the welding seams and paint the product with heat-resistant enamel. If you do everything carefully, such a heater will look no worse than the factory counterpart. After the paint has dried, the stove is connected to the chimney pipe that enters the street.

It is the easiest to perform and practical option... Despite the fact that such a potbelly stove takes up quite a lot of space, it is used for heating more often than other models. It is also very convenient that on the surface of the tank you can heat water in a kettle or a saucepan, as well as dry your laundry.

Potbelly stove from a gas cylinder

The used gas bottle is very suitable for the stove. It's practically finished form for a potbelly stove, which requires minimal modifications.

The upper part of the cylinder, where the tap is located, is cut off, and a plug is welded in its place. A square cutout is made in the bottom of the cylinder - this will be a firebox. The cut piece must be turned into a firebox door. To do this, it is scalded with metal and a handle is attached to it to open it. Subsequently, you will need to weld to the hole metal hinges on which the door will be worn. Install it yourself door leaf better at the very end, when the potbelly stove is already completely ready.

The upper part of the cylinder, where the tap is located, is cut off, and a plug is welded in its place. A square cutout is made in the bottom of the cylinder - this will be a firebox. The cut piece must be turned into a firebox door. To do this, it is scalded with metal and a handle is attached to it to open it. Subsequently, you will need to weld to the hole metal hinges on which the door will be worn. Install it yourself door leaf better at the very end, when the potbelly stove is already completely ready.

In order for air to enter the firebox, several holes are drilled in the bottom of the cylinder. They will give thrust and serve as grates. In order to prevent burnt firewood from falling to the floor, a metal box is welded to the bottom of the cylinder - an ash pan. It can be made from a more subtle sheet metal... The ash pan is also equipped with doors.

After that, legs from a metal corner or pipe scraps are attached to the cylinder.

The back of the stove will have a smoke exhaust pipe. To do this, cut a round hole in the upper part that matches the diameter of the pipe and weld it there.

From above, you can equip an impromptu cooking stove. It can be made from a metal grid or reinforcement by welding the frame to the top of the cylinder.

Such a potbelly stove is an excellent option for heating a summer cottage, garage or change house. It is versatile and does not take up much indoor space.

Potbelly stove rectangular

Of all possible options, such a stove is the most compact and neat look. It is used in residential premises, where, thanks to rectangular shape, the stove is easy to decorate and make it almost invisible.

The most popular is the factory model "Gnome". Its structure is quite simple, and the heat dissipation is very efficient.

The most popular is the factory model "Gnome". Its structure is quite simple, and the heat dissipation is very efficient.

This stove consists of just a few elements: swamps, ash pan and chimney. The stove is installed on four legs. The second figure shows more complex construction firebox that retains heat for a long time.

It is quite possible to build such a structure yourself. Let's take a closer look at how to do this.

To do this, you will need the following consumables: a sheet of metal, at least 4 mm thick, a chimney pipe and a steel corner. In addition, you need to purchase a burner cover.

You need to cut out four walls, the bottom and the upper hob. In order for the fuel to completely burn out in the firebox, it is necessary to use special plates that are located inside the stove. Thus, more heat will be produced in the combustion chamber.

The holes for the firebox and blower are cut in the front of the structure. Subsequently, hinged doors with handles and locks will be attached to them.

The holes for the firebox and blower are cut in the front of the structure. Subsequently, hinged doors with handles and locks will be attached to them.

A hole for the burner is cut out from above, corresponding to the dimensions of the part, and a hole for the pipe, through which the smoke will come out.

Legs from the prepared corner are welded to the bottom of the stove.

The place where the grate will lie is marked on the side panels. Sections from the corners are welded here, which will serve as supports for the grate. The grate can be made by yourself. To do this, you need to drill a large number of holes in the steel sheet so that it becomes like a sieve, or weld a grid of steel rods.

At a short distance (at least 15 cm) from hob in the upper part of the stove, the plate is welded. It should correspond to the size of the stove, but not reach the end of 8-9 cm. The second plate of the same is placed just below. It should also not reach the end of the container, only in the front of it. These plates form additional ribbon-like passages inside the stove. Heat from the burning fuel will enter the formed corridor and heat the plate. Thus, more heat will remain inside the tank, rather than flying straight into the pipe.

Safe rules when using a potbelly stove

Fire safety rules are very important when using a homemade heater. In order for a potbelly stove to bring warmth and comfort to the room and not pose a threat to health, you must remember the following safety measures.

It is necessary to place the stove on a fireproof base. It could be tile, sheet of metal or brickwork... Walls near the stove must also be protected from overheating. You can paste over them with fireproof material or use non-combustible drywall. In no case should you place furniture and any other flammable objects near the stove.

The slightest spark or too much heat the surface of the stove can cause a fire.

In order to exclude the possibility of accumulation of combustion products in the room, use ventilation. Think in advance where your potbelly stove will be located, and how you can ensure the flow fresh air into the room, and the outflow of carbon monoxide from it.

Install the stove in a place where there is less traffic of people, do not allow children to play games near the stove. Observing these simple rules, you will provide for yourself inexpensive heat in the cold season.

Beautiful a budget option heating and cooking stove - potbelly stove. It is incredibly convenient and easy to design and operate. It is good to have such a device in the country, in the workshop, in and in many other places. A water stove can heat several rooms. On sale today there are many of the most different models, from unassuming functional to sophisticated retro. But their price cannot be called low. Therefore, craftsmen who have some experience, have tools and a suitable metal, you can try to make an effective potbelly stove with your own hands.

We cut out from the balloon

We cut out from the balloon The simplest version of a potbelly stove can be made from scrap materials. A thick-walled barrel, an old industrial can or a gas cylinder (of course, empty) is suitable for this.

Resourceful craftsmen they use pipes of a suitable diameter, disks from overall wheels and sheets of metal.

When choosing a starting tool for work, it should be borne in mind that too thin metal is deformed with strong heating, and the product from it will lose its shape. The optimum material thickness is 3-4 mm.

For a comfortable and effective work to make even a small potbelly stove with your own hands, you will need the following:

Stove stoves are different types but the essence is the same

Stove stoves are different types but the essence is the same - - angle grinder, as well as special consumable to it - grinding wheels and cutting discs.

- Metal brush.

- Welding machine with electrodes, protective mask and work suit.

- Slag separating hammer.

- Measuring tools: tape measure, marker, chalk, metal ruler, folding rule.

- Chisel, pliers, hammer.

- Drill for metal with a set of drills.

The choice of a particular model depends on many components: the place of the future placement, its size, the purpose of the furnace. For residential premises, it should have a more aesthetic appearance, therefore, for room placement, it is better to prefer the option from a pipe segment or from metal sheets.

Do-it-yourself neat potbelly stove

Do-it-yourself neat potbelly stove Events with balloon # 1

Several rows of holes are drilled in the bottom of the potential firebox (the sidewall of the cylinder), which will play the role of a kind of grate. An ash pan is located along it - in our case, a box made of thick metal. It should be equipped with a sealed door to prevent ash and hot coals from getting out.

On the sides of the ash pan, the legs of the structure should be welded. A round hole is made on top of the lying balloon.

The vertical part of the potbelly stove will stand on it. It is convenient to make the door from the head of the second cylinder; a branch pipe with a valve is not welded in - to regulate the intensity of combustion. If the door hinges are placed at the top, then the cover, under its weight, will fit snugly against the firebox opening, which will reduce air suction to a minimum.

Events with balloon # 2

The most important thing here is cutting out along the markings of such a shape, which will fit exactly on the first cylinder: they are connected by welding. In this part of the furnace (vertical) there will be an additional heat exchange chamber. Getting into it, the smoke lingers, not going straight into the pipe, but circulating for some time.

The most important thing here is cutting out along the markings of such a shape, which will fit exactly on the first cylinder: they are connected by welding. In this part of the furnace (vertical) there will be an additional heat exchange chamber. Getting into it, the smoke lingers, not going straight into the pipe, but circulating for some time.

Metal plates with holes made are welded inside a vertical cavity at a distance of 25-40 cm... The holes are closer to the edge of the circumference of the web, and correspond to the holes on the adjacent plates.

The best option- three equidistant jumpers. A vertical cylinder with jumpers on top is welded to a horizontal one, and is equipped with a chimney pipe (by welding).

Barrel stove stove

A barrel stove is more voluminous than others, and it also needs more space. But it is also capable of heating a much more spacious room.

A barrel stove is more voluminous than others, and it also needs more space. But it is also capable of heating a much more spacious room.

Like the first model, a stove-stove from a cylinder, it can be made both horizontally and vertically.

Both are suitable for heating technical, utility and residential premises. For work you need: a pipe for a stove stove 10-15 cm, a sheet of metal and the barrel itself.

Vertical model

On the surface of the workpiece, the future location of the firebox and blower doors, the place of the cut are marked.

The barrel is cut in half, with each part to be separate work... A circle is cut out of a sheet of steel around the diameter of the barrel, in which a hole is made for the chimney pipe.

The barrel is cut in half, with each part to be separate work... A circle is cut out of a sheet of steel around the diameter of the barrel, in which a hole is made for the chimney pipe.

In the upper part of the workpiece itself, a hole is made to align with a similar one. hob.

The chimney pipe is welded into the hole prepared for it in the barrel, the hob is threaded through the hole at the top and installed. It is welded to the sides of the barrel itself. The air space between them will allow the hob to stay warm longer without cooling.

Grate(a prepared round part with holes) is welded from the bottom of the upper part. When the top panel and the bottom of this half are ready, you can cut out a hole for the firebox (its door). The opening is scalded with metal strips, the door is equipped with a handle with a latch and hinges.

Grate(a prepared round part with holes) is welded from the bottom of the upper part. When the top panel and the bottom of this half are ready, you can cut out a hole for the firebox (its door). The opening is scalded with metal strips, the door is equipped with a handle with a latch and hinges.

They are neatly welded to the barrel so that the door slides back and forth easily and the latch fits into the hook holder. At the very bottom of the barrel, an opening is made for the ash pan (blower)... The door is made and hung in the same way as for the firebox. Both halves are reattached into one piece by welding.

Horizontal model –

the process of its manufacture is almost completely analogous to the manufacture of a horizontal oven from a cylinder.

Easy with your own hands: stove potbelly stove "Gnome"

A compact furnace made of thick metal sheets is one of the most popular homemade stoves this type. It looks like a factory, intelligent and neat, and will perfectly fit into the design of any room. In terms of size, this is a wonderful stove-stove for: it will take up little space, while remarkably heating the room and being used for cooking.

A compact furnace made of thick metal sheets is one of the most popular homemade stoves this type. It looks like a factory, intelligent and neat, and will perfectly fit into the design of any room. In terms of size, this is a wonderful stove-stove for: it will take up little space, while remarkably heating the room and being used for cooking.

You can make an ordinary, simplest body, divided into an ash pan and a firebox. If you equip it with partition plates inside, it will acquire additional heat transfer properties. Such a device will allow you to keep heat longer, and sometimes it is extremely necessary.

Drawing of the stove "Gnome"

Drawing of the stove "Gnome" For the manufacture of this model, you need a thick sheet of steel (0.3-0.4 cm), a steel pipe, a corner of 5/5 or 4/4 cm suitable in size.The cover for the burner can be found in a profile store, or you can make it yourself ...

We provide you with drawings, guided by which, you can get to work. The outlines of future parts of the stove are applied to the blanks. These are its future walls, plates for placement inside, a grate. In the front panel, holes are made for the blower and the firebox (rectangular).

Doors are made from the metal pieces obtained in the process: scalded with a corner, equipped with hinges and latches, mounted on the front panel. One of the prepared plates is welded onto it, but from the inside. In size, it should be 10 cm smaller than the side walls of the product.

A horizontal potbelly stove from a pipe is one of the simplest, but most productive designs of home-made stoves operating on solid fuels. The simplicity of design and low cost allow even novice home craftsmen to make such a stove.

Collapse

First, beginners need to understand how the oven works, what parts it consists of.

Principle of operation

The principle of operation of such a furnace is simple:

- firewood is put into the firebox;

- for kindling, thin chips are placed closer to the door;

- the door in the ash pan and the slide gate must be open;

- firewood is set on fire and must close the door;

- the flame heats up all the planes of the furnace. Metal, giving off heat, gradually heats the room;

- for the second bookmark, you can use coal or carpentry waste.

Stages of work

Before starting work, it is necessary to determine the size of the furnace, and prepare necessary materials, tool and welding equipment.

Drawing and diagram

Drawing of a stove from a horizontal pipe

Another drawing option

The simplest pipe stove runs on solid fuel and consists of several main parts:

- body - it is made different in shape, depending on the materials used for its production. It can be rectangular when using sheet metal or cylindrical, in this case, the body is made of a gas cylinder or large diameter pipe;

- grate. It serves to protect the bottom from burning out and remove ash to a special compartment;

- ash pan - in this part is going wood ash, this cavity serves as a blower to improve traction when burning firewood;

- combustion chamber. Firewood or coal is laid here;

- to remove carbon monoxide, the stoves are equipped with a chimney outlet. In some cases, it is withdrawn vertically from the top of the oven or with an outlet extending from the rear plane. But in any case, the chimney outlet is located at the top of the structure;

- a reflective screen is installed above the door. It is positioned over the entire surface of the oven, leaving an air passage in the rear cavity. In this case, the heat does not immediately go out into the chimney, but passes through the stove, heats the walls and only then enters the pipe;

- combustion chamber doors. Here they use ready-made cast-iron or steel doors or home-made ones from a piece of thick metal;

- the most efficient potbelly stove is equipped with additional convection pipes, such drawings homemade oven can be found on forums on the Internet or check out industrial ovens Professor Butakov or the Bullerian model.

A potbelly stove from a pipe with an inner diameter of 500 mm is made according to the drawing, taking into account the main dimensions of the structure:

The dimensions of the remaining parts and their installation locations will be taken from the drawing.

Let's analyze the process of making a homemade stove.

What kind of pipe do you need?

Any pipe can be used. The most important thing is that it is not previously used on gas supply pipelines and for sewerage. Such ovens, together with heat, will spread throughout the room unpleasant odors long time. In size - it all depends on the needs and capabilities of the master.

For heating small garage it will be enough to make a stove with a diameter of 400-500 mm. For a large room, you can make a potbelly stove larger diameter or install a few small ones. The main thing before work is to clean the walls from limescale, dirt or oil and only then start to work.

Materials and their quantity

For the production of a potbelly stove, we need to prepare:

- steel pipe with a section of 550 mm, with a wall thickness of 10 mm - length 650 mm;

- for the top of the furnace made of steel 4-5 mm, cut out a workpiece 700/420 mm and bend it along the length of the shelf, marking 40 mm from the edge of each side;

- the front and back walls of the stove - 2 parts, 560/560 mm in size;

- for a reflective screen, cut out a workpiece from a sheet of 500/420 mm in size;

- for the grate, you will need to prepare reinforcement, with a section of 10 mm - 2 pieces of 600 mm each and 32 pieces of 380 mm each;

- for the outlet of the chimney, we prepare a piece of pipe with a section of 100 mm, a length of 260 mm;

- the top provides for the installation of a cooking zone. You can use ready-made cast iron or make from steel sheet 12-14 mm thick, cutting a circle with a plasma cutter with a diameter of 220 mm and turning the workpiece on an emery or grinder;

- from a 40 mm profile we prepare 4 legs 400 mm long;

- we get ready-made hinges or you can make it yourself from a profile and a bar;

- for the door, we cut out a blank of 340/340 mm from the sheet;

- 6 pieces of angle bar for laying the grate.

This is a list of basic materials, small parts we will make in the process of work.

Tools and equipment

We will need:

- a set of locksmith tools;

- welding machine with clothing and protection of eyes and hands "

- grinder with stripping and stock of cutting discs;

- workbench with a vice;

- sand for filling the bottom of the furnace.

Step-by-step manufacturing instructions

Having prepared the entire set of tools and materials for work, we proceed to the process of making a potbelly stove from a pipe with our own hands:

- Place the finished pipe section on a flat surface, set the protective screen at a distance of 5 mm from front side and grab it to the pipe. It is important to have experience in performing ceiling tacks, although there is practically no load on the screen. We put potholders every 60-80 mm.

- At the bottom of the furnace, we retreat 50 mm, mark the longitudinal lines along the entire length of the pipe and grab the corners for laying the grate. To make it, we place long pieces of reinforcement, insert the lintels along the edges and grab them. Now, stepping back from the jumper 10 mm, we join the next jumper. Thus, we collect a grid of reinforcement, 600/400 mm in size. After that, turning the grate over, put the tacks on the back side.

- We put the grate in place and join the metal sheets from the front and back sides. Skewing and large gaps between the sheet and the pipe must not be allowed. If the pipe is cut crookedly, you will have to level the workpiece by grinding the walls with a grinder. Having checked the correctness of the assembly, we proceed to the welding of the joints. The seam must be airtight, so after welding, beat off the slag and boil the burns, sinks and lack of fusion.

- There is another option for installing the grate, which is more practical. At the bottom of the pipe, a rectangle is cut out with small indents at the edges, a blank is welded from the bottom of the pipe shaped pipe(for collecting ash). A grate is placed on top. This is how it looks:

- We grind the protruding corners and the junction of the parts with a cleaning stone. Then we turn the workpiece face up and mark the opening for laying firewood. We put on the grinder cutting disc and cut a groove along the markings.

- We remove the burrs with a file, lay out the door with a welded handle and a latch and install it on ready-made hinges. On the sheet, we expose and grab the counterpart of the lock, and on the door we expose a homemade lock - the latch.

- We turn over and place the stove with the bottom up, mark and weld the legs from the profile pipe, having previously cut the corners for better joining to the body. At the bottom, we cut the legs at a small angle and weld the nickels from the sheet, for better stability of the potbelly stove.

- We install the stove on the legs and put a blank with holes for the chimney pipe and burner on top of the stove. Having placed it with the curved edges down and checking the correct installation, we grab the plate.

- We burn holes in the pipe with electric welding and install a pipe with a diameter of 120 mm for the hood and pancake for pots.

- Parts are scalded in a circle, the joints must be sealed. At the end of the ventilation pipe, we weld a slide gate to regulate the draft.

- Opening the door, placing the grate in place, cover the bottom of the stove with a layer of sand.

The stove - the stove from the pipe is ready.

Look at a few more manufacturing options to consolidate your understanding:

Features of operation

When testing the stove, it is better to open all doors and windows. We make sure that there is a draft and an open damper. Then, putting firewood through the door, we ignite the flame. We close the door and go out into the street. The potbelly stove will smoke a lot, but you should not be afraid of this, this will burn out oil and other debris.

Heating process

After using the oven for the first time, it may be necessary to correct welding defects. And then enjoy the warmth in your garage or other space. The main thing is to remember the fire safety rules, periodically clean the chimney and remove the ash, periodically replacing the sand in the stove.

Output

Even a novice master is quite capable of making such a structure on his own. The main thing is to want to make a reliable potbelly stove and carefully and responsibly perform all the work, taking into account step by step instructions provided in the article.

← Previous article Next article →To create such a variant, the following types of material are required:

- metal sheet, several pieces, 5 mm thick. We will make all the details, blanks from them.

- Pipes for some structural elements.

- Chimney pipe.

Process of creation

In the below drawing of a stove stove, all the necessary parts are presented, indicating their dimensions.

So, we will divide all the work on creating a potbelly stove using mining as raw materials into sequential steps:

- We mark all the necessary details on a sheet of metal, and then cut them out using grinder... The resulting blanks need to be well cleaned off the edges.

- We take a pipe of the required length and drill round holes in it. In the future, using this pipe, the upper and lower stove tanks will be connected.

- We take the upper tank and cut an opening of the required size from above. This opening will not be located in the center, but will shift to the left of it. We prepare this hole for the chimney.

On the lower side, we cut out an opening, shifting it to the right. It will serve as an inlet for the connecting pipe. - We weld two circles to the part of the pipe, along which the thickness of the upper container is determined.

- We will do the same with the bottom of the stove. But now we will cut the opening for the incoming connecting pipe in the center of the container. In addition, you need to cut another hole - the neck through which we will fill the stove with fuel. On this hole, we provide for the presence of a sliding cover.

- Weld 3-4 legs on the back of the lower tank. This will ensure sustainability.

- To give the structure rigidity, to strengthen it, we connect both tanks to each other using metal brackets.

- The main work points are over, it's time to think about beauty. We carefully clean the welded seams, after which we paint the stove using heat-resistant paint. Painting the oven will also help prevent premature rusting.

- The last step is the installation of the chimney.

Principle of operation

The work of this type of potbelly stove can be described as follows: pour used oil into the lower container through the neck. Next, using a splinter or paper, ignite the fuel through the opening. As soon as the oil has ignited in the tank, close the opening with the sliding lid.

The combustion process is enhanced by the air entering the connecting pipe through the holes made. The air heats up and rises through the pipe to the upper part of the structure, while heating the surface of the container so that you can easily warm the kettle on it. A big plus of such a potbelly stove model is that there will be no unpleasant situations with a lack of fuel, since motorists always have used oil in the garage.

Why it is impossible to extinguish boiling oil, fat, paraffin with water. If you use a stove for testing, then there must be a fire extinguisher and sand.

Model No. 2 - stove-stove from a metal barrel or pipe

For this construction, we take metal barrel or a pipe with a certain diameter. Great option for a house in the country, and if it is still beautiful to complete the assembly, refine it, then it will look quite good in the living room, while also heating excellently.

Step-by-step execution instructions:

- We take a container for the stove and mark out two rectangles. These will be the entrances for the firebox and ash pan. We cut out these holes.

- We do not discard the cut rectangles, as they will serve as material for the doors. To do this, each door is brought to the required size, for which it is framed with metal strips. Next, we install the latch handle.

- Inside the container (barrels, pipes), stepping back 10 cm from the firebox door, we attach the corner brackets. Then we will place the grate on them.

- The grate can be bought ready-made, or you can do it yourself by welding it from reinforcing rods.

- If a pipe was taken as the basis, then now its bottom and upper part should be welded.

- To give stability, to raise it above the floor, we weld several legs to the bottom of the container.

- In the upper part of the tank, we prepare an opening for the chimney, where we then weld it.

- We fix the hinges and hang the doors on them. We mark and fix the hook under the lock.

- Appearance plays an important role, so the surface and seams should be cleaned. Coating the stove with heat-resistant paint will allow our design to compete with the factory model.

- When the stove structure is completely assembled, it is necessary to connect it to the chimney, which we take outside, to the street.

This type of potbelly stove is a good option for heating a room, provided there is sufficient space, since the stove is quite large. But another plus is its spacious top panel, on which you can install both a kettle and a frying pan.

Model No. 3 - potbelly stove from a gas cylinder

The gas cylinder has an almost perfect, ready-made shape for a furnace structure. A potbelly stove from a cylinder is well suited for heating a garage and a country house.

Consider how you can build a furnace from a cylinder:

- Let's start by cutting off the top of the cylinder, where the tap was, and weld a plug here.

- Next, cut a square opening at the bottom of the cylinder. This will be the entrance to the firebox. We will not discard the cut off part, since we will make a door from it. You just need to scald this part, bringing it to the desired size.

- We weld on the hinges, install the door, attach the lock handle to it.

- We make holes on the side of the cylinder, which will become the bottom of the structure. They will take over the function of the grate.

- We prepare the box, making it from metal of a smaller thickness, and fix it under the holes - a grate. The box will play the role of an ash pan, into which the remnants of combustion products fall, and also act as a blower at the same time. You need to attach a door to the ash pan.

- For the stove structure, it remains to make the legs. To do this, we will use a pipe or metal corner. Weld them to the bottom of the fuel tank.

- In the upper part, on the opposite side from the firebox, we cut an opening in the ash pan and weld on the chimney.

- If desired, a cooking panel can be built on the upper plane of the stove. This is done simply - a frame made of steel reinforcement is welded. Such a panel turns out to be quite roomy, you can put two items at the same time.

Model No. 4 - rectangular potbelly stove

According to many experts, this type is considered the most optimal, aesthetic, compact of all the models of stoves listed before. This design is perfect for heating a living space.

A rectangular potbelly stove can be made in two variations:

Main purpose

The main task of a rectangular potbelly stove is to heat a room up to 15 sq. m. An ordinary potbelly stove is characterized by rapid heat transfer, but at the same time it cools down very quickly as soon as the wood burns out. This disadvantage can be partially eliminated by covering the stove with bricks. But this is not an option, since the bricks will significantly slow down the rate of heat transfer, and thermal energy will only be kept for a short time.

Furnace modernization

Changes made to the design of the stove, a different way of supplying fuel made it possible to improve the operational properties. At the same time, its main positive characteristics were preserved: fast heat transfer, small dimensions, ease of installation, arrangement, without additional construction of the foundation, creation of a capital pipe.

What did they do for this? In the fuel tank itself, in its upper part, 2 plates were welded, which form a labyrinth. Thus, the path of passage of gases has been increased, which means that they leave in the furnace large quantity heat. By expanding metal surfaces the heat exchange between gases and the walls of the vessel has become more efficient.

The fire-prevention components of such a model have also been improved: its chimney does not heat up, but remains hot at the same time. Correct location the pipe head will provide sufficient traction. In this case, the head is placed so as to exclude being in the zone high blood pressure whatever the wind is. Therefore, it will be better to install it higher than the ridge of the roof.

Since there is a draft reserve formed due to the temperature of the furnace gases, several additional plates - labyrinths - can be installed in the furnace. This will greatly increase the effectiveness of work. oven device.

Another feature of such a stove is the most dense arrangement of the doors on the body of the fuel tank. This is possible by performing high-quality straightening and cleaning of doors on emery. In this case, the door handles are made in the form of wedges. They are not just handles, but also latches that go into the hooks.

Oven operation

The process of using, the operation of the stove is as follows: work begins with heating the stove with chips, splinters. When there is no draft, the lid is removed from the brewing opening, and burning paper is placed under the pipe, and the lid is put back in place. The combustion process can be controlled by fully or partially opening the ash pan door.

When the required air temperature in the room is reached, you need to put four not very thick logs, 40 cm long, in the stove on the coals, and then close the doors well. Lack of oxygen leads to a decrease in the intensity of combustion, which turns into smoldering. Moisture, size, wood species affect the smoldering process, which can last for several hours. And all this time the stove will give off heat to the environment.

In an insulated house, without cracks, even on cold days with sub-zero temperature you can safely spend the night, having such a stove for heating.

As for the danger of poisoning carbon monoxide then this is excluded. The carbon formed during combustion is much lighter than air and furnace gases, so it stretches out, floats out through chimney... Moreover, the combustion process is regulated by doors, not views. Even if the doors are left open, you are only in danger of fast burning out of fuel.

Preparation method

Immediately, we note that you can take your own sizes, based on the material available. We used a sheet of steel 200x450 mm. Moreover, its thickness was 3 mm.

You can collect such a potbelly stove by performing the following operations:

- Weld the walls of the structure together.

- Weld the cover up.

- Expose the labyrinth plates, grate, attach them using welding. In order to maintain the distance between the plates and the grill, place wooden blocks between them. They do not need to be specially removed later - they themselves will burn out during the fire. Some recommend making a grate for the grate not from rods, but using a sheet for this, on which holes are made, 20 mm in diameter.

- Make a bottom for the stove.

- Install the chimney pipe. Better to take a steel pipe with thick walls. An important point: the pipe must be all-welded throughout the entire location in the house. If the pipe is straight, then - it's easy. When you need to bring the pipe outside through the wall, it is recommended to make a wire template and weld the pipe and turns along it. Outside the house, outside, the pipe can be extended by simply putting one piece of pipe on top of another.

Why should the pipe be integral in the room, because a bad-smelling condensate appears in the pipe under the influence of furnace gases. It is he who, seeping through loosely-fitting joints, spreads a specific smell.

Fire safety rules

To improve operational safety the stove is installed on refractory material, for example, bricks, asbestos cement slab... To protect against falling out of coals, sparks, the floor near the doors is covered sheet metal or laying tiles.

To protect walls, pieces of furniture and other things from ignition, protective screens made of asbestos-cement sheets... In this case, it is possible not to cover the boiler surfaces with heat-resistant material. The shields are attached to threaded rods or bolts with bushings.

Although the pipe is not as hot as the rest of the models, it should still be passed through the wall using a cut. It implies finding a pipe in it, keeping a distance of 20 cm. In this case, the empty space is filled with a mixture of asbestos and liquid clay.

These are all the rules, the implementation of which will ensure safe operation.

Outcome

We have considered the most effective potbelly stove that you can make with your own hands. Unfortunately, there is no clear leader among them. For each condition, its own option is suitable.

But still the most effective potbelly stove can be called a working oven. In it Maximum efficiency, since there is a pyrolysis effect (afterburning of gases).

In second place is a rectangular potbelly stove with an internal labyrinth of gases. This also greatly helps to increase efficiency.

I would like to note that each of the furnaces has great potential for modifications and improvements. There are a lot of different options how to increase the efficiency of the stove. From directing a fan to it, to creating a water circuit. We will highlight this point in a separate article.

Conclusion

Each stove has its own pros and cons. Each is suitable for certain conditions. But she can serve you for a long time, helping in many household chores, and not only in heating the room. To do this, you just need to think carefully, choose the model that is right for your room.

But if you do not have sufficient skills, then you can always buy a stove. At the local forum in your region, there is always a craftsman with ready-made products or ready to make a custom-made oven.