Potbelly stoves are metal. We make a mini-potbelly stove

An easy-to-manufacture stove-stove can heat a medium-sized room or a small house. Such a hearth is made literally in a day, after which it can be installed even in a city apartment and used not only for heating, but also for cooking, which is very beneficial in extreme conditions. In this article, we will look at the technology for the production of homemade metal stoves.

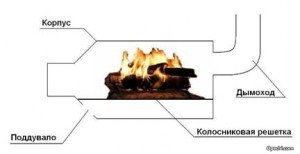

How is a potbelly stove - ash pan, firebox and chimney

To make a stove-stove, you must understand its structure. The potbelly stove scheme is extremely simple. In fact, this focus consists of three main zones. The ash pan is a section in the lower part of the body, separated from the rest of the furnace by a grate. Air necessary for fuel combustion enters the furnace through the cells of this grate. In the opposite direction, small unburned particles of firewood or coal (ash or slag) are poured.

The ash pan has its own door, which can be used as a regulating damper, controlling the volume of air flow and the intensity of combustion.

Firebox - a section above the grate of the ash pan. In simple stoves, to which the potbelly stove of interest belongs to us, the firebox fills the rest of the body. Firewood, coal, peat or pellets are loaded into this chamber, so the firebox should have a wide door with a reliable lock. It is only necessary to clean this chamber from unburned fuel residues if coal is used as such, which forms a solid slag during combustion. In all other cases, unburned residues wake up through the grate into the ash pan.

Chimney - an air duct cut into the upper part of the firebox from the side opposite to the location of the door for loading fuel. In stove stoves, the chimney is assembled from metal and consists of an elbow (corner section), a horizontal hopper and a vertical channel for diverting gaseous combustion products to the street. In most cases, the chimney of a potbelly stove goes out into the street through the wall, so there are a knee and bobbles inside the room, and the vertical section is located outside the house. Therefore, this part of the chimney is made of both metal and brick, asbestos-cement or ceramic pipes.

The hearth arranged in this way is equipped on the basis of any sealed metal container. To do this, cut openings in the container under the doors, divide it inner part into two zones - an ash pan and a firebox, and cut into the pre-drilled part of the chimney knee. As you can see, making such a system with your own hands is not so difficult. And further in the text we will offer you two options for step-by-step instructions describing the technology for assembling such heat generators.

This project is based on a hull structure assembled from six blanks. And inside such a furnace, there is one grate with grates and two cutters, which do not allow heat to leave the furnace body very quickly. You can see the drawings of this potbelly stove below in the text.

Before you is a typical Loginov oven-generator, generating about 5 kW of thermal energy.

To implement this project, we need the following blanks:

- 200 × 450 × 4 mm - 2 parts (lid and bottom);

- 450 × 450 × 4 mm - 2 pieces (side walls);

- 200 × 450 × 4 mm - 2 blanks (front and rear);

- Corner 30 × 30 mm - 6 pieces, 442 mm each (supports for the dividers and grate);

- 192 × 400 × 4 mm - 2 parts (splitters);

- 192 × 442 × 4 mm - 1 copy (perforated grate).

The process of assembling the structure itself begins with perforating the grate blank: we cut through strips with a grinder with a step of 1.5 centimeters. Next, we are preparing the front panel of the furnace: we cut an opening for the ash pan door 180 × 60 mm and a hole 180 × 120 mm for the furnace door. At the end of this stage, we screw the hinges into the front panel and hang the doors of the firebox and ash pan, equipping the wedge valves.

Next, you need to tackle the blanks of the bottom and cover of the furnace. We weld 6 legs to the bottom - four in the corners of the structure and two in the center area. In the lid, at a distance of 50 millimeters from the 200-millimeter end, we cut round hole with a diameter of 100 mm and weld in there a 30-degree steel chimney elbow. The next step is to prepare the side walls. It consists in welding the corners at a distance of 80 millimeters from the bottom and top of the sheet. The third corner is welded to the wall at a distance of 80 millimeters from the first upper stop. On this preliminary work considered complete.

The assembly of the oven itself takes place in the following sequence. We put the bottom on the welding table and weld the back panel and sides to it, maintaining an angle of 90 degrees between the elements. We put the grate on the lower guides (from the side of the empty front part) and grab it by welding. We mount a cut-off device on the first row of upper guides (corners), pushing it to the rear wall of the furnace, and fix the sheet by welding. We put the next cutter on the second row of corners and fix it flush with the front.

Next, we need to weld the front panel with doors and a lid with a welded grate to the structure. After that, it is necessary to weld along all the external joints, achieving the maximum tightness of the seam along the edges and in the grate insert zone. This completes the oven assembly. And you can use this heating device to heat a 40-50 space square meters using wood or pellets as fuel.

We collect a potbelly stove from a gas cylinder

A sheet of metal 3-4 millimeters thick, and it is from this material that blanks for the stove are cut out, is not cheap. Therefore, most home craftsmen make metal stoves based on any containers or metal structures that are unsuitable for further use in the household.

And the best base for the potbelly stove body is the old one gas bottle... It has a cylindrical shape, so it fits both vertically and horizontally. Its body is sealed "by nature", so no one expects special skills in welding from the manufacturer of burzhuikas in this case. In addition, at the walls of the cylinder, the initially required metal thickness, and it itself is made of very strong steel... Therefore, you don't even need to look for a more perfect blank for the stove.

Well, the very manufacture of a potbelly stove from a cylinder is as follows:

- First, you bleed off the remaining gas by opening the valve all the way on the street. This should not be done in an unventilated room! Next, you need to unscrew the gas valve itself and pour water into the cylinder, filling it up to the neck.

- The next day, the water is drained in a remote place - the container contains an odorous fragrance that "tints" the aroma natural gas... After that, you can start cutting the holes for the ash pan and firebox.

- The opening for the ash pan is arranged at a distance of a centimeter from the bottom of the container, making a horizontal cut parallel to the lower weld. The incision is 20 centimeters wide. The second 20 cm incision is made 10 cm above the first. Next, we cut through the sides, getting both the opening and the door for the ash pan - it can be made from the sawn part.

- We cut the opening for the firebox above the entrance to the ash pan, retreating 5-8 centimeters from the cut hole. The first horizontal incision of the container body is made by 30 centimeters. We make a second incision of the same width at a distance of 20 centimeters from the first. Next, we make vertical cuts, getting the entrance to the firebox and the door for it.

- The next step is the arrangement of the grates. To do this, on the inner walls of the container, between the entrance to the ash pan and the firebox, we weld 8 mm rods bent with an arc. They will serve as a support for a lattice welded from the same rods. It is collected separately and inserted into the cylinder through the opening of the combustion door.

- Next, you need to tackle the chimney. Around the threaded hole for the gas valve, a 10-centimeter circle is drilled with 10-millimeter drills and the chimney knee is welded into it.

- In the end, doors are hung on the openings, screwing them to ordinary hinges with self-tapping screws for metal.

On this, the work on assembling the oven with your own hands can be considered complete. You just have to install it in a corner or against a wall and bring the horizontal section of the chimney (boletus) to the street, connecting it with a vertical channel. After that, the stove can be heated, heating the dwelling with an area of 20-25 square meters.

And in a private country house, and in your own garage or workshop, it is always a good idea to have a mobile or stationary stove-stove. To date, there are a lot of different models these heating devices, but they can be expensive. Therefore, if you have experience with metal, a suitable material and the right tools, often they make stoves on their own.

Which model of a wood-burning stove with your own hands to choose is up to the master, since these homemade appliances may have the most different kind and be made both from new material and from improvised metal objects.

Craftsmen have learned to adapt metal barrels with walls 2.5-3 mm thick, gas or oxygen cylinders, pipes of medium diameter, metal sheets and even discs from large automobile wheels for the manufacture of stoves-stoves.

Tools for making potbelly stoves

To work with metal, you will need special tools, some of them are available in almost every private house, while others will have to be bought or rented.

- Angle grinder machine - "grinder" and consumables in the form of cutting discs and grinding wheels.

- Welding machine with a power of 200 A, and also consumables - electrodes Ø 3 and 4 mm. In addition, you will definitely need a special mask and protective suit.

- Metal brush.

- Slag hammer.

- Measuring tools - folding rule, long metal ruler, tape measure, chalk or marker.

- Pliers, hammer, chisel.

- Drill with metal drills of various diameters.

The choice of a stove model most often depends on where it is planned to be located, since a more aesthetic one is required for residential premises. appearance heater and increased security. Therefore, for installation in a house, an option made of metal sheets or a piece of medium-diameter pipe is best suited.

Any of the existing models is suitable for, but it is better to choose one that will help not only bring warmth into the room, but also warm the water.

To finally decide on the choice, it is worth considering different variants and get acquainted with the process of their manufacture.

Gas cylinder stove

Installation of a potbelly stove from a cylinder can take place in different ways:

- Using one cylinder with its vertical or horizontal arrangement;

- Using two cylinders, which are placed on top of each other perpendicularly.

The second model will give more heat, since the heating area of the furnace is almost twice as large.

The cylinder itself has a neat appearance, you can make a hob on it, and if you give the finished stove a decent appearance, then it can be installed even in a living room.

Materials for making

For the manufacture of the first model will need one cylinder, for the second, respectively, two, but besides this for the manufacture of the oven will require:

- A steel sheet with a thickness of at least 3 mm - from it will be made a lintel between the firebox and the ash pan, as well as the hob.

- If you want the stove to look more respectable, then you need to purchase a ready-made cast-iron door with a cast pattern for the firebox and ash pan.

- If the appearance is not so important, then the door can be made from a piece of metal cut from the cylinder itself or from a steel sheet.

- Chimney pipe with a diameter of 90 — 100 mm.

- Reinforcing rod with a diameter of 12 — 15 mm or steel angle for making grate and legs. cast iron can also be purchased in a specialized store or the bottom of a horizontally laid cylinder, in which holes are drilled, can serve as a grate.

Any of the models can be made not only from cylinders big size, but also from small ones - this will depend on the place that is allotted for the stove.

Gas cylinder preparation

Before starting work, the cylinder must be prepared, especially if the container is not new, but has already been in operation. In this case, a certain concentration of gas can always remain inside the cylinder, and if a spark occurs during cutting, an explosion is possible. Measures for the appropriate preparation of the container must not be neglected, since do work will be extremely dangerous.

Preparation is carried out in the following sequence:

- First of all, the valve is unscrewed, which is located on top of the cylinder, the hole in which it is installed is released. The container is left on the street or in the utility room for about a day, filling it to the top with water.

- After this time, the water is drained from the cylinder. It should be borne in mind that the liquid will have an unpleasant odor, so it must be drained away from the house.

- The flushed cylinder may well be used in operation, since the last gas residues must be removed from it along with the water.

Making a vertical furnace from a cylinder

- The first step is to mark the prepared cylinder - the location of the firebox and ash pan are indicated on it. For this procedure you will need a marker and a flexible measuring tape - thanks to her quite rigid, but elastic tape can be measured and drawn location doors.

- The next step is to neatly cut out the marked parts using a grinder. The cut out fragments are almost always used for further work.

Cutting openings for the doors of the firebox and ash pan

Cutting openings for the doors of the firebox and ash pan - These elements are scalded by adding sides, hinges and a latch-handle, and they make excellent doors.

- Next, the inner diameter of the cylinder is measured, and according to this measurement, a ring is rolled up from a thick wire, which will become the basis for welding the reinforcement. Thus, a grate for the furnace is made.

- Then, the level of installation of the grate is outlined. The grate should be located 30 ÷ 50 mm below the edge of the cut-out opening for the firebox door. Thus, the grate becomes a separator between the ash pan chamber and the firebox. Reinforcing rods are welded at a distance of 8 ÷ 10 mm from each other.

- Hinges attached to the door are welded to one of the sides of the firebox opening. It is very important to accurately align the installation site so that the doors can be easily closed and opened.

- On the opposite side from the hinges, an open-top loop-hook for the latch is fixed. She must securely keep the door closed while the oven is being heated.

- In the same way, the door is fixed on the ash pan.

- It is recommended to cut off the top of the cylinder to weld on top of a round metal panel that will act as hob.

- The chimney can be discharged both through the top of the cylinder and through the rear or side wall of the furnace. If you choose the second option, then the upper hob will be much larger, since it will be freed from the chimney.

If the cylinder is upright, it will take much less space than the horizontal option, but it must also be remembered that any oven should be located at a distance of 200 mm from the wall, and the walls themselves must be closed with heat-resistant material.

Efficient stove stove from two gas cylinders

To make such a potbelly stove, you will need two cylinders, which, when heated, are able to heat the room much faster. In addition, if desired, it is quite possible to arrange a water-heating tank in the vertical part of the furnace, if you install a hermetically sealed container inside, bring out the tap and cut in the pipes for supplying and withdrawing water.

- The first step is to prepare the balloon, which will stand horizontally. The upper part is cut off from it, so that a round hole with a diameter of about 30 - 35 mm and less than the inner diameter of the cylinder is obtained.

- In the bottom part of the future firebox, holes with a diameter of 10 - 12 mm are drilled in several lines, which in this case will serve as a kind of grate.

- A metal box is welded under this "grate" - this will ash pan... A tightly closing door must then be installed on it to prevent coal and ash from falling out. As an air regulator it used in this model will not be.

- Legs from corners or fittings are welded next to the ash pan.

- A round hole is cut out on top of a horizontally located cylinder, on the side opposite to the furnace door, on which the vertical part of the furnace will be installed.

- A door is installed, which will be best made from the head of another cylinder. A hole is cut in the center, into which a branch pipe with a diameter of about 76 mm is welded. This branch pipe is equipped with a valve, with which you can regulate the flow of air into the furnace, and therefore the intensity of firewood burning. It is recommended to place the door hinges on top - under the influence of its gravity, the cover will reliably close the combustion chamber window and minimize air suction.

- The most difficult thing in preparing the upper, vertical part of the potbelly stove is the process of marking and cutting out a certain shape, which is ideal for putting on and is welded to the horizontal body.

- In this case, an additional heat exchange chamber is arranged in the vertical part of the furnace, i.e. the smoke entering this section does not immediately go into the chimney, but lingers in the arranged chamber.

- For this, metal plates with holes are welded inside the vertical body at a certain distance, which can vary from 250 to 400 mm. Holes should be cut closer to the edge of the metal round piece. When installing them, the hole on the first lintel should be located on the opposite side from from holes on the second lintel and so on. The best option in this case, there will be an installation of three similar jumpers located equidistant from each other.

- The vertical assembly with pre-assembled baffles is installed and welded from above to the horizontally installed body. A branch pipe is welded onto the upper cylinder for connection.

Video: stove stove from two gas cylinders

Potbelly stove from a cylinder installed horizontally

This version of the potbelly stove is made from one cylinder, and the technology of work is in many ways similar to the option described above. Therefore, it is worth considering only difference of some elements.

- Instead of a vertical assembly in the rear upper part of the cylinder, only a branch pipe is welded to connect the chimney.

- A rectangular hole is cut out for the furnace door - it can be easily adjusted in size to the finished cast-iron door. If it will be purchased in a store, then you should pay attention to the doors designed for blowing holes. brick ovens- sometimes they are ideal for a potbelly stove from a cylinder.

- You can make a door and from a cut from a balloon rectangular part. In terms of the size of the sides, it will fit well for the resulting hole, but there will be a hole from the valve in the middle of it. It will need to be welded with a patch cut from a metal sheet.

- In both the previous and in this version, a hob can be added. For this, for example, from a steel bar with a thickness of 5 — 8 mm, a rectangle is bent, which is welded onto the container, creating a small but fairly flat surface.

- Instead of wire, you can use two steel strips welded on both sides of the cylinder for its entire length.

Potbelly stove from a barrel

A potbelly stove made from a barrel is more voluminous and takes up much more space than a stove from a cylinder. That is why it is able to heat a room with a larger area. Such a stove can also be horizontal or vertical, but both the first and second options are used to heat not only utility and technical premises, but also housing.

To make this potbelly stove, you will need metal barrel, steel sheet and chimney with a diameter of 100-150 mm.

Vertical potbelly stove

- The barrel is measured and marked on its surface location blower and firebox doors, as well as the place of the cut. It should pass below the edge of the firebox by 30 ÷ 50mm.

- Then the barrel is cut into two parts, and with each of them the work is carried out separately at first.

- A round plate is cut out of the steel sheet, equal in diameter to the size of the barrel. It provides an opening for the passage of the chimney pipe.

- A hole is also cut out at the top of the barrel so that it can be aligned with the hole in the round piece that will become the hob.

- Pipe branch chimney welded into the hole in the barrel, and then from above, through the hole on the pipe, a hob is threaded and laid, which is welded to the sides of the barrel. The air space created between them, which makes up the height of the side, will help for more long term keep the hob hot.

- Further, a round metal part with holes cut in it - a grate - is also welded to the lower side of the upper part. Another option is to weld two semicircular brackets under the finished cast iron grate. The photo clearly shows how these elements look and are located.

- When the bottom and top panel of this part of the stove are ready, you can cut a hole for the firebox door using the markings made earlier.

- The cut out part is scalded around with metal strips, hinges and a handle with a vertical latch are attached to the door.

- Further, the hinges for the door and the hook for the latch are welded to the body. This process must be carried out very carefully, accurately calculating the distances for installation, since the door must be easy to open and close, and the latch must freely enter the holder arranged by the hook.

- At the bottom of the barrel, an opening is cut for an ash-pan. The door is prepared and hung in the same way as in the case of the combustion chamber.

- After that, both parts are connected into a single structure with a weld seam.

Horizontal potbelly stove from a barrel

Manufacturing process horizontal option potbelly stoves from a barrel are carried out in almost the same way as from a cylinder.

- In the upper plane, a window is marked and cut out, on which a door made from a cut out piece of metal will be installed. Connections of the door with hinges and hinges to the body are made with rivets.

- A standard hole for pressure relief in a barrel, with a diameter of 20 mm, is used as a blower. There is no separate door for the ash pan. provided.

- It is recommended to immediately make a stand for placing the future stove. It is made from scraps of pipes or a corner, so that the shelves ensure the stability of the barrels laid on them, without backlash.

- The next stage is the manufacture of a grate from a metal sheet with a thickness of 3-4 mm. First, the area is measured and, according to the data obtained, a panel of the required size is cut out in which holes for air supply are drilled. The finished grate is placed on the bottom of the barrel so that at the highest point, in the center, the distance between the grate and inner surface barrels were about 70 mm. The grate is not rigidly fixed - it should be easily removed to clean the stove from accumulated ash.

- For the chimney, a special connecting unit is made in the rear upper part. After marking for the required diameter with a grinder, diametrical slots are cut at an angle of 15 º from one another - a total of 12 cuts will be obtained. The resulting "teeth" are bent upward - the then inserted chimney pipe will be attached to them with rivets.

Video: the simplest horizontal potbelly stove from a barrel

Potbelly stove from rims

A stove-stove can also be made of two discs from large wheels and a piece of large-diameter pipe - it must be matched to the diameter of the prepared discs. The height of the cut can vary depending on the preferences of the master and the stability of the structure, but is usually limited to 300 - 450 mm.

There is nothing complicated in the scheme and manufacturing process of this version of the potbelly stove, but it is more suitable for technical and utility rooms than for residential ones.

- Are being prepared individual elements the future stove - two discs, a piece of pipe, a metal sheet and a pipe for the chimney.

- All three parts are welded together into a single vertical structure. To facilitate the adjustment of the pipe diameter to the discs, it is permissible to cut off the outermost rib from the latter along the circumference, on one side.

- Further, an opening for the firebox is marked on the pipe and cut out with a grinder.

- The cut out part is scalded around the perimeter, a latch and hinges are installed on it, thereby obtaining the necessary door.

- Then, you need to make a hole for the blower, otherwise the fire in the stove will simply not burn. For this, a window of 100-120 mm in width and height is cut out in the lower disc.

- A hole for the chimney is cut from the back of the upper disc and a pipe is welded into it.

- It is recommended to make the hob on the upper disc from a steel sheet with a thickness of 4 — 5 mm. It is tightly welded to the edge of the upper disc, thus becoming an additional heat exchanger.

- The same is done with the bottom of the furnace in order to arrange a full-fledged ash pan and increase the safety of operation of the stove.

In fact, such a potbelly stove is, rather, a fire fenced with metal, and is neither economical nor usable. However, for garage needs and subject to free source materials, this is a perfectly acceptable option.

Video: an example of an effective potbelly stove from rims

Potbelly stove "Gnome"

One of the most popular of all homemade bourgeois is compact. It looks neat and can be designed to fit in any room. This potbelly stove is well suited in size for small country houses, since it does not take up much space and is an indispensable assistant in cooking and heating rooms.

One of the most common models is the "Gnome" potbelly stove

One of the most common models is the "Gnome" potbelly stove A similar model of a potbelly stove can be equipped with internal partitions - plates, then it will receive the properties of additional heat transfer, or you can make the most ordinary case with a division into a firebox and an ash pan.

The first version of the stove will keep the heat indoors for a long time, and this is very important if summer residents live outside the city from early spring to late autumn, when the nights are cold.

In order to make such a potbelly stove, you need to purchase a steel sheet with a thickness of 3 — 4 mm, chimney, angle 40 × 40 or 50 × 50 mm. For the burner, you can make a cover yourself or buy it ready-made.

- Relying on drawing, on metal sheets draw details potbelly stoves: panels all walls, grate and two plates for fixing them inside the structure.

- Rectangular holes are cut in the front panel for the firebox and blower, and the cut pieces of metal are used to make the doors. They are scalded with a corner and latches and hinges are immediately attached to them. Then, the doors are attached to the front panel.

- On the same panel, only from its inner side at a distance of 150 ÷ 160 mm from the top, one of the plates is welded, which will regulate the output of heated air. The plates should be 80 ÷ 100 mm shorter than the length of the side walls of the body.

- After that, to the back wall, at a distance of 70 — 80 mm from the top, the second plate is welded. Together, these two plates form a zigzag labyrinth for smoke when the furnace burns. Thanks to this, each of the corners of the stove body will warm up.

- V hob two holes are cut - for the burner and for the chimney.

- Legs made of thick reinforcement or a corner are welded to the bottom wall of the body. You can choose a frame option from a corner, which includes legs and a base to secure the bottom and bottom ribs of the side panels to it.

- Before welding the side parts to the frame or to the bottom panel, it is necessary to mark and weld the corners on them along the entire length of the panel, they must be welded at the same level, since their role is to serve as brackets for laying the grate.

- In the panel prepared for the grate, holes with a diameter of 12 ÷ 15 mm are drilled in a checkerboard pattern, at a distance of 30 ÷ 40 mm from each other. Another option for the grate can be a lattice welded from reinforcing rods. You should not discount the possibility of purchasing a finished cast-iron grate.

- Installation and welding of all walls of the stove are carried out. The main thing is to achieve complete tightness of the welded seams, so sometimes it becomes superfluous to install a 30 × 30 mm metal corner outside. This will make it a little heavier. general design, but will give it additional strength and reliability.

- A top cover with a chimney and a hob is welded on.

- To make the stove look respectable, you need to clean all the welds and cover its surface with heat-resistant paint.

It makes sense to additionally install a screen on the side and rear surfaces, which will increase the safety of the furnace and create a powerful convection flow of hot air, which significantly accelerates the heating of the room. The screen panels are mounted on racks in such a way that they are spaced from the stove body at a distance of 30 to 50 mm.

Video: master class on making a stove from steel sheet

What to consider when installing a potbelly stove

Self-made will bring warmth and comfort to the house or outbuildings, without causing problems, only if safety rules are followed during its installation.

- The surface on which the oven is installed must be rigid and fire resistant. This could be, for example, brickwork or ceramic tiles. You can also use asbestos sheet which the top is covered with a metal sheet.

- Heat-resistant drywall or asbestos sheets are installed on the walls around the furnace. Wall cladding is also suitable. ceramic tiles or brick.

- It is forbidden to place flammable materials and compounds near the stove, near the firebox.

- The chimney must also be insulated from combustible surfaces when passing through a wall or attic.

- It is very important for safety to equip a reliable ventilation system, so that carbon monoxide cannot accumulate in the room.

- In order for the furnace to work for a long time and efficiently, only high-quality material must be chosen for its manufacture.

- Before installing the stove in its permanent place, it is imperative to carry out street tests, paying special attention to the quality of the welds and the accuracy of fitting all parts.

A horizontal potbelly stove from a pipe is one of the simplest, but most productive designs of home-made stoves operating on solid fuels. Simplicity of design and low cost allow even novice home craftsmen to make such a stove.

Collapse

First, beginners need to understand how the oven works, what parts it consists of.

Principle of operation

The principle of operation of such a furnace is simple:

- firewood is put into the firebox;

- for kindling, thin chips are placed closer to the door;

- the door in the ash pan and the slide gate must be open;

- firewood is set on fire and must close the door;

- the flame heats up all the planes of the furnace. Metal, giving off heat, gradually heats the room;

- for the second bookmark, you can use coal or carpentry waste.

Stages of work

Before starting work, it is necessary to determine the size of the furnace, and prepare necessary materials, tool and welding equipment.

Drawing and diagram

Drawing of a potbelly stove from a horizontal pipe

Another drawing option

The simplest pipe stove runs on solid fuel and consists of several main parts:

- body - it is made different in shape, depending on the materials used for its production. It can be rectangular when used sheet metal or cylindrical, in this case the body is made of a gas cylinder or large diameter pipe;

- grate. It serves to protect the bottom from burning out and remove ash to a special compartment;

- ash pan - in this part is going wood ash, this cavity serves as a blower to improve traction when burning firewood;

- combustion chamber. Firewood or coal is laid here;

- to remove carbon monoxide, the furnaces are equipped with a chimney outlet. In some cases, it is withdrawn vertically from the top of the oven or with an outlet extending from the rear plane. But in any case, the chimney outlet is located at the top of the structure;

- a reflective screen is installed above the door. It is positioned over the entire surface of the oven, leaving an air passage in the rear cavity. In this case, the heat does not immediately go out into the chimney, but passes through the stove, heats the walls and only then enters the pipe;

- combustion chamber doors. Here they use ready-made cast-iron or steel doors or home-made ones from a piece of thick metal;

- the most efficient stove equipped with additional convection pipes, such drawings homemade oven can be found on forums on the Internet or check out industrial furnaces Professor Butakov or the Bullerian model.

A potbelly stove from a pipe with an inner diameter of 500 mm is made according to the drawing, taking into account the main dimensions of the structure:

The dimensions of the remaining parts and their installation locations will be taken from the drawing.

Let's analyze the process of making a homemade stove.

What kind of pipe do you need?

Any pipe can be used. The most important thing is that it is not previously used on gas supply pipelines and for sewerage. Such ovens, together with heat, will spread throughout the room unpleasant odors long time. In size - it all depends on the needs and capabilities of the master.

To heat a small garage, it will be enough to make a stove with a diameter of 400-500 mm. For a large room, you can make a potbelly stove larger diameter or install a few small ones. The main thing before work is to clean the walls from limescale, dirt or oil and only then start to work.

Materials and their quantity

For the production of a potbelly stove, we need to prepare:

- steel pipe with a cross section of 550 mm, with a wall thickness of 10 mm - length 650 mm;

- for the top of the furnace made of steel 4-5 mm, cut out a workpiece 700/420 mm and bend it along the length of the shelf, marking 40 mm from the edge of each side;

- the front and back walls of the stove - 2 parts, 560/560 mm in size;

- for a reflective screen, cut out a workpiece from a sheet of 500/420 mm in size;

- for the grate, you will need to prepare reinforcement, with a section of 10 mm - 2 pieces of 600 mm each and 32 pieces of 380 mm each;

- for the outlet of the chimney, we prepare a piece of pipe with a section of 100 mm, a length of 260 mm;

- the top provides for the installation of a cooking zone. You can use a ready-made cast iron or make it from a steel sheet with a thickness of 12-14 mm by cutting a circle with a plasma cutter with a diameter of 220 mm and turning the workpiece on an emery or grinder;

- from a 40 mm profile we prepare 4 legs 400 mm long;

- we get ready-made hinges or you can make it yourself from a profile and a bar;

- for the door, we cut out a blank of 340/340 mm from the sheet;

- 6 pieces of corner for laying the grate.

This is a list of basic materials, we will make small parts in the process.

Tools and equipment

We will need:

- a set of locksmith tools;

- welding machine with clothing and eye and hand protection "

- grinder with stripping and stock of cutting discs;

- workbench with a vice;

- sand for filling the bottom of the furnace.

Step-by-step manufacturing instructions

Having prepared the entire set of tools and materials for work, we proceed to the process of making a potbelly stove from a pipe with our own hands:

- We place the finished pipe section on a flat surface, set the protective screen at a distance of 5 mm from the front side and grab it to the pipe. It is important to have experience in making ceiling tacks, although there is practically no load on the screen. We put potholders every 60-80 mm.

- At the bottom of the furnace, we retreat 50 mm, mark the longitudinal lines along the entire length of the pipe and grab the corners for laying the grate. To make it, we place long parts from the reinforcement, insert the lintels along the edges and grab them. Now, stepping back from the jumper 10 mm, we join the next jumper. Thus, we collect a grid from reinforcement, 600/400 mm in size. After that, turning the grate over, put the tacks on the back side.

- We put the grate in place and join the metal sheets from the front and back sides. Skewing and large gaps between the sheet and the pipe must not be allowed. If the pipe is cut crookedly, you will have to level the workpiece by grinding the walls with a grinder. Having checked the correctness of the assembly, we proceed to the welding of the joints. The seam must be airtight, so after welding, beat off the slag and boil the burns, sinks and lack of fusion.

- There is another option for installing the grate, which is more practical. At the bottom of the pipe, a rectangle is cut out with small indents at the edges, a workpiece from shaped pipe(for collecting ash). A grate is placed on top. This is how it looks:

- We grind the protruding corners and the junction of the parts with a cleaning stone. Then we turn the workpiece face up and mark the opening for laying firewood. We put on the grinder cutting disc and cut out a groove according to the markings.

- We remove the burrs with a file, lay out the door with a welded handle and a latch and install it on ready-made hinges. On the sheet, we expose and grab the counterpart of the lock, and on the door we expose a homemade lock - the latch.

- We turn over and place the potbelly stove bottom up, mark and weld the legs from the profile pipe, having previously cut the corners for better joining to the body. At the bottom, we cut the legs at a small angle and weld the nickels from the sheet, for better stability of the potbelly stove.

- We install the stove on the legs and put a blank with holes for the chimney pipe and burner on top of the stove. Having placed it with the curved edges down and checking the correct installation, we grab the plate.

- We burn holes in the pipe with electric welding and install a pipe with a diameter of 120 mm for the hood and pancake for pots.

- Parts are scalded in a circle, the joints must be tight. At the end of the ventilation pipe, we weld a slide gate to regulate the draft.

- Opening the door, placing the grate in place, fill the bottom of the furnace with a layer of sand.

The stove - the stove from the pipe is ready.

Look at a few more manufacturing options to consolidate your understanding:

Features of operation

When testing the stove, it is better to open all doors and windows. We make sure that there is a draft and an open damper. Then, putting firewood through the door, we ignite the flame. We close the door and go out into the street. The potbelly stove will smoke a lot, but you should not be afraid of this, this will burn out oil and other debris.

Heating process

After using the oven for the first time, it may be necessary to correct welding defects. And then enjoy the warmth in your garage or other space. The main thing to remember is the rules fire safety, periodically clean the chimney and remove ash, periodically replacing the sand in the stove.

Output

Even a novice master is quite capable of making such a design on his own. The main thing is to want to make a reliable potbelly stove and carefully and responsibly perform all the work, taking into account step by step instructions provided in the article.

← Previous article Next article →A compact stove for heating a small room, in the common people simply called a potbelly stove, will soon celebrate its 100th anniversary. Having appeared in the 1920s, such metal stoves with a chimney became simply irreplaceable during the Great Patriotic War... The stove-stove does not give up its positions to this day, remaining necessary attribute garage, greenhouse or country house. Such a stove is needed wherever people need to warm up and cook food, despite the lack of central heating.

The potbelly stove has its advantages and disadvantages. The undoubted advantages of such a heater include:

- energy independence and autonomy;

- cheap fuel in the form of coal, firewood, sawdust, wood chips, peat, waste industrial oil, diesel fuel, paint waste, etc .;

- quick warm-up;

- small size;

- installation without foundation;

- no capital needed;

- ease of use;

- low financial costs in the case of making a stove with your own hands.

However, the stove-stove also has disadvantages:

- required good ventilation in room;

- high fuel consumption;

- the need for constant monitoring of the fuel level;

- rapid cooling (however, we can fix this drawback - to increase the efficiency, the stove can be overlaid with a brick).

Note: If you feel the need for such a device, then you have two options - to buy an industrial-made metal stove or to make it yourself.

First, let's talk about purchased stove-stoves, the cost of which starts from about 4,000 rubles (for example, the Ugolyok stove) and rises to 40,000 rubles and above (this cost is typical for stove-stoves with beautiful names"Bavaria", "Baron", etc.).

With heat exchanger

In the middle of this price range fall, for example, stove stoves with a water heating circuit and a heat exchanger, army cast iron stove, potbelly stove of long burning "Klondike" type.

Materials for stoves and fireplaces-stoves, made in workshops, usually become stainless steel and cast iron. Standard drawing assumes the presence of a bunker with a firebox door, an ash pan, a chimney pipe. However, it happens that a stove stove is equipped with a hob, burners and even an oven. At the enterprises, they also make heaters-heaters, as well as stove-stoves, in which a ceramic or steel casing is installed to increase efficiency, which significantly increases heat transfer. If you wish, you can buy a stove-stove or just a stove with a gas generator for your home.

Homemade potbelly stove

Making a potbelly stove with your own hands is not difficult even without a drawing. The materials at hand are suitable for work, be it a gas cylinder, a milk can, a barrel, a piece of pipe or sheet metal lying around in the garage. Having decided what can be used, choose a drawing of a rectangular or circular section of the combustion chamber for the stove with your own hands.

For example, you need to make your own heating in country house and you have an unused milk can (for arranging the stove itself), a bent piece of pipe (to create a chimney) and a piece of metal fittings with a diameter of at least 6 mm (for the grate). To make a stove out of all this, it is enough to be friends with the tools, and also apply a little ingenuity.

The can is installed on its side - this is the basis of our handmade potbelly stove, its combustion chamber. A rectangular blower is cut out under the neck, the edges are processed with a file. The blower can be left in this form, or you can attach a damper to it, having received a stove with an adjustable draft at the output.

In the upper part of the bottom of the can, you need to make the markings for the chimney yourself (it should be 2-3 mm less than the diameter of the pipe). We cut out a hole and tightly drive a piece of pipe adapted for a chimney into it. Half of the work is done.

Next, we are engaged in the insides of the stove-stove. With our own hands we make a grate in the form of a "snake" from a metal rod. We insert the rod into the neck of the can and place it so that the grate stands horizontally in the future combustion chamber. That's all! If you wish, you can put the resulting stove on an iron pallet and a brick rack. This will help to avoid heating the floor and will also minimize the likelihood of fire.

Note that a similar algorithm of actions can also be applied if you want you to have a potbelly stove from a barrel. Long burning such stoves cannot boast, but they cope well with the function of fast heating of the room.

The second life of a gas cylinder

A good idea for a small stove is to recycle containers that can withstand high heat. We have already talked about barrels, but how do you, for example, a potbelly stove from a gas cylinder or even two? These containers are good because they allow you to make yourself a stove for a country house or garage, both vertically and horizontally.

To create such a stove-stove, you will need the following tools:

- welding machine;

- grinding machine with wheels;

- drill with drills;

- brush with metal bristles;

- tape measure and construction pencil for marking;

- hammer, chisel, pliers.

Materials for making do-it-yourself stoves are needed as follows:

- 1 or 2 gas cylinders;

- Metal sheet for ash pan and hob (thickness must be at least 3 mm);

- cast iron doors (old ones are suitable, for example, from wood stove, or do-it-yourself sheet metal);

- chimney pipe;

- thick metal fittings for making legs and grate.

Before starting work in a gas cylinder, open the valve and leave it in this state for at least 12 hours to ventilate the container. Another way to clean the bottle is to fill it to the top with water and then empty it completely.

For a vertical stove-stove, the gas cylinder is placed in a standard position for it, the neck is released and the markings are made for the future firebox and blower. The marked pieces are cut out with a grinder. The grate is manufactured separately - for this, the fittings cut to the required dimensions are welded in the places marked on the bottom of the cylinder.

Hinges are welded to the cylinder, on which the doors are hung. Further, the latch is equipped, which are designed to secure and raise the efficiency of the stove. A pipe is welded to the top or side of the cylinder to remove the smoke.

For a horizontal stove-stove, the cylinder is installed on the "legs" sideways. A square hole for the door and a round hole for the chimney pipe are cut in it. Instead of a grate, a number of holes are drilled at the bottom, and below the cylinder is welded rectangular container for collecting ash. The stove is almost ready, it remains to hang the door with your own hands and install the chimney.

If desired, the complete set of vertical and horizontal stoves from gas cylinders can be expanded with a hob made of a sheet of metal attached from above.

Free fuel

Note: If you want to minimize fuel costs for a stove stove, consider making homemade construction for heating with car oil drained from the car.

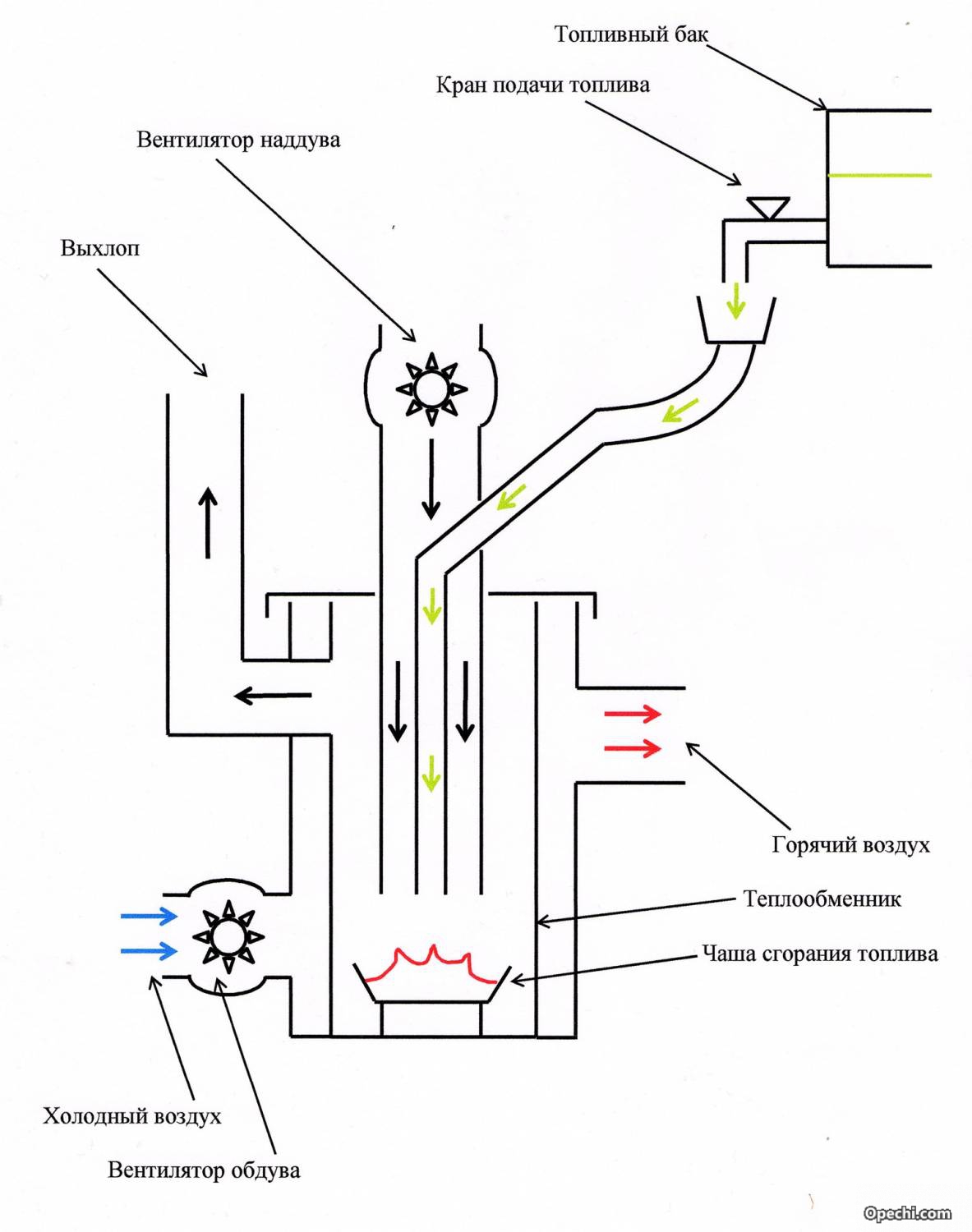

The potbelly stove for mining is especially good for garage owners. The design drawing includes two tanks connected by a pipe, as well as a chimney.

To create a working stove, you will need the following materials:

- Metal 4 mm thick for a potbelly stove.

- 6mm metal for the top tank lid.

- Metal rods for stove legs (3-4 pieces of suitable thickness).

- A pipe made of heat-resistant material for connecting tanks (diameter not less than 100 mm, length about 400 mm).

- Chimney pipe (length at least 4 m).

Work on the formation of a potbelly stove during mining is carried out in the following order:

- Legs are welded to the lower tank.

- A lid with holes for oil and air is welded onto this tank from above.

- At least 50 holes with a diameter of 9 mm are made on the connecting tube.

- Weld the tube to the bottom tank lid.

- A second tank with a filler neck and a chimney pipe is welded on top.

It is easy to use such a stove-stove. Oil is poured into the cold apparatus through the filler neck almost to the top, just a few centimeters short of the tank lid. Firing material in the form of rags or newsprint is also laid there. It remains to ignite, and soon you will enjoy the warmth.

As a rule, such stoves "consume" from 700 to 2000 ml of waste oil per hour. Potbelly stoves on working off allow you to boil water and cook simple food. However, their operation presupposes the obligatory presence of good ventilation in the room for the removal of carbon monoxide, as well as compliance with fire safety rules (you cannot place combustible materials near the stove, use flammable materials such as gasoline, acetone, etc.). The waste reservoir must be protected from water ingress. Refueling with oil is carried out only after the stove has completely cooled down.

Sheet metal

How to make a potbelly stove from metal? You can implement this project yourself if you have experience in welding, as well as necessary tool... From the materials you will need the following:

- sheet metal (its quantity determines the size of the stove);

- steel corners 5 mm thick;

- metal tube about 30 cm long;

- pipe with a diameter of 180 mm.

To obtain a stove-stove, you need to weld a rectangle of metal sheets joined end-to-end (so far without a lid). On one side, place the blower and the furnace door. Inner space stoves are divided into a smoke circulation, a firebox and an ash pan.

In the last two compartments, a grate is installed, which will hold solid fuel... To do this, steel corners are welded inside the stove on the sides at a height of up to 15 cm. A pre-welded grid is laid on them (it can be made from steel strips welded to thick metal rods at a distance of about 5 cm). It is better to make the grate removable, so that later, when it burns out, it would be possible to replace it without any problems. In addition, the removable grate structure makes it easier to clean the heating appliance.

Let's go back to the construction of the stove. For the sake of increasing the efficiency of the stove, you can make mounts for a removable reflector (metal sheet with a thickness of at least 12 mm), which will separate the firebox and smoke circulation. For this, two metal rods are welded on top. After installing the reflector, you should get a smoke channel.

Having equipped the insides of the stove, you can weld on the upper metal sheet, which will become the cover of the structure. In advance, a hole is made in it to secure the chimney. Further, the stove is equipped with jumpers, delimiting the doors, made for the ash pan, reflector and grate. As a rule, a small door is equipped under the ash pan, but two steel ones are made in the full width of the stove, so that it is convenient to get the reflector and the grate.

The next stage is welding to the structure of latches and legs (metal pipes with a diameter of up to 3 cm and a length of 10 cm are suitable for them), as well as chimney pipes from a curved pipe with a diameter of about 18 cm (note that the chimney is placed on a 20-cm sleeve ). The sheet metal potbelly stove is ready.

Warm brick

A potbelly stove fired with wood, coal and other types of fuel can significantly increase its efficiency. To do this, it is enough to erect a screen of fired clay bricks around it with your own hands. If you look closely at the drawings of such a mini-building, you can see that the bricks are laid at a short distance from the walls of the stove (about 10-15 cm), and, if desired, around the chimney.

Bricks require a foundation. Do you want the masonry to last a long time? Then fill the base at a time to form a monolith. It is better to take concrete as the material for the foundation, which should be reinforced with steel reinforcement with your own hands. It is advisable to make a layer of reinforcement approximately 5 cm from the surface of the concrete pad.

At the bottom and top of the brickwork, holes are made for ventilation, which will ensure the movement of air (heated masses will go up, and cold air flows from below). Ventilation also prolongs the life of the metal walls of the stove, postponing the moment of their burning out due to cooling by circulating air.

The bricks laid out around the stove accumulate heat, and then give it away for a long time, warming the air in the room even after the stove has gone out. In addition, brickwork additionally protects the objects surrounding the stove from fire.

If desired, the stove can be completely laid out of bricks. Such a structure is beneficial in that it will serve long years without additional effort on the part of the owner. However, there are also certain disadvantages. The disadvantages of this option include the following:

- the process of laying out such a stove is quite laborious and is suitable only for those people who have experience in masonry with their own hands;

- a brick stove is quite expensive, since it requires the use of refractory materials, including special clay for mortar.

In order to get a small potbelly stove on the wood, it is enough to lay out a cone measuring 2 by 2.5 bricks, 9 bricks high. In the combustion chamber 2-4 rows are laid out of fireclay bricks. Ordinary fired clay brick is suitable for a chimney, into which you must remember to insert a stainless steel sleeve.

Whatever the method of making a miniature stove or a stove-stove with your own hands, you make them according to a drawing or by eye, the main thing is that at the output you get an effective heating device, and in the extended configuration there is also a hob for cooking. Look around for suitable materials (barrels, sheet metal, etc.) and forward to your own homemade stove or even a stove-stove!

The stove-stove is a faithful companion of summer residents, security guards, and those who like to repair cars in their own garage. Owners of small private houses also often use this option heating as the most economical and mobile.

Such a stove is quite capable of heating a small room in a matter of minutes, and thanks to modern design solutions, she will not spoil the interior at all country house... Almost everyone who sets himself up with such a goal can make a potbelly stove with his own hands. We will look at how to do this in this article.

Tools for the job

In order for the manufacture of the heating device to take you a minimum amount of time, you need to prepare the following tools:

Welding machine (not less than 200A)

Welding electrodes and protective mask

Bulgarian

Cut-off and grinding wheels for metal

Slag hammer

Metal brush

Pliers, simple hammer, chisel

Drill with drills

Measuring device(tape measure, meter)

What are homemade potbelly stoves?

The appearance and technical characteristics of the stove-stove may be different. For each premises will do its own stove, which can both heat it up and harmoniously fit into the interior. The future of the stove can be based on sheets of metal or applied already ready product: a medium-sized metal pipe, barrel, gas cylinder or tank. In any case, the wall thickness should not be less than 3-5 mm.

The appearance and technical characteristics of the stove-stove may be different. For each premises will do its own stove, which can both heat it up and harmoniously fit into the interior. The future of the stove can be based on sheets of metal or applied already ready product: a medium-sized metal pipe, barrel, gas cylinder or tank. In any case, the wall thickness should not be less than 3-5 mm.

If you need to heat the garage, then almost any option will do, since such a stove only requires heating a small room. For the potbelly stove, which will be in the house, the aesthetic side is also important - the appearance of the unit, so it is better to refuse some options right away. An important point is also the type of fuel that is used

Do-it-yourself potbelly stove

This is an option that is just not suitable for heating residential premises. Due to the pungent smell that is emitted during the combustion of oil waste, it is not very pleasant to be in such a room for a long time. Even if a good hood works, all things in the house will be saturated with this specific "aroma". This stove is perfect for heating a garage and other non-residential premises.

To make it, you will need a 4-5 mm metal sheet, which will be cut into pieces, and a chimney pipe. All elements of the stove are cut out using a grinder. The edges of the pieces are trimmed. Before cutting, it is necessary to make the correct marking of all parts, according to the drawing.

To make it, you will need a 4-5 mm metal sheet, which will be cut into pieces, and a chimney pipe. All elements of the stove are cut out using a grinder. The edges of the pieces are trimmed. Before cutting, it is necessary to make the correct marking of all parts, according to the drawing.

Round holes are made in the pipe of the required length. This pipe is designed to connect the upper and lower potbelly stove tanks. Two round holes must also be drilled in the upper tank: one for the chimney pipe (top left), the other for the connecting pipe (bottom right). The lower tank of the stove is done in the same way, only a cutout for the pipe is made in the center of the container. For filling fuel, it is necessary to provide a filler neck, which is equipped with a sliding cover.

The lower part of the tank is made flat, four or three legs are welded onto it. In order to prevent the lower and upper parts from loosening, they are reinforced with additional stiffening brackets. Welds it is necessary to thoroughly clean, and cover the furnace with high-temperature enamel, which will protect the metal from rust.

How does such an oven work?

The potbelly stove produces heat in the following way: a long thin stick or curled paper ignites the used oil in the lower container. When the mining has caught fire, the filler cap should be closed. Combustion air will flow through a pipe that is connected to the top tank. Rising up, hot air heats the top of the stove to a high temperature. It gets so hot that you can even heat the kettle on it.

Such a stove - perfect option for the garage, as it successfully heats a small area, and used materials for the firebox will always be found by car owners.

Stove stove from a pipe or barrel

If you are planning to construct a heater from a pipe or barrel, you need to choose a suitable diameter. It directly depends on the size of the room that needs to be provided with heat.

A potbelly stove from a barrel can also be used in a living room, provided that it is made accurately and correctly. This type is most popular for heating country houses.

Two rectangular holes, which will be connected to the firebox and ash pan. The cut pieces are used for the doors. They are cut to the desired size, framed with strips of metal and attached to such improvised doors with handles and a latch.

Two rectangular holes, which will be connected to the firebox and ash pan. The cut pieces are used for the doors. They are cut to the desired size, framed with strips of metal and attached to such improvised doors with handles and a latch.

Inside the barrel (pipe), two angle-shaped brackets are welded. These are grate holders, which are located just below the doors. As a grate, you can use welded fittings or buy a ready-made one in a store.

A piece of pipe is welded tightly, and supports are welded to its lower part. A hole for the chimney is cut out on top of the pipe, into which the pipe is inserted and welded.

Only then are the doors installed. They are attached to door hinges and install the latch hook, having measured the desired level in advance.

To make the stove aesthetically pleasing, it is necessary to thoroughly clean the welding seams and paint the product with heat-resistant enamel. If you do everything carefully, such a heater will look no worse than the factory counterpart. After the paint has dried, the stove is connected to the chimney pipe that enters the street.

This is the easiest and most practical option. Despite the fact that such a potbelly stove takes up quite a lot of space, it is used for heating more often than other models. It is also very convenient that on the surface of the tank you can heat water in a kettle or a saucepan, as well as dry your laundry.

Potbelly stove from a gas cylinder

The used gas bottle is very suitable for the stove. It's practically finished form for a potbelly stove, which requires minimal modifications.

The upper part of the cylinder, where the tap is located, is cut off, and a plug is welded in its place. A square cutout is made in the bottom of the cylinder - this will be a firebox. The cut piece must be turned into the firebox doors. To do this, it is scalded with metal and a handle is attached to it to open it. Subsequently, you will need to weld to the hole metal hinges on which the door will be worn. Install it yourself door leaf better at the very end, when the potbelly stove is already completely ready.

The upper part of the cylinder, where the tap is located, is cut off, and a plug is welded in its place. A square cutout is made in the bottom of the cylinder - this will be a firebox. The cut piece must be turned into the firebox doors. To do this, it is scalded with metal and a handle is attached to it to open it. Subsequently, you will need to weld to the hole metal hinges on which the door will be worn. Install it yourself door leaf better at the very end, when the potbelly stove is already completely ready.

In order for air to enter the firebox, several holes are drilled in the bottom of the cylinder. They will give thrust and serve as grates. In order to prevent burnt firewood from falling to the floor, a metal box is welded to the bottom of the cylinder - an ash pan. It can be made from thinner sheet metal. The ash pan is also equipped with doors.

After that, legs from a metal corner or pipe scraps are attached to the cylinder.

At the back of the stove, there will be a smoke exhaust pipe. To do this, cut a round hole in the upper part that matches the diameter of the pipe and weld it there.

From above, you can equip an impromptu cooking stove. It can be made from a metal grid or reinforcement by welding the frame to the top of the cylinder.

Such a potbelly stove is an excellent option for heating a summer cottage, garage or change house. It is versatile and does not take up much indoor space.

Potbelly stove rectangular

Of all the possible options, such a stove is the most compact and neat look. It is used in residential premises, where, thanks to rectangular shape, the stove is easy to decorate and make it almost invisible.

The most popular is the factory model "Gnome". Its structure is quite simple, and the heat dissipation is very efficient.

The most popular is the factory model "Gnome". Its structure is quite simple, and the heat dissipation is very efficient.

This stove consists of just a few elements: swamps, ash pan and chimney. The stove is installed on four legs. The second figure shows a more complex firebox design that retains heat for a long time.

It is quite possible to build such a structure yourself. Let's take a closer look at how to do this.

To do this, you need the following expendable materials: a sheet of metal, at least 4 mm thick, a chimney pipe and a steel corner. In addition, you need to purchase a cover for the burner.

You need to cut out four walls, the bottom and the upper hob. In order for the fuel to completely burn out in the firebox, it is necessary to use special plates that are located inside the stove. Thus, more heat will be produced in the combustion chamber.

The holes for the firebox and blower are cut in the front of the structure. Subsequently, hinged doors with handles and locks will be attached to them.

The holes for the firebox and blower are cut in the front of the structure. Subsequently, hinged doors with handles and locks will be attached to them.

A hole for the burner is cut out from above, corresponding to the dimensions of the part, and a hole for the pipe, through which the smoke will come out.

Legs from the prepared corner are welded to the bottom of the stove.

The place where the grate will lie is marked on the side panels. Sections from the corners are welded here, which will serve as supports for the grate. The grate can be made by yourself. To do this, you need to drill a large number of holes in steel sheet so that it becomes like a sieve, or weld a lattice of steel rods.

At a short distance (at least 15 cm) from hob in the upper part of the potbelly stove, a plate is welded. It should correspond to the size of the stove, but not reach the end of 8-9 cm. The second same plate is placed just below. It should also not reach the end of the container, only in the front of it. These plates form additional ribbon-like passages inside the stove. The heat from the burning fuel will enter the formed corridor and heat the plate. Thus, more heat will remain inside the tank, rather than flying straight into the pipe.

Safe rules when using a potbelly stove

Fire safety rules are very important when using a homemade heater. In order for a potbelly stove to bring warmth and comfort to the room and not pose a threat to health, it is necessary to remember the following safety measures.

It is necessary to place the stove on a fireproof base. This can be tile, sheet metal, or brickwork. Walls near the stove must also be protected from overheating. You can paste over them with fireproof material or use non-combustible drywall. In no case should you place furniture and any other flammable objects near the stove.

The slightest spark or too much heat the surface of the stove can cause a fire.

In order to exclude the possibility of accumulation of combustion products in the room, use ventilation. Think in advance where your potbelly stove will be located, and how you can ensure the flow fresh air into the room, and the outflow of carbon monoxide from it.

Install the stove in a place where there is less traffic of people, do not allow children to play games near the appliance. By following these simple rules, you will provide yourself inexpensive heat in the cold season.